Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (6): 662-670.DOI: 10.15541/jim20230557

Special Issue: 【结构材料】陶瓷基复合材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

SUN Haiyang( ), JI Wei(

), JI Wei( ), WANG Weimin, FU Zhengyi(

), WANG Weimin, FU Zhengyi( )

)

Received:2023-12-04

Revised:2024-01-19

Published:2024-06-20

Online:2024-01-22

Contact:

FU Zhengyi, professor. E-mail: zyfu@whut.edu.cn;About author:SUN Haiyang (1999-), male, Master candidate. E-mail: sunhaiyang@whut.edu.cn

Supported by:CLC Number:

SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units[J]. Journal of Inorganic Materials, 2024, 39(6): 662-670.

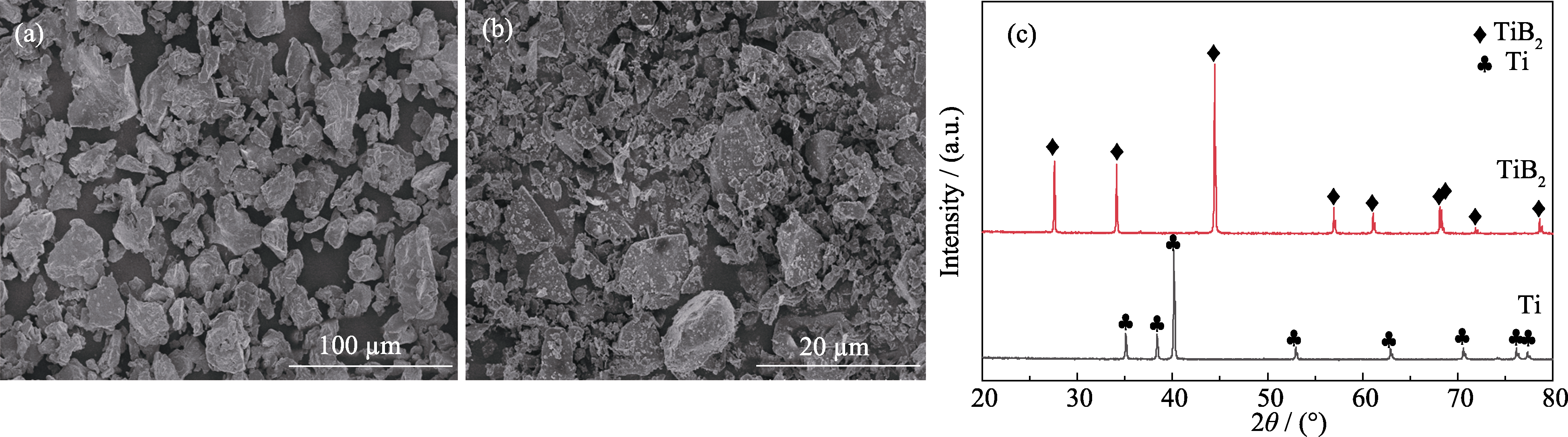

Fig. 1 Morphologies and phase compositions of raw materials (a, b) Microstructures of (a) Ti powder and (b) TiB2powder; (c) XRD patterns of Ti and TiB2powders

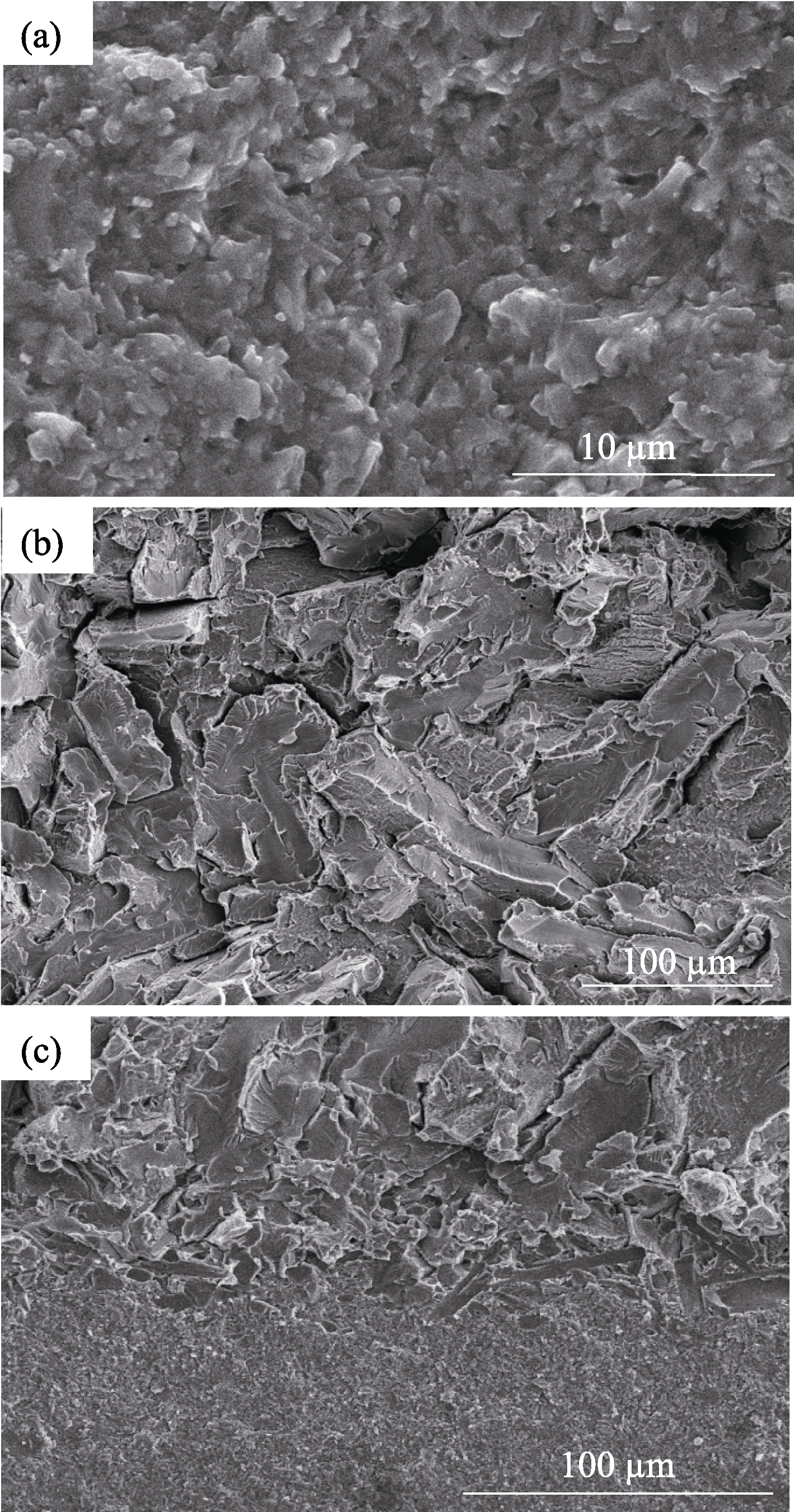

Fig. 4 Fractural microstructures of TiB-Ti composites prepared by SPS (a) TiB fracture surface; (b) Ti fracture surface; (c) Two-phase interface fracture

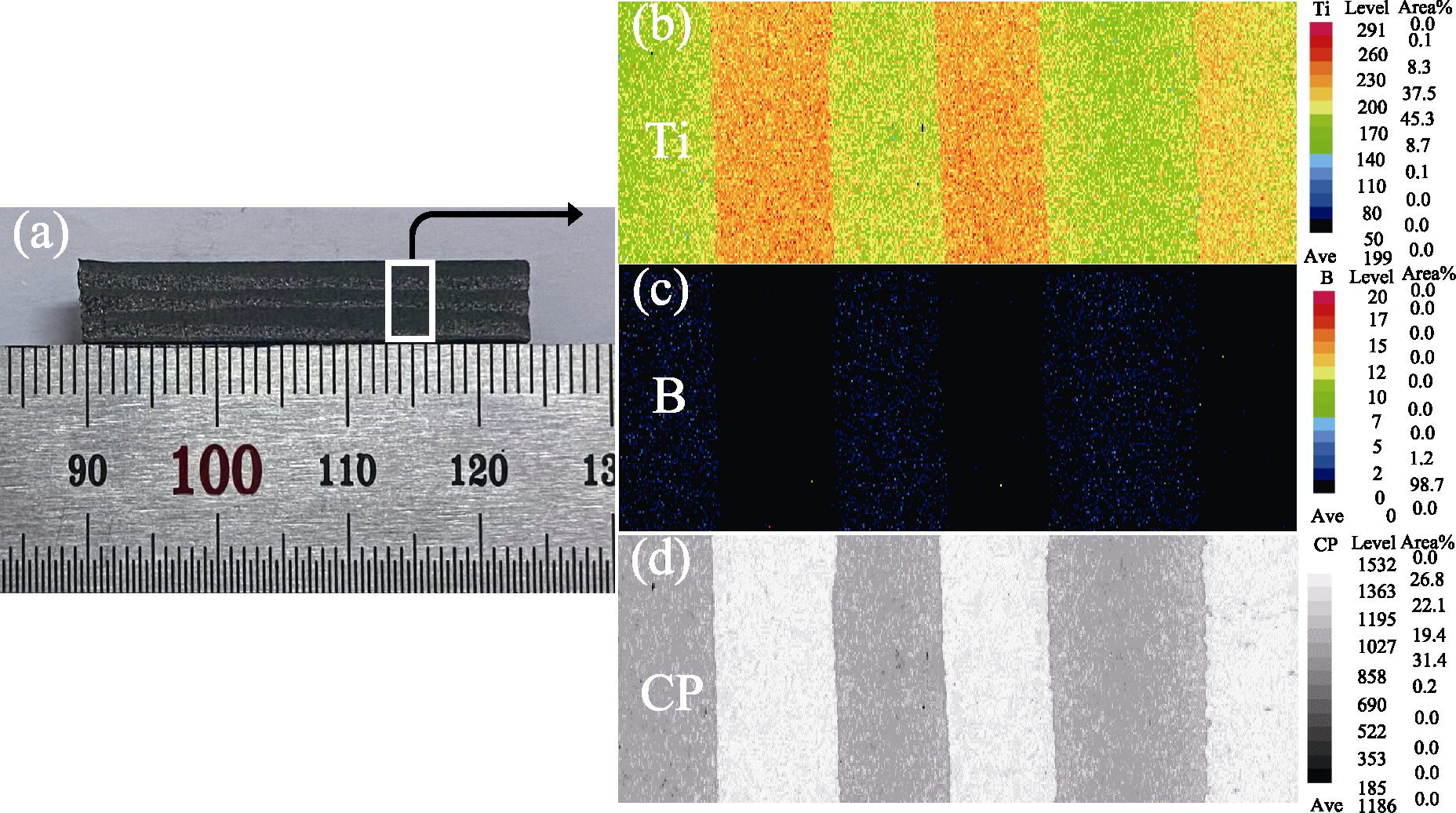

Fig. 5 Distribution of elements on ababab section of TiB-Ti periodic ordered composite tested by EPMA (a) Sample selection photo; (b) Ti element distribution; (c) B element distribution; (d) Backscattered electron (BSE) image

| Parameter | TiB | Ti |

|---|---|---|

| Density/(g·cm-3) | 4.56 | 4.50 |

| E/GPa | 370 | 110 |

| KIC/(MPa·m1/2) | 6.1 | 29.3 |

| Bending strength/MPa | 489.95 | 238.32 |

| Compressive strength/MPa | 1035.43 | 1596.26 |

| Hardness/GPa | 20.0 | 1.7 |

Table1 Mechanical properties of TiB ceramic and Ti metal materials

| Parameter | TiB | Ti |

|---|---|---|

| Density/(g·cm-3) | 4.56 | 4.50 |

| E/GPa | 370 | 110 |

| KIC/(MPa·m1/2) | 6.1 | 29.3 |

| Bending strength/MPa | 489.95 | 238.32 |

| Compressive strength/MPa | 1035.43 | 1596.26 |

| Hardness/GPa | 20.0 | 1.7 |

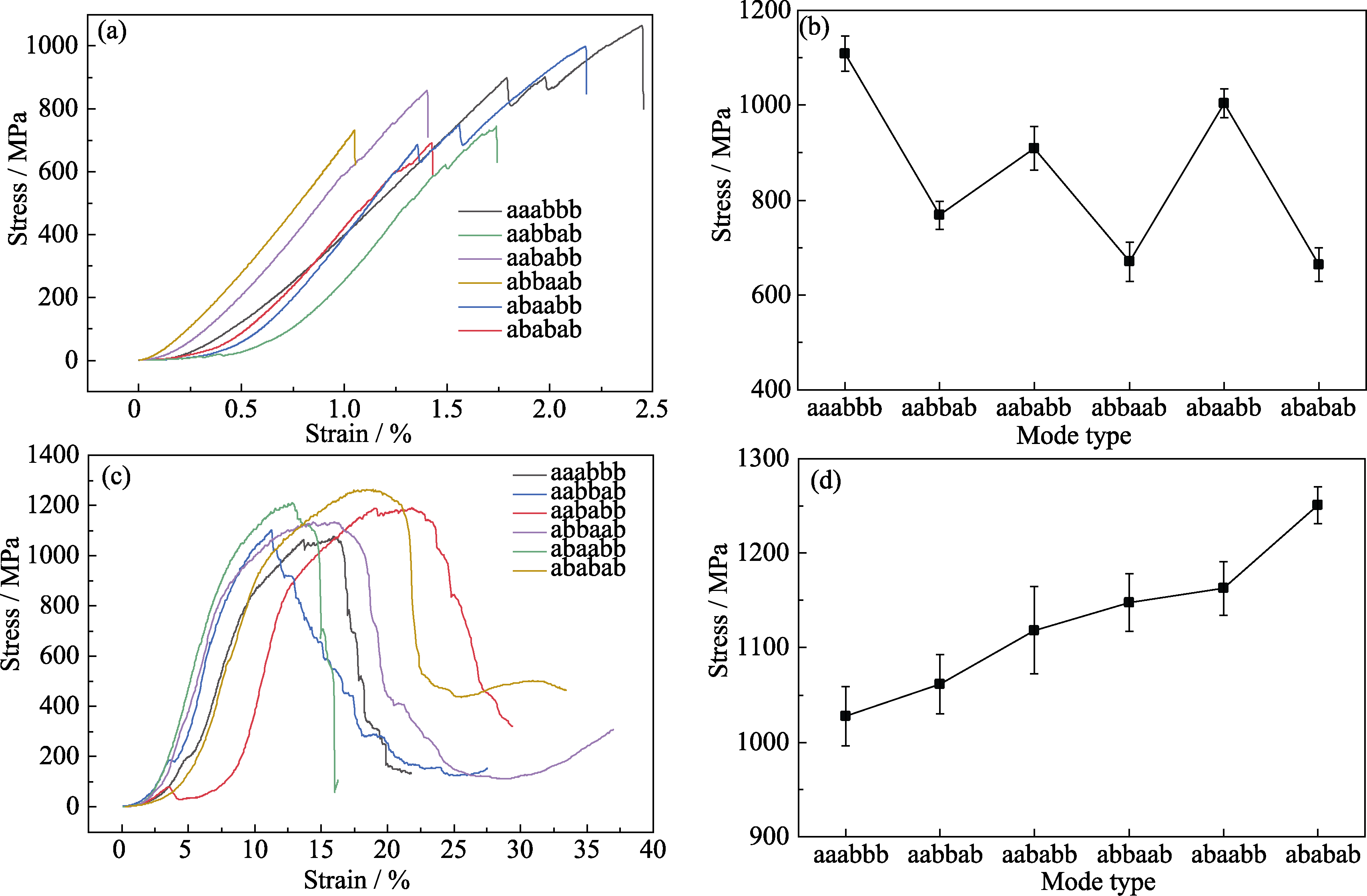

Fig. 7 Mechanical properties of six TiB-Ti periodic ordered composites (a) Bending strength stress-strain curves; (b) Bending strength line chart; (c) Compressive strength stress-strain curves; (d) Compressive strength line chart; Colorful figures are available on website

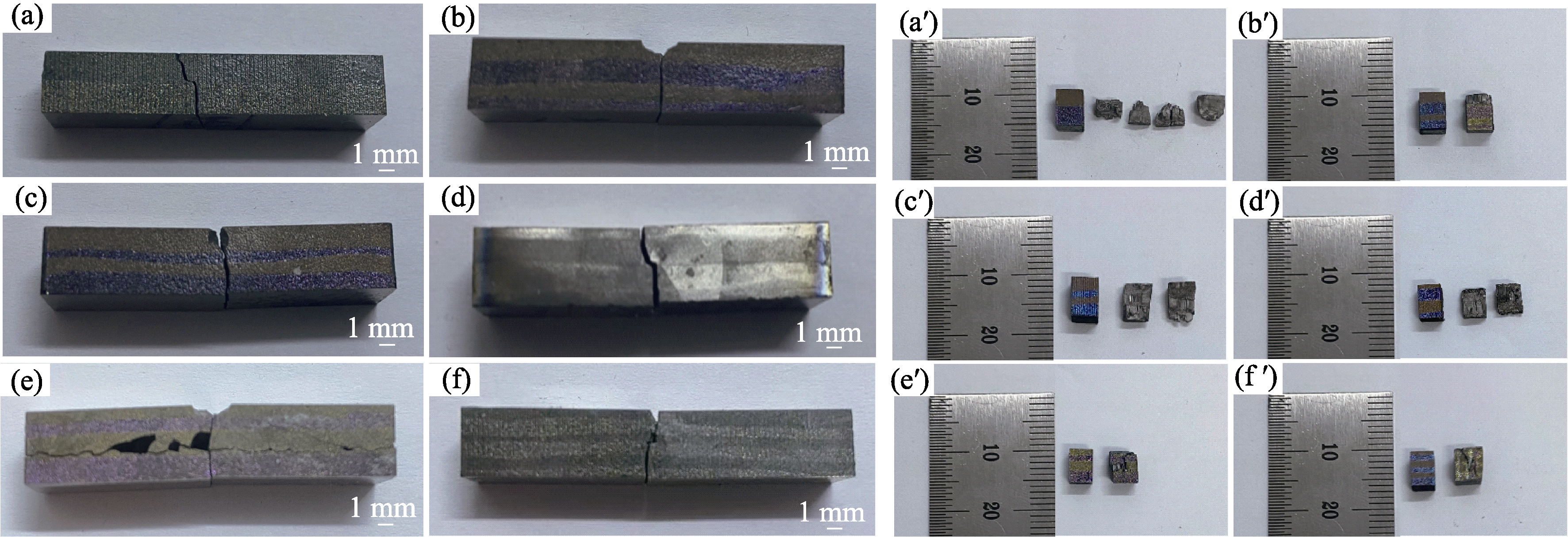

Fig. 8 Macro-cracked morphologies (a-f) and fracture appearances (a'-f') of six TiB-Ti periodic ordered composite bending samples and compressed samples (a, a') aaabbb; (b, b') aabbab; (c, c') aababb; (d, d') abbaab; (e, e') abaabb; (f, f') ababab

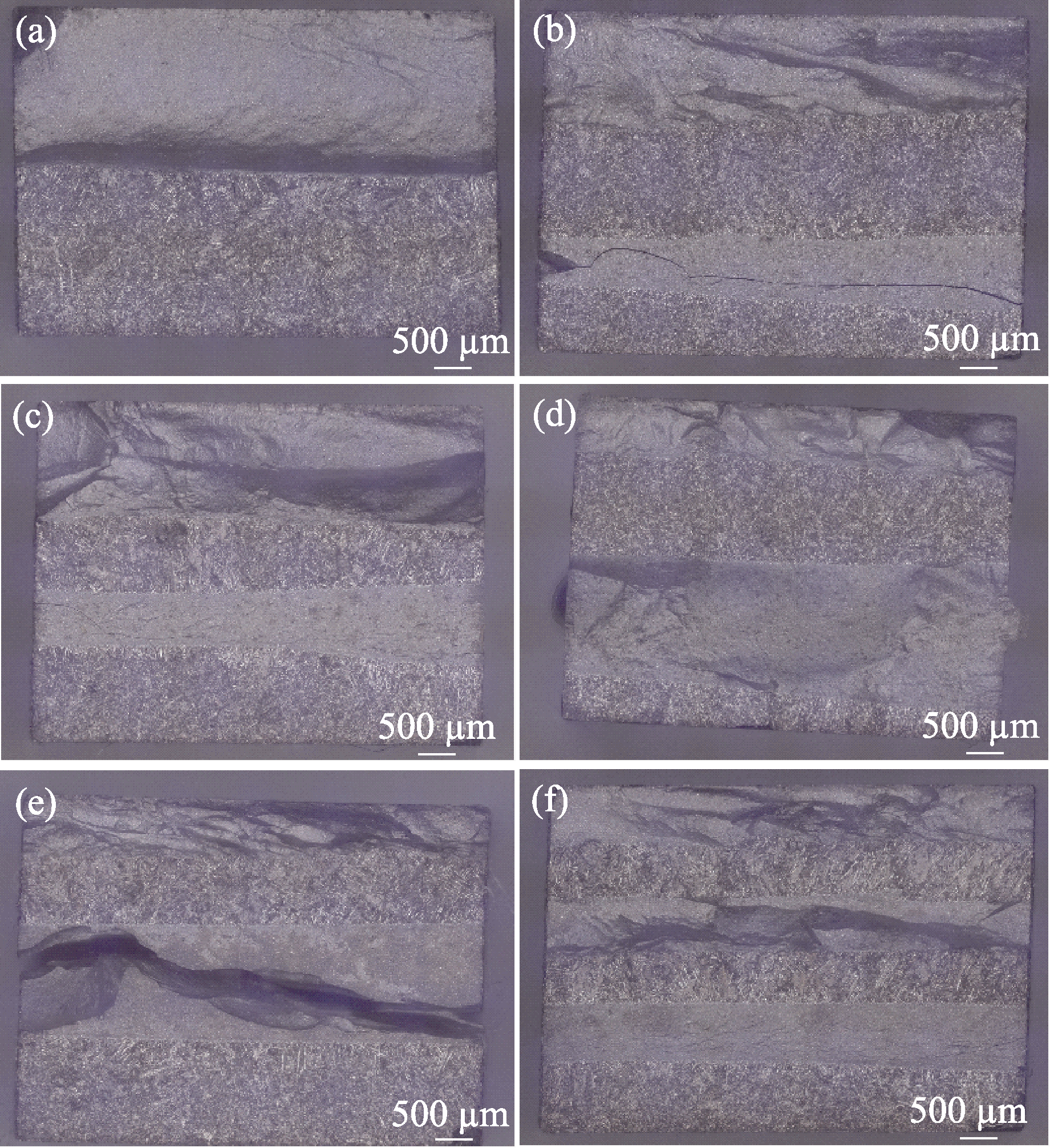

Fig. 9 Macro fracture morphologies of six TiB-Ti periodic ordered composite bending samples (a) aaabbb; (b) aabbab; (c) aababb; (d) abbaab; (e) abaabb; (f) ababab

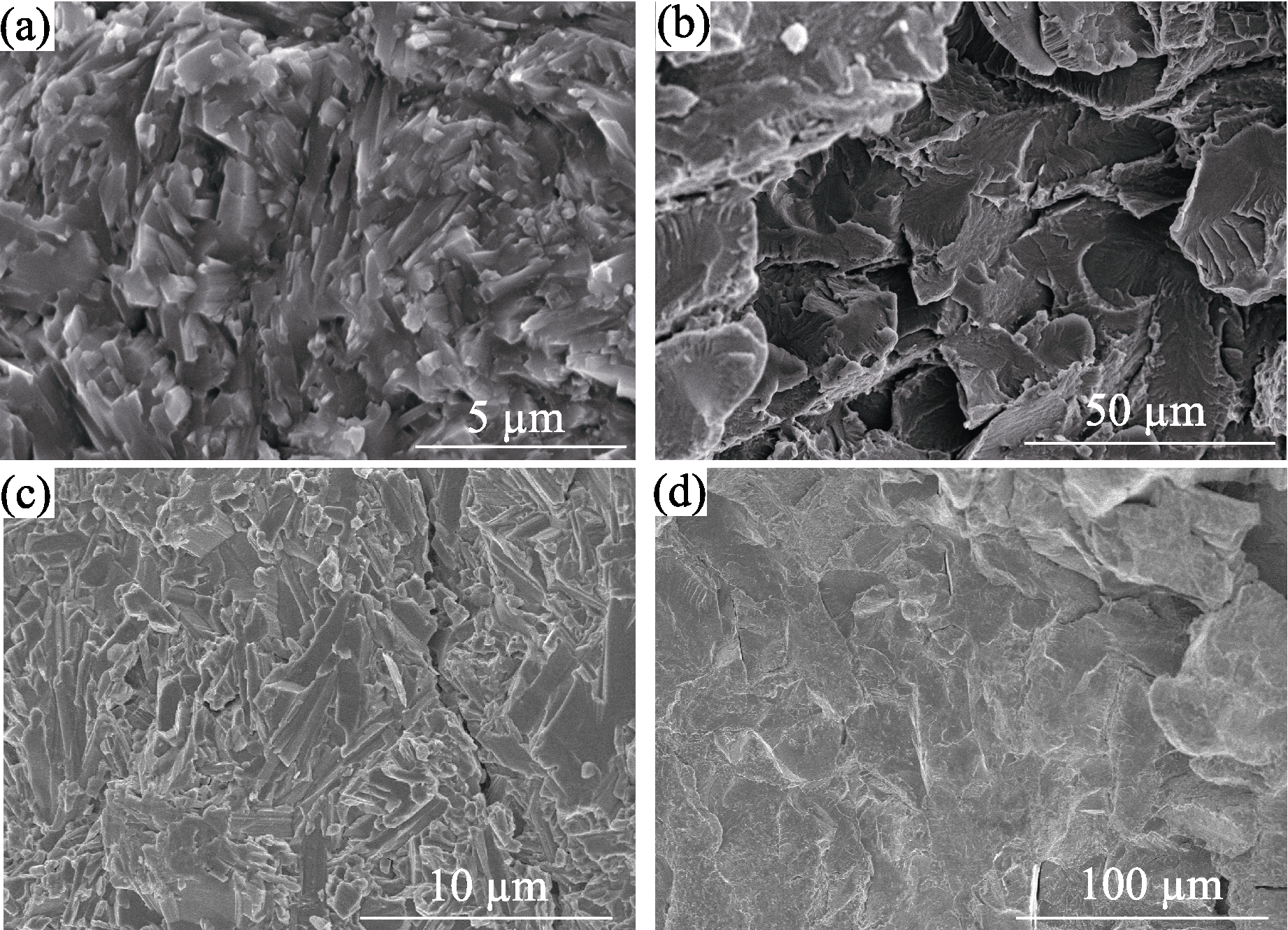

Fig. 11 Microscopic fracture morphologies of TiB-Ti periodic ordered composite bending samples (a, b) and compressed samples (c, d) (a, c) TiB layer; (b, d) Ti layer

| [1] | OYA T, TIESLER N, KAWANISHI S, et al. Experimental and numerical analysis of multilayered steel sheets upon bending. Journal of Materials Processing Technology, 2010, 210(14): 1926. |

| [2] | GO Y H, CHO J, JEONG C Y, et al. Stress distribution of bulk metallic glass/metal laminate composites during uni-axial fracture. Materials Science and Engineering A, 2007, 460/461: 377. |

| [3] | AGHDAM M M, KAMALIKHAH A. Micromechanical analysis of layered systems of MMCs subjected to bending-effects of thermal residual stresses. Composite Structures, 2004, 66(1-4):563. |

| [4] | KUO, D H; KRIVEN, W M. Fracture of multilayer oxide composites. Materials Science and Engineering: A, 1998, 241(1):241. |

| [5] | LUO W, YAN S, ZHOU J. Ceramic-based dielectric metamaterials. Interdisciplinary Materials, 2022, 1(1):11. |

| [6] | LUO J. Computing grain boundary “phase” diagrams. Interdisciplinary Materials, 2023, 2(1):137. |

| [7] | EAST D, GIBSON M A, LIANG D, et al. Production and mechanical properties of roll bonded bulk metallic glass/aluminum laminates. Metallurgical and Materials Transaction A, 2013, 44(5): 2010. |

| [8] | CARREÑO F, CHAO J, POZUELO M, et al. Microstructure and fracture properties of an ultrahigh carbon steel-mild steel laminated composite. Scripta Materialia, 2003, 48(8):1135. |

| [9] | SYN C K, LESUER D R, SHERBY O D. Enhancing tensile ductility of a particulate-reinforced aluminum metal matrix composite by lamination with Mg-9%Li alloy. Materials Science and Engineering, 1996, 206(2):201. |

| [10] | OHASHI Y, WOLFENSTINE J, KOCH J, et al. Fracture behavior of a laminated steel-brass composite in bend tests. Materials Science and Engineering, 1992, 151(1):37. |

| [11] | SMITH D J, ZUO Y Q, PARTRIDGE P G, et al. Bend stiffness and strength of laminates composed of titanium alloy and titanium metal matrix composite. Materials Science and Technology, 1997, 13(1):35. |

| [12] | LIU B X, HUANG L J, GENG L, et al. Fabrication and superior ductility of laminated Ti-(TiBw/Ti) composites by diffusion welding. Journal of Alloys and Compounds, 2014, 602: 187. |

| [13] | LIU B X, HUANG L J, GENG L, et al. Gradient grain distribution and enhanced properties of novel laminated TiTiBw/Ti composites by reaction hot-pressing. Materials Science and Engineering: A, 2014, 595: 257. |

| [14] | LIU B X, HUANG LJ, GENG L, et al. Microstructure and tensile behavior of novel laminated Ti-TiBw/Ti composites by reaction hot pressing. Materials Science and Engineering A, 2013, 583: 182. |

| [15] | GUPTA N, MUKHOPADHYAY A, PAVANI K, et al. Spark plasma sintering of novel ZrB2-SiC-TiSi2 composites with better mechanical properties. Materials Science and Engineering: A, 2012, 534: 111. |

| [16] | MALIK P, KADOLI R. Thermo-elastic response of SUS316-Al2O3 functionally graded beams under various heat loads. International Journal of Mechanical Sciences, 2017, 128: 206. |

| [17] | KHOA N D, THIEM H T, DUC N D. Nonlinear buckling and postbuckling of imperfect piezoelectric S-FGM circular cylindrical shells with metal-ceramic-metal layers in thermal environment using Reddy’s third-order shear deformation shell theory. Mechanics of Advanced Materials and Structures, 2019, 26(3):248. |

| [18] | FENG H B, JIA D C, ZHOU Y. Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites. Composites Part A: Applied Science and Manufacturing, 2005, 36(5):558. |

| [19] | 神祥博, 张朝晖, 王富耻, 等. 放电等离子烧结法制备 TiB 陶瓷刀具材料的显微结构和力学性能. 模具制造, 2010, 10(12):92. |

| [20] | NAMBU S, MICHIUCHI M, INOUE J, et al. Effect of interfacial bonding strengthon tensile ductility of multilayered steel composites. Composites Science and Technology, 2009, 69(11/12): 1936. |

| [21] | WADGAONKAR S C, PARAMESWARAN V. Structure of near-tip stress field and variation of stress intensity factor for a crack in a transversely graded material. Journal of Applied Mechanics, 2009, 76(1):011014. |

| [22] | KIDANE A, ADDIS A. Quasi-static and dynamic fracture initiation toughness of Ti/TiB layered functionally graded material under thermo-mechanical loading. Engineering Fracture Mechanics, 2010, 77(3):479. |

| [23] | LIU B X, HUANG L J, GENG L, et al. Fracture behaviors and micro-structural failure mechanisms of laminated Ti-TiBw/Ti composites. Material Science and Engineering: A, 2014; 611: 290. |

| [24] | HAN Y F, DUAN H Q, LU W J, et al. Fabrication and characterization of laminated Ti-(TiB+La2O3)/Ti composite. Progress in Natural Science: Materials International, 2015, 25(5):453. |

| [25] | LIU B X, HUANG L J, GENG L. Elastic and plastic behaviors of laminated Ti-TiBw/Ti composites. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2015, 30(3):596. |

| [26] | KOSEKI T, INOUE J, NAMBU S. Development of multilayer steels for improved combinations of high strength and high ductility. Materials Transactions, 2014, 55(2):227. |

| [27] | STEIF P S. Bimaterial interface instabilities in plastic solids. International Journal of Solids and Structures, 1986, 22(2):195. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [9] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [10] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [11] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [12] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [13] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [14] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [15] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||