Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 411-417.DOI: 10.15541/jim20200426

• RESEARCH PAPER • Previous Articles Next Articles

ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie( ), GAO Feng

), GAO Feng

Received:2020-08-05

Revised:2020-09-14

Published:2021-04-20

Online:2020-10-30

Contact:

XU Jie, associate professor. E-mail: xujie@nwpu.edu.cn

About author:ZHU Jiatong(1997-), male, Master candidate. E-mail: zhujiatong@mail.nwpu.edu.cn

Supported by:CLC Number:

ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics[J]. Journal of Inorganic Materials, 2021, 36(4): 411-417.

| Sample | ρthr/(g·cm-3) | ρexp/(g·cm-3) | Porosity/% | dgrain/μm |

|---|---|---|---|---|

| 4RETaO4 | 8.593 | 8.441 | 1.77 | 2.96 |

| 5RETaO4 | 8.735 | 8.597 | 1.58 | 6.63 |

| 6RETaO4 | 8.983 | 8.758 | 2.50 | 3.29 |

Table 1 Theoretical density, experimental density, porosity, and average grain size of high-entropy tantalates

| Sample | ρthr/(g·cm-3) | ρexp/(g·cm-3) | Porosity/% | dgrain/μm |

|---|---|---|---|---|

| 4RETaO4 | 8.593 | 8.441 | 1.77 | 2.96 |

| 5RETaO4 | 8.735 | 8.597 | 1.58 | 6.63 |

| 6RETaO4 | 8.983 | 8.758 | 2.50 | 3.29 |

| Sample | a/nm | b/nm | c/nm | β/(°) | $r_{RE^{3+}}$/nm |

|---|---|---|---|---|---|

| 4RETaO4 | 0.544 | 1.112 | 0.508 | 95.65 | 10.767 |

| 5RETaO4 | 0.542 | 1.108 | 0.508 | 95.64 | 10.668 |

| 6RETaO4 | 0.537 | 1.099 | 0.504 | 95.57 | 10.581 |

Table 2 Detail structure information of high-entropy RETaO4 ceramics and the average radii of doped rare-earth ions

| Sample | a/nm | b/nm | c/nm | β/(°) | $r_{RE^{3+}}$/nm |

|---|---|---|---|---|---|

| 4RETaO4 | 0.544 | 1.112 | 0.508 | 95.65 | 10.767 |

| 5RETaO4 | 0.542 | 1.108 | 0.508 | 95.64 | 10.668 |

| 6RETaO4 | 0.537 | 1.099 | 0.504 | 95.57 | 10.581 |

| Sample | HV/GPa |

|---|---|

| 4RETaO4 | (7.92±2.33) |

| 5RETaO4 | (6.15±1.60) |

| 6RETaO4 | (9.97±2.20) |

Table 3 HV hardness of high-entropy tantalates

| Sample | HV/GPa |

|---|---|

| 4RETaO4 | (7.92±2.33) |

| 5RETaO4 | (6.15±1.60) |

| 6RETaO4 | (9.97±2.20) |

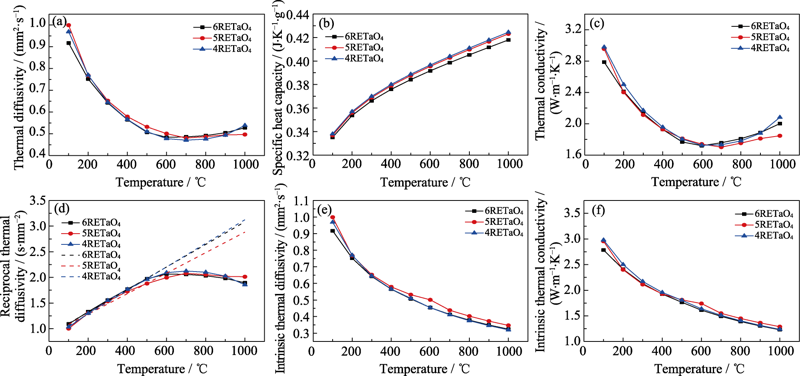

Fig. 8 Thermal properties of high-entropy RETaO4 (a) Thermal diffusivity; (b) Constant pressure heat capacity; (c) Thermal conductivity; (d) Reciprocal thermal conductivity; (e) Intrinsic thermal diffusivity; (f) Intrinsic thermal conductivity

| Material | 6RETaO4 | NdTaO4 | SmTaO4 | EuTaO4 | GdTaO4 | DyTaO4 | HoTaO4 | YSZ |

|---|---|---|---|---|---|---|---|---|

| Thermal conductivity/(W·m-1·K-1) | 2.78-1.30 | 3.41-1.75 | 2.70-1.45 | 3.23-1.26 | 3.94-1.28 | 3.45-1.80 | 3.35-1.47 | 3.02-2.38 |

Table 4 Thermal conductivity of 6RETaO4, single rare earth tantalates, and YSZ (100-900 ℃)

| Material | 6RETaO4 | NdTaO4 | SmTaO4 | EuTaO4 | GdTaO4 | DyTaO4 | HoTaO4 | YSZ |

|---|---|---|---|---|---|---|---|---|

| Thermal conductivity/(W·m-1·K-1) | 2.78-1.30 | 3.41-1.75 | 2.70-1.45 | 3.23-1.26 | 3.94-1.28 | 3.45-1.80 | 3.35-1.47 | 3.02-2.38 |

| [1] |

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002,296(5566):280-284.

URL PMID |

| [2] | CAO X Q, VASSEN R, STOVER D. Ceramic materials for thermal barrier coatings. Journal of the European Ceramics Society, 2004,24(1):1-10. |

| [3] | RACEK O, BEMDT C C. Mechanical property variations within thermal barrier coatings. Surface Coating Technology, 2007,202(2):362-369. |

| [4] | FENG J, REN X R, WANG X Y, et al. Thermal conductivity of ytterbia-stabilized zirconia. Script Materialia, 2012,66(1):41-44. |

| [5] | ZHAO M, REN X R, YANG J, et al. Thermo-mechanical properties of ThO2-doped Y2O3 stabilized ZrO2 for thermal barrier coatings. Ceramics International, 2016,42(1):501-508. |

| [6] | ZHENG Q, WU F S, CHEN L, et al. Thermophysical and mechanical properties of YTaO4 ceramic by niobium substitution tantalum. Materials Letters, 2020,268:127586. |

| [7] | SHIAN S, SARIN P, GURAK M, et al. The tetragonal-monoclinic, ferroelastic transformation in yttrium tantalate and effect of zirconia alloying. Acta Materialia, 2014,69:196-202. |

| [8] | WANG J, CHONG X Y, ZHOU R, et al. Microstructure and thermal properties of RETaO4 (RE= Nd, Eu, Gd, Dy, Er, Yb, Lu) as promising thermal barrier coating materials. Scripta Materialia, 2017,126:24-28. |

| [9] | YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303. |

| [10] | OSES C, TOHER C, CURTAROLO S, et al. High-entropy ceramics. Nature Reviews Materials, 2020,5(4):295-309. |

| [11] | 顾俊峰, 邹冀, 张帆, 等. 高熵陶瓷材料研究进展. 中国材料研究进展, 2019,38(9):855-865. |

| [12] | CHEN L, WANG K, SU W T, et al. Research progress of transition metal non-oxide high-entropy ceramics. Journal of Inorganic Materials, 2020,35(7):748-758. |

| [13] | MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017,122:448-511. |

| [14] |

ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015,6:8485.

URL PMID |

| [15] | YAN X L, CONSTANTIN L, LU Y F, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491. |

| [16] | LIU D, LIU H H, NING S S, et al. Synthesis of high-purity high-entropy metal diboride powders by boro/carbothermal reduction. Journal of the American Ceramic Society, 2019,102(12):7071-7076. |

| [17] | JIN T, SANG X H, UNOCIC R R, et al. Mechanochemical-assisted synthesis of high-entropy metal nitride via a soft urea strategy. Advanced Materials, 2018,30(23):1707512. |

| [18] | BRAUN J L, ROST C M, LIM M, et al. Charge-induced disorder controls the thermal conductivity of entropy-stabilized oxides. Advanced Materials, 2018,30(24):1805004. |

| [19] | LI F, ZHOU L, LIU J X, et al. High-entropy pyrochlores with low thermal conductivity for thermal barrier coating materials. Journal of Advanced Ceramics, 2019,8(4):576-582. |

| [20] | WRIGHT A J, WANG Q Y, HUANG C Y, et al. From high-entropy ceramics to compositionally-complex ceramics: a case study of fluorite oxides. Journal of the European Ceramic Society, 2020,40(54):2120-2129. |

| [21] | ZHOU L, LI F, LIU J X, et al. High-entropy thermal barrier coating of rare-earth zirconate: a case study on (La0.2Nd0.2Sm0.2Eu0.2Gd0.2)2Zr2O7 prepared by atmospheric plasma spraying. Journal of the European Ceramic Society, 2020,40(15):5731-5739. |

| [22] | REN K, WANG Q K, SHAO G, et al. Multicomponent high-entropy zirconates with comprehensive properties for advanced thermal barrier coating. Scripta Materialia, 2020,78:382-386. |

| [23] | SCHLICHTING K W, PADTURE N P, KLEMENS P G. Thermal conductivity of dense and porous yttria-stabilized zirconia. Journal of Materials Science, 2001,36(12):3003-3010. |

| [24] | EVANS A G, CHARLES E A. Fracture toughness determinations by indentation. Journal of the American Ceramic Society, 1976,59(7/8):371-372. |

| [25] | CHEN L, HU M Y, WU P, et al. Thermal expansion performance and intrinsic lattice thermal conductivity of ferroelastic RETaO4 ceramics. Journal of the American Ceramic Society, 2019,102(8):4809-4821. |

| [26] | WU P, CHEN L, CHEN W, et al. Investigation on microstructures and thermo-physical properties of ferroelastic (Y1-xDyx)TaO4 ceramics. Materialia, 2018,4:478-486. |

| [27] | LAI C H, LIN S J, YEH J W, et al. Preparation and characterization of AlCrTaTiZr muti-element nitride coatings. Surface Coating Technology, 2006,201(6):3275-3280. |

| [1] | ZHANG Yuchen, LU Zhiyao, HE Xiaodong, SONG Guangping, ZHU Chuncheng, ZHENG Yongting, BAI Yuelei. Predictions of Phase Stability and Properties of S-group Elements Containing MAX Borides [J]. Journal of Inorganic Materials, 2024, 39(2): 225-232. |

| [2] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [3] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [4] | CHI Zheren, ZHANG Liao, GUO Zhiqian, LI Yongsheng, NIU Dechao. Flav7-loaded Silica-based Hybrid Micelles: Synthesis and Photothermal Performance [J]. Journal of Inorganic Materials, 2022, 37(11): 1236-1244. |

| [5] | ZHANG Xiaoyan, LIU Xinyue, YAN Jinhua, GU Yaohang, QI Xiwei. Preparation and Property of High Entropy (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 Perovskite Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 379-385. |

| [6] | GUO Xiaojie, BAO Weichao, LIU Jixuan, WANG Xingang, ZHANG Guojun, XU Fangfang. Study on the Solid Solution Structures of High-Entropy Ceramics by Transmission Electron Microscopy [J]. Journal of Inorganic Materials, 2021, 36(4): 365-371. |

| [7] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [8] | ZHANG Ze,WANG Xiaodong,SHEN Jun. Effect of Organic-inorganic Crosslinking Degree on the Mechanical and Thermal Properties of Aerogels [J]. Journal of Inorganic Materials, 2020, 35(4): 454-460. |

| [9] | Bo-Le MA, Wen MA, Wei HUANG, Yu BAI, Rui-Ling JIA, Hong-Ying DONG. Thermophysical Property of Single-phase Strontium Zirconate Co-doped with Double Rare-earth Oxides as a Thermal Barrier Coating Material [J]. Journal of Inorganic Materials, 2019, 34(4): 394-400. |

| [10] | WANG Lin, DING Kun-Ying, LIN Xiao-Ping, LI Ze, ZHENG Run-Guo, YANG Lian-Wei. Defect Evolution and Microcracks of 8YSZ Double-layer Thermal Barrier Coatings by Water Immersion Ultrasound Macroscopic Detection [J]. Journal of Inorganic Materials, 2019, 34(12): 1265-1271. |

| [11] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, DENG Chang-Guang, CHEN Huan-Tao. Thermal Shock Analysis of Surface Al-modified 7YSZ Nano-thermal Barrier Coatin [J]. Journal of Inorganic Materials, 2017, 32(9): 973-979. |

| [12] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [13] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [14] | MA Rong-Bin, CHENG Xu-Dong, ZOU Jun, LI Qing-Yu, HUANG Xia. Toughness and Thermal Shock of SiC Fiber/Yttria-stabilized-zirconia Composite Thick Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2016, 31(2): 190-194. |

| [15] | ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, HAN Tao, Song Jin-Bing, LIU-Min. Erosion Failure Mechanism and Model Establishment of Thermal Barrier Coatings Based on Roughness [J]. Journal of Inorganic Materials, 2014, 29(3): 294-300. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||