Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (3): 245-255.DOI: 10.15541/jim20240344

Special Issue: 【制备方法】3D打印(202506)

• REVIEW • Previous Articles Next Articles

YIN Jie1,2( ), GENG Jiayi1,2, WANG Kanglong1, CHEN Zhongming1, LIU Xuejian1,2, HUANG Zhengren1,2,3(

), GENG Jiayi1,2, WANG Kanglong1, CHEN Zhongming1, LIU Xuejian1,2, HUANG Zhengren1,2,3( )

)

Received:2024-07-19

Revised:2024-10-05

Published:2025-03-20

Online:2025-03-12

Contact:

HUANG Zhengren, professor. E-mail: zhrhuang@mail.sic.ac.cnAbout author:YIN Jie (1986-), male, professor. E-mail: jieyin@mail.sic.ac.cn

Supported by:CLC Number:

YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics[J]. Journal of Inorganic Materials, 2025, 40(3): 245-255.

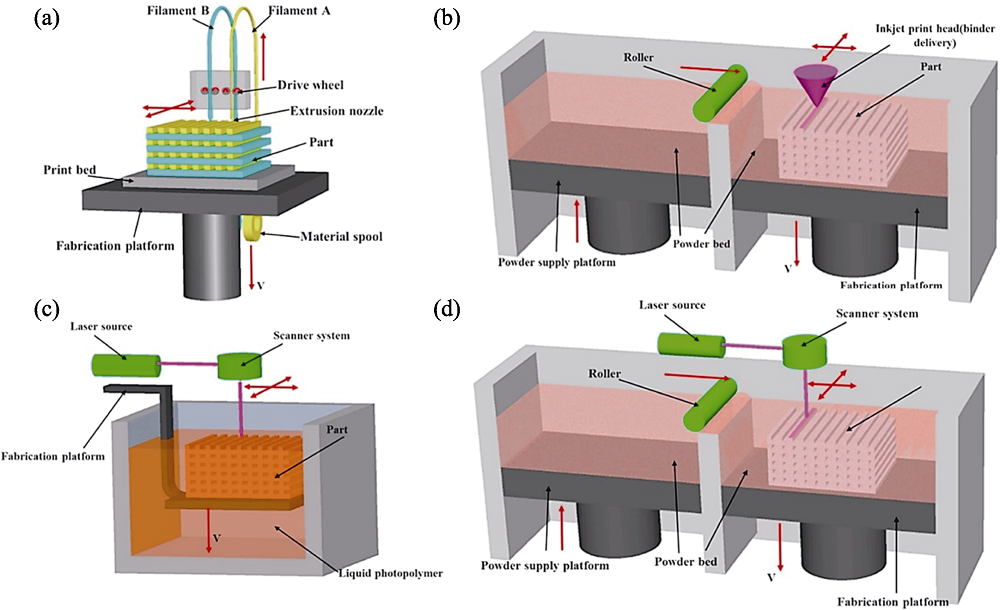

Fig. 1 Schematic diagrams of typical 3D printing technology for ceramics[13] (a) Fused deposition modeling; (b) Direct ink writing; (c) Stereolithography; (d) Selective laser sintering

| Sintering method | Sintering temperature/℃ | Mechanical property | Fracture mechanism | Mass transfer |

|---|---|---|---|---|

| Solid-phase sintering | 2000-2200 | High flexure strength, low fracture toughness, and being sensitive to cracks | Transgranular fracture | Diffusion |

| Liquid-phase sintering | 1850-2000 | High flexure strength and fracture toughness | Intergranular fracture | Viscous flow |

Table 1 Characteristics of solid-phase sintered and liquid-phase sintered SiC ceramics[50]

| Sintering method | Sintering temperature/℃ | Mechanical property | Fracture mechanism | Mass transfer |

|---|---|---|---|---|

| Solid-phase sintering | 2000-2200 | High flexure strength, low fracture toughness, and being sensitive to cracks | Transgranular fracture | Diffusion |

| Liquid-phase sintering | 1850-2000 | High flexure strength and fracture toughness | Intergranular fracture | Viscous flow |

| Additive manufacturing process | Mechanical property | Advantage | Challenge | Ref. |

|---|---|---|---|---|

| FDM | Bulk density: 3.12 g/cm3 Flexure strength: 465 MPa | Being simple, efficient preparation process and low requirements for equipment | Poor surface roughness, additional support for complex structures, and obvious step effect of layered structure | [60] |

| DIW | Bulk density: 3 g/cm3 Flexure strength: 406.1 MPa | High adaptability of raw materials, simple preparation process, and low manufacturing cost | Dimensional restrictions, and low precision | [16] |

| SLA | Bulk density: 2.85 g/cm3 Flexure strength: 234.8 MPa | High printing accuracy and surface finish, enabling design of macro- and micro-structures | Low green body strength, additional support structures required for complex structures, and toxic photosensitive resins | [23] |

| SLS | Bulk density: 3.1 g/cm3 Flexure strength: 794 MPa | High molding efficiency, and recoverable powder | High thermal stress, and being prone to defects | [39] |

Table 2 Mechanical properties, advantages and challenges of SiC ceramics by 3D printing techniques[16,23,39,60]

| Additive manufacturing process | Mechanical property | Advantage | Challenge | Ref. |

|---|---|---|---|---|

| FDM | Bulk density: 3.12 g/cm3 Flexure strength: 465 MPa | Being simple, efficient preparation process and low requirements for equipment | Poor surface roughness, additional support for complex structures, and obvious step effect of layered structure | [60] |

| DIW | Bulk density: 3 g/cm3 Flexure strength: 406.1 MPa | High adaptability of raw materials, simple preparation process, and low manufacturing cost | Dimensional restrictions, and low precision | [16] |

| SLA | Bulk density: 2.85 g/cm3 Flexure strength: 234.8 MPa | High printing accuracy and surface finish, enabling design of macro- and micro-structures | Low green body strength, additional support structures required for complex structures, and toxic photosensitive resins | [23] |

| SLS | Bulk density: 3.1 g/cm3 Flexure strength: 794 MPa | High molding efficiency, and recoverable powder | High thermal stress, and being prone to defects | [39] |

| [1] | ZOCCA A, COLOMBO P, GOMES C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities. Journal of the American Ceramic Society, 2015, 98(7): 1983. |

| [2] | BAUX A, JACQUES S, ALLEMAND A, et al. Complex geometry macroporous SiC ceramics obtained by 3D-printing, polymer impregnation and pyrolysis (PIP) and chemical vapor deposition (CVD). Journal of the European Ceramic Society, 2021, 41(6): 3274. |

| [3] | SHEN T, XIONG H, LI Z, et al. Fused deposition fabrication of high-quality zirconia ceramics using granular feedstock. Ceramics International, 2021, 47(24): 34352. |

| [4] | CHEN A, SU J, LI Y, et al. 3D/4D printed bio-piezoelectric smart scaffolds for next-generation bone tissue engineering. International Journal of Extreme Manufacturing, 2023, 5(3): 032007. |

| [5] | SHAHZAD A, LAZOGLU I. Direct ink writing (DIW) of structural and functional ceramics: recent achievements and future challenges. Composites Part B: Engineering, 2021, 225: 109249. |

| [6] | JIANG Q, YANG D, YUAN H, et al. Fabrication and properties of Si2N2O-Si3N4 ceramics via direct ink writing and low-temperature sintering. Ceramics International, 2022, 48(1): 32. |

| [7] | HOSSAIN S S, LU K. Recent progress of alumina ceramics by direct ink writing: ink design, printing and post-processing. Ceramics International, 2023, 49(7): 10199. |

| [8] | TANG J, CHANG H, GUO X, et al. Preparation of carbon fiber- reinforced SiC ceramics by stereolithography and secondary silicon infiltration. Ceramics International, 2022, 48(17): 25159. |

| [9] | BAI X, DING G, ZHANG K, et al. Stereolithography additive manufacturing and sintering approaches of SiC ceramics. Open Ceramics, 2021, 5: 100046. |

| [10] | HE R, ZHOU N, ZHANG K, et al. Progress and challenges towards additive manufacturing of SiC ceramic. Journal of Advanced Ceramics, 2021, 10(4): 637. |

| [11] | HASSANIN H, ESSA K, ELSHAER A, et al. Micro-fabrication of ceramics: additive manufacturing and conventional technologies. Journal of Advanced Ceramics, 2021, 10(1): 1. |

| [12] | CHEN X, YIN J, HUANG L, et al. Microstructural tailoring, mechanical and thermal properties of SiC composites fabricated by selective laser sintering and reactive melt infiltration. Journal of Advanced Ceramics, 2023, 12(4): 830. |

| [13] | NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites Part B: Engineering, 2018, 143: 172. |

| [14] | MEI H, YAN Y, FENG L, et al. First printing of continuous fibers into ceramics. Journal of the American Ceramic Society, 2019, 102(6): 3244. |

| [15] | LI F F, MA N N, CHEN J, et al. SiC ceramic mirror fabricated by additive manufacturing with material extrusion and laser cladding. Additive Manufacturing, 2022, 58: 102994. |

| [16] | WEN J, ZENG T, PAN X, et al. Effect of solid loading and carbon additive on microstructure and mechanical properties of 3D-printed SiC ceramic. International Journal of Applied Ceramic Technology, 2022, 19(6): 3007. |

| [17] | XIONG H, CHEN H, ZHAO L, et al. SiCw/SiCp reinforced 3D-SiC ceramics using direct ink writing of polycarbosilane-based solution: microstructure, composition and mechanical properties. Journal of the European Ceramic Society, 2019, 39(8): 2648. |

| [18] | XIA Y, LU Z, CAO J, et al. Microstructure and mechanical property of Cf/SiC core/shell composite fabricated by direct ink writing. Scripta Materialia, 2019, 165: 84. |

| [19] | LIU Y, CHENG Y, MA D, et al. Continuous carbon fiber reinforced ZrB2-SiC composites fabricated by direct ink writing combined with low-temperature hot-pressing. Journal of the European Ceramic Society, 2022, 42(9): 3699. |

| [20] | LI Z, CHEN Z, LIU J, et al. Additive manufacturing of lightweight and high-strength polymer-derived SiOC ceramics. Virtual and Physical Prototyping, 2020, 15(2): 163. |

| [21] | ECKEL Z C, ZHOU C, MARTIN J H, et al. Additive manufacturing of polymer-derived ceramics. Science, 2016, 351(6268): 58. |

| [22] | FU S, ZHU M, ZHU Y. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4): 457. |

| [23] | TANG J, GUO X, CHANG H, et al. The preparation of SiC ceramic photosensitive slurry for rapid stereolithography. Journal of the European Ceramic Society, 2021, 41(15): 7516. |

| [24] | LIU T, YANG L, CHEN Z, et al. Effects of SiC content on the microstructure and mechanical performance of stereolithography-based SiC ceramics. Journal of Materials Research and Technology, 2023, 25: 5184. |

| [25] | FU X, HUCK D, MAKEIN L, et al. Effect of particle shape and size on flow properties of lactose powders. Particuology, 2012, 10(2): 203. |

| [26] | LU H, GUO X, LIU Y, et al. Effect of particle size on flow mode and flow characteristics of pulverized coal. KONA Powder and Particle Journal, 2015, 32: 143. |

| [27] | JULIANO P, MUHUNTHAN B, BARBOSA-CÁNOVAS G V. Flow and shear descriptors of preconsolidated food powders. Journal of Food Engineering, 2006, 72(2): 157. |

| [28] | KRANTZ M, ZHANG H, ZHU J. Characterization of powder flow: static and dynamic testing. Powder Technology, 2009, 194(3): 239. |

| [29] | SCHÜSSELE A, BAUER-BRANDL A. Note on the measurement of flowability according to the European Pharmacopoeia. International Journal of Pharmaceutics, 2003, 257(1/2): 301. |

| [30] | WU S, YANG L, WANG C, et al. Si/SiC ceramic lattices with a triply periodic minimal surface structure prepared by laser powder bed fusion. Additive Manufacturing, 2022, 56: 102910. |

| [31] | CHEN X, YIN J, LIU X, et al. Effect of laser power on mechanical properties of SiC composites rapidly fabricated by selective laser sintering and direct liquid silicon infiltration. Ceramics International, 2022, 48(13): 19123. |

| [32] | POPPER P, DAVIES D G S. The preparation and properties of self-bonded silicon carbide. Powder Metallurgy, 1961, 4(8): 113. |

| [33] | HAYUN S, FRAGE N, DARIEL M P. The morphology of ceramic phases in BxC-SiC-Si infiltrated composites. Journal of Solid State Chemistry, 2006, 179(9): 2875. |

| [34] | 邓明进.高性能反应烧结碳化硅陶瓷材料制备及其性能研究. 武汉: 武汉理工大学博士学位论文, 2010. |

| [35] | 武七德, 朱齐, 吴小兵, 等. 素坯结构对RBSC材料性能的影响. 武汉理工大学学报, 1996, 18(3): 34. |

| [36] | 李连跃, 孙洪鸣, 田素贵, 等. 炭黑含量对反应烧结碳化硅组织与性能的影响. 中国陶瓷工业, 2017, 24(1): 18. |

| [37] | LI S, ZHANG Y, HAN J, et al. Random chopped fibers in reaction bonded SiC composite: morphology, etching and reinforcing properties. Materials Science and Engineering: A, 2012, 551: 104. |

| [38] | 黄清伟, 乔冠军, 高积强, 等. 生坯制备参数对反应烧结碳化硅显微组织与性能的影响. 稀有金属材料与工程, 2001, 30(2): 149. |

| [39] | WU Q, YANG C, ZHANG H, et al. Fabrication and characterization of reaction-bonded silicon carbide with poly(methyl methacrylate) as pore-forming agent. Ceramics International, 2013, 39(5): 5295. |

| [40] | LIU K, WANG J, WU T, et al. Effects of carbon content on microstructure and mechanical properties of SiC ceramics fabricated by SLS/RMI composite process. Ceramics International, 2020, 46(14): 22015. |

| [41] | PELANCONI M, COLOMBO P, ORTONA A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. Journal of the European Ceramic Society, 2021, 41(10): 5056. |

| [42] | ZHONG H, WANG Z, ZHOU H, et al. Properties and microstructure evolution of Cf/SiC composites fabricated by polymer impregnation and pyrolysis (PIP) with liquid polycarbosilane. Ceramics International, 2017, 43(10): 7387. |

| [43] | ZOU Y, LI C H, TANG Y, et al. Preform impregnation to optimize the properties and microstructure of RB-SiC prepared with laser sintering and reactive melt infiltration. Journal of the European Ceramic Society, 2020, 40(15): 5186. |

| [44] | ZHAO H, LIU W, LV X, et al.β-SiC nano-particles enhanced thermal conductivity of pressureless solid-phase sintering SiC. Ceramics International, 2024, 50(2): 2772. |

| [45] | WANG K, YIN J, CHEN X, et al. Microstructure and properties of liquid phase sintered SiC ceramics fabricated via selective laser printing and precursor impregnation and pyrolysis. Ceramics International, 2024, 50(3): 4315. |

| [46] | XING Y, WU H, LIU X, et al. Grain Composition on solid-state-sintered SiC ceramics. Journal of Inorganic Materials, 2018, 33(11): 1167. |

| [47] | SHAFFER P T B. The SiC phase in the system SiC-B4C-C. Materials Research Bulletin, 1969, 4(3): 213. |

| [48] | MADDRELL E R. Pressureless sintering of silicon carbide. Journal of Materials Science Letters, 1987, 6(4): 486. |

| [49] | WANG K, YIN J, CHEN X, et al. Effect of particle grading on properties of silicon carbide ceramics by selective laser printing combined with solid phase sintering at atmospheric pressure. Journal of Inorganic Materials, 2024, 39(7): 754. |

| [50] | 陈宇红, 韩凤兰, 吴澜尔. 碳化硅陶瓷的无压烧结技术. 宁夏工程技术, 2002, 1(1): 32. |

| [51] | KINGERY W D. Densification during sintering in the presence of a liquid phase. I. Theory. Journal of Applied Physics, 1959, 30(3): 301. |

| [52] | GERMAN R M, SURI P, PARK S J. Review: liquid phase sintering. Journal of Materials Science, 2009, 44(1): 1. |

| [53] | BISWAS K, RIXECKER G, ALDINGER F. Gas pressure sintering of SiC sintered with rare-earth-(III)-oxides and their mechanical properties. Ceramics International, 2005, 31(5): 703. |

| [54] | PEREVISLOV S N. Mechanism of liquid-phase sintering of silicon carbide and nitride with oxide activating additives. Glass and Ceramics, 2013, 70(7/8): 265. |

| [55] | 孙国帅, 刘荣军, 曹英斌, 等. CVI-GSI工艺制备C/C-SiC复合材料的组成结构与力学性能. 材料工程, 2017, 45(12): 58. |

| [56] | LIU R, WANG F, ZHANG J, et al. Effects of CVI SiC amount and deposition rates on properties of SiCf/SiC composites fabricated by hybrid chemical vapor infiltration (CVI) and precursor infiltration and pyrolysis (PIP) routes. Ceramics International, 2021, 47(19): 26971. |

| [57] | TERRANI K, JOLLY B, TRAMMELL M. 3D printing of high-purity silicon carbide. Journal of the American Ceramic Society, 2020, 103(3): 1575. |

| [58] | FU H, ZHU W, XU Z, et al. Effect of silicon addition on the microstructure, mechanical and thermal properties of Cf/SiC composite prepared via selective laser sintering. Journal of Alloys and Compounds, 2019, 792: 1045. |

| [59] | WANG C, CHEN X, WANG Z, et al. A novel mullite anti-gyroid/SiC gyroid ceramic metastructure based on digital light processing 3D printing with enhanced electromagnetic wave absorption and mechanical properties. Journal of Advanced Ceramics, 2024, 13(8): 1212. |

| [60] | LI F, ZHU M, CHEN J, et al. High-strength and low-silicon SiC ceramics prepared by extrusion molding 3D printing. Journal of the European Ceramic Society, 2024, 44(2): 617. |

| [1] | YU Shengyang, SU Haijun, JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin. A Review of Pore Defects in Ultra-high Temperature Oxide Ceramics by Laser Additive Manufacturing: Formation and Suppression [J]. Journal of Inorganic Materials, 2025, 40(9): 944-956. |

| [2] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [3] | XIAO Xiaolin, WANG Yuxiang, GU Peiyang, ZHU Zhenrong, SUN Yong. Advances in Regulation of Damaged Skin Regeneration by Two-dimensional Inorganic Materials [J]. Journal of Inorganic Materials, 2025, 40(8): 860-870. |

| [4] | MA Jingge, WU Chengtie. Application of Inorganic Bioceramics in Promoting Hair Follicle Regeneration and Hair Growth [J]. Journal of Inorganic Materials, 2025, 40(8): 901-910. |

| [5] | ZHANG Hongjian, ZHAO Ziyi, WU Chengtie. Inorganic Biomaterials on Regulating Neural Cell Function and Innervated Tissue Regeneration: A Review [J]. Journal of Inorganic Materials, 2025, 40(8): 849-859. |

| [6] | AI Minhui, LEI Bo. Micro-nanoscale Bioactive Glass: Functionalized Design and Angiogenic Skin Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 921-932. |

| [7] | WANG Yutong, CHANG Jiang, XU He, WU Chengtie. Advances in Silicate Bioceramic/Bioglass for Wound Healing: Effects, Mechanisms and Application Ways [J]. Journal of Inorganic Materials, 2025, 40(8): 911-920. |

| [8] | MA Wenping, HAN Yahui, WU Chengtie, LÜ Hongxu. Application of Inorganic Bioactive Materials in Organoid Research [J]. Journal of Inorganic Materials, 2025, 40(8): 888-900. |

| [9] | LUO Xiaomin, QIAO Zhilong, LIU Ying, YANG Chen, CHANG Jiang. Inorganic Bioactive Materials Regulating Myocardial Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 871-887. |

| [10] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [11] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [12] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [13] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [14] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [15] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||