Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 418-424.DOI: 10.15541/jim20200367

• RESEARCH PAPER • Previous Articles Next Articles

ZENG Jianjun1( ), ZHANG Kuibao1,2(

), ZHANG Kuibao1,2( ), CHEN Daimeng1, GUO Haiyan1, DENG Ting1, LIU Kui1

), CHEN Daimeng1, GUO Haiyan1, DENG Ting1, LIU Kui1

Received:2020-07-02

Revised:2020-09-18

Published:2021-04-20

Online:2020-10-30

Contact:

ZHANG Kuibao, professor. E-mail: xiaobao320@163.com

About author:ZENG Jianjun(1997-), male, Master candidate. E-mail: zeng_jianjun@126.com

Supported by:CLC Number:

ZENG Jianjun, ZHANG Kuibao, CHEN Daimeng, GUO Haiyan, DENG Ting, LIU Kui. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7 High-entropy Transparent Ceramics by Vacuum Sintering[J]. Journal of Inorganic Materials, 2021, 36(4): 418-424.

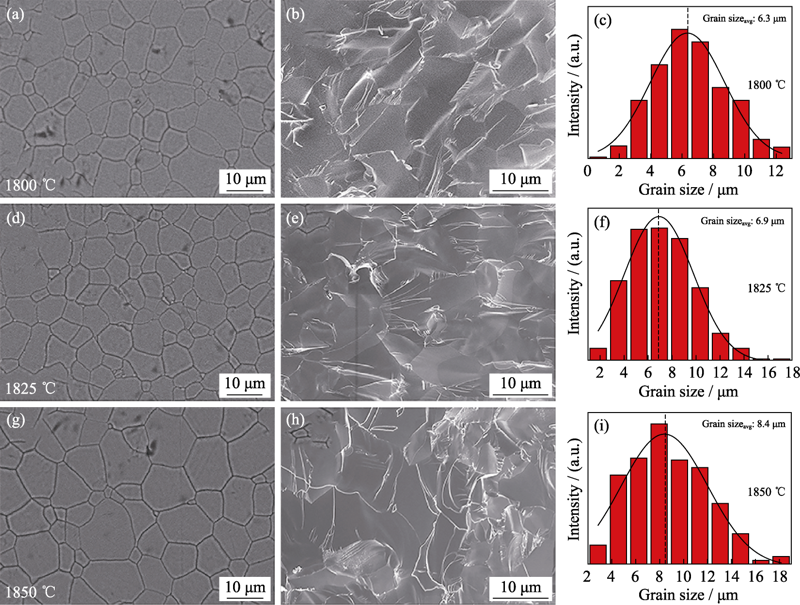

Fig. 3 SEM images of final high-entropy ceramics after hot corrosion (a, d, g), SEM images of fractured final high-entropy ceramics (b, e, h), histograms of grain distribution (c, f, i) of final high-entropy ceramics

| [1] | FU ZHENGYI, GU JUNFENG, ZOU JI, et al. Recent progress in high-entropy ceramic materials. Materials China, 2019,38(9):855-865. |

| [2] | YEH JIENWEI, CHEN SWEKAI, SUJIEN LIN, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303. |

| [3] | CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A, 2004,375:213-218. |

| [4] |

NIU CHANGNING, LAROSA CARLYN R, MIAO JIASHI, et al. Magnetically-driven phase transformation strengthening in high entropy alloys. Nature Communications, 2018,9(1):1363.

URL PMID |

| [5] | PRAVEEN S, KIM H S. High-entropy alloys: potential candidates for high-temperature applications-an overview. Advanced Engineering Materials, 2018,20(1):1700645. |

| [6] |

MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017,122:448-511.

DOI URL |

| [7] | YEH J. Recent progress in high-entropy alloys. Annales De Chimie-Science Des Materiaux, 2006,31(6):633-648. |

| [8] |

CHUANG MINGHAO, TSAI MINGHUNG, WANG WOEIREN, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Materialia, 2011,59(16):6308-6317.

DOI URL |

| [9] |

LI ZHIMING, PRADEEP K G, DENG YUN, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature, 2016,534(7606):227-230.

URL PMID |

| [10] | BUTLER T M, ALFANO J P, MARTENS R L, et al. High-temperature oxidation behavior of Al-Co-Cr-Ni-(Fe or Si) multicomponent high-entropy alloys. JOM, 2014,67(1):246-259. |

| [11] | ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015,6(1):8485. |

| [12] | CHELLALI M R, SARKAR A, NANDAM S H, et al. On the homogeneity of high entropy oxides: an investigation at the atomic scale. Scripta Materialia, 2019,166:58-63. |

| [13] | LEI ZHIFENG, LIU XIONGJUN, WANG HUI, et al. Development of advanced materials via entropy engineering. Scripta Materialia, 2019,165:164-169. |

| [14] | JIANG SICONG, HU TAO, GILD JOSHUA, et al. A new class of high-entropy perovskite oxides. Scripta Materialia, 2018,142:116-120. |

| [15] | DJENADIC R, SARKAR A, CLEMENS O, et al. Multicomponent equiatomic rare earth oxides. Materials Research Letters, 2016,5(2):102-109. |

| [16] | BRAIC V, VLADESCU A, BALACEANU M, et al. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surface and Coatings Technology, 2012,211:117-121. |

| [17] | JIN T, SANG X, UNOCIC R R, et al. Mechanochemical-assisted synthesis of high-entropy metal nitride via a soft urea strategy. Advanced Materials, 2018,30(23):1707512. |

| [18] | WEI XIAO-FENG, LIU JI-XUAN, LI FEI, et al. High entropy carbide ceramics from different starting materials. Journal of the European Ceramic Society, 2019,39:2989-2994. |

| [19] | YAN XUELIANG, CONSTANTIN LOIC, LU YONGFENG, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491. |

| [20] | GILD J, BRAUN J, KAUFMANN K, et al. A high-entropy silicide: (Mo0.2Nb0.2Ta0.2Ti0.2W0.2)Si2. Journal of Materiomics, 2019,5(3):337-343. |

| [21] | MAYRHOFER P H, KIRNBAUER A, ERTELTHALER P, et al. High-entropy ceramic thin films; a case study on transition metal diborides. Scripta Materialia, 2018,149:93-97. |

| [22] | LIU DA, WEN TONGQI, YE BEILIN, et al. Synthesis of superfine high-entropy metal diboride powders. Scripta Materialia, 2019,167:110-114. |

| [23] | SUBRAMANIAN M A, ARAVAMUDAN G, RAO G V. Oxide pyrochlores—a review. Progress in Solid State Chemistry, 1983,15(2):55-143. |

| [24] | TROJAN P J, ZYCH E, KOSIŃSKA M. Fabrication and spectroscopic properties of nanocrystalline La2Hf2O7: Pr. Radiation Measurements, 2010,45(3):432-434. |

| [25] | WHITTLE K R, CRANSWICK L M D, REDFERN S A T, et al. Lanthanum pyrochlores and the effect of yttrium addition in the systems La2-xYxZr2O7 and La2-xYxHf2O7. Journal of Solid State Chemistry, 2009,182(3):442-450. |

| [26] | WANG ZHENGJUAN, ZHOU GUOHONG, JIANG DANYU, et al. Recent development of A2B2O7 system transparent ceramics. Journal of Advanced Ceramics, 2018,7(4):289-306. |

| [27] | SU S J, DING Y, SHU X Y, et al. Nd and Ce simultaneous substitution driven structure modifications in Gd2-xNdxZr2-yCeyO7, Journal of the European Ceramic Society, 2014,35(6):1847-1853. |

| [28] | LI FEI, ZHOU LIN, LIU JIXUAN, et al. High-entropy pyrochlores with low thermal conductivity for thermal barrier coating materials. Journal of Advanced Ceramics, 2019,8(4):576-582. |

| [29] | HE ZONGSHENG, ZHANG KUIBAO, XUE JIALI, et al. Self-propagation high-temperature synthesis of Sm-doped pyrochlores ceramic form and its aqueous durability. Materials Reports, 2018,32(32):247-250. |

| [30] |

SICKAFUS K E, MINERVINI L, GRIMES R W, et al. Radiation tolerance of complex oxides. Science, 2000,289:748-751.

URL PMID |

| [31] |

EL-ATWANI O, LI N, LI M, et al. Outstanding radiation resistance of tungsten-based high-entropy alloys. Science Advances, 2019,5(3):eaav2002.

URL PMID |

| [32] | KAREER A, WAITE J C, LI B, et al. Low activation, refractory, high entropy alloys for nuclear applications, Journal of Nuclear Materials, 2019,526:151744. |

| [33] | JI YAMING, JIANG DANYU, FEN TAO, et al. Fabrication of transparent La2Hf2O7 ceramics from combustion synthesized powders. Materials Research Bulletin, 2005,40(3):553-559. |

| [34] | ZHAO WENWEN, ZHANG KUIBAO, LI WEIWEI, et al. Fabrication and optical properties of transparent LaErZr2O7 ceramic with high excess contents of La and Er. Ceramics International, 2019,45(9):11717-11722. |

| [35] | WANG ZHENGJUAN, ZHOU GUOHONG, QIN XIANPENG, et al. Fabrication and phase transition of La2-xLuxZr2O7 transparent ceramics. Journal of the European Ceramic Society, 2014,34(15):3951-3958. |

| [36] | WANG ZHENGJUAN, ZHOU GUOHONG, ZHANG FANG, et al. Fabrication and properties of La2-xGdxHf2O7 transparent ceramics. Journal of Luminescence, 2016,169:612-615. |

| [37] | YI HAILAN, ZOU XIAOQING, YANG YAN, et al. Fabrication of highly transmitting LaGdHf2O7 ceramics. Journal of the American Ceramic Society, 2011,94(12):4120-4122. |

| [38] | ZHOU GUOHONG, WANG ZHENGJUAN, ZHOU BOZHU, et al. Fabrication of transparent Y2Hf2O7 ceramics via vacuum sintering. Optical Materials, 2013,35(4):774-777. |

| [39] | HU Y L, BAI L H, TONG Y G, et al. First-principle calculation investigation of NbMoTaW based refractory high entropy alloys. Journal of Alloys and Compounds, 2020,827:153963. |

| [40] | ZHANG GUANGRAN, MILISAVLJEVIC IVA, ZYCH EUGENIUSZ, et al. High-entropy sesquioxide X2O3 upconversion transparent ceramics. Scripta Materialia, 2020,186:19-23. |

| [41] | CHEN XIANQIANG, WU YIQUAN. High-entropy transparent fluoride laser ceramics. Journal of the American Ceramic Society, 2019,103(2):750-756. |

| [42] | ZHANG KUIBAO, LI WEIWEI, ZENG JIANJUN, et al. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Yb0.2)2Zr2O7 high-entropy transparent ceramic using combustion synthesized nanopowder. Journal of Alloys and Compounds, 2020,817(15):153328. |

| [43] | LI WEIWEI, ZHANG KUIBAO, ZHAO WENWEN, et al. Vacuum sintering and optical properties of Gd2-xNdxZr2O7 transparent ceramics using combustion synthesized nanopowders. Optical Materials, 2020,100:109622. |

| [44] | LI WEIWEI, ZHANG KUIBAO, XIE DAYAN, et al. Characterizations of vacuum sintered Gd2Zr2O7 transparent ceramics using combustion synthesized nanopowder. Journal of the European Ceramic Society, 2020,40(4):1665-1670. |

| [45] |

LEE Y H, SHEU H S, DENG J P, et al. Preparation and fluorite- pyrochlore phase transformation in Gd2Zr2O7. Journal of Alloys and Compounds, 2009,487:595-598.

DOI URL |

| [46] | GLERUP M, NIELSEN O F, POULSEN F W. The structural transformation from the pyrochlore structure, A2B2O7, to the fluorite structure, AO2, studied by raman spectroscopy and defect chemistry modeling. Journal of Solid State Chemistry, 2001,160(1):25-32. |

| [47] | ZOU XIAOQING, ZHOU GUOHONG, YI HAILAN, et al. Fabrication of transparent Y2Hf2O7 ceramic from combustion synthesized powders. Journal of Inorganic Materials, 2011,26:929-932. |

| [48] | GUPTA S K, REGHUKUMAR C, SUDARSHAN K, et al. Orange-red emitting Gd2Zr2O7:Sm3+: structure-property correlation, optical properties and defect spectroscopy . Journal of Physics and Chemistry of Solids, 2018,116:360-366. |

| [49] | TROJAN-PIEGZA J, BRITES C D S, RAMALHO J F C B. et al. La0.4Gd1.6Zr2O7:0.1%Pr transparent sintered ceramic-a wide-range luminescence thermometer. Journal of Materials Chemistry C, 2020,8:7005-7011. |

| [1] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [2] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [3] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [4] | YE Junhao, ZHOU Zhenzhen, HU Chen, WANG Yanbin, JING Yanqiu, LI Tingsong, CHENG Ziqiu, WU Junlin, IVANOV Maxim, HRENIAK Dariusz, LI Jiang. Yb:Sc2O3 Transparent Ceramics Fabricated from Co-precipitated Nano-powders: Microstructure and Optical Property [J]. Journal of Inorganic Materials, 2025, 40(2): 215-224. |

| [5] | BAO Weichao, GUO Xiaojie, XIN Xiaoting, PENG Pai, WANG Xingang, LIU Jixuan, ZHANG Guojun, XU Fangfang. Establishment of Symbiotic Structure with Metal Atomic-layer Phase-separation in Carbide Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 17-22. |

| [6] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [7] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [8] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| [9] | LÜ Zhaoyang, XU Yong, YANG Jiuyan, TU Guangsheng, TU Bingtian, WANG Hao. Effect of MgF2 Additive on Preparation and Optical Properties of MgAl1.9Ga0.1O4 Transparent Ceramics [J]. Journal of Inorganic Materials, 2024, 39(5): 531-538. |

| [10] | ZHANG Wenyu, GUO Ruihua, YUE Quanxin, HUANG Yarong, ZHANG Guofang, GUAN Lili. High-entropy Phosphide Bifunctional Catalyst: Preparation and Performance of Efficient Water Splitting [J]. Journal of Inorganic Materials, 2024, 39(11): 1265-1274. |

| [11] | GUO Lingxiang, TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia. Ablation Resistance of High-entropy Oxide Coatings on C/C Composites [J]. Journal of Inorganic Materials, 2024, 39(1): 61-70. |

| [12] | GUO Tianmin, DONG Jiangbo, CHEN Zhengpeng, RAO Mumin, LI Mingfei, LI Tian, LING Yihan. Enhanced Compatibility and Activity of High-entropy Double Perovskite Cathode Material for IT-SOFC [J]. Journal of Inorganic Materials, 2023, 38(6): 693-700. |

| [13] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [14] | WANG Dewen, WANG Junping, YUAN Houcheng, LIU Zhang, ZHOU Jin, DENG Jiajie, WANG Xin, WU Benhua, ZHANG Jian, WANG Shiwei. Metre-scale Y3Al5O12 (YAG) Transparent Ceramics by Vacuum Reactive Sintering [J]. Journal of Inorganic Materials, 2023, 38(12): 1483-1484. |

| [15] | LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range [J]. Journal of Inorganic Materials, 2022, 37(9): 969-975. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||