Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (6): 634-646.DOI: 10.15541/jim20230530

Special Issue: 【结构材料】高导热陶瓷(202506)

• REVIEW • Previous Articles Next Articles

WANG Weiming1( ), WANG Weide1,2(

), WANG Weide1,2( ), SU Yi1, MA Qingsong1, YAO Dongxu3, ZENG Yuping3(

), SU Yi1, MA Qingsong1, YAO Dongxu3, ZENG Yuping3( )

)

Received:2023-11-14

Revised:2024-01-15

Published:2024-06-20

Online:2024-01-22

Contact:

WANG Weide, associate professor. E-mail: nudtwwd@163.com;About author:WANG Weiming (1995-), male, PhD candidate. E-mail: wangweiming1207@163.com

Supported by:CLC Number:

WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives[J]. Journal of Inorganic Materials, 2024, 39(6): 634-646.

| Material | Thermal conductivity/ (W·m-1·K-1) | Fracture toughness/ (MPa·m1/2) | Bending strength/ MPa |

|---|---|---|---|

| Al2O3 | 18-24 | 3.5-4.0 | 300-400 |

| AlN | 150-270 | 3.0-3.5 | 220-310 |

| ZTA | 28 | 4.5 | 650 |

| Si3N4 | 80-177 | 6.5-7.5 | 600-800 |

Table 1 Properties of ceramic substrate materials[2]

| Material | Thermal conductivity/ (W·m-1·K-1) | Fracture toughness/ (MPa·m1/2) | Bending strength/ MPa |

|---|---|---|---|

| Al2O3 | 18-24 | 3.5-4.0 | 300-400 |

| AlN | 150-270 | 3.0-3.5 | 220-310 |

| ZTA | 28 | 4.5 | 650 |

| Si3N4 | 80-177 | 6.5-7.5 | 600-800 |

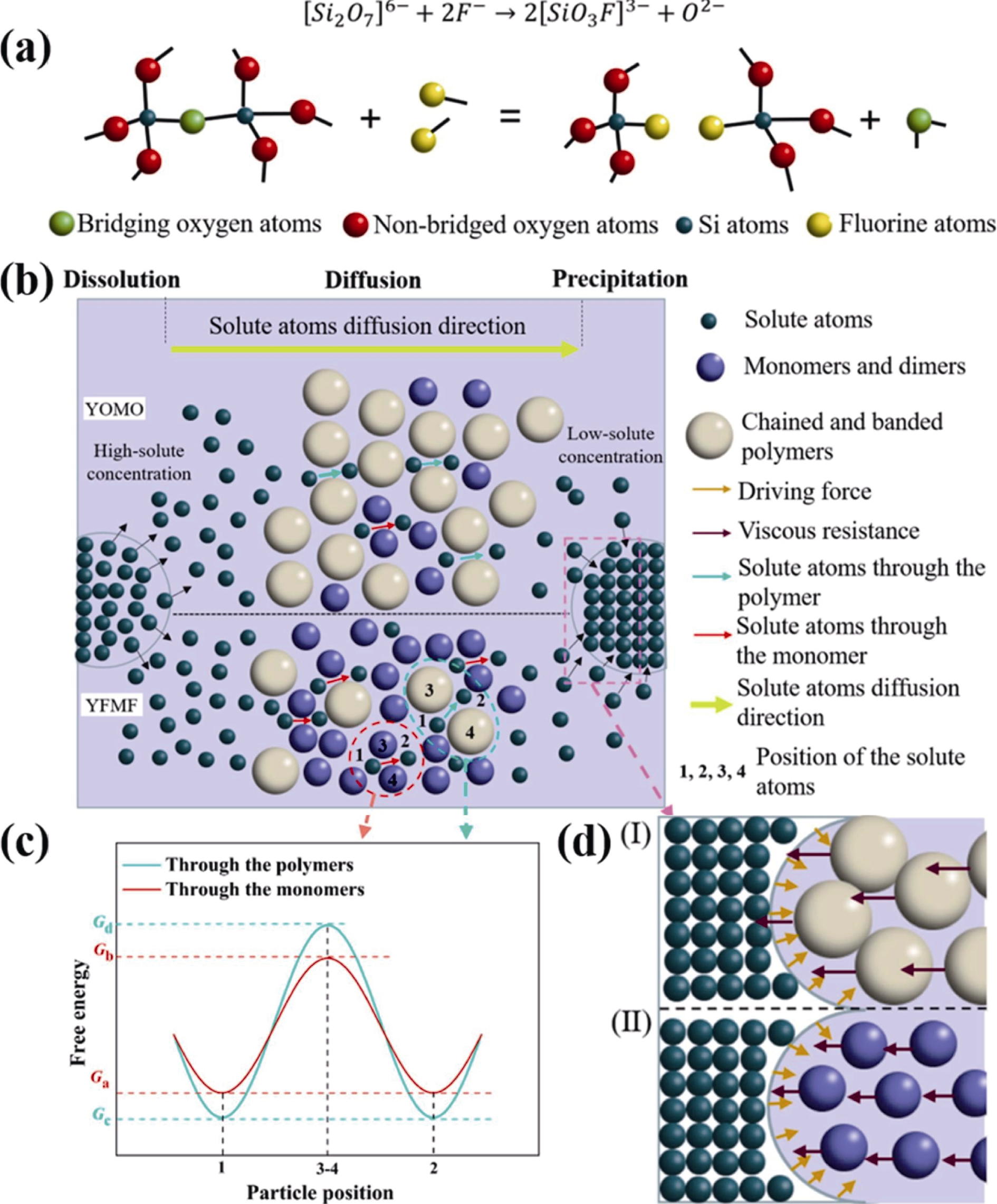

Fig. 7 Depolymerization mechanism of F atom in silicate melts[22] (a) F atom breaks the network structure by replacing the bridging oxygen atoms; (b) Solute atom solution-diffusion-precipitation mechanism during liquid-phase sintering in samples YOMO and YFMF; (c) Free energy barriers overcome by solute atoms in melts Y-Si-O-N and Y-Si-O-N-F; (d) Mechanism of solute drag effect on grain boundary migration

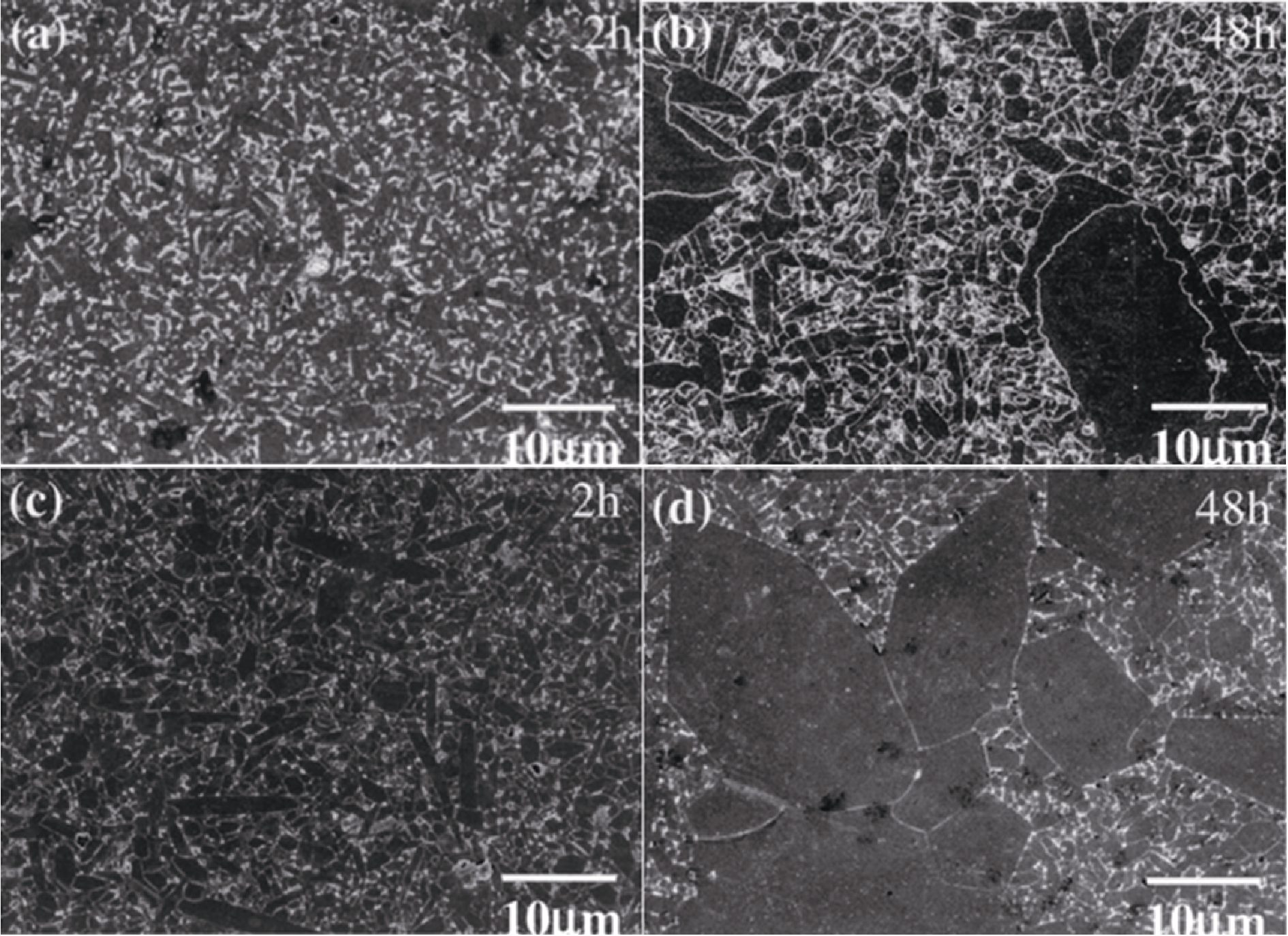

Fig. 8 SEM morphologies of the polished surfaces of Si3N4 ceramics after gas pressure sintering (GPS) with different additives added[24] (a) MgO-doped for 2 h; (b) MgO-doped for 48 h; (c) MgSiN2-doped for 2 h; (d) MgSiN2-doped for 48 h

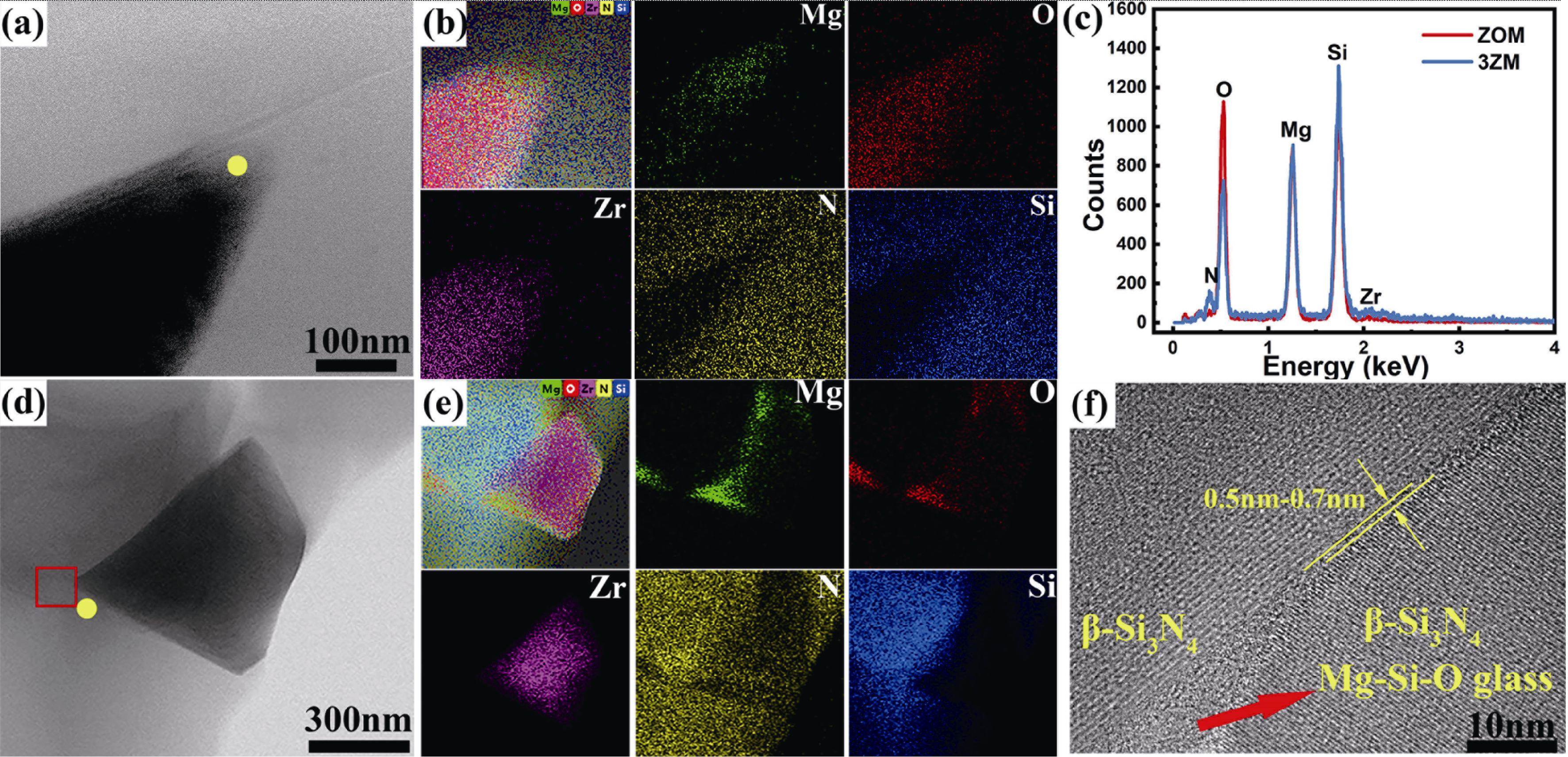

Fig. 14 STEM-EDS characterizations of Si3N4 ceramics with the addition of ZrO2 and ZrH2[47] (a, d) Bright-field TEM images for Si3N4 ceramics with the addition of (a) ZrO2 and (d) ZrH2; (b, e) Elements distribution for Si3N4 ceramics with the addition of (b) ZrO2 and (e) ZrH2; (c) EDS analysis of the marked points in (a, d) images; (f) HRTEM image presenting the grain boundary film marked by the red rectangle in (d) image

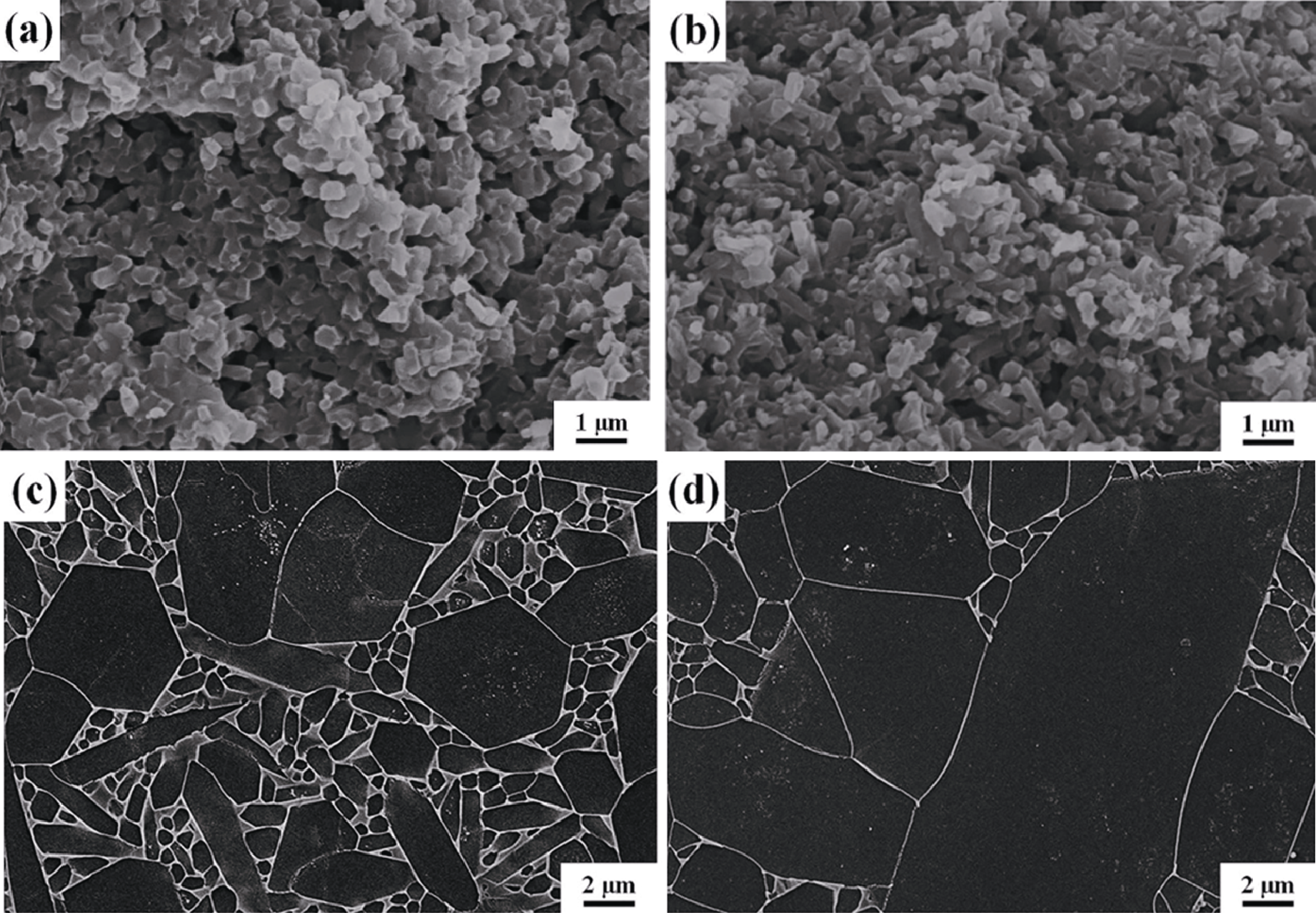

Fig. 15 SEM images on the fracture surfaces of nitrided samples (a, b) and post-sintered samples (c, d) without (a, c) and with (b, d) graphite powder bed addition[57]

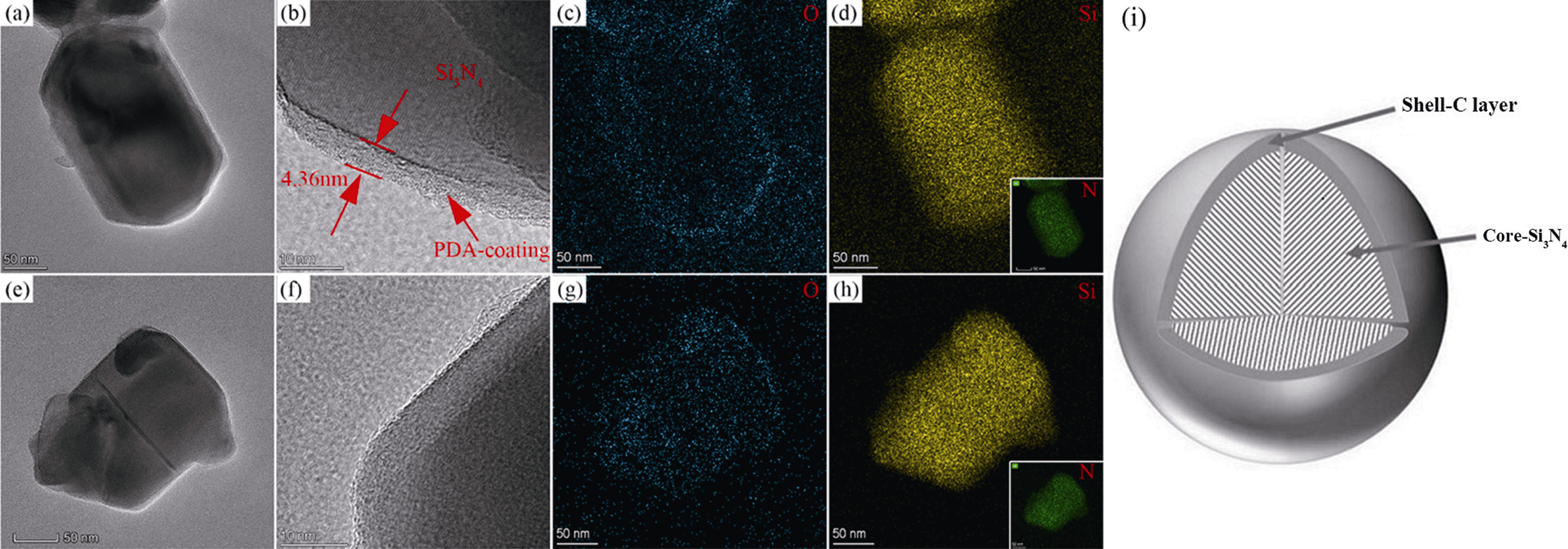

Fig. 16 TEM images of PDA-coated powder and schematic of Si3N4-C core-shell structure[59-60] (a, e) Overall morphologies of PDA-coated (a) and PDA-free (e) powder; (b, f) Partial magnified images of (a, e), respectively; (c, g) O distributions of PDA-coated (c) and PDA-free (g) powder; (d, h) Si and N distributions of PDA-coated (d) and PDA-free (h) powder; (i) Schematic of Si3N4-C core-shell structure

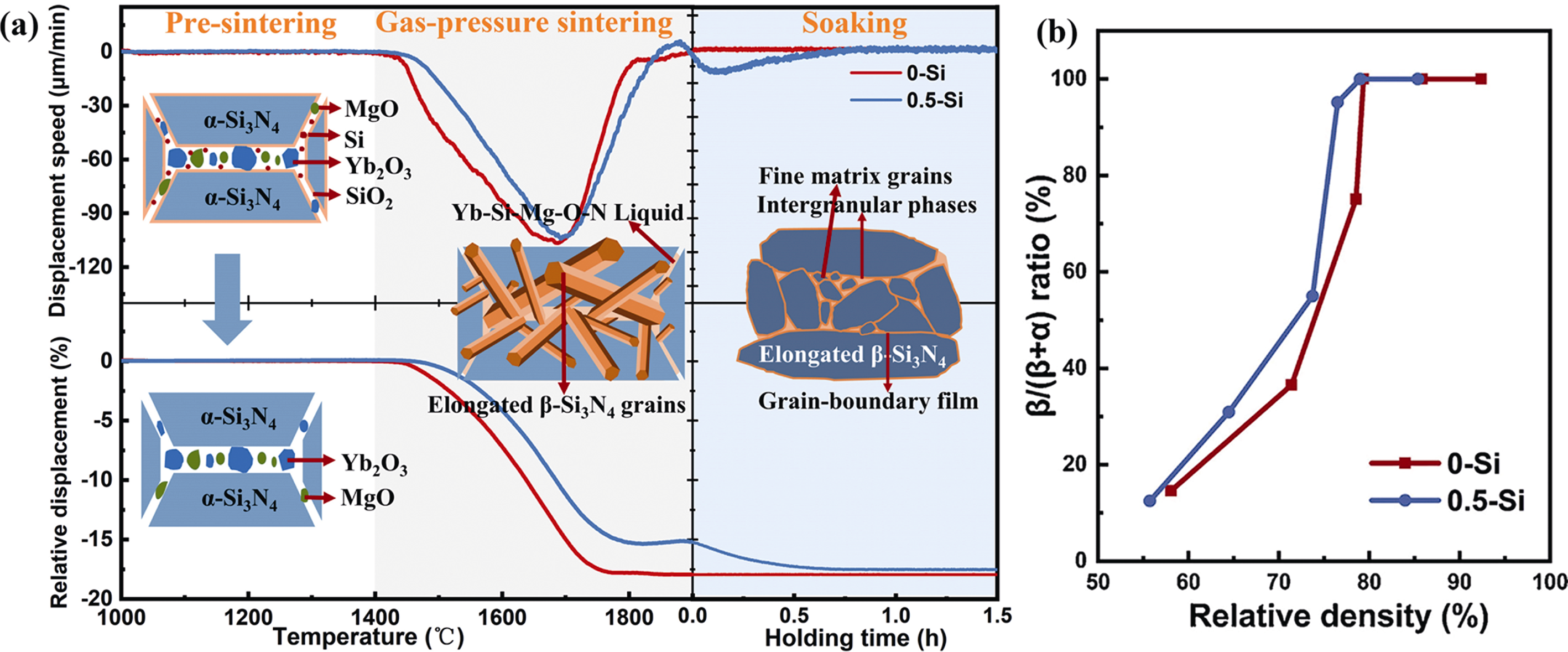

Fig. 17 (a) Shrinkage behaviors and densification mechanism of Si3N4 ceramics during sintering, and (b) relationship between β phase ratio and relative density[62]

| [1] | Tobiasreimann U N, 李毅, 魏宇浩. 现代功率模块及器件应用技术(3). 电源技术应用, 2005, 8(3):59. |

| [2] | UTSCHIG T, DESCHER P, RAUER M, et al. Metal ceramic substrates for highly reliable power modules-not only in electric vehicles. Interceram-International Ceramic Review, 2020, 69(2):20. |

| [3] | 张兆生, 卢振亚, 陈志武. 电子封装用陶瓷基片材料的研究进展. 材料导报, 2008, 22(11):16. |

| [4] | YAMAGIWA M. Packaging technologies of power modules for hybrid electric vehicles and electric vehicles. Bulletin of the Ceramic Society of Japan, 2010, 45(6):432. |

| [5] | HAGGERTY J S, LIGHTFOOT A. Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing. Ceramic Engineering and Science Proceedings, 1995, 16: 475. |

| [6] | HIROSAKI N, OGATA S, KOCER C, et al. Molecular dynamics calculation of the ideal thermal conductivity of single-crystal α- and β-Si3N4. Physical Review B, 2002, 65(13):134110. |

| [7] | ZHOU H, FENG T. Theoretical upper limits of the thermal conductivity of Si3N4. Applied Physics Letters, 2023, 122(18):182203. |

| [8] | WATARI K, HIRAO K, BRITO M E, et al. Hot isostatic pressing to increase thermal conductivity of Si3N4 ceramics. Journal of Materials Research, 1999, 14(4):1538. |

| [9] |

ZHOU Y, HYUGA H, KUSANO D, et al. A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39):4563.

DOI |

| [10] | 王为得. 基于液相组成和显微结构调控的高热导率氮化硅陶瓷的研究. 上海: 中国科学院上海硅酸盐研究所博士论文, 2021. |

| [11] | ZHU X, ZHOU Y, HIRAO K, et al. Potential use of only Yb2O3 in producing dense Si3N4 ceramics with high thermal conductivity by gas pressure sintering. Science and Technology of Advanced Materials. 2010, 11(6):065001. |

| [12] | KITAYAMA M, HIRAO K, WATARI K, et al. Thermal conductivity of β-Si3N4: III, effect of rare earth (RE = La, Nd, Cd, Y, Yb, and Sc) oxide additives. Journal of the American Ceramic Society, 2001, 84(2):353. |

| [13] | KITAYAMA M, HIRAO K, TORIYAMA M, et al. Thermal conductivity of β-Si3N4: I, effects of various microstructural factors. Journal of the American Ceramic Society, 1999, 82(11):3105. |

| [14] | KITAYAMA M, HIRAO K, TSUGE A, et al. Thermal conductivity of β-Si3N4: II, effect of lattice oxygen. Journal of the American Ceramic Society. 2000, 83(8): 1985. |

| [15] | KITAYAMA M, HIRAO K, TSUGE A, et al. Oxygen content in β-Si3N4 crystal lattice. Journal of the American Ceramic Society. 1999, 82(11):3263. |

| [16] | FU S, YANG Z C, LI J T. Progress of high strength and high thermal conductivity Si3N4 ceramics for power module packaging. Journal of Inorganic Materials, 2023, 38(10):1117. |

| [17] | ZHOU Y, HYUGA H, KUSANO D, et al. Development of high-thermal-conductivity silicon nitride ceramics. Journal of Asian Ceramic Societies, 2015, 3(3):221. |

| [18] | ÇALIŞKAN F, TATLI Z, GENSON A, et al. Pressureless sintering of β-SiAlON ceramic compositions using fluorine and oxide additive system. Journal of the European Ceramic Society, 2012, 32(7):1337. |

| [19] | HU F, ZHAO L, XIE Z. Silicon nitride ceramics with high thermal conductivity and excellent mechanical properties fabricated with MgF2 sintering aid and post-sintering heat treatment. Journal of Ceramic Science and Technology, 2016, 7(4):423. |

| [20] | LUO C, ZHANG Y, DENG T. Pressureless sintering of high performance silicon nitride ceramics at 1620 ℃. Ceramics International, 2021, 47(20):29371. |

| [21] | BAI B, FU T, NING X. Thermal conductivity and mechanical property of Si3N4 ceramics sintered with CeF3/LaF3 additives. Advanced Materials Research, 2010, 105-106: 171. |

| [22] | LIAO S J, ZHOU L, JIANG C, et al. Thermal conductivity and mechanical properties of Si3N4 ceramics with binary fluoride sintering additives. Journal of the European Ceramic Society, 2021, 41(14):6971. |

| [23] | HILLINGER G, HLAVACEK V. Direct synthesis and sintering of silicon nitridenitanium nitride composite. Journal of the American Ceramic Society, 1995, 78(2):495. |

| [24] | HAYASHI H, HIRAO K, TORIYAMA M, et al. MgSiN2 addition as a means of increasing the thermal conductivity of β-silicon nitride. Journal of the American Ceramic Society, 2001, 84(12):3060. |

| [25] | PENG G, LIANG M, LIANG Z, et al. Spark plasma sintered silicon nitride ceramics with high thermal conductivity using MgSiN2 as additives. Journal of the American Ceramic Society, 2009, 92(9): 2122. |

| [26] | FU S, YANG Z C, LI H H, et al. Mechanical properties and thermal conductivity of Si3N4 ceramics with composite sintering additives. Journal of Inorganic Materials, 2022, 37(9):947. |

| [27] | HU F, ZHU T, XIE Z, et al. Effect of composite sintering additives containing non-oxide on mechanical, thermal and dielectric properties of silicon nitride ceramics substrate. Ceramics International, 2021, 47(10):13635. |

| [28] | ZHANG J, CUI W, LI F, et al. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceramics International, 2020, 46(10):15719. |

| [29] | 李聪, 张博, 胡加斌, 等. MgSiN2-Y2O3复合烧结助剂对Si3N4陶瓷力学及导热性能的影响. 硅酸盐学报, 2021, 49(12):2556. |

| [30] | 杨建辉, 陈义祥, 刘光华, 等. 自蔓延高温合成制备单相氮化硅镁粉体. 硅酸盐学报, 2011, 39(2):177. |

| [31] | LI Y, KIM H, WU H, et al. Enhanced thermal conductivity in Si3N4 ceramic with the addition of Y2Si4N6C. Journal of the American Ceramic Society, 2018, 101(9):4128. |

| [32] | LIANG H, WANG W, ZUO K, et al. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceramics International, 2020, 46(11):17776. |

| [33] | BOYER S M, MOULSON A J. A mechanism for the nitridation of Fe-contaminated silicon. Journal of Materials Science, 1978, 13(8):1637. |

| [34] | MUKERJI J, BISWAS S K. Effect of iron, titanium, and hafnium on second-stage nitriding of silicon. Journal of the American Ceramic Society, 1981, 64(9):549. |

| [35] | WANG L, QI Q, CAI P, et al. New route to improve the fracture toughness and flexural strength of Si3N4 ceramics by adding FeSi2. Scripta Materialia, 2017, 126: 11. |

| [36] | WANG W D, YAO D, CHEN H, et al. ZrSi2-MgO as novel additives for high thermal conductivity of β-Si3N4 ceramics. Journal of the American Ceramic Society, 2020, 103(3): 2090. |

| [37] | SAJGALIK P, DUSZA J, HOFFMANN M J. Relationship between microstructure, toughening mechanisms, and fracture-toughness of reinforced silicon-nitride ceramics. Journal of the American Ceramic Society, 1995, 78(10):2619. |

| [38] | PARK H, KIM H E, NIIHARA K. Microstructural evolution and mechanical properties of Si3N4 with Yb2O3 as a sintering additive. Journal of the American Ceramic Society, 1997, 80(3):750. |

| [39] | WANG W D, YAO D, LIANG H Q, et al. Effect of the binary nonoxide additives on the densification behavior and thermal conductivity of Si3N4 ceramics. Journal of the American Ceramic Society, 2020, 103(10):5891. |

| [40] | YAN M, LIU Y, LIU Y, et al. Simultaneous gettering of oxygen and chlorine and homogenization of the β phase by rare earth hydride additions to a powder metallurgy Ti-2.25Mo-1.5Fe alloy. Scripta Materialia, 2012, 67(5):491. |

| [41] | HAMPSHIRE S. Oxynitride glasses. Journal of the European Ceramic Society, 2008, 28(7):1475. |

| [42] | LEMERCIER H, ROUXEL T, FARGEOT D, et al. Yttrium SiAlON glasses: structure and mechanical properties-elasticity and viscosity. Journal of Non-Crystalline Solids, 1996, 201(1/2):128 |

| [43] | HAKEEM A S, DAUC R, LEONOVA E, et al. Silicate glasses with unprecedented high nitrogen and electropositive metal contents obtained by using metals as precursors. Advanced Materials, 2005, 17(18): 2214. |

| [44] | WANG W D, YAO D, LIANG H Q, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. Journal of the European Ceramic Society, 2020, 40(15):5316. |

| [45] | WANG W D, CHEN H B, LI S H, et al. Preparation of silicon nitride with high thermal conductivity and high flexural strength using YbH2-MgO as sintering additive. Journal of Inorganic Materials, 2021, 36(9):959. |

| [46] | WANG W D, YAO D, LIANG H, et al. Improved thermal conductivity of β-Si3N4 ceramics through the modification of the liquid phase by using GdH2 as a sintering additive. Ceramics International, 2021, 47(4):5631. |

| [47] | WANG W D, YAO D, LIANG H, et al. Enhanced thermal conductivity in Si3N4ceramics prepared by using ZrH2 as an oxygen getter. Journal of Alloys and Compounds, 2021, 855: 157451. |

| [48] | DUAN Y, ZHANG J, LI X, et al. High thermal conductivity silicon nitride ceramics prepared by pressureless sintering with ternary sintering additives. International Journal of Applied Ceramic Technology, 2019, 16(4):1399. |

| [49] | 李勇霞.高热导Si3N4基复合材料的制备与性能研究. 哈尔滨: 哈尔滨工业大学博士学位论文, 2018. |

| [50] | LUO H, LI C, DENG L, et al. C0.3N0.7Ti-SiC toughed silicon nitride hybrids with non-oxide additives Ti3SiC2. Materials, 2020, 13(6):1428. |

| [51] | LEE B, LEE D, LEE J H. Enhancement of toughness and wear resistance in boron nitride nanoplatelet (BNNP) reinforced Si3N4 nanocomposites. Scientific Reports, 2016, 6: 27609. |

| [52] | LIANG H, WANG W, ZUO K, et al. YB2C2: a new additive for fabricating Si3N4 ceramics with superior mechanical properties and medium thermal conductivity. Ceramics International, 2020, 46(4):5239. |

| [53] | HUANG M, HUANG Y, OU J, et al. Effect of a new nonoxide additive, Y3Si2C2, on the thermal conductivity and mechanical properties of Si3N4 ceramics. International Journal of Applied Ceramic Technology, 2022, 19(6):3403. |

| [54] | WATARI K, KAWAMOTO M, ISHIZAKI K. Carbon behavior in sintered silicon nitride grain boundaries. Materials Science and Engineering A, 1989, 109: 89. |

| [55] | HNATKO M, SAJGALIK P, LENČÉŠ Z, et al. Carbon reduction reaction in the Y2O3-SiO2 glass system at high temperature. Journal of the European Ceramic Society, 2001, 21(16):2797. |

| [56] | KIM H D, HAN B D, PARK D S, et al. Novel two-step sintering process to obtain a bimodal microstructure in silicon nitride. Journal of the American Ceramic Society, 2002, 85(1):245. |

| [57] | LI Y, KIM H, WU H, et al. Improved thermal conductivity of sintered reaction-bonded silicon nitride using a BN/graphite powder bed. Journal of the European Ceramic Society, 2017, 37(15):4483. |

| [58] | LI Y, KIM H, WU H, et al. Enhanced thermal conductivity in Si3N4 ceramic by addition of a small amount of carbon. Journal of the European Ceramic Society, 2019, 39(2/3):157. |

| [59] | LU D, YANG P, HUANG Y, et al. Enhanced thermal conductivity in Si3N4 ceramics by carbonizing polydopamine coatings. Ceramics International, 2022, 48(13):18615. |

| [60] | 伍尚华, 杨平, 李建斌. 一种用碳包覆制备低氧含量、高热导的氮化硅陶瓷的方法及其应用: CN202010588120. 3. 2020-11-03. |

| [61] | LINDLEY M, PITMAN K, JONES B, et al. The influence of hydrogen in the nitriding gas on the strength, structure and composition of reaction-sintered silicon nitride. Journal of Materials Science, 1979, 14(1):70. |

| [62] | WANG W D, YAO D, LIANG H, et al. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. Journal of the European Ceramic Society, 2021, 41(2):1735. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [8] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [9] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [10] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [11] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [12] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [13] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [14] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [15] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||