Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (7): 803-809.DOI: 10.15541/jim20230513

Special Issue: 【结构材料】热障与环境障涂层(202506); 【结构材料】核用陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

FAN Wugang1( ), CAO Xiong2, ZHOU Xiang2, LI Ling2, ZHAO Guannan2, ZHANG Zhaoquan1(

), CAO Xiong2, ZHOU Xiang2, LI Ling2, ZHAO Guannan2, ZHANG Zhaoquan1( )

)

Received:2023-11-03

Revised:2024-01-10

Published:2024-07-20

Online:2024-01-22

Contact:

ZHANG Zhaoquan, professor. E-mail: zhangzq@mail.sic.ac.cnAbout author:FAN Wugang (1978-), male, associated professor. E-mail: fanwugang@mail.sic.ac.cn

Supported by:CLC Number:

FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor[J]. Journal of Inorganic Materials, 2024, 39(7): 803-809.

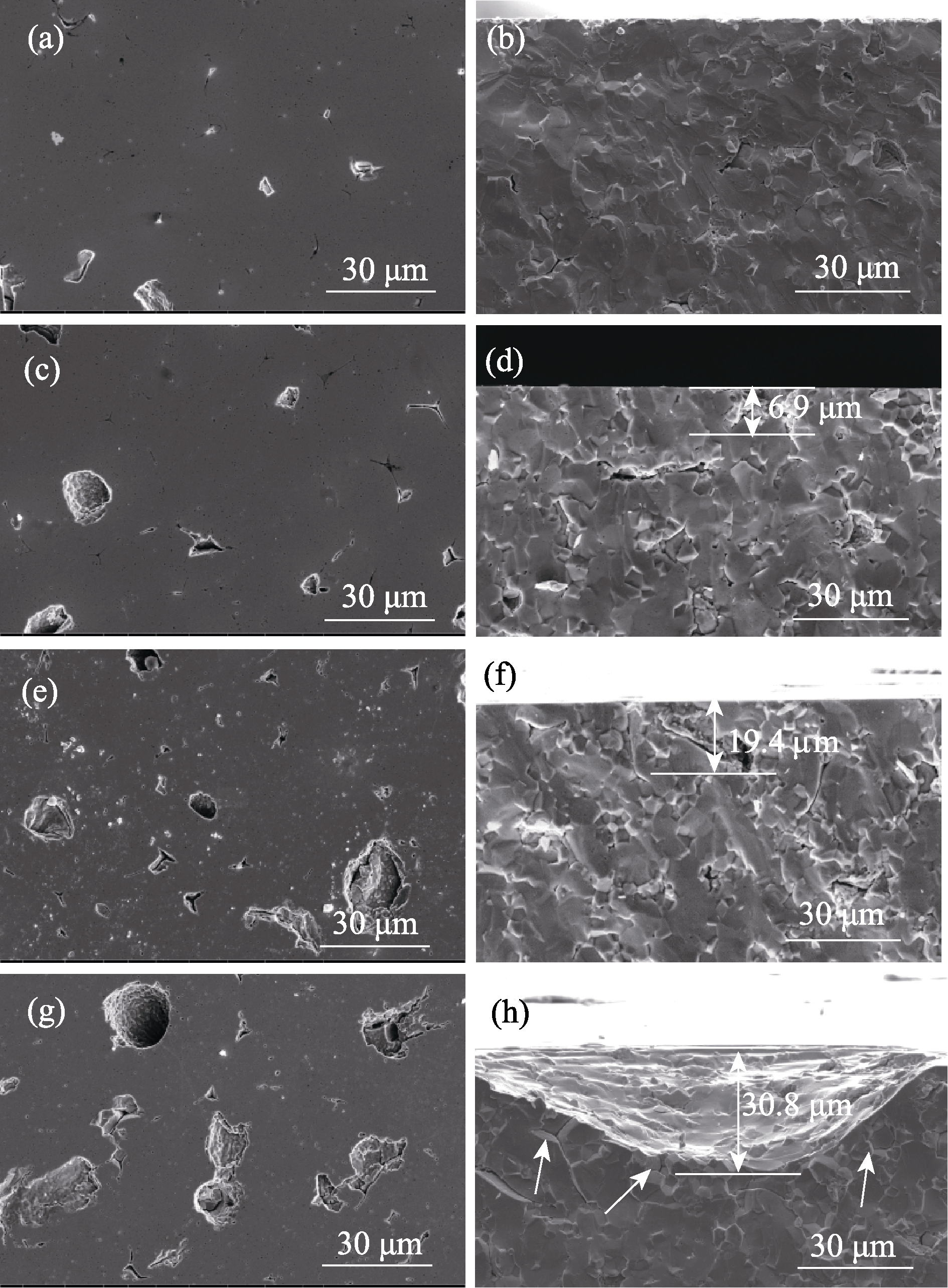

Fig. 4 SEM images for surfaces (a, c, e, g) and cross sections (b, d, f, h) of 8YSZ ceramics before and after corrosion for different periods (a, b) 0 h; (c, d) 350 h; (e, f) 700 h; (g, h) 1050 h

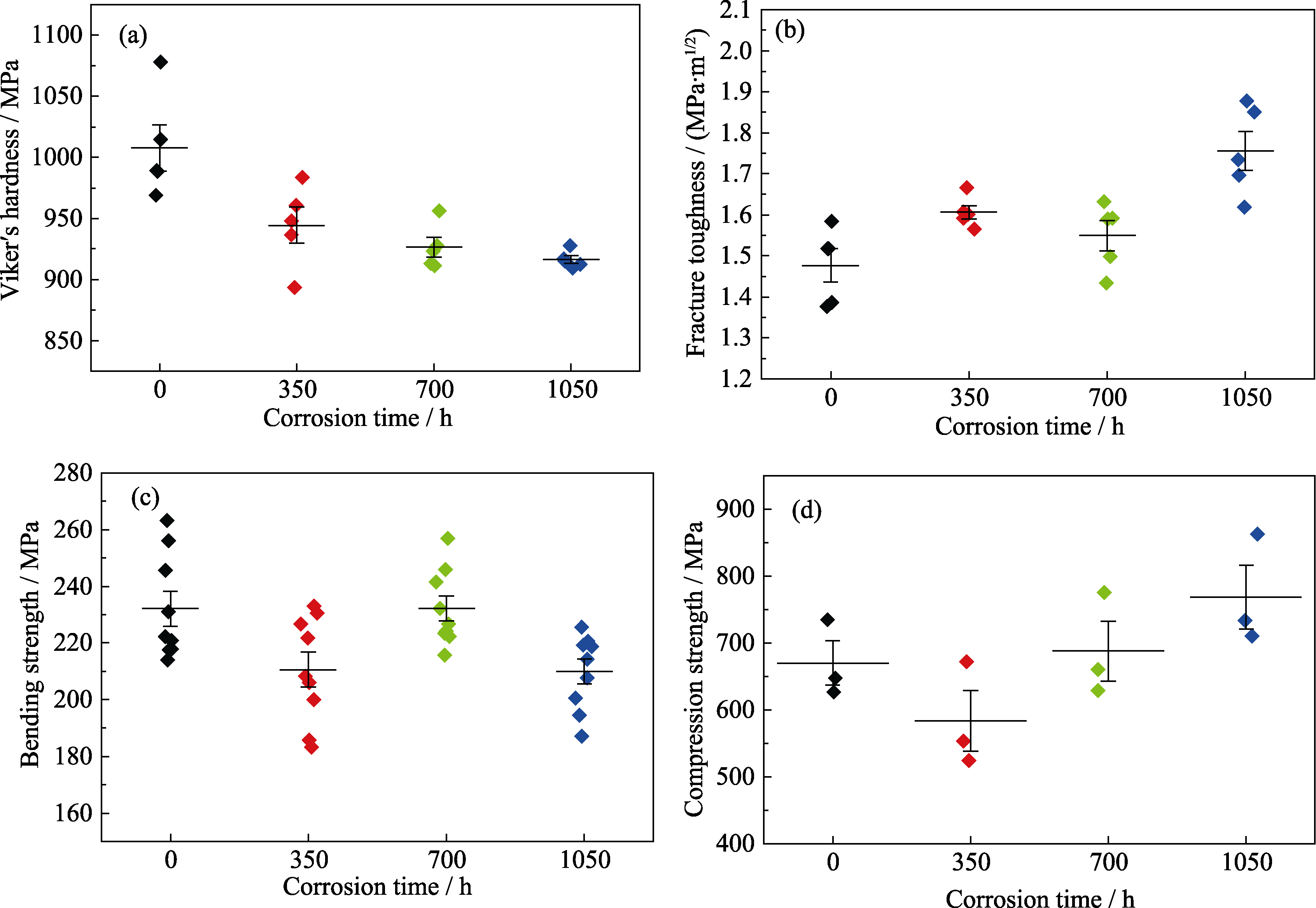

Fig. 5 Mechanical properties of 8YSZ ceramics before and after corrosion for different periods (a) Viker’s harness; (b) Fracture toughness; (c) Bending strength; (d) Compression strength

| Corrosion time/h | Zr | Y | Fe | Cr | Ni |

|---|---|---|---|---|---|

| 0 | 0 | - | 0 | - | 0 |

| 350 | 0.04 | 0.01 | - | - | 0.01 |

| 700 | 0.01 | - | 0.01 | 0.01 | 0.05 |

| 1050 | 0.01 | - | 0.01 | 0.02 | 0.09 |

Table 1 Contents of chemical compositions in water circulation before and after corrosion tests (mg/L)

| Corrosion time/h | Zr | Y | Fe | Cr | Ni |

|---|---|---|---|---|---|

| 0 | 0 | - | 0 | - | 0 |

| 350 | 0.04 | 0.01 | - | - | 0.01 |

| 700 | 0.01 | - | 0.01 | 0.01 | 0.05 |

| 1050 | 0.01 | - | 0.01 | 0.02 | 0.09 |

| [1] | MANICONE P F, ROSSI IOMMETTI P, RAFFAELLI L. An overview of zirconia ceramics: basic properties and clinical applications. Journal of Dentistry, 2007, 35(11): 819. |

| [2] | HUNT C, ALLEMEIER J K, DRISCOLL D, et al. Molybdenum oxide and nickel nitrate as cooperative sintering aids for yttria- stabilized zirconia. Materials, 2020, 13(12): 2875. |

| [3] | BATISTA R M, MUCCILLO E N S. Structure, microstructure and electrical conductivity of 8YSZ containing NiO. Ceramics International, 2011, 37(6): 1929. |

| [4] | WEI L, ZHANG J, YU F, et al. A novel fabrication of yttria- stabilized-zirconia dense electrolyte for solid oxide fuel cells by 3D printing technique. International Journal of Hydrogen Energy, 2019, 44(12): 6182. |

| [5] | DEY S, DRAZIN J W, WANG Y, et al. Radiation tolerance of nanocrystalline ceramics: insights from yttria stabilized zirconia. Scientific Report, 2015, 5: 7746. |

| [6] | SICKAFUS H M, HARTMANN T, YASUDA K, et al. Radiation damage effects in zirconia. Journal of Nuclear Materials, 1999, 274: 66. |

| [7] | SVITLYK V, WEISS S, HENNIG C. Stability of doped zirconia under extreme conditions: toward long-term and secure storage of radioactive waste. Journal of the American Ceramic Society, 2022, 105(12): 7831. |

| [8] | KURAKHMEDOV A E, ALIN M, TEMIR A M, et al. Study of the effect of doping ZrO2 ceramics with MgO to increase the resistance to polymorphic transformations under the action of irradiation. Nanomaterials, 2021, 11: 3172. |

| [9] | WU J, YOSHIAKI O. Improved single pass core design for high temperature super LWR. Nuclear Engineering and Design, 2014, 267: 100. |

| [10] | BARRETT F, HUANG X, GUZONAS D. Characterization of TiO2-doped yttria-stabilized zirconia (YSZ) for supercritical water-cooled reactor insulator application. Journal of Thermal Spray Technology, 2013, 22 (5): 734. |

| [11] | GUO S, XU D, LIANG Y, et al. Corrosion characterization of ZrO2 and TiO2 ceramic coatings via air plasma spraying on 316 stainless steel in oxygenated sub- and supercritical water. Journal of Supercritical Fluids, 2020, 157: 104716. |

| [12] | PARK J Y, KIM I H, JUNG Y I, et al. Long-term corrosion behavior of CVD SiC in 360 ℃ water and 400 ℃ steam. Journal of Nuclear Materials, 2013, 443(1/2/3): 603. |

| [13] | NOWICKA A, EL-MAGHRABY H F, ŠVANČÁRKOVÁA, et al. Corrosion and low temperature degradation of 3Y-TZP dental ceramics under acidic conditions. Journal of the European Ceramic Society, 2020, 40 (15): 6114. |

| [14] | RT5ZHU D, LIANG J, ZHANG X. Progress on hydrothermal stability of dental zirconia ceramics. Journal of Inorganic Materials, 2020, 35 (7): 759. |

| [15] | FRANGAN K, CHEVALIER J, ZHANG F, et al. Is a zirconia dental implant safe when it is available on the market? Ceramics, 2019, 2(4): 568. |

| [16] | SUN C, HUI R, QU W, et al. Progress in corrosion resistant materials for supercritical water reactors. Corrosion Science, 2009, 51(11): 2508. |

| [17] | CHEN K, SEO D, CANTEENWALLA P, et al. The effect of high-temperature water vapour on degradation and failure of hot section components of gas turbine engines. Coatings, 2021, 11: 1061. |

| [18] | SEBERT-TIMMER A, BICHLER L. Degradation of SPS-fabricated YSZ and Nd2O3-YSZ ceramics in supercritical water. Journal of Materials Engineering and Performance, 2016, 25(4): 1426. |

| [19] | ASTM G2/G2M-19. Standard test method for corrosion testing of products of zirconium, hafnium, and their alloys in water at 680 °F (360 ℃) or in steam at 750 °F (400 ℃). |

| [20] | HERRMANN M, KLEMM H. Corrosion of ceramic material. In: Vinod K S. Comprehensive hard materials. Amsterdam: Elsevier, 2014: 413. |

| [21] | SIEBERT-TIMMER A, BICHLER L, MONDAL K. Degradation of spark plasma sintered yttria stabilized zirconia (YSZ) and CeO2-YSZ ceramics in supercritical water. International Journal of Applied Ceramic Technology, 2015, 12(6): 1103. |

| [22] | GHATEE M, SHARIAT M H, IRVINE J T S. Investigation of electrical and mechanical properties of 3YSZ/8YSZ composite electrolytes. Solid State Ionics, 2009, 180(1): 57. |

| [23] | KONTOYANNIS C G, ORKUALA M. Quantitative determination of the cubic, tetragonal and monoclinic phases in partially stabilized zirconia by Raman spectroscopy. Journal of Materials Science, 1994, 29: 5316. |

| [24] | SOBOL A A, VORONKO Y K. Stress-induced cubic-tetragonal transformation in partially stabilized ZrO2: Raman spectroscopy study. Journal of Physics and Chemistry of Solids, 2004, 65(6): 1103. |

| [25] | TAKEUCHI T, KONDOH I, TAMARI N, et al. Improvement of mechanical strength of 8 mol% yttria-stabilized zirconia ceramics by spark-plasma sintering. Journal of the Electrochemical Society, 2002, 149(4): A455. |

| [26] | FRANKEL G S, VIENNA J D, LIAN J, et al. A comparative review of the aqueous corrosion of glasses, crystalline ceramics, and metals. npj Materials Degradation, 2018, 2:15. |

| [27] | HERRMANN M. Corrosion of ceramics in aqueous environments. In: Pomeroy M. Encyclopedia of materials: technical ceramics and glasses. Amsterdam: Elsevier, 2021: 921. |

| [28] | CHEN X, FAN W, ZHANG Z. Thermos-physical properties and corrosion behaviors of monoclinic Gd4Al2O9 ceramic exposed to pressurized water at 360 ℃. Chemical Physics Letters, 2023, 823: 140523. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [9] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [10] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [11] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [12] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [13] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [14] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [15] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||