Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (1): 61-70.DOI: 10.15541/jim20230370

Special Issue: 【结构材料】热障与环境障涂层(202506); 【结构材料】高熵陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

GUO Lingxiang( ), TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia(

), TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia( )

)

Received:2023-08-14

Revised:2023-10-18

Published:2024-01-20

Online:2023-10-15

Contact:

SUN Jia, associate professor. E-mail: j.sun@nwpu.edu.cnAbout author:GUO Lingxiang(1997-), male, PhD candidate. E-mail: guolingxiang@mail.nwpu.edu.cn

Supported by:CLC Number:

GUO Lingxiang, TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia. Ablation Resistance of High-entropy Oxide Coatings on C/C Composites[J]. Journal of Inorganic Materials, 2024, 39(1): 61-70.

| Label | Constituent | |

|---|---|---|

| M1R3O | (Hf0.125Zr0.125Sm0.25Er0.25Y0.25)O2-δ | 1/3 |

| M2R3O | (Hf0.2Zr0.2Sm0.2Er0.2Y0.2)O2-δ | 2/3 |

| M3R3O | (Hf0.25Zr0.25Sm0.167Er0.167Y0.167)O2-δ | 3/3 |

Table 1 Compositions and component molar ratios of high-entropy oxides in this study

| Label | Constituent | |

|---|---|---|

| M1R3O | (Hf0.125Zr0.125Sm0.25Er0.25Y0.25)O2-δ | 1/3 |

| M2R3O | (Hf0.2Zr0.2Sm0.2Er0.2Y0.2)O2-δ | 2/3 |

| M3R3O | (Hf0.25Zr0.25Sm0.167Er0.167Y0.167)O2-δ | 3/3 |

| Parameter | Value |

|---|---|

| Current/A | 410-430 |

| Voltage/V | 100-120 |

| Primary gas Ar/(L·min-1) | 65-70 |

| Second gas H2/(L·min-1) | 3.5-5.0 |

| Powder flow Ar/(L·min-1) | 5-7 |

| Spray distance/mm | 100 |

| Powder feed rate/(g·min-1) | 5-6 |

Table 2 Parameters of SAPS for high-entropy oxide coatings

| Parameter | Value |

|---|---|

| Current/A | 410-430 |

| Voltage/V | 100-120 |

| Primary gas Ar/(L·min-1) | 65-70 |

| Second gas H2/(L·min-1) | 3.5-5.0 |

| Powder flow Ar/(L·min-1) | 5-7 |

| Spray distance/mm | 100 |

| Powder feed rate/(g·min-1) | 5-6 |

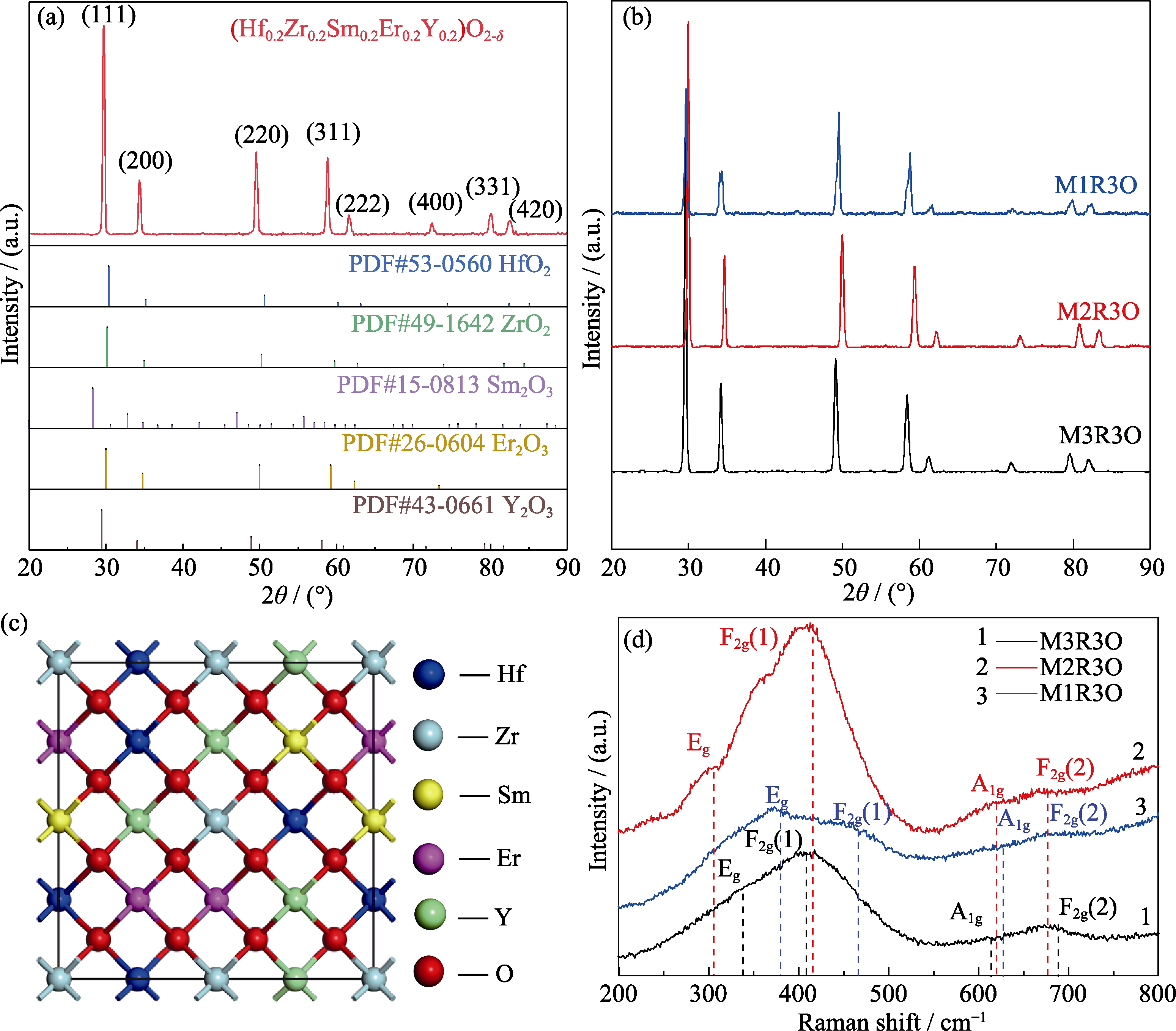

Fig. 1 Phase characterizations of high-entropy oxide powders (a) XRD pattern of M2R3O and standard diffraction peaks for each single-component oxide; (b) XRD patterns of three high-entropy oxides; (c) Ideal crystal structure; (d) Raman spectra of three high-entropy oxides

Fig. 2 TEM analyses of M2R3O powders (a) Morphology; (b) High-resolution TEM (HRTEM) image; (c) Selective area electron diffraction (SAED) pattern; (d) High-angle annular dark field (HAADF) image and corresponding element mappings

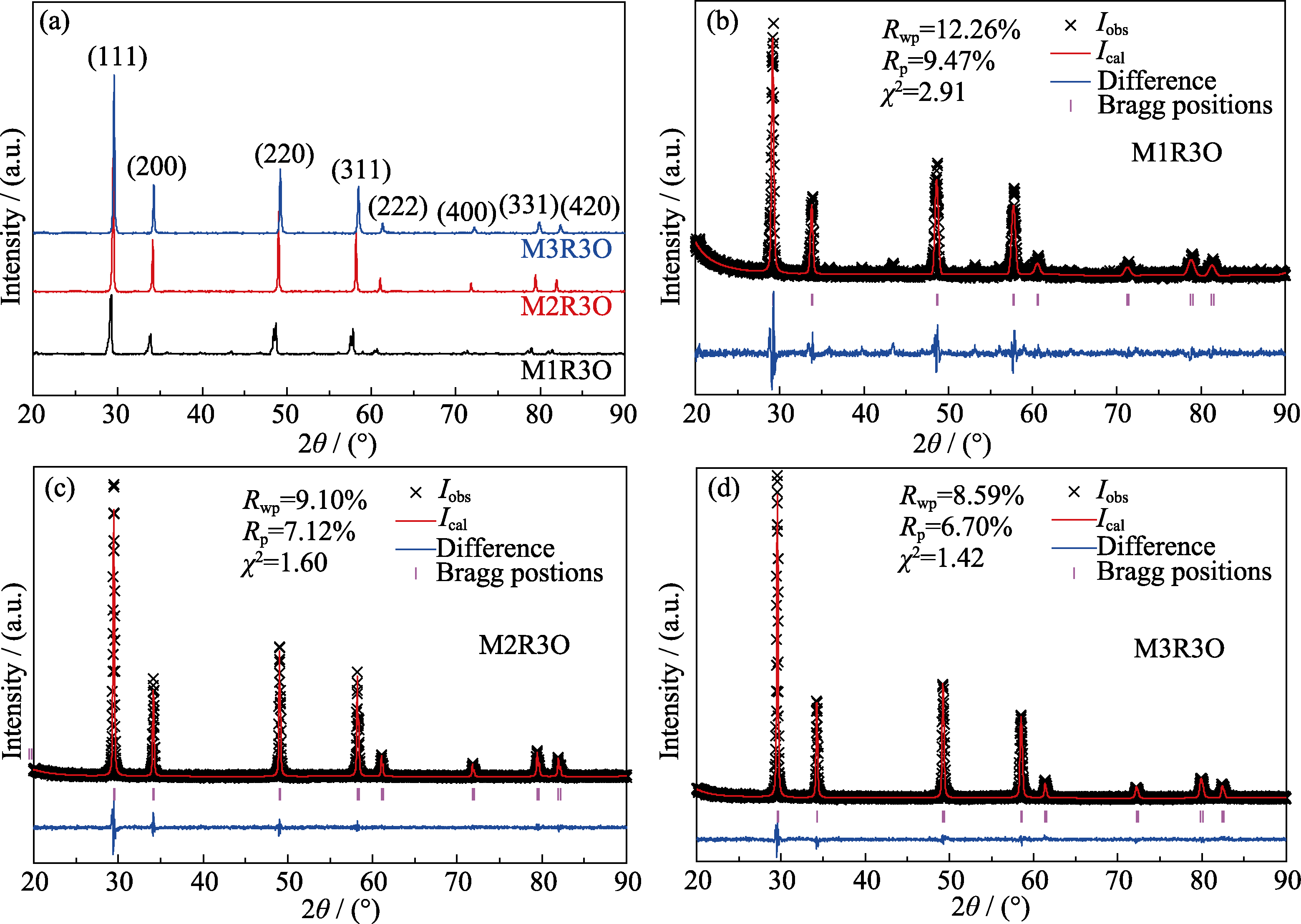

Fig. 4 XRD patterns of high-entropy oxide coatings (a) Full spectrum diffraction; (b) M1R3O coating and refinement pattern; (c) M2R3O coating and refinement pattern; (d) M3R3O coating and refinement pattern

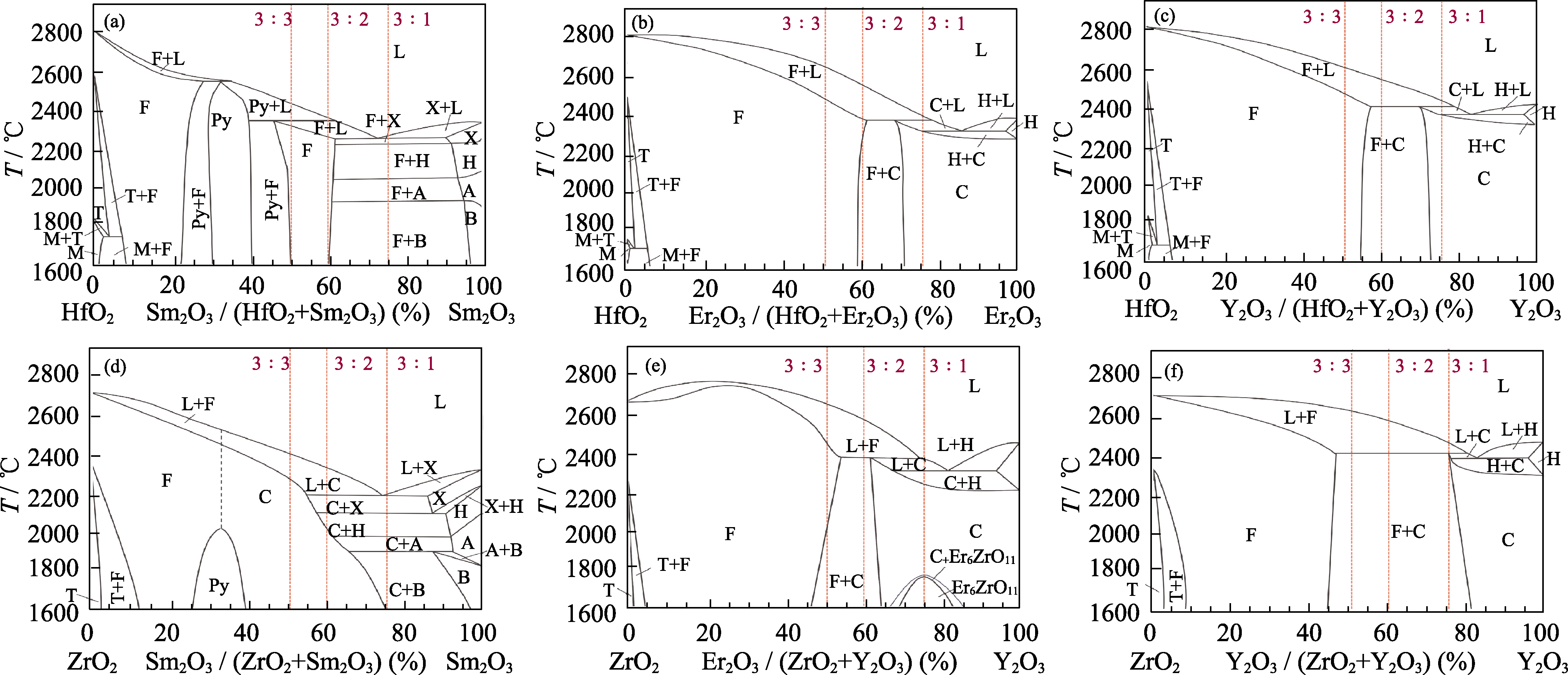

Fig. 5 Binary phase diagrams of HfO2-RE2O3 and ZrO2-RE2O3 (RE=Sm, Er and Y)[30] (a) HfO2-Sm2O3; (b) HfO2-Er2O3; (c) HfO2-Y2O3; (d) ZrO2-Sm2O3; (e) ZrO2-Er2O3; (f) ZrO2-Y2O3

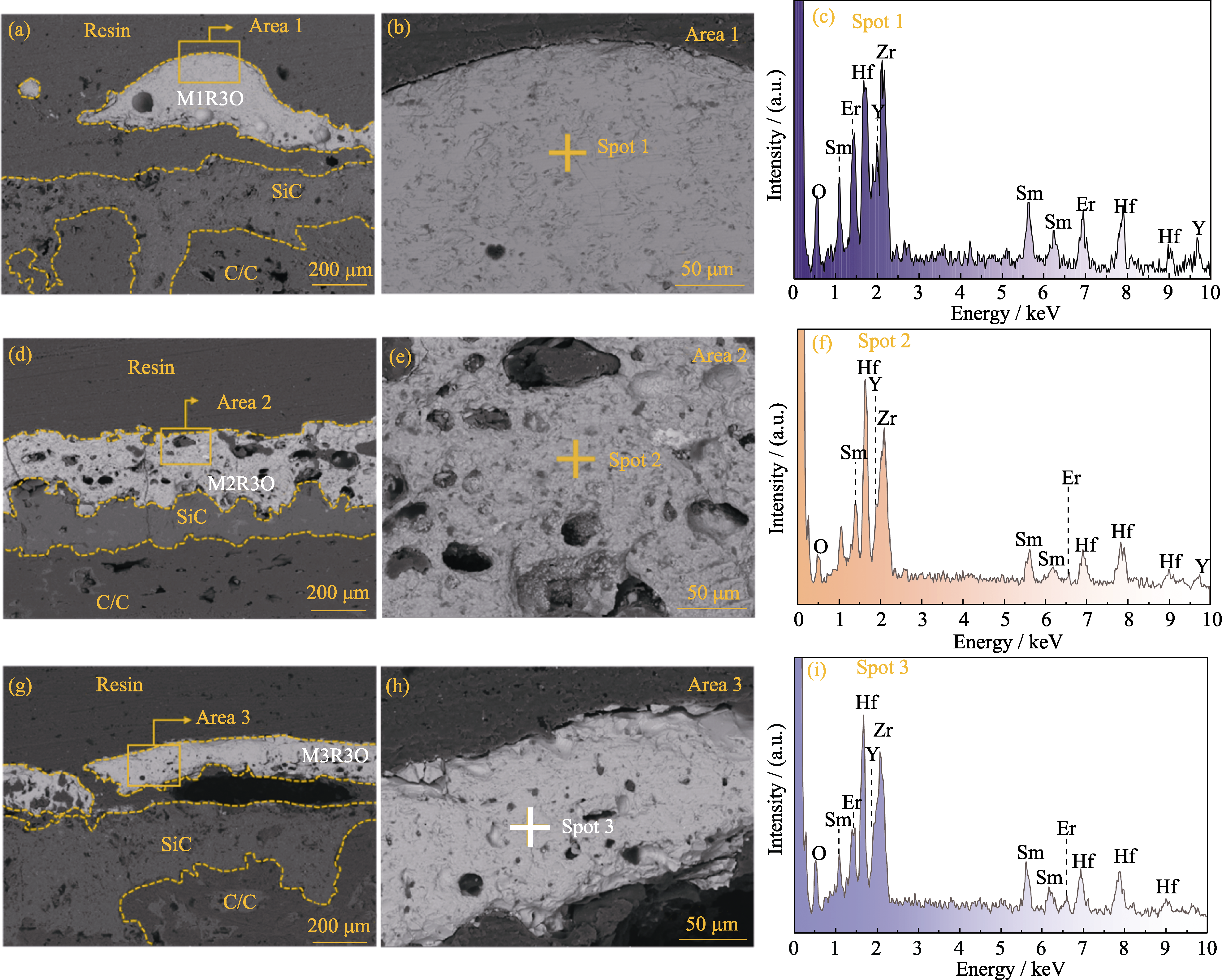

Fig. 10 Cross-section morphologies and EDS analyses of high-entropy oxide coatings after cyclic ablation for 180 s(a-c) M1R3O; (d-f) M2R3O; (g-i) M3R3O

| Hf | Zr | Sm | Er | Y | Si | O | |

|---|---|---|---|---|---|---|---|

| Spot A/(%, in atom) | 10.5 | 5.6 | 9.3 | 8.5 | 8.4 | — | 57.7 |

| Spot B/(%, in atom) | 5.6 | 4.7 | 5.1 | 8.7 | 10.4 | 3.8 | 61.7 |

Tabel S1 EDS element point scanning analysis

| Hf | Zr | Sm | Er | Y | Si | O | |

|---|---|---|---|---|---|---|---|

| Spot A/(%, in atom) | 10.5 | 5.6 | 9.3 | 8.5 | 8.4 | — | 57.7 |

| Spot B/(%, in atom) | 5.6 | 4.7 | 5.1 | 8.7 | 10.4 | 3.8 | 61.7 |

| [1] |

NI D, CHENG Y, ZHANG J, et al. Advances in ultra-high temperature ceramics, composites, and coatings. Journal of Advanced Ceramics, 2022, 11(1):1.

DOI |

| [2] | DU H. Research progress on integrated thermal management and key technology of hypersonic vehicles. Equipment Environmental Engineering, 2023, 20(1):43. |

| [3] |

REGHU V R, SHANKAR V, RAMASWAMY P. Challenges in plasma spraying of 8%Y2O3-ZrO2 thermal barrier coatings on Al alloy automotive piston and influence of vibration and thermal fatigue on coating characteristics. Materials Today: Proceedings, 2018, 5(11):23927.

DOI URL |

| [4] | WANG J, LU X, HU M, et al. Phase stability, thermophysical properties, thermal shock behavior and CMAS resistance of Sc2O3-CeO2 co-stabilized ZrO2 TBCs. Surface and Coatings Technology, 2023, 467: 129679. |

| [5] |

LI C, FAN H, NI L, et al. Phase transformation and thermal conductivity of the APS Y2O3 doped HfO2 coating with hybrid structure. Ceramics International, 2022, 48(14):19633.

DOI URL |

| [6] |

WU Y, HONG D, ZHONG X, et al. Research progress on hafnium-based thermal barrier coatings materials. Ceramics International, 2023, 49(13):21133.

DOI URL |

| [7] | WU H, DUAN Y, LIU K, et al. First-principles study of phase transition and band structure of ZrO2 under pressure. Journal of Alloys and Compounds, 2015, 645: 352. |

| [8] |

MANDAL G, JANA R, SAHA P, et al. Study of structural phase transition of HfO2 at high pressure. Materials Today: Proceedings, 2016, 3(9):2997.

DOI URL |

| [9] |

PAN L, HE L, NIU Z, et al. Corrosion behavior of ytterbium hafnate exposed to water-vapor with Al(OH)3 impurities. Journal of the European Ceramic Society, 2023, 43(2):612.

DOI URL |

| [10] |

HE L, PAN L, ZHOU W, et al. Thermal corrosion behavior of Yb4Hf3O12 ceramics exposed to calcium-ferrum-alumina-silicate (CFAS) at 1400 ℃. Journal of the European Ceramic Society, 2023, 43(9):4114.

DOI URL |

| [11] |

LIU X Y, CHE J W, YI H, et al. Influence of powder states on the composition and phase stability of LZ/YSZ composite thermal barrier coatings. Ceramics International, 2018, 44(16):20291.

DOI URL |

| [12] | LIU D, WEN T, YE B, et al. Synthesis of superfine high-entropy metal diboride powders. Scripta Materialia, 2019, 167: 110. |

| [13] | YE B, WEN T, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high- entropy ceramics. Acta Materialia, 2019, 170: 15. |

| [14] |

SUN L, REN X, DU T, et al. High entropy engineering: new strategy for the critical property optimizations of rare earth silicates. Journal of Inorganic Materials, 2020, 36(4):339.

DOI URL |

| [15] |

SUN Y, YE L, ZHAO W, et al. Synthesis of high entropy carbide nano powders via liquid polymer precursor route. Journal of Inorganic Materials, 2021, 36(4):393.

DOI URL |

| [16] | ANAND G, WYNN A P, HANDLEY C M, et al. Phase stability and distortion in high-entropy oxides. Acta Materialia, 2018, 146: 119. |

| [17] |

PIANASSOLA M, ANDERSON K L, SAFIN J, et al. Tuning the melting point and phase stability of rare-earth oxides to facilitate their crystal growth from the melt. Journal of Advanced Ceramics, 2022, 11(9):1479.

DOI |

| [18] |

SUN J, GUO L, ZHANG Y, et al. Superior phase stability of high entropy oxide ceramic in a wide temperature range. Journal of the European Ceramic Society, 2022, 42(12):5053.

DOI URL |

| [19] | LI Y, LIU Y, GUO C, et al. Ablation resistance of ZrC-based composite coating with multi-layer structure for carbon/carbon composites above 2200 ℃. Corrosion Science, 2022, 207: 110600. |

| [20] |

GUO X, ZHANG Y, LI T, et al. High-entropy rare-earth disilicate (Lu0.2Yb0.2Er0.2Tm0.2Sc0.2)2Si2O7: a potential environmental barrier coating material. Journal of the European Ceramic Society, 2022, 42(8):3570.

DOI URL |

| [21] |

WANG J, WU F, ZOU R, et al. High-entropy ferroelastic rare-earth tantalite ceramic: (Y0.2Ce0.2Sm0.2Gd0.2Dy0.2)TaO4. Journal of the American Ceramic Society, 2021, 104(11):5873.

DOI URL |

| [22] |

ZHANG F, GUO M, MIAO Y, et al. Preparation and sintering behavior of high entropy ceramic (Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ. Journal of Inorganic Materials, 2021, 36(4):372.

DOI URL |

| [23] | ZHAO Z, CHEN H, XIANG H, et al.(Y0.25Yb0.25Er0.25Lu0.25)2 (Zr0.5Hf0.5) 2O7: a defective fluorite structured high entropy ceramic with low thermal conductivity and close thermal expansion coefficient to Al2O3. Journal of Materials Science & Technology, 2020, 39: 167. |

| [24] |

GILD J, SAMIEE M, BRAUN J L, et al. High-entropy fluorite oxides. Journal of the European Ceramic Society, 2018, 38(10):3578.

DOI URL |

| [25] | WRIGHT A J, WANG Q, HU C, et al. Single-phase duodenary high-entropy fluorite/pyrochlore oxides with an order-disorder transition. Acta Materialia, 2021, 211: 116858. |

| [26] |

ZHOU L, LI F, LIU J, et al. High-entropy thermal barrier coating of rare-earth zirconate: a case study on (La0.2Nd0.2Sm0.2Eu0.2Gd0.2)2Zr2O7 prepared by atmospheric plasma spraying. Journal of the European Ceramic Society, 2020, 40(15):5731.

DOI URL |

| [27] |

DA COSTA PINTO C, CHAUDHURI P, GHOSH A, et al. Mechanical alloying synthesis of Sm3NbO7 defect fluorite and structural characterization by X-ray diffraction, Raman spectroscopy and DFT calculation. Ceramics International, 2021, 47(7):8936.

DOI URL |

| [28] | FENG G, YAO X, YU Y, et al. Synthesis and performance characterization of Hafnium-based multilayer coating applied over carbon/carbon composites with sharp leading edge. Journal of Materials Science & Technology, 2023, 153: 254. |

| [29] |

HU D, ZHANG Y, DONG Z, et al. Relationship analyses on environmental factors-ablation performance based on ZrC-TaC system: oxygen partial pressure and gas flow scouring. Journal of the European Ceramic Society, 2023, 43(6):2331.

DOI URL |

| [30] |

ANDRIEVSKAYA E R. Phase equilibria in the refractory oxide systems of zirconia, hafnia and yttria with rare-earth oxides. Journal of the European Ceramic Society, 2008, 28(12):2363.

DOI URL |

| [31] | ANANDKUMAR M, TROFIMOV E. Synthesis, properties, and applications of high-entropy oxide ceramics: current progress and future perspectives. Journal of Alloys and Compounds, 2023, 960: 170690. |

| [32] | HU D, FU Q, TONG M, et al. Multiple cyclic ablation behaviors of multilayer ZrC-TaC coating with ZrC-SiC interface layer. Corrosion Science, 2022, 200: 110215. |

| [33] | ZE Y, WANG D, XIONG X, et al. Ablation-resistant carbide Zr0.8Ti0.2C0.74B0.26 for oxidizing environments up to 3000 ℃. Nature Communications, 2017, 8: 15836. |

| [34] |

GU S, ZHANG S, LIU F, et al. New anti-ablation candidate for carbon/carbon composites: preparation, composition and ablation behavior of Y2Hf2O7 coating under an oxyacetylene torch. Journal of the European Ceramic Society, 2018, 38(15):5082.

DOI URL |

| [35] |

YU Y, FENG G, JIA Y, et al. Nanosized (Zr, Hf)O2 coating reinforced by AlN whiskers for the ablation protection of SiC coated C/C composites. Journal of the European Ceramic Society, 2023, 43(9):3959.

DOI URL |

| [36] | FENG G, LI H, YAO X, et al. Investigation on the relationship between multilayer architecture and ablation behavior using an oxyacetylene torch. Corrosion Science, 2022, 198: 110104. |

| [37] |

ZHANG J, ZHANG Y, ZHANG T, et al. Cyclic ablation behavior and microstructure evolution of multi-layer coating on C/C composites under oxyacetylene torch. Ceramics International, 2022, 48(15):21709.

DOI URL |

| [38] |

FENG G, LI H, YAO X, et al. Ablation resistance of HfC- TaC/HfC-SiC alternate coating for SiC-coated carbon/carbon composites under cyclic ablation. Journal of the European Ceramic Society, 2021, 41(6):3207.

DOI URL |

| [39] |

REN J, ZHANG Y, ZHANG P, et al. Ablation resistance of HfC coating reinforced by HfC nanowires in cyclic ablation environment. Journal of the European Ceramic Society, 2017, 37(8):2759.

DOI URL |

| [40] | LI J, ZHANG Y, WANG H, et al. Long-life ablation resistance ZrB2-SiC-TiSi2 ceramic coating for SiC coated C/C composites under oxidizing environments up to 2200 K. Journal of Alloys and Compounds, 2020, 824: 153934. |

| [41] | ZHANG Y, SUN J, GUO L, et al. Ablation behavior under oxyacetylene torch of ZrC coating modified by SiC/TaC nanocomposites. Corrosion Science, 2022, 205: 110423. |

| [42] | ZHANG Y, HU H, ZHANG P, et al. SiC/ZrB2-SiC-ZrC multilayer coating for carbon/carbon composites against ablation. Surface and Coatings Technology, 2016, 300: 1. |

| [43] | FENG G, CHEN L, YAO X, et al. Design and characterization of zirconium-based multilayer coating for carbon/carbon composites against oxyacetylene ablation. Corrosion Science, 2021, 192: 109785. |

| [1] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [2] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [3] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [4] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [5] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [6] | GUO Xiaoyang, ZHANG Xiaolin, JIANG Yan, TIAN Yuan, GENG Zhi. Ti-doped Hf(Zr)B2-SiC Anti-ablation Coatings: Preparation and Ablation Resistance Mechanism [J]. Journal of Inorganic Materials, 2024, 39(12): 1357-1366. |

| [7] | XIE Tian, SONG Erhong. Effect of Elastic Strains on Adsorption Energies of C, H and O on Transition Metal Oxides [J]. Journal of Inorganic Materials, 2024, 39(11): 1292-1300. |

| [8] | TAO Shunyan, YANG Jiasheng, SHAO Fang, WU Yingchen, ZHAO Huayu, DONG Shaoming, ZHANG Xiangyu, XIONG Ying. Thermal Spray Coatings for Aircraft CMC Hot-end Components: Opportunities and Challenges [J]. Journal of Inorganic Materials, 2024, 39(10): 1077-1083. |

| [9] | CAI Jia, ZHAO Fangxia, FAN Dong, HUANG Liping, NIU Yaran, ZHENG Xuebin, ZHANG Zhenzhong. Pyrolysis Behavior and Laser Ablation Resistance of PCS in Polycarbosilane Composite Coatings [J]. Journal of Inorganic Materials, 2023, 38(11): 1271-1280. |

| [10] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [11] | SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun. Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic [J]. Journal of Inorganic Materials, 2021, 36(4): 405-410. |

| [12] | ZHANG Xiaoyan, LIU Xinyue, YAN Jinhua, GU Yaohang, QI Xiwei. Preparation and Property of High Entropy (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 Perovskite Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 379-385. |

| [13] | GUO Xiaojie, BAO Weichao, LIU Jixuan, WANG Xingang, ZHANG Guojun, XU Fangfang. Study on the Solid Solution Structures of High-Entropy Ceramics by Transmission Electron Microscopy [J]. Journal of Inorganic Materials, 2021, 36(4): 365-371. |

| [14] | CHEN Lei,WANG Kai,SU Wentao,ZHANG Wen,XU Chenguang,WANG Yujin,ZHOU Yu. Research Progress of Transition Metal Non-oxide High-entropy Ceramics [J]. Journal of Inorganic Materials, 2020, 35(7): 748-758. |

| [15] | WU Xiaojun,YANG Jie,ZHENG Rui,ZHANG Zhaofu,YANG Yi. Effect of Ablation Surface Microstructure on Plasma Arc Ablation Properties of C/C Throat Insert Fabricated via CVI+HPIC Methods [J]. Journal of Inorganic Materials, 2020, 35(6): 654-660. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||