Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (5): 511-520.DOI: 10.15541/jim20240477

Special Issue: 【结构材料】高熵陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

CUI Ning1( ), ZHANG Yuxin1,3, WANG Lujie2,3,4(

), ZHANG Yuxin1,3, WANG Lujie2,3,4( ), LI Tongyang2,3,4, YU Yuan2, TANG Huaguo2,3, QIAO Zhuhui2,3,4(

), LI Tongyang2,3,4, YU Yuan2, TANG Huaguo2,3, QIAO Zhuhui2,3,4( )

)

Received:2024-11-12

Revised:2024-12-22

Published:2025-05-20

Online:2025-01-09

Contact:

WANG Lujie, associate professor. E-mail: ljwang@licp.cas.cn;About author:CUI Ning (1987-), male, associate professor. E-mail: cuining@qut.edu.cn

Supported by:CLC Number:

CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics[J]. Journal of Inorganic Materials, 2025, 40(5): 511-520.

| Raw powder | Average particle size/µm | Purity/% | Crystal structure | Lattice constant/Å |

|---|---|---|---|---|

| TiC | 1 | 99.9 | fcc | 4.33 |

| VC | 1 | 99.9 | fcc | 4.18 |

| NbC | 1 | 99.9 | fcc | 4.47 |

| Mo2C | 1 | 99.9 | hcp | a=3.01, c=4.74 |

| WC | 1 | 99.9 | hcp | a=2.91, c=2.83 |

| W | 1 | 99.9 | bcc | a=3.165 |

| Graphite | 0.05 | 99.9 |

Table 1 Basic parameters of raw material powders

| Raw powder | Average particle size/µm | Purity/% | Crystal structure | Lattice constant/Å |

|---|---|---|---|---|

| TiC | 1 | 99.9 | fcc | 4.33 |

| VC | 1 | 99.9 | fcc | 4.18 |

| NbC | 1 | 99.9 | fcc | 4.47 |

| Mo2C | 1 | 99.9 | hcp | a=3.01, c=4.74 |

| WC | 1 | 99.9 | hcp | a=2.91, c=2.83 |

| W | 1 | 99.9 | bcc | a=3.165 |

| Graphite | 0.05 | 99.9 |

| C/TM | Mass fraction/% | ||||||

|---|---|---|---|---|---|---|---|

| TiC | VC | NbC | Mo2C | WC | W | Graphite | |

| 1.0 | 11.26 | 11.84 | 19.74 | 19.18 | 36.85 | 0 | 1.13 |

| 0.9 | 11.39 | 11.98 | 19.96 | 19.40 | 37.27 | 0 | 0 |

| 0.8 | 11.53 | 12.12 | 20.19 | 19.62 | 18.85 | 17.69 | 0 |

| 0.7 | 11.66 | 12.26 | 20.43 | 19.85 | 0 | 35.80 | 0 |

Table 2 Raw material composition of samples with different C/TM

| C/TM | Mass fraction/% | ||||||

|---|---|---|---|---|---|---|---|

| TiC | VC | NbC | Mo2C | WC | W | Graphite | |

| 1.0 | 11.26 | 11.84 | 19.74 | 19.18 | 36.85 | 0 | 1.13 |

| 0.9 | 11.39 | 11.98 | 19.96 | 19.40 | 37.27 | 0 | 0 |

| 0.8 | 11.53 | 12.12 | 20.19 | 19.62 | 18.85 | 17.69 | 0 |

| 0.7 | 11.66 | 12.26 | 20.43 | 19.85 | 0 | 35.80 | 0 |

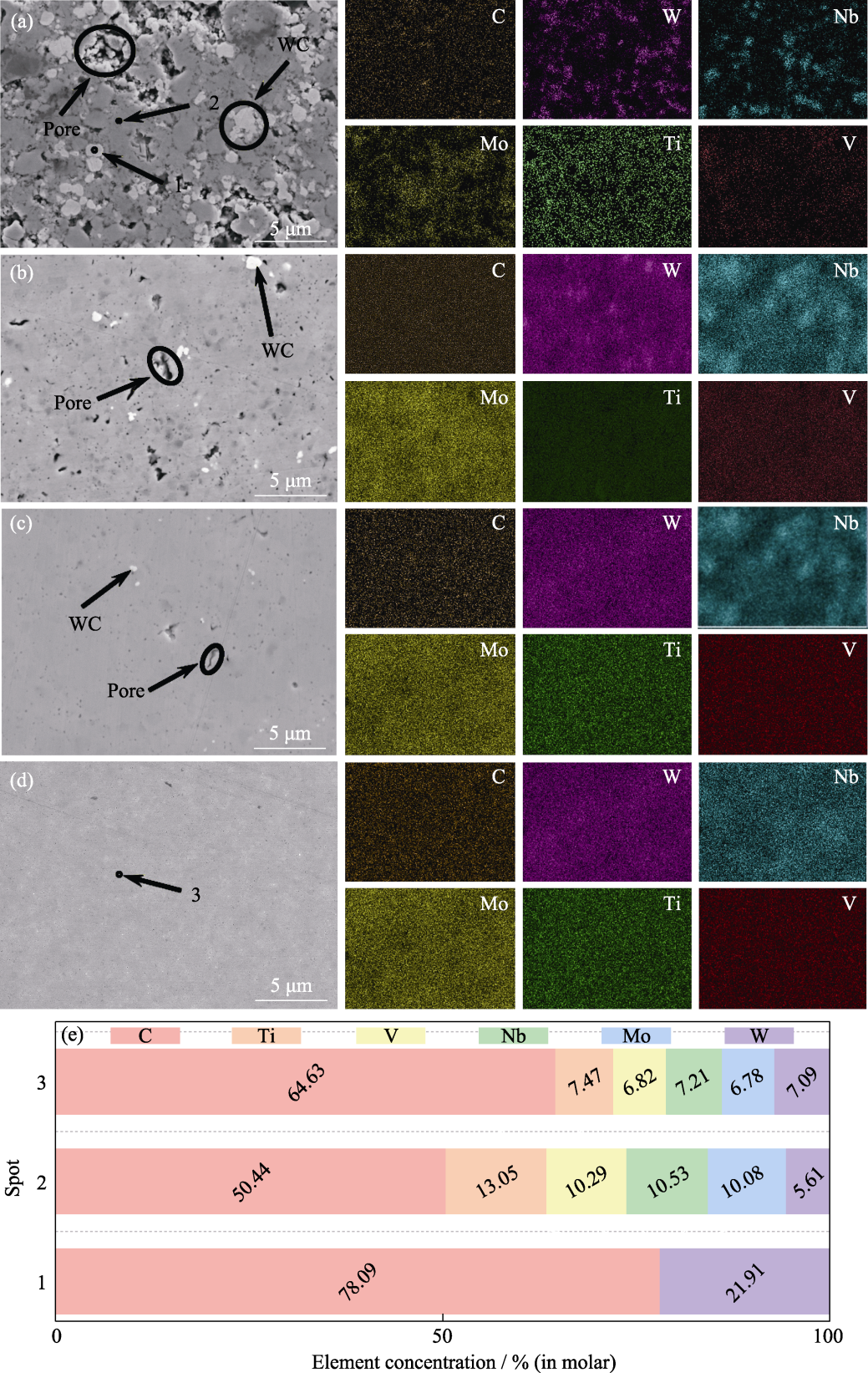

Fig. 4 SE-SEM images and EDS analyses of samples with C/TM of 0.9 sintered at different temperatures (a) 1500 ℃; (b) 1600 ℃; (c) 1700 ℃; (d) 1800 ℃; (e) EDS analyses of spots in Fig. (a-d). Colorful figures are available on website

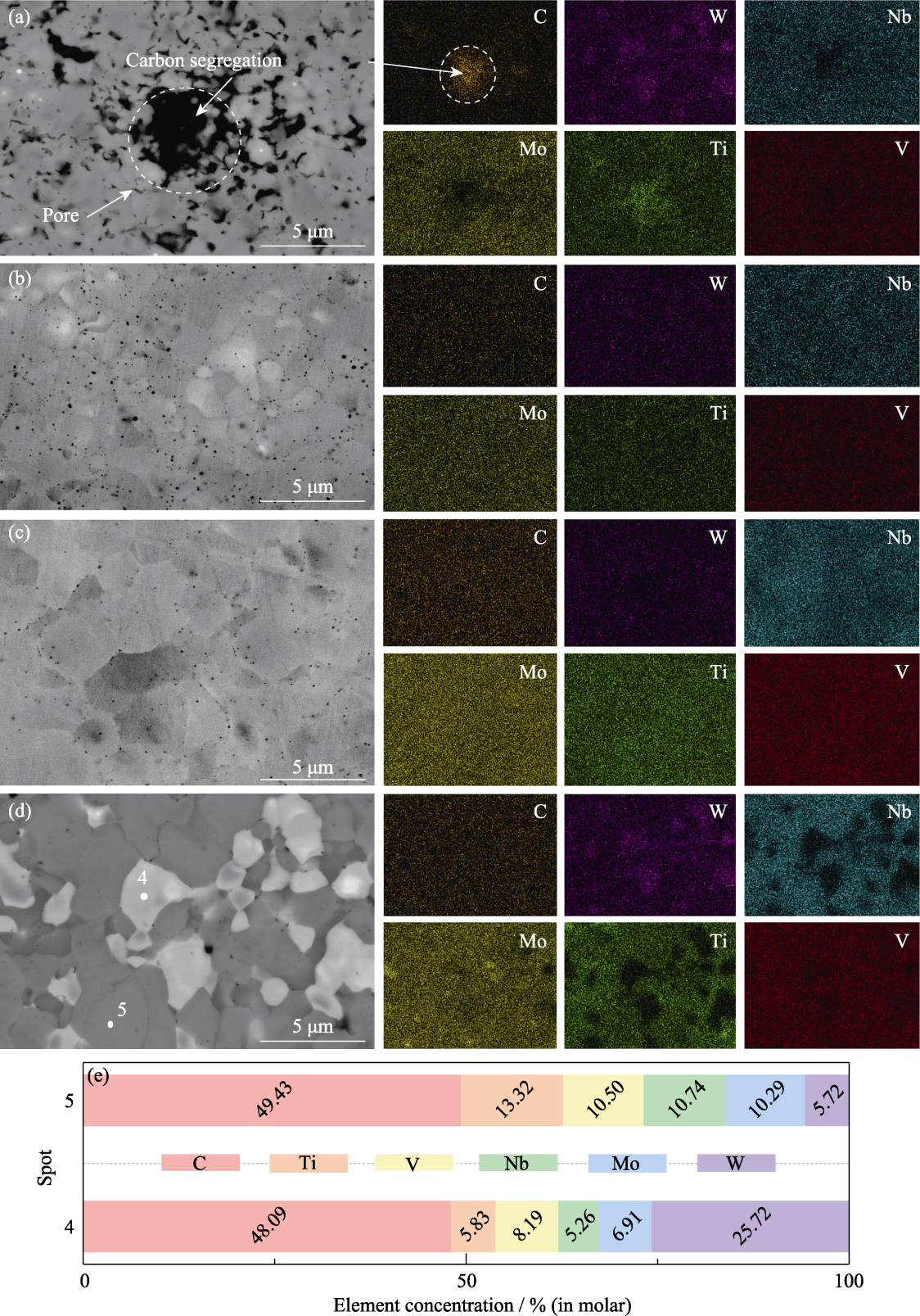

Fig. 5 BE-SEM images and EDS analyses of different C/TM samples sintered at 1800 ℃ (a) C/TM=1.0; (b) C/TM=0.9; (c) C/TM=0.8; (d) C/TM=0.7; (e) EDS analyses of spots in Fig. (d). Colorful figures are available on website

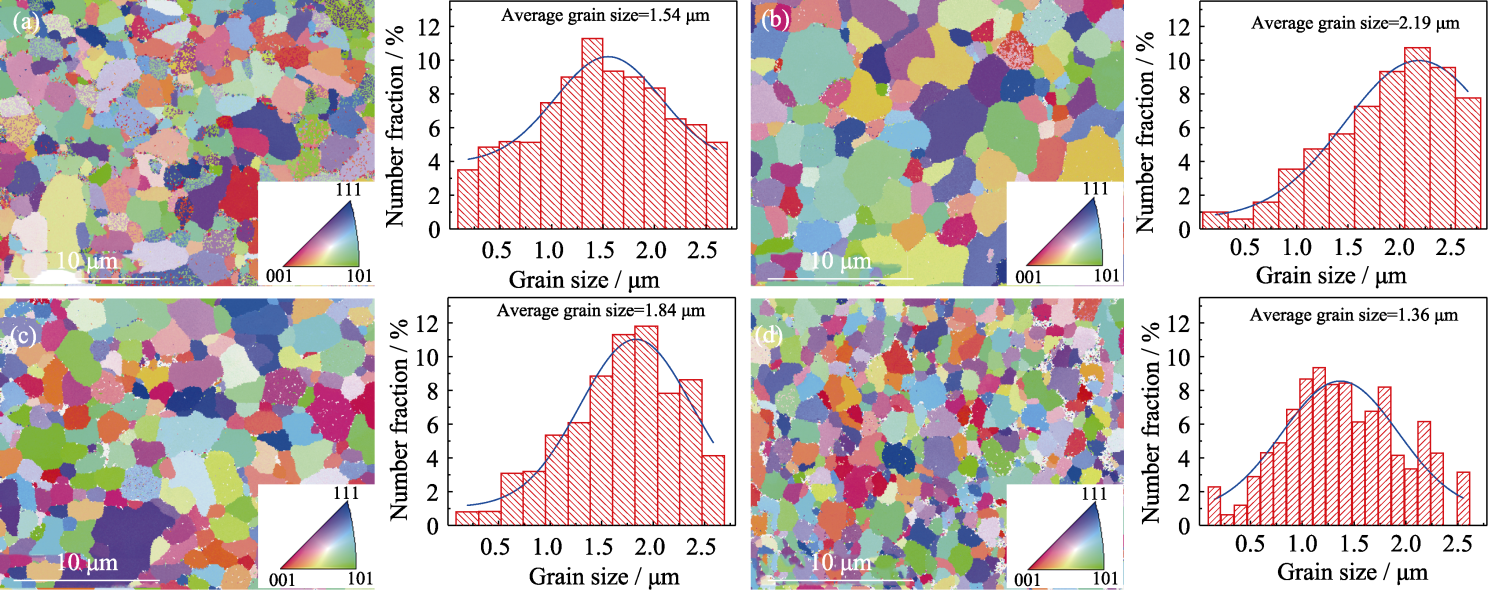

Fig. 8 EBSD mappings and corresponding grain size distributions of different C/TM samples sintered at 1800 ℃ (a) C/TM=1.0; (b) C/TM=0.9; (c) C/TM=0.8; (d) C/TM=0.7

| Sample | Hardness/GPa | Elastic modulus/GPa | Fracture toughness/(MPa·m1/2) |

|---|---|---|---|

| 1800-1.0 | 20.60±1.42 | 421.34±7.88 | 3.32±0.09 |

| 1800-0.9 | 26.98±1.51 | 452.86±9.33 | 2.87±0.10 |

| 1800-0.8 | 30.64±0.93 | 502.37±8.85 | 3.94±0.09 |

| 1800-0.7 | 28.01±1.10 | 490.53±5.79 | 3.00±0.10 |

Table 3 Hardness, elastic modulus and fracture toughness of different C/TM samples sintered at 1800 ℃

| Sample | Hardness/GPa | Elastic modulus/GPa | Fracture toughness/(MPa·m1/2) |

|---|---|---|---|

| 1800-1.0 | 20.60±1.42 | 421.34±7.88 | 3.32±0.09 |

| 1800-0.9 | 26.98±1.51 | 452.86±9.33 | 2.87±0.10 |

| 1800-0.8 | 30.64±0.93 | 502.37±8.85 | 3.94±0.09 |

| 1800-0.7 | 28.01±1.10 | 490.53±5.79 | 3.00±0.10 |

| [1] | LIU S Y, ZHANG S, LIU S, et al. Phase stability, mechanical properties and melting points of high-entropy quaternary metal carbides from first-principles. Journal of the European Ceramic Society, 2021, 41(13): 6267. |

| [2] | CHEN H, WU Z, LIU M, et al. Synthesis, microstructure and mechanical properties of high-entropy (VNbTaMoW)C5 ceramics. Journal of the European Ceramic Society, 2021, 41(15): 7498. |

| [3] | CHENG Z, LU W, CHEN L, et al. Compressive creep properties and mechanisms of (Ti-Zr-Nb-Ta-Mo)C high entropy ceramics at high temperatures. Journal of the European Ceramic Society, 2022, 42(13): 5280. |

| [4] | CHEN H, XIANG H, DAI F Z, et al. Low thermal conductivity and high porosity ZrC and HfC ceramics prepared by in-situ reduction reaction/partial sintering method for ultrahigh temperature applications. Journal of Materials Science & Technology, 2019, 35(12): 2778. |

| [5] | ZHOU J, ZHANG J, ZHANG F, et al. High-entropy carbide: a novel class of multicomponent ceramics. Ceramics International, 2018, 44(17):22014. |

| [6] | ZHOU Y, ZHAO B, CHEN H, et al. Electromagnetic wave absorbing properties of TMCs (TM=Ti, Zr, Hf, Nb and Ta) and high entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C. Journal of Materials Science & Technology, 2021, 74: 105. |

| [7] | 陈克丕, 李泽民, 马金旭, 等. 高熵陶瓷材料研究进展与展望. 陶瓷学报, 2020, 41(2): 157. |

| [8] | WEI X F, LIU J X, LI F, et al. High entropy carbide ceramics from different starting materials. Journal of the European Ceramic Society, 2019, 39(10): 2989. |

| [9] | YU D, YIN J, ZHANG B, et al. Pressureless sintering and properties of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics: the effect of pyrolytic carbon. Journal of the European Ceramic Society, 2021, 41(6): 3823. |

| [10] | ISTOMIN P, ISTOMINA E, NADUTKIN A, et al. Preparation of (Ti,Zr,Hf,Nb,Ta)C high-entropy carbide ceramics through carbosilicothermic reduction of oxides. Journal of the European Ceramic Society, 2021, 41(14): 6934. |

| [11] | HAI W, WU Z, ZHANG S, et al. Microstructure, mechanical and tribological properties of high-entropy (TaTiVW)C4 ceramics. International Journal of Refractory Metals and Hard Materials, 2023, 112: 106114. |

| [12] | CAI F Y, NI D W, DONG S M. Research progress of high-entropy carbide ultra-high temperature ceramics. Journal of Inorganic Materials, 2024, 39(6): 591. |

| [13] | LI J, FAN H, ZHANG Q, et al. Carbon vacancies enhanced oxidation resistance of high-entropy carbides (Ti0.2V0.2Nb0.2Mo0.2W0.2)Cx. Ceramics International, 2024, 50(6): 9926. |

| [14] | LI J, ZHOU Y, SU Y, et al. Synthesis and mechanical and elevated temperature tribological properties of a novel high-entropy (TiVNbMoW)C4.375 with carbon stoichiometry deviation. Journal of Advanced Ceramics, 2023, 12(2): 242. |

| [15] | LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear, 2000, 246(1/2): 1. |

| [16] | LUO S C, GUO W M, FANG Z L, et al. Effect of carbon content on the microstructure and mechanical properties of high-entropy (Ti0.2Zr0.2Nb0.2Ta0.2Mo0.2)Cx ceramics. Journal of the European Ceramic Society, 2022, 42(2): 336. |

| [17] | CHEN J, ZHU Y, CHAI J, et al. Microstructure, mechanical, and thermal properties of (MoTaTiVW)Cx high entropy ceramics with different carbon stoichiometries. Ceramics International, 2024, 50(16): 28168. |

| [18] | MAO H R, DONG E T, JIN S B, et al. Ultrafast high-temperature synthesis and densification of high-entropy carbides. Journal of the European Ceramic Society, 2022, 42(10): 40535. |

| [19] | ANSTIS G R, CHANTIKUL P, LAWN B R, et al. A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. Journal of the American Ceramic Society, 1981, 64(9): 533. |

| [20] | WANG K, CHEN L, XU C, et al. Microstructure and mechanical properties of (TiZrNbTaMo)C high-entropy ceramic. Journal of Materials Science & Technology, 2020, 39: 99. |

| [21] | TSAI M H, YEH J W. High-entropy alloys: a critical review. Materials Research Letters, 2014, 2(3): 107. |

| [22] | SARKER P, HARRINGTON T, TOHER C, et al. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nature Communications, 2018, 9: 4980. |

| [23] | LI T X, MIAO J W, GUO E Y, et al. Tungsten-containing high-entropy alloys: a focused review of manufacturing routes, phase selection, mechanical properties, and irradiation resistance properties. Tungsten, 2021, 3(2): 181. |

| [24] | LI R, LUO R Y, LIN N, et al. A novel strategy for fabricating (Ti,Ta,Nb,Zr,W)(C,N) high-entropy ceramic reinforced with in situ synthesized W2C particles. Ceramics International, 2022, 48(21): 32540. |

| [25] | SONG J, CHEN G, XIANG H, et al. Regulating the formation ability and mechanical properties of high-entropy transition metal carbides by carbon stoichiometry. Journal of Materials Science & Technology, 2022, 121: 181. |

| [26] | LI L, LAN H, TANG S, et al. First-principles study of hydrogen trapping and diffusion mechanisms in vanadium carbide with connecting carbon vacancies. International Journal of Hydrogen Energy, 2024, 91: 611. |

| [27] | LI J, ZHANG Q, CHEN S, et al. Carbon-deficient high-entropy (Zr0.17Nb0.2Ta0.2Mo0.2W0.2)C0.89: a potential high temperature and vacuum wear-resistant material. Materials & Design, 2023, 226: 111680. |

| [1] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [2] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [5] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [6] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [9] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [10] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [11] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [12] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [13] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [14] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [15] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||