Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (2): 159-167.DOI: 10.15541/jim20240256

Special Issue: 【结构材料】热障与环境障涂层(202506); 【结构材料】高熵陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

FAN Wenkai1,2( ), YANG Xiao1, LI Honghua1, LI Yong1, LI Jiangtao1(

), YANG Xiao1, LI Honghua1, LI Yong1, LI Jiangtao1( )

)

Received:2024-05-22

Revised:2024-08-03

Published:2025-02-20

Online:2024-08-19

Contact:

LI Jiangtao, professor. E-mail: lijiangtao@mail.ipc.ac.cnAbout author:FAN Wenkai (1998-), male, PhD candidate. E-mail: fanwenkai21@mails.ucas.ac.cn

Supported by:CLC Number:

FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance[J]. Journal of Inorganic Materials, 2025, 40(2): 159-167.

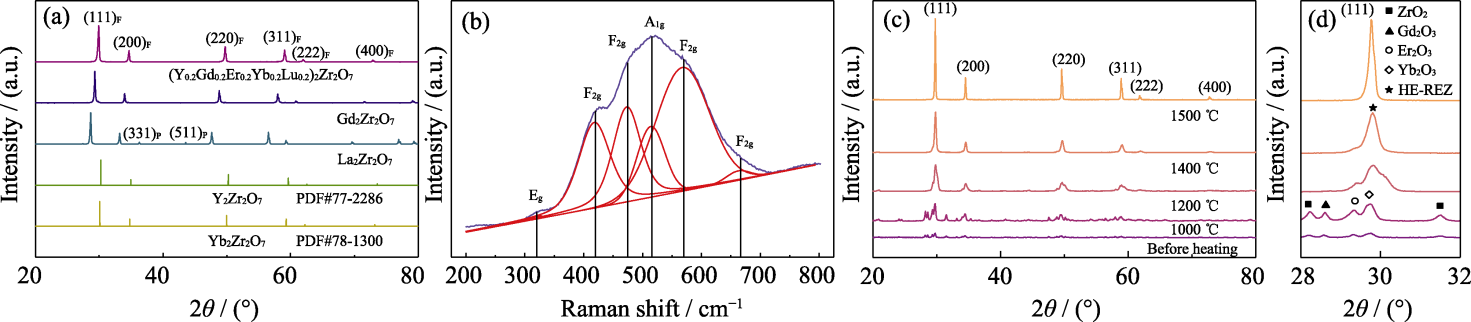

Fig. 1 Phase composition of rare-earth zirconates (REZs) (a) XRD patterns of HE-REZ vs. other REZs with P indicating pyrochlore structure and F indicating defect fluorite structure; (b) Raman spectrum of HE-REZ; (c, d) XRD patterns of HE-REZ synthesized at different temperatures

| Element | Coordination number | Valency | Ionic radius/pm |

|---|---|---|---|

| Zr | 6 | +4 | 72.0 |

| Lu | 8 | +3 | 97.7 |

| Yb | 8 | +3 | 98.5 |

| Er | 8 | +3 | 100.4 |

| Y | 8 | +3 | 101.9 |

| Gd | 8 | +3 | 105.3 |

| Sm | 8 | +3 | 107.9 |

| Nd | 8 | +3 | 110.9 |

| La | 8 | +3 | 116.0 |

Table 1 Shannon ionic radii of some cations

| Element | Coordination number | Valency | Ionic radius/pm |

|---|---|---|---|

| Zr | 6 | +4 | 72.0 |

| Lu | 8 | +3 | 97.7 |

| Yb | 8 | +3 | 98.5 |

| Er | 8 | +3 | 100.4 |

| Y | 8 | +3 | 101.9 |

| Gd | 8 | +3 | 105.3 |

| Sm | 8 | +3 | 107.9 |

| Nd | 8 | +3 | 110.9 |

| La | 8 | +3 | 116.0 |

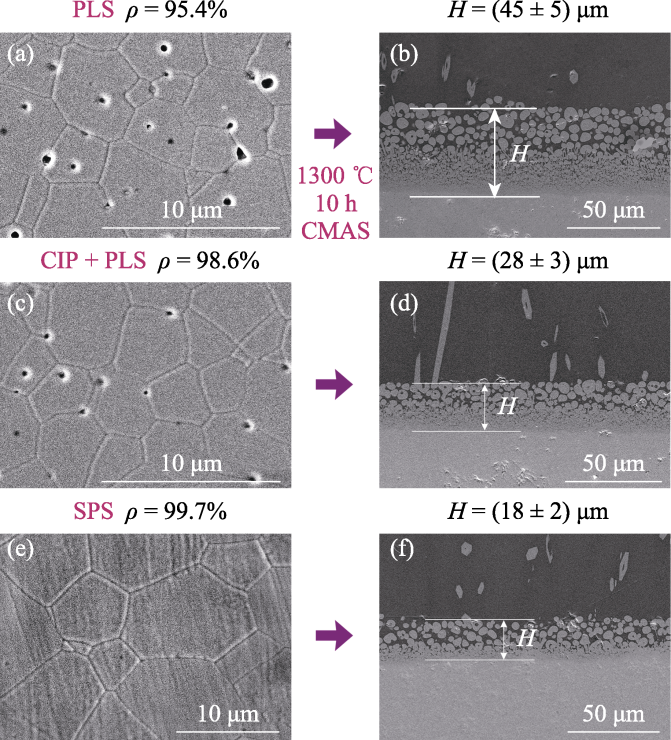

| Sample | Preparation method | Relative density/% | Average grain size/μm | Corrosion depth (1300 ℃, 10 h)/μm |

|---|---|---|---|---|

| HE1 | SPS | 99.7 | 7.20±3.20 | 18±2 |

| HE2 | PLS | 95.4 | 2.60±0.80 | 45±5 |

| HE3 | CIP+PLS | 98.6 | 2.40±0.60 | 28±3 |

| GZO | CIP+PLS | 98.3 | 2.70±0.80 | 124±8 |

| 7YSZ | CIP+PLS | 97.2 | 0.36±0.14 | 1070±10 |

Table 2 Summary of some properties of bulk ceramic samples prepared in this work

| Sample | Preparation method | Relative density/% | Average grain size/μm | Corrosion depth (1300 ℃, 10 h)/μm |

|---|---|---|---|---|

| HE1 | SPS | 99.7 | 7.20±3.20 | 18±2 |

| HE2 | PLS | 95.4 | 2.60±0.80 | 45±5 |

| HE3 | CIP+PLS | 98.6 | 2.40±0.60 | 28±3 |

| GZO | CIP+PLS | 98.3 | 2.70±0.80 | 124±8 |

| 7YSZ | CIP+PLS | 97.2 | 0.36±0.14 | 1070±10 |

Fig. 2 Macroscopic and microscopic morphologies and EDS analyses of HE-REZ bulk ceramic (HE3) prepared by CIP+PLS (a) Photo of bulk sample; (b) SEM image of surface; (c-h) EDS element mappings of Fig. (b)

Fig. 3 Crystalline morphologies and CMAS corrosion depths of HE-REZ bulk samples with different relative densities (a, b) HE2 (by PLS); (c, d) HE3 (by CIP+PLS); (e, f) HE1 (by SPS)

Fig. 4 Corrosion depths and Si distributions of bulk ceramic synthesized by CIP+PLS under the same CMAS corrosion condition (a) HE-REZ (HE3); (b) GZO; (c) 7YSZ

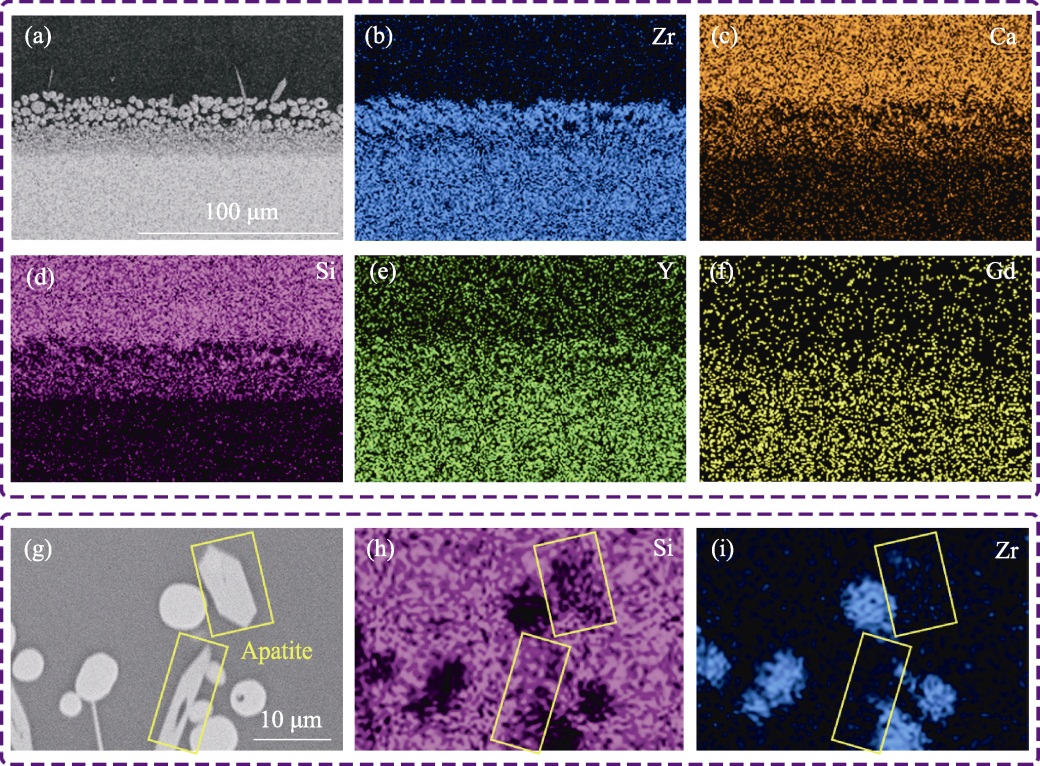

Fig. 6 Morphology and element distribution in the reaction zone of HE-REZ after CMAS corrosion (a) SEM image of reaction zone; (b-f) EDS element mappings of Fig. (a); (g-i) Partial enlarged images showing hexagonal apatite crystals (yellow box)

Fig. 7 CMAS corrosion kinetics of HE-REZ bulk ceramic (a-e) SEM images of HE-REZ after CMAS corrosion for different time; (f) Mathematical relationship between corrosion depth (H) and corrosion time

Fig. 8 Schematic diagram of CMAS corrosion kinetics for HE-REZ ceramic (a) RE3+ diffusing into CMAS; (b) ZrO2 forming; (c) Apatite precipitating out as RE3+ saturated

| [1] | HU W, LEI Y, ZHANG J, et al. Mechanical and thermal properties of RE4Hf3O12 (RE=Ho, Er, Tm) ceramics with defect fluorite structure. Journal of Materials Science & Technology, 2019, 35(9): 2064. |

| [2] | ZHANG X C, XU B S, WANG H D, et al. Modeling of the residual stresses in plasma-spraying functionally graded ZrO2/ NiCoCrAlY coatings using finite element method. Materials & Design, 2006, 27(4): 308. |

| [3] | 周舟, 张晶晶, 汪伟, 等. 模拟CMAS腐蚀用玻璃的制备及其析晶性能. 大连工业大学学报, 2022, 41(4): 292. |

| [4] | SCHULZ U, BRAUE W. Degradation of La2Zr2O7 and other novel EB-PVD thermal barrier coatings by CMAS (CaO-MgO-Al2O3- SiO2) and volcanic ash deposits. Surface and Coatings Technology, 2013, 235: 165. |

| [5] | DULUARD S, DELON E. Transient and steady states of Gd2Zr2O7 and 2ZrO2∙Y2O3 (ss) interactions with calcium magnesium aluminium silicates. Journal of the European Ceramic Society, 2019, 39(4): 1451. |

| [6] | HE Y, WANG X, WANG C, et al. Significantly improved corrosion resistance of high-entropy rare-earth silicate multiphase ceramics against molten CMAS. Journal of the American Ceramic Society, 2023, 106(5): 2744. |

| [7] | DREXLER J M, ORTIZ A L, PADTURE N P. Composition effects of thermal barrier coating ceramics on their interaction with molten Ca-Mg-Al-silicate (CMAS) glass. Acta Materialia, 2012, 60: 5437. |

| [8] | KRAUSE A R, LI X, PADTURE N P. Interaction between ceramic powder and molten calcia-magnesia-alumino-silicate (CMAS) glass, and its implication on CMAS-resistant thermal barrier coatings. Scripta Materialia, 2016, 112: 118. |

| [9] | ZHOU X, ZOU B, HE L, et al. Hot corrosion behaviour of La2(Zr0.7Ce0.3)2O7 thermal barrier coating ceramics exposed to molten calcium magnesium aluminosilicate at different temperatures. Corrosion Science, 2015, 100: 566. |

| [10] |

ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015, 6: 8485.

DOI PMID |

| [11] | ZHAO Z, XIANG H, DAI F Z, et al. (La0.2Ce0.2Nd0.2Sm0.2Eu0.2)2Zr2O7: a novel high-entropy ceramic with low thermal conductivity and sluggish grain growth rate. Journal of Materials Science & Technology, 2019, 35(11): 2647. |

| [12] | REN K, WANG Q, SHAO G, et al. Multicomponent high-entropy zirconates with comprehensive properties for advanced thermal barrier coating. Scripta Materialia, 2020, 178: 382. |

| [13] | WRIGHT A J, WANG Q, KO S T, et al. Size disorder as a descriptor for predicting reduced thermal conductivity in medium- and high-entropy pyrochlore oxides. Scripta Materialia, 2020, 181: 76. |

| [14] | DENG S, HE G, YANG Z, et al. Calcium-magnesium-alumina- silicate (CMAS) resistant high entropy ceramic (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 for thermal barrier coatings. Journal of Materials Science & Technology, 2022, 107: 259. |

| [15] | 夏校良. 阳离子掺杂稀土锆酸盐的有序无序转变与电学性能研究. 哈尔滨: 哈尔滨工业大学博士学位论文, 2011. |

| [16] | WRIGHT A J, WANG Q, LUO J. Single-phase duodenary high- entropy fluorite/pyrochlore oxides with an order-disorder transition. Acta Materialia, 2021, 211: 116858. |

| [17] | JIANG S, HU T, GILD J, et al. A new class of high-entropy perovskite oxides. Scripta Materialia, 2018, 142: 116. |

| [18] | LIN G, WANG Y, YANG L. CMAS corrosion behavior of a novel high entropy (Nd0.2Gd0.2Y0.2Er0.2Yb0.2)2Zr2O7 thermal barrier coating materials. Corrosion Science, 2023, 224: 111529. |

| [19] | PELLEG J. Diffusion in Ceramics. Berlin: Springer Publishing, 2016: 301. |

| [20] | MAHADE S, LI R, CURRY N, et al. Isothermal oxidation behavior of Gd2Zr2O7/YSZ multilayered thermal barrier coatings. International Journal of Applied Ceramic Technology, 2016, 13(3): 443. |

| [1] | SHEN Hao, CHEN Qianqian, ZHOU Boxiang, TANG Xiaodong, ZHANG Yuanyuan. Preparation and Energy Storage Properties of A-site La/Sr Co-doped PbZrO3 Thin Films [J]. Journal of Inorganic Materials, 2024, 39(9): 1022-1028. |

| [2] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [3] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [4] | GUO Lingxiang, TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia. Ablation Resistance of High-entropy Oxide Coatings on C/C Composites [J]. Journal of Inorganic Materials, 2024, 39(1): 61-70. |

| [5] | WANG Xueyao, WANG Wugang, LI Yingwei, PENG Qi, LIANG Ruihong. Correlation between Constitutive Behavior and Fracture Performance of PZT Ceramics [J]. Journal of Inorganic Materials, 2023, 38(7): 839-844. |

| [6] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [7] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [8] | SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun. Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic [J]. Journal of Inorganic Materials, 2021, 36(4): 405-410. |

| [9] | ZHANG Xiaoyan, LIU Xinyue, YAN Jinhua, GU Yaohang, QI Xiwei. Preparation and Property of High Entropy (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 Perovskite Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 379-385. |

| [10] | GUO Xiaojie, BAO Weichao, LIU Jixuan, WANG Xingang, ZHANG Guojun, XU Fangfang. Study on the Solid Solution Structures of High-Entropy Ceramics by Transmission Electron Microscopy [J]. Journal of Inorganic Materials, 2021, 36(4): 365-371. |

| [11] | CHEN Lei,WANG Kai,SU Wentao,ZHANG Wen,XU Chenguang,WANG Yujin,ZHOU Yu. Research Progress of Transition Metal Non-oxide High-entropy Ceramics [J]. Journal of Inorganic Materials, 2020, 35(7): 748-758. |

| [12] | YANG Jin-Ping, JI Wen-Ling, ZHANG Hao, LIU Pan, CUI Yi, WEI Heng-Yong. Preparation and Luminescence Property of Eu 3+ Doped Porous Lanthanum Zirconate Powder [J]. Journal of Inorganic Materials, 2019, 34(7): 727-733. |

| [13] | DUAN Yu-Sen, ZHANG Jing-Xian, LI Xiao-Guang, HUANG Ming-Ming, SHI Ying, XIE Jian-Jun, JIANG Dong-Liang. Rare Earth Oxides on Property of Pressureless Sintered Si3N4 Ceramics [J]. Journal of Inorganic Materials, 2017, 32(12): 1275-1279. |

| [14] | YANG Yu-Jia, WANG Jing, HE Hui-Fen. Synthesis and Luminescence Properties of Tb3+ Doped BaZrO3 Powders [J]. Journal of Inorganic Materials, 2016, 31(1): 27-33. |

| [15] | LONG Lian-Jun, XU Jian-Mei, GONG Yan-Sheng, WU Ming-Yang, CUI Xin-You. Effect of Microwave Sintering on Electrical Properties of PLZT Ceramics [J]. Journal of Inorganic Materials, 2015, 30(5): 500-504. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||