Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (6): 715-725.DOI: 10.15541/jim20230564

Special Issue: 【结构材料】高熵陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Rui( ), ZHANG Kan(

), ZHANG Kan( ), YUAN Mengya, GU Xinlei, ZHENG Weitao

), YUAN Mengya, GU Xinlei, ZHENG Weitao

Received:2023-12-07

Revised:2024-02-26

Published:2024-06-20

Online:2024-05-24

Contact:

ZHANG Kan, professor. E-mail: kanzhang@jlu.edu.cnAbout author:ZHANG Rui (2001-), female, PhD candidate. E-mail: zhangr22@mails.jlu.edu.cn

Supported by:CLC Number:

ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance[J]. Journal of Inorganic Materials, 2024, 39(6): 715-725.

Fig. 1 SEM images and corresponding EDS mappings of the surfaces for (a) NbMoTaW, (b) (NbMoTaW)N0.59, (c) (NbMoTaW)N0.80, and (d) (NbMoTaW)N0.95 thin films

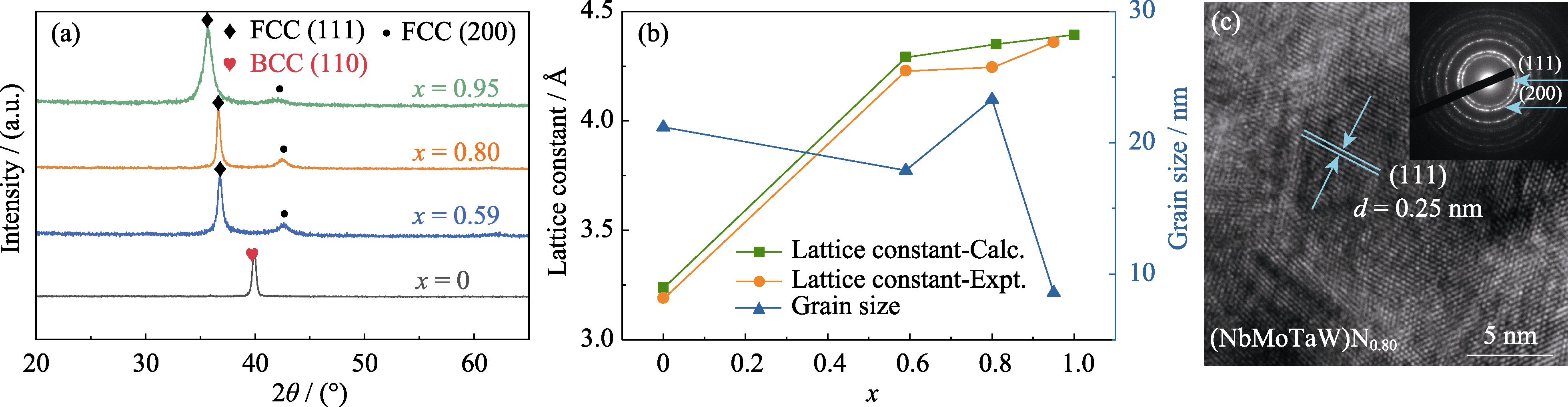

Fig. 2 Analysis of the structural change trends (a) XRD patterns of (NbMoTaW)Nx thin films on Si(100) substrate; (b) Lattice constants of (NbMoTaW)Nx thin films obtained from XRD patterns and DFT calculations, and grain sizes of (NbMoTaW)Nx thin films calculated from XRD patterns; (c) HRTEM image and SAED pattern of (NbMoTaW)N0.80 sample

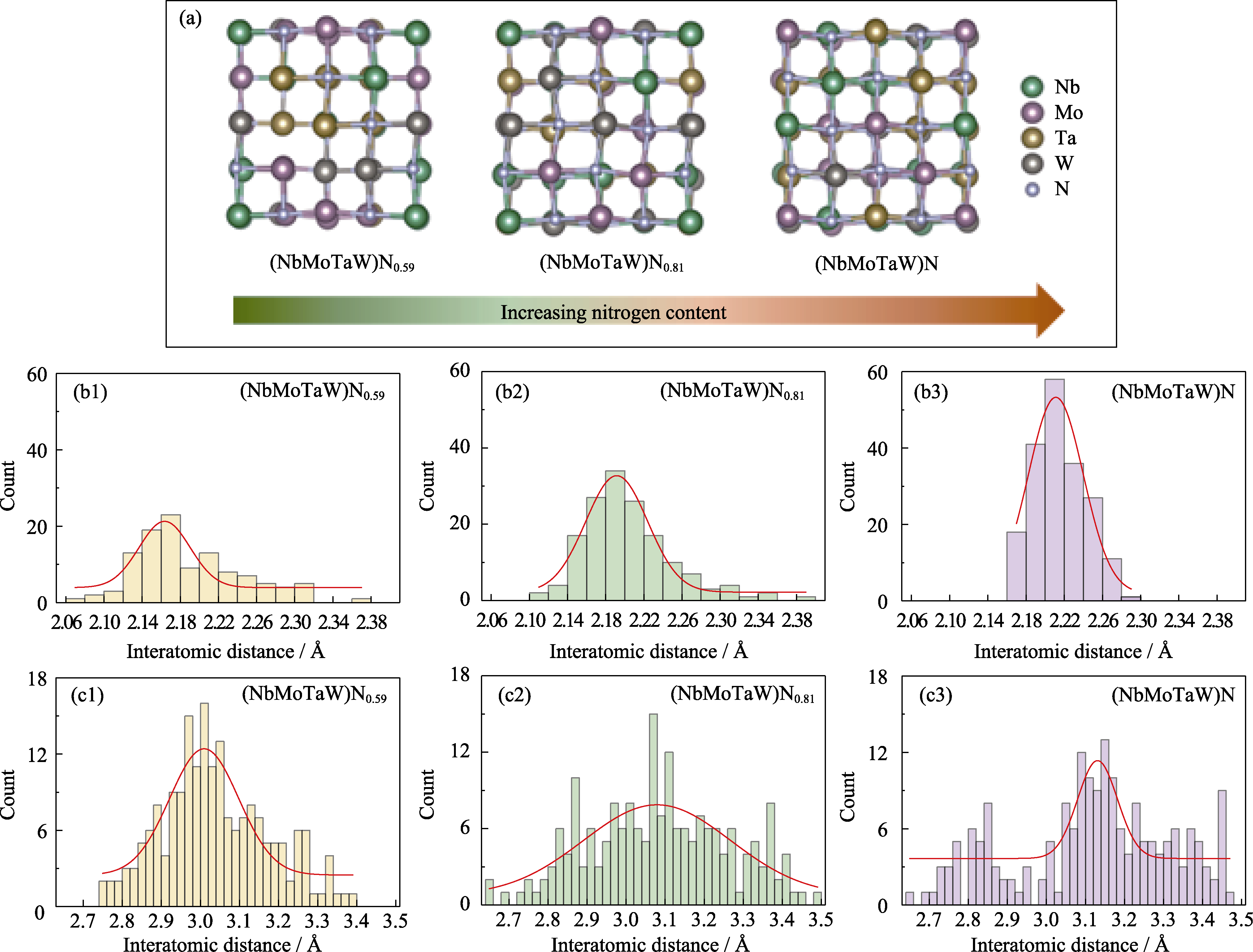

Fig. 3 Bond-length distributions of (NbMoTaW)Nx (x = 0.59, 0.81, 1.00) (a) Schematic representation of the crystal structure after structural optimization; (b1-b3) 1NN atomic distance distribution of Me-N in the supercell and Gaussian fitting curves; (c1-c3) 1NN atomic distance distribution of Me-Me in the supercell and Gaussian fitting curves

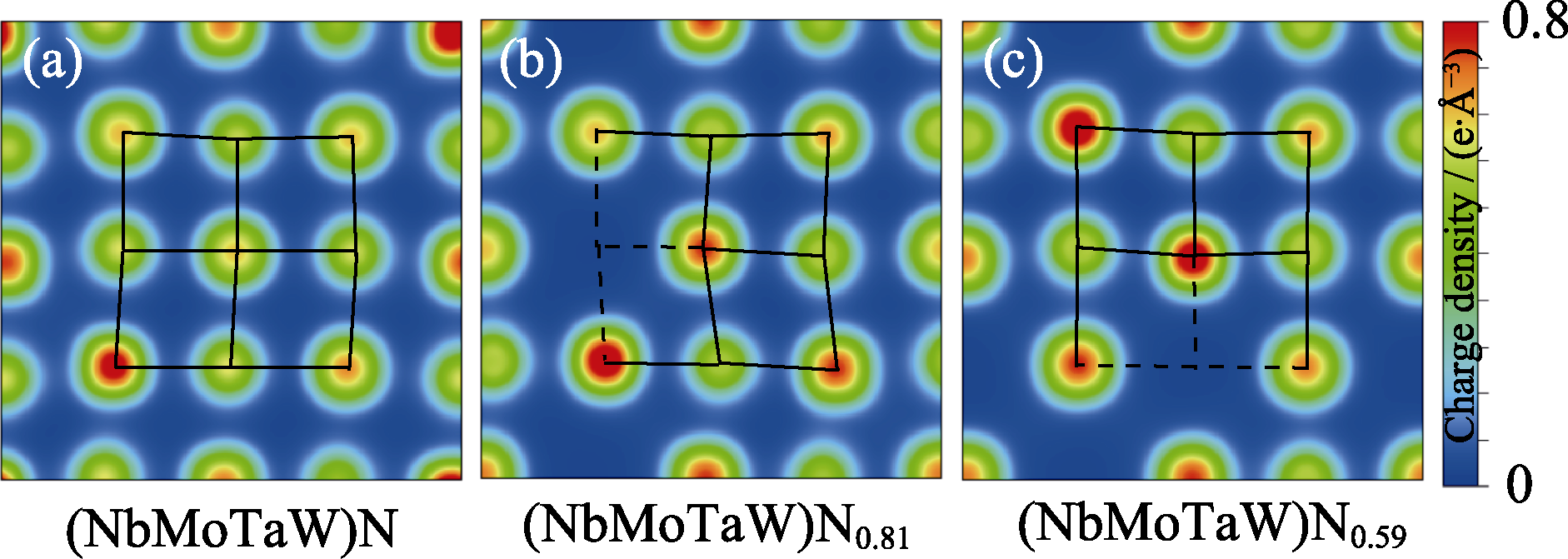

Fig. 4 Schematic diagram of charge density on the (001) plane of (NbMoTaW)Nx compounds when x = (a) 1.00, (b) 0.81, (c) 0.59 Black lines indicating atomic lattice, while dashed lines indicating empty lattice points

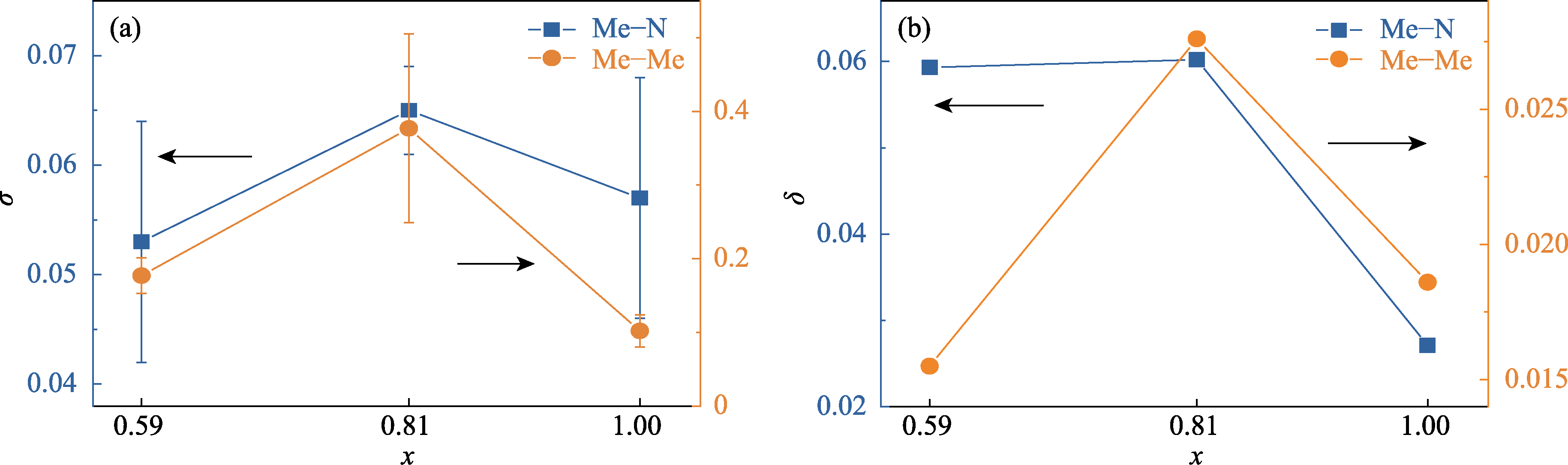

Fig. 5 Trends in lattice distortions of nitrogen and metal sublattices in (NbMoTaW)Nx (x = 0.59, 0.81, 1.00) as function of nitrogen content x evaluated by two methods (a) Method one: lattice distortions σ obtained from the peak width of Gaussian fitting results as described in Fig. 3; (b) Method two: lattice distortions δ calculated using equations

Fig. 7 SEM images of wear tracks at 10000 laps and corresponding EDS mappings for (a) NbMoTaW, (b) (NbMoTaW)N0.59, (c) (NbMoTaW)N0.80, and (d) (NbMoTaW)N0.95 thin films

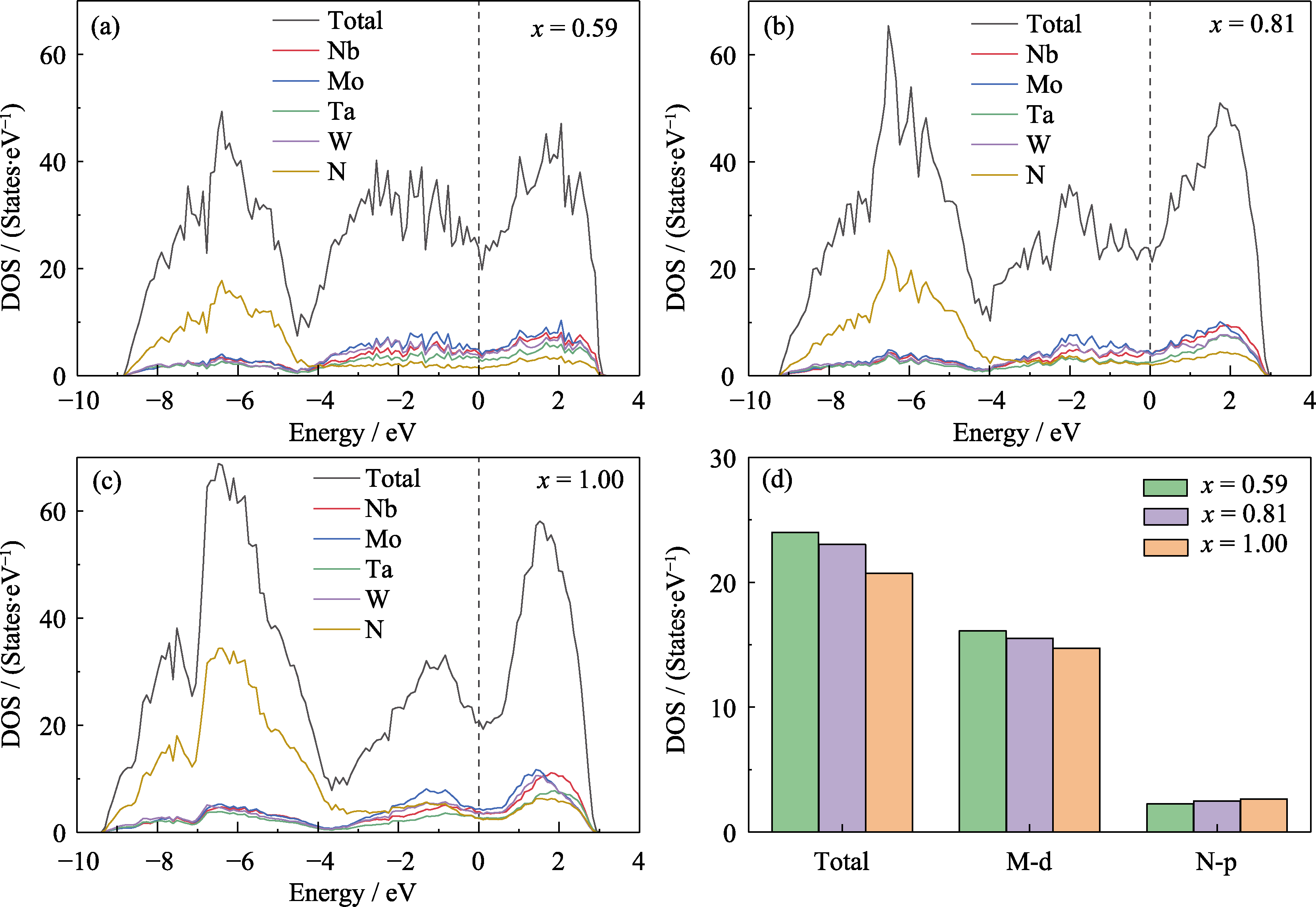

Fig. 8 Density of states (DOS) and partial density of states (PDOS) for (a) (NbMoTaW)N0.59, (b) (NbMoTaW)N0.81 and (c) (NbMoTaW)N, and (d) DOS at the Fermi level for the three thin films The position of the Fermi surface is indicated by dotted lines; Colorful figures are available on website

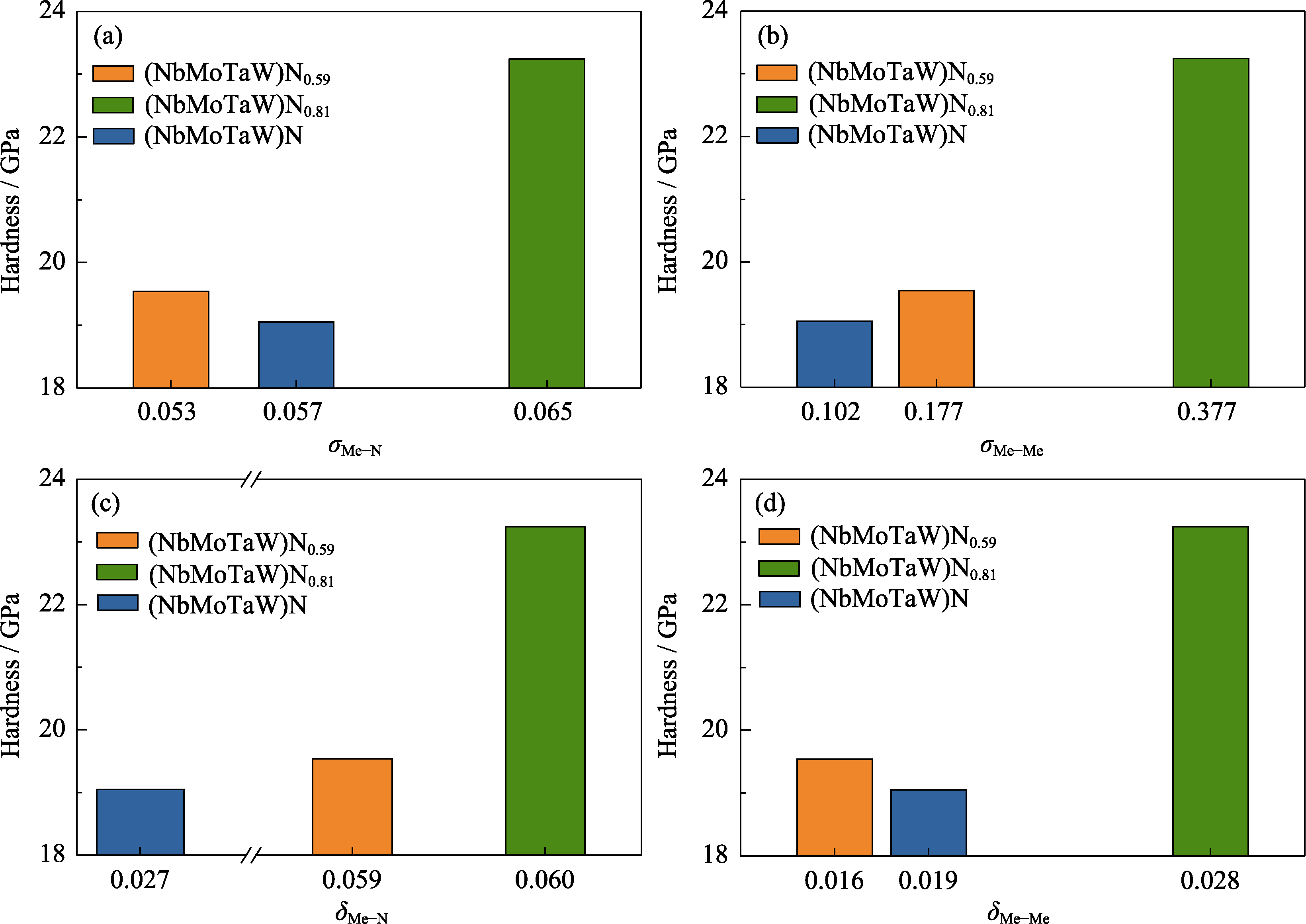

Fig. 9 Trend in hardness of (NbMoTaW)Nx (x = 0.59, 0.81, 1.00) with respect to lattice distortion (a, b) Lattice distortions obtained through the peak width of Gaussian fitting results of (a) nitrogen sublattice (σMe-N) and (b) metal sublattice (σMe-Me); (c, d) Calculated lattice distortions using equations of (c) nitrogen sublattice (δMe-N) and (d) metal sublattice (δMe-Me); Colorful figures are available on website

| [1] | MAMUN M A, FARHA A H, ER A O, et al. Nanomechanical properties of NbN films prepared by pulsed laser deposition using nanoindendation. Applied Surface Science, 2012, 258: 4308. |

| [2] | ZHANG K, BALASUBRAMANIAN K, OZSDOLAY B D, et al. Growth and mechanical properties of epitaxial NbN(001) films on MgO(001). Surface and Coatings Technology, 2016, 288: 105. |

| [3] | TANG Z, WEN Z, LIU Y, et al. Rapid experimental screening of high-entropy diborides for superior oxidation resistance. Advanced Functional Materials, 2024, 34(12):2312239. |

| [4] | YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004, 6: 299. |

| [5] | CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A, 2004, 375-377: 213. |

| [6] | SENKOV O N, WILKS G B, MIRACLE D B, et al. Refractory high-entropy alloys. Intermetallics, 2010, 18: 1758. |

| [7] | YEH J W. Alloy design strategies and future trends in high-entropy alloys. JOM, 2013, 65: 1759. |

| [8] |

ZHANG G J, WANG Y J. Non-order is the new order: high-entropy ceramics. Journal of Inorganic Materials, 2021, 36(4):337.

DOI |

| [9] | ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015, 6: 8485. |

| [10] | GILD J, ZHANG Y, HARRINGTON T, et al. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 2016, 6: 37946. |

| [11] | ALPER J S. The Gibbs phase rule revisited: interrelationships between components and phases. Journal of Chemical Education, 1999, 76: 1567. |

| [12] | FRACCHIA M, CODURI M, GHIGNA P, et al. Phase stability of high entropy oxides: a critical review. Journal of the European Ceramic Society, 2024, 44: 585. |

| [13] | EVANS D, CHEN J, BOKAS G, et al. Visualizing temperature- dependent phase stability in high entropy alloys. npj Computational Materials, 2021, 7: 151. |

| [14] | YE Y F, WANG Q, LU J, et al. High-entropy alloy: challenges and prospects. Materials Today, 2016, 19: 349. |

| [15] | ZHANG Y, ZUO T T, TANG Z, et al. Microstructures and properties of high-entropy alloys. Progress in Materials Science, 2014, 61: 1. |

| [16] | MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017, 122: 448. |

| [17] | CHEN T K, SHUN T T, YEH J W, et al. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surface and Coatings Technology, 2004, 188/189: 193. |

| [18] | CHEN T K, WONG M S, SHUN T T, et al. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surface and Coatings Technology, 2005, 200: 1361. |

| [19] | LAI C H, LIN S J, YEH J W, et al. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surface and Coatings Technology, 2006, 201: 3275. |

| [20] | LEWIN E. Multi-component and high-entropy nitride coatings—a promising field in need of a novel approach. Journal of Applied Physics, 2020, 127: 160901. |

| [21] | YAN X H, LI J S, ZHANG W R, et al. A brief review of high- entropy films. Materials Chemistry and Physics, 2018, 210: 12. |

| [22] | YUAN M, GAO X, GU X, et al. Simultaneous enhancement of hardness and wear and corrosion resistance of high-entropy transition-metal nitride. Journal of the American Ceramic Society, 2022, 106: 1356. |

| [23] | LO W L, HSU S Y, LIN Y C, et al. Improvement of high entropy alloy nitride coatings (AlCrNbSiTiMo)N on mechanical and high temperature tribological properties by tuning substrate bias. Surface and Coatings Technology, 2020, 401: 126247. |

| [24] | WANG Y, YANG Y, YANG H, et al. Microstructure and wear properties of nitrided AlCoCrFeNi high-entropy alloy. Materials Chemistry and Physics, 2018, 210: 233. |

| [25] | JHI S H, IHM J, LOUIE S G, et al. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature, 1999, 399: 132. |

| [26] | GU X, LIU C, GUO H, et al. Sorting transition-metal diborides: new descriptor for mechanical properties. Acta Materialia, 2021, 207: 116685. |

| [27] | GU X, LIU C, GAO X, et al. Solving strength-toughness dilemma in superhard transition-metal diborides via a distinct chemically tuned solid solution approach. Research, 2023, 6: 0035. |

| [28] | ZHANG R, GU X, ZHANG K, et al. Core electron count as a versatile and accurate new descriptor for sorting mechanical properties of diverse transition metal compounds. Advanced Materials, 2023, 35: 2304729. |

| [29] | IVANOVSKII A L. Ternary carbides and nitrides based on transition metals and subgroup ⅢB, ⅣB elements: electronic structure and chemical bonding. Russian Chemical Reviews, 1996, 65: 461. |

| [30] | ABADIAS G, KANOUN M B, GOUMRI-SAID S, et al. Electronic structure and mechanical properties of ternary ZrTaN alloys studied by ab initio calculations and thin-film growth experiments. Physical Review B, 2014, 90: 144107. |

| [31] | LIU C, GAO X, ZHANG K, et al. Exceptional strain strengthening and tuning of mechanical properties of TiN. Physical Review B, 2022, 106: 054112. |

| [32] | XU Y, LI G, XIA Y. Synthesis and characterization of super-hard AlCrTiVZr high-entropy alloy nitride films deposited by hipims. Applied Surface Science, 2020, 523: 146529. |

| [33] | MA C H, HUANG J H, CHEN H. Nanohardness of nanocrystalline tin thin films. Surface and Coatings Technology, 2006, 200: 3868. |

| [34] | LIU C, GU X, ZHANG K, et al. Superhard metallic compound TaB2 via crystal orientation resolved strain stiffening. Physical Review B, 2022, 105: 024105. |

| [35] | ZHAO S. Effects of local elemental ordering on defect-grain boundary interactions in high-entropy alloys. Journal of Alloys and Compounds, 2021, 887: 161314. |

| [36] | ZHAO S. Role of chemical disorder and local ordering on defect evolution in high-entropy alloys. Physical Review Materials, 2021, 5: 103604. |

| [37] | GLUDOVATZ B, HOHENWARTER A, CATOOR D, et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 2014, 345: 1153. |

| [38] | PSHYK A V, VASYLENKO A, BAKHIT B, et al. High-entropy transition metal nitride thin films alloyed with Al: microstructure, phase composition and mechanical properties. Materials Design, 2022, 219: 110789. |

| [39] | CUI P, LI W, LIU P, et al. Effects of nitrogen content on microstructures and mechanical properties of (AlCrTiZrHf)N high-entropy alloy nitride films. Journal of Alloys and Compounds, 2020, 834: 155063. |

| [40] | TUCK J R, KORSUNSKY A M, BULL S J, et al. On the application of the work-of-indentation approach to depth-sensing indentation experiments in coated systems. Surface Coatings Technology, 2001, 137: 217. |

| [41] | KRESSE G, HAFNER J. Ab initio molecular dynamics for liquid metals. Physical Review B-Condensed Matter, 1993, 47: 558. |

| [42] | KRESSE G, FURTHMULLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Physical Review B, 1996, 54: 11169. |

| [43] | BLOCHL P E. Projector augmented-wave method. Physical Review B-Condensed Matter, 1994, 50: 17953. |

| [44] | PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple. Physical Review Letters, 1996, 77: 3865. |

| [45] | ZUNGER A, WEI S, FERREIRA L G, et al. Special quasirandom structures. Physical Review Letters, 1990, 65: 353. |

| [46] | MONKHORST H J, PACK J D. Special points for brillouin-zone integrations. Physical Review B, 1976, 13: 5188. |

| [47] | PACK J D, MONKHORST H J. "Special points for brillouin-zone integrations"—a reply. Physical Review B, 1977, 16: 1748. |

| [48] | ZOU Y, MA H, SPOLENAK R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nature Communications, 2015, 6: 7748. |

| [49] | FRITZE S, HANS M, RIEKEHR L, et al. Influence of carbon on microstructure and mechanical properties of magnetron sputtered taw coatings. Materials & Design, 2020, 196: 109070. |

| [50] | CHENG K H, LAI C H, LIN S J, et al. Structural and mechanical properties of multi-element (AlCrMoTaTiZr)Nx coatings by reactive magnetron sputtering. Thin Solid Films, 2011, 519: 3185. |

| [51] | CHANG C C, HSIAO Y T, CHEN Y L, et al. Lattice distortion or cocktail effect dominates the performance of tantalum-based high- entropy nitride coatings. Applied Surface Science, 2022, 577: 151894. |

| [52] | SHULUMBA N, ALLING B, HELLMAN O, et al. Vibrational free energy and phase stability of paramagnetic and antiferromagnetic crn fromab initiomolecular dynamics. Physical Review B, 2014, 89: 174108. |

| [53] | BALASUBRAMANIAN K, KHARE S, GALL D. Vacancy-induced mechanical stabilization of cubic tungsten nitride. Physical Review B, 2016, 94: 174111. |

| [54] | ISAEV E I, SIMASK S I, ABRIKOSOV I A, et al. Phonon related properties of transition metals, their carbides, and nitrides: a first- principles study. Journal of Applied Physics, 2007, 101: 123519. |

| [55] | 谷鑫磊, 张侃, 文懋, 等. 过渡族金属轻元素化合物薄膜强韧化的研究进展. 中国材料进展, 2021, 40(3):167. |

| [56] | MORGAN W L. Universal resputtering curve. Applied Physics Letters, 1989, 55: 106. |

| [57] | SENKOV O N, WILKS G B, SCOTT J M, et al. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics, 2011, 19: 698. |

| [58] | ZAID H, TANAKA K, LIAO M, et al. Self-organized growth of 111-oriented (VNbTaMoW)N nanorods on MgO(001). Nano Letters, 2020, 21: 577. |

| [59] | ZAID H, TANAKA K, CIOBANU C V, et al. Growth of elastically- stiff, nanostructured, high-entropy alloy nitride, (VNbTaMoW) N/Al2O3(0001) thin film. Scripta Materialia, 2021, 197: 113813. |

| [60] | SHIN C S, GALL D, HELLGREN N, et al. Vacancy hardening in single-crystal TiNx(001) layers. Journal of Applied Physics, 2003, 93: 6025. |

| [61] | GU Z, HU C, HUANG H, et al. Identification and thermodynamic mechanism of the phase transition in hafnium nitride films. Acta Materialia, 2015, 90: 59. |

| [62] | BALASUBRAMANIAN K, HUANG L, GALL D. Phase stability and mechanical properties of Mo1-xNx with 0≤x≤1. Journal of Applied Physics, 2017, 122: 195101. |

| [63] | QI Z, WU Z, ZHANG D, et al. Microstructure, mechanical properties and oxidation behaviors of magnetron sputtered NbNx coatings. Journal of Alloys and Compounds, 2016, 675: 22. |

| [64] | LEE C, CHOU Y, KIM G, et al. Lattice-distortion-enhanced yield strength in a refractory high-entropy alloy. Advanced Materials, 2020, 32: e2004029. |

| [65] | GUO Z, YUAN W, SUN Y, et al. Thermodynamic assessment of the Si-Ta and Si-W systems. Journal of Phase Equilibria and Diffusion, 2009, 30: 564. |

| [66] | LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear, 2000, 246: 1. |

| [67] | DAHLQVIST M, JANSSON U, ROSEN J. Influence of boron vacancies on phase stability, bonding and structure of MB2 (M = Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W) with AlB2 type structure. Journal of Physics: Condensed Matter, 2015, 27: 435702. |

| [68] | LU K, LEI Z, DENG S, et al. Synergistic effects of grain sizes on the corrosion behavior and mechanical properties in a metastable high-entropy alloy. Corrosion Science, 2023, 225: 111588. |

| [69] | NIE J, LIU Y, WANG F, et al. Key roles of particles in grain refinement and material strengthening for an aluminum matrix composite. Materials Science and Engineering: A, 2021, 801: 140414. |

| [70] | MA M D, HAN Y J, ZHAO A S, et al. Ultrafine-grained high-entropy zirconates with superior mechanical and thermal properties. Journal of Materiomics, 2023, 9: 370. |

| [71] | LEE C, SONG G, GAO M C, et al. Lattice distortion in a strong and ductile refractory high-entropy alloy. Acta Materialia, 2018, 160: 158. |

| [72] | WANG P, WU Y, LIU J, et al. Impacts of atomic scale lattice distortion on dislocation activity in high-entropy alloys. Extreme Mechanics Letters, 2017, 17: 38. |

| [1] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [2] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [5] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [6] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [9] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [10] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [11] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [12] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [13] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [14] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [15] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||