|

|

High Entropy Engineering: New Strategy for the Critical Property Optimizations of Rare Earth Silicates

SUN Luchao, REN Xiaomin, DU Tiefeng, LUO Yixiu, ZHANG Jie, WANG Jingyang

2021 Vol. 36 (4): 339–346

Abstract

Abstract(

2273 )

HTML

HTML(

109)

PDF

PDF(5804KB)(

2886

)

Environmental barrier coatings (EBCs) have been developed to improve the durability of SiCf/SiC CMC components against harsh combustion environment. Among the most promising EBC candidates, rare-earth (RE) silicates attract attentions for their low thermal expansion coefficient, excellent high temperature water vaper and CMAS corrosion resistance, and good thermal and chemical compatibility with silicon-based ceramics and composites. Herein, we reviewed the optimizations of critical key properties of rare-earth silicates through strategic high entropy design to modify the current performance deficiencies of rare-earth silicates like thermal properties (coefficient of thermal expansion and thermal conductivity), CMAS corrosion resistance and high temperature phase stability. The present advancements demonstrate the merits of high entropy engineering for advanced EBCs for the improvement of crucial properties in engine applications.

|

|

|

Application of Entropy Engineering in Thermoelectrics

YANG Qingyu, QIU Pengfei, SHI Xun, CHEN Lidong

2021 Vol. 36 (4): 347–354

Abstract

Abstract(

1781 )

HTML

HTML(

67)

PDF

PDF(1016KB)(

2685

)

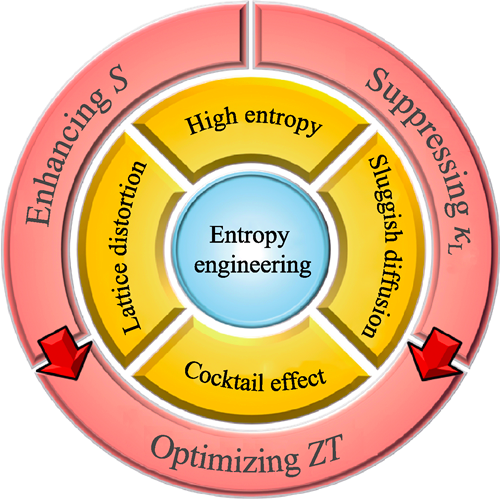

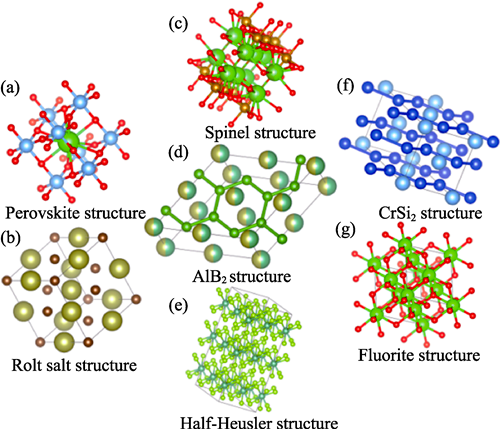

As the extension of high-entropy alloy, entropy engineering has been already extensively used in thermoelectrics because it can guide the optimization of thermoelectric (TE) performance from the aspects of both electrical and thermal transports. Due to the inherent material gene-like feature, entropy can be used as a performance indicator to rapidly screen new multicomponent TE materials. In this review, we first reveal the reason why entropy can be used as the performance indicator of TE materials. The physical mechanisms of enhanced structure symmetry, improved Seebeck coefficient, and suppressed lattice thermal conductivity as a result of the increased configurational entropy are discussed. Then, the applications of entropy engineering in typical TE materials, such as liquid-like materials and IV-VI semiconductors, are outlined, and the approach to screen and identify candidate multicomponent TE materials with high configurational entropy is introduced. Finally, the future directions for entropy engineering are highlighted.

|

|

|

Research Progress of High Entropy Transition Metal Carbide Ceramics

WANG Haoxuan, LIU Qiaomu, WANG Yiguang

2021 Vol. 36 (4): 355–364

Abstract

Abstract(

2162 )

HTML

HTML(

134)

PDF

PDF(1452KB)(

13243

)

As a new emergence material, high-entropy ceramics possess unique properties due to its high configurational entropy. Among these ceramics, high-entropy transition metal carbide ceramics (HETMCC) are expected to be the potential candidates for the thermal protection system of hypersonic aircraft. Compared with single-component ceramics, the comprehensive performance of single-phase HETMCC is greatly improved. At present, the research on HETMCC is still in the initial stage, and the composition design and theoretical analysis of HETMCC are lack of sufficient research support. In addition, it is necessary to further explore the preparation of high purity HETMCC. In terms of the properties of HETMCC, further in-depth research has been conducted. In this paper, the theoretical design and preparation methods of high-entropy ceramics are reviewed. Research progress of the mechanical properties, thermal conductivity, and oxidation resistance properties of HETMCC are introduced in detail. The concerned scientific issues of HETMCC are pointed out and their future development direction are also prospected.

|

|

|

Study on the Solid Solution Structures of High-Entropy Ceramics by Transmission Electron Microscopy

GUO Xiaojie, BAO Weichao, LIU Jixuan, WANG Xingang, ZHANG Guojun, XU Fangfang

2021 Vol. 36 (4): 365–371

Abstract

Abstract(

1743 )

HTML

HTML(

97)

PDF

PDF(7521KB)(

2858

)

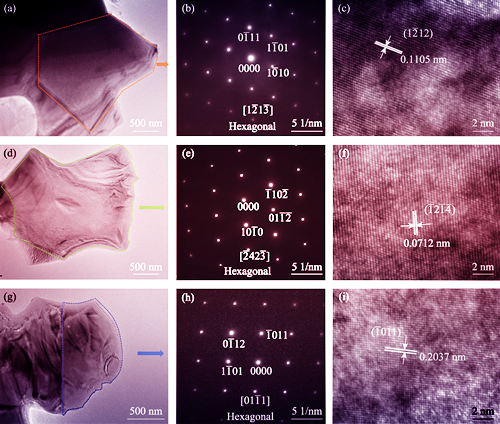

High-entropy brings high-entropy effect on thermodynamics, lattice distortion effect on structure, diffusion retardation effect on dynamics and “cocktail” effect on properties in materials. It is a hotspot to improve the properties of ceramics by high-entropy design. However, it still lacks the study of high-entropy structures and their correlation to the properties through transmission electron microscopy (TEM). In this study, high-entropy borides and carbides powders were fabricated by using metal oxides, boron carbide and graphite as raw materials. The high-entropy (TiZrHfNbTa)B2 and (TiZrHfNbTa)C ceramics were then synthesized by spark plasma sintering of the as-fabricated powders. Transmission electron microscope and energy dispersive spectrometry were used to characterize the structure of the two high-entropy ceramics at the nano-scale and atomic-scale. The integrity of crystal structure maintained after solid solution of five transition metal elements which were found to uniformly distribute in the ceramics. However, at atomic scales, concentration oscillations of solid solution elements, atomic dispersion and lattice strain were observed. The solid solution structures at atomic scales as-obtained in this work can help to understand the structure-property relationship of high-entropy ceramics and provide experimental basis for the composition and structure design of high-entropy ceramics.

|

|

|

Preparation and Sintering Behavior of High Entropy Ceramic (Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ

ZHANG Fengnian, GUO Meng, MIAO Yang, GAO Feng, CHENG Chufei, CHENG Fuhao, LIU Yufeng

2021 Vol. 36 (4): 372–378

Abstract

Abstract(

1051 )

HTML

HTML(

52)

PDF

PDF(3010KB)(

1755

)

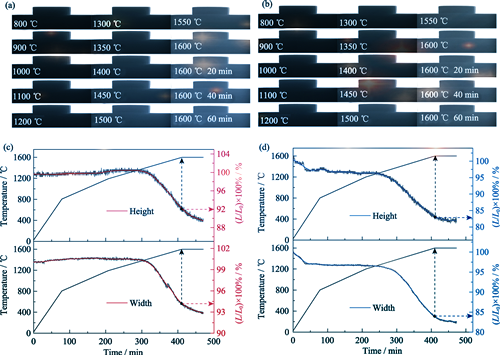

High entropy ceramics (HECs) typically refer to a kind of solid solution consisting of five or more principal elements. In recent years, different kinds of HECs have developed rapidly whereas high entropy oxides with fluorite structure are still in their nascent state. In this study, a new type of high entropy fluorite oxide was successfully synthesized using mechanical ball-milling followed by conventional sintering. Phase transformation, surface morphology and sintering behavior of ceramic were characterized. The results demonstrate that (Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ is a non-equimolar high entropy ceramic in which all elements distribute homogenously. The powders derived from wet-milling or dry-milling possess different crystal structure and particle size. Raw materials transform into single-phase structure at 1600 ℃ and 1300 ℃, respectively. After dwelling at 1600 ℃ for 1 h, the shrinkage of two discs are 8.5% and 17.8%, approximately, at the same time, the relative densities are 82.25% and 93.23%. These miscellaneous distinctions indicate that ball-milling process is a crucial factor affecting sinterability of HECs. In order to avoid cracks caused by rapid shrinkage and improve density of ceramic, it is vital to decrease heating rate and prolong dwell time in the range of 1300-1600 ℃ as preparing (Zr1/7Hf1/7Ce1/7Y2/7La2/7)O2-δ by conventional sintering.

|

|

|

Preparation and Property of High Entropy (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 Perovskite Ceramics

ZHANG Xiaoyan, LIU Xinyue, YAN Jinhua, GU Yaohang, QI Xiwei

2021 Vol. 36 (4): 379–385

Abstract

Abstract(

1792 )

HTML

HTML(

82)

PDF

PDF(2414KB)(

7345

)

High entropy ceramic is a kind of ceramic developed based on the high entropy alloy in recent years. The appearance of high entropy ceramics provides a new concept and route for developing non-metallic materials with excellent properties. In present work, a series of high-entropy ceramics with a molar ratio of A site—(La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 were successfully synthesized by solid state reaction. The effects of sintering temperature on phase, microstructure and electric properties were investigated. Results show that the high-entropy ceramics sintered at current temperatures are of cubic perovskite structure, and exhibit excellent insulation, with low leakage current density of J value around 10-8-10-6 A/cm2. Although the grain size increases with the increase of sintering temperature, the correlation between microstructure and dielectric properties of (La0.2Li0.2Ba0.2Sr0.2Ca0.2)TiO3 ceramics is not significant. The dielectric constant reaches its maximum value at 1350 ℃, with the value of 230 at the frequency of 100 Hz. Meanwhile, this high-entropy ceramic has relaxation behavior, and the relaxation peak of the permittivity moves towards high temperature with the increase of frequency.

|

|

|

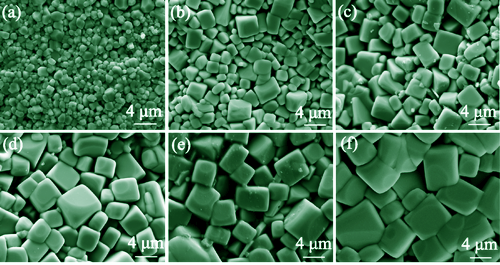

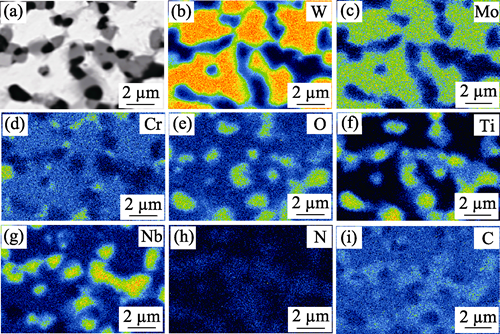

Preparation and Mechanical Property of the Ceramic-reinforced Cr0.5MoNbWTi Refractory High-entropy Alloy Matrix Composites

LÜ Shasha, ZU Yufei, CHEN Guoqing, ZHAO Bojun, FU Xuesong, ZHOU Wenlong

2021 Vol. 36 (4): 386–392

Abstract

Abstract(

1065 )

HTML

HTML(

29)

PDF

PDF(2464KB)(

1574

)

As promising high-temperature structural materials, refractory high-entropy alloys have widely applications due to their excellent mechanical properties, high-temperature stability and oxidation resistance. For further improving the mechanical properties, ceramic-reinforced refractory high-entropy alloy matrix composites were prepared by utilizing in-situ reaction sintering. The supersaturated body centered cubic (BCC) solid solution of Cr0.5MoNbWTi doped with nonmetallic elements of carbon, nitrogen and oxygen was prepared by mechanical alloying. During spark plasma sintering, (Nb,Ti)(N,C) and Ti2O3 ceramic reinforcements were formed by in-situ reaction between nonmetallic and metallic elements. The ceramic reinforcements were well dispersed in BCC matrix. The formation mechanism and the strengthening effects of the ceramic reinforcements were discussed in this paper. With the assistance of the fine-grained ceramic reinforcements, the composites exhibited ultra-high ambient-temperature strength (4033 MPa), ambient-temperature hardness (11.57 GPa), and superior high-temperature yield strength (572 MPa at 1400 ℃).

|

|

|

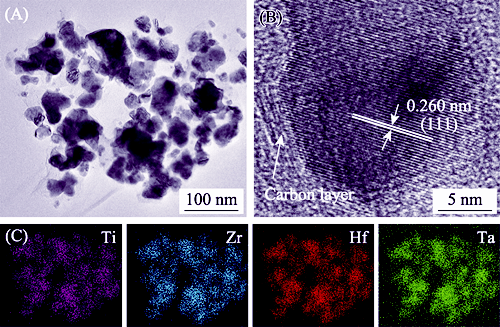

Synthesis of High Entropy Carbide Nano Powders via Liquid Polymer Precursor Route

SUN Yanan, YE Li, ZHAO Wenying, CHEN Fenghua, QIU Wenfeng, HAN Weijian, LIU Wei, ZHAO Tong

2021 Vol. 36 (4): 393–398

Abstract

Abstract(

1407 )

HTML

HTML(

50)

PDF

PDF(1845KB)(

4152

)

High entropy carbide ceramics have been proposed in recent years for their promising properties as high hardness, high modulus and low thermal conductivity. Liquid polymer precursor method, of which multiple elements distribute homogeneously during the pyrolysis process, is considered to be favorable in fabricating high entropy ceramics. However, few reports have studied the synthesis of liquid precursor. In this work, liquid polymer precursor of (Ti, Zr, Hf, Ta)C were synthesized by co-hydrolysis and polycondensation of equiatomic metal containing monomers, and adding allyl-functional novolac resin (AN) as carbon source. The obtained polymer precursors of high entropy carbide ceramics (PHECs) were soluble in propyl alcohol and stable for months. The corresponding high entropy carbide ceramic nano powders were obtained by pyrolyzing PHEC at 1800 ℃ for 2 h in vacuum. The precursors and ceramic powders were characterized by different methods. Results reveal that the ceramic sample pyrolyzed at 800 ℃ are composed of t-ZrO2 and oxide solid solutions, and carbothermal reduction reaction began after pyrolyzed at 1000 ℃, with carbide solid solutions being generated. After being pyrolyzed at 1800 ℃, the samples convert to target high entropy carbide ceramics. As-obtained ceramics are characterized to be high purity with uniform distribution of nanosized particles (~100 nm). The synthesized precursor has high ceramic yield (28.6wt%), low viscosity (150 mPa·s), and good solubility in polar solvents. Therefore, the proposed liquid polymer precursor method is reliable in preparation of high entropy ceramic nano powders, ceramic fibers and ceramic matrix composites.

|

|

|

Designing High Entropy Structure in Thermoelectrics

CAI Jianfeng, WANG Hongxiang, LIU Guoqiang, JIANG Jun

2021 Vol. 36 (4): 399–404

Abstract

Abstract(

1450 )

HTML

HTML(

36)

PDF

PDF(1220KB)(

3585

)

With the fascinating properties observed in high entropy alloys, the idea of high entropy design has been applied to many material fields. Thermoelectric materials have some particular requirements for high entropy structure according to their transport characteristics. Here, we revealed that the high entropy structure for thermoelectrics required less lattice distortion, and the doping sites should have less influence on the Fermi surface. In the designed compound of Cu0.8Ag0.2Zn0.1Ga0.4Ge0.1In0.4Te2, the room-temperature thermal conductivity is reduced by 80% as compared to the matrix, and the maximum ZT is enhanced to 1.02. In SnTe, the solid solution of AgSbSe2 reduces the room-temperature thermal conductivity by 80%, reaching 1.3 W·m-1·K-1. This study shows that the high entropy structure following the proposed designing rules could be an important strategy for thermoelectrics.

|

|

|

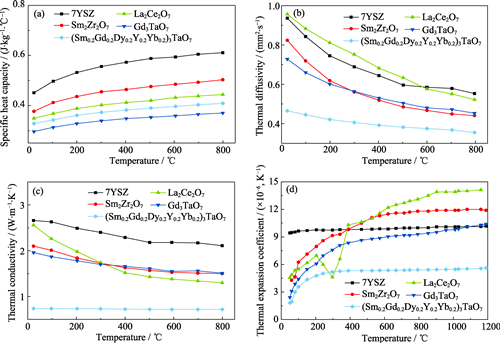

Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic

SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun

2021 Vol. 36 (4): 405–410

Abstract

Abstract(

964 )

HTML

HTML(

38)

PDF

PDF(1157KB)(

3730

)

Developing novel ceramic materials with excellent thermophysical properties is one of the hotspots in the field of thermal barrier coatings. The (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 high-entropy ceramic was fabricated via high-temperature solid-state reaction. The crystal structure, microstructure, phase stability and thermophysical properties were investigated. Results indicate that (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 high-entropy ceramic has single defective fluorite structure, its elements are homogenously distributed, its grain size ranges from 0.2 to 3 μm. After high-temperature thermal cycling, the sample still remains single fluorite structure, showing excelleent phase stability at high temperature. Thermal conductivity lies in the range of 0.72-0.74 W/(m·K), lower than that of 7YSZ. Thermal expansion coefficient at 1200 ℃ is 5.6×10-6 K-1, lower than requirement of thermal barrier coatings (TBCs) for surface ceramic layer. However, its thermal expansion coefficient is close to that of the silicon-based ceramics substrate of environmental barrier coatings (EBCs) ((3.4-5.5)×10-6 K-1).

|

|

|

Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics

ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng

2021 Vol. 36 (4): 411–417

Abstract

Abstract(

1426 )

HTML

HTML(

48)

PDF

PDF(8772KB)(

4642

)

Single-phase solid solution monoclinic structure high-entropy tantalates (Nd1/6Sm1/6Eu1/6Gd1/6Dy1/6Ho1/6) TaO4(6RETaO4), (Nd1/5Sm1/5Eu1/5Gd1/5Dy1/5)TaO4(5RETaO4), (Nd1/4Sm1/4Eu1/4Gd1/4)TaO4(4RETaO4) were prepared by solid state method. STEM-EDS result shows the rare earth elements are uniformly distributed without segregation. The ferroelastic domain observed through SEM derived from the second ferroelastic phase transition. The thermal expansion experiment suggests the good thermal stability below 1200 ℃, where the thermal expansion coefficient of 6RETaO4 reaches 9.25×10-6K-1 at 1200 ℃. Due to the increase of phonon scattering derived from high-entropy effect, RETaO4 ceramics exhibit lower intrinsic thermal conductivity (2.98-1.23 W·m-1·K-1, 100-1000 ℃) and enhanced mechanical properties (6RETaO4, (9.97±2.2) GPa), which indicates that it is a potential material for thermal barrier coatings.

|

|

|

Preparation of (La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7 High-entropy Transparent Ceramics by Vacuum Sintering

ZENG Jianjun, ZHANG Kuibao, CHEN Daimeng, GUO Haiyan, DENG Ting, LIU Kui

2021 Vol. 36 (4): 418–424

Abstract

Abstract(

1300 )

HTML

HTML(

50)

PDF

PDF(5628KB)(

2766

)

High-entropy ceramic is a hot topic in the recent study of ceramic materials. High-entropy ceramics with excellent properties is the development trend of ceramic materials. In this research, high-entropy transparent ceramic was synthesized by combustion method combined with vacuum sintering. The result indicates that the mean grain size of high-entropy (La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7 powder is about 8 nm. And the high-entropy powder is disordered deficient fluorite structure. The final transparent ceramics sintered in vacuum furnace at different temperatures exhibit ordered pyrochlore structure. Sintering temperature has little effect on the transmittance of ceramics. And the in-line transmittance of as-prepared transparent ceramic can reach 74% at 1730 nm. There are many absorption peaks in the transmittance spectrum. With the increase of sintering temperature, the body density and grain size of ceramics increase, but the HV hardnesses decrease.

|

|

|

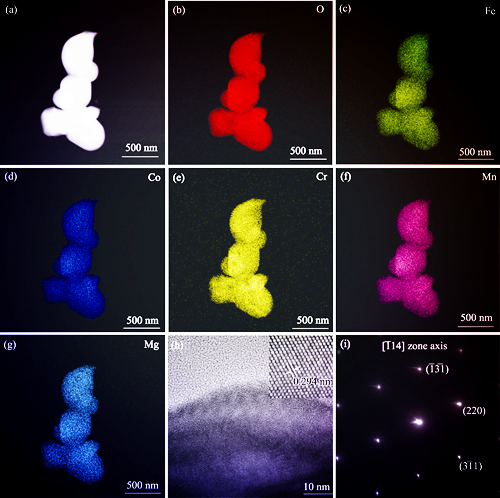

Facile Synthesis and Supercapacitor Performance of M3O4(M=FeCoCrMnMg) High Entropy Oxide Powders

WANG Yiliang, AI Yunlong, YANG Shuwei, LIANG Bingliang, ZHENG Zhenhuan, OUYANG Sheng, HE Wen, CHEN Weihua, LIU Changhong, ZHANG Jianjun, LIU Zhiyong

2021 Vol. 36 (4): 425–430

Abstract

Abstract(

1498 )

HTML

HTML(

53)

PDF

PDF(9307KB)(

2500

)

High-entropy oxides have attracted more and more attention due to their unique structures and potential applications. In this work, M3O4(M=FeCoCrMnMg) high entropy oxide powders were synthesized by a facile solid-state reaction method. The powders were characterized by different methods. Furthermore, M3O4/Ni foam (M3O4/NF) electrode was prepared by a coating method, followed by investigation of its supercapacitor performance. The results showed that, with the increase of calcining temperature, Fe2O3(H)/Co3O4(S)/Cr2O3(E) and Mn2O3(B) dissolved successively in the crystal lattice of spinel structure. After M3O4 powders being calcined at 900 ℃ for 2 h, single spinel structure (FCC, Fd-3m, a=0.8376 nm) was obtained with uniform distribution of Fe, Co, Cr, Mn, and Mg elements, the typical characteristic of high entropy oxide. In addition, the mass specific capacitance of M3O4/NF composite electrode is 193.7 F·g-1, with 1 mol/L KOH as electrolyte and 1 A·g-1 as current density, which indicated that the M3O4 high entropy oxide can be considered as a promising candidate for the electrode material in the field of supercapacitor applications.

|

|

|

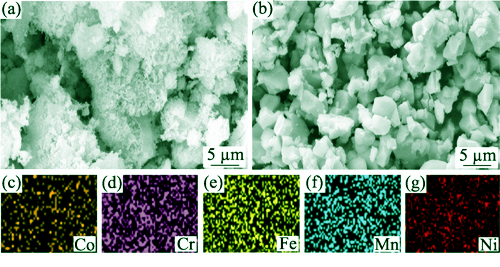

Preparation and Electrical Properties of High Entropy La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 Perovskite Ceramics Powder

GUO Meng, ZHANG Fengnian, MIAO Yang, LIU Yufeng, YU Jun, GAO Feng

2021 Vol. 36 (4): 431–435

Abstract

Abstract(

1575 )

HTML

HTML(

87)

PDF

PDF(709KB)(

2730

)

High entropy La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 perovskite ceramics powder were prepared using coprecipitation method combined with calcination process, and synthesis temperature of the high entropy perovskite ceramics was significantly reduced. The phases and morphology of the ceramics powder were characterized by different methods. The results show that when the calcination temperature is 800 ℃, perovskite structure with a small amount of second phase was formed in the ceramics powder. When the calcination temperature is 1000 ℃, pure perovskite structure is formed in the La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 high entropy ceramics powder. Three electrode system was used to test the electrical properties of the working electrode made from the La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 high entropy ceramics powder, including cyclic voltammetry (CV) test and constant current charge-discharge (GCD) test. At the current density of 1 A/g, specific capacity of the working electrode reaches 154.8 F/g, while the current density increased to 10 A/g, the electrode material can still maintain 47%(73 F/g) of the initial specific capacity. All results indicate that high entropy La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 perovskite ceramics have good rate properties.

|

|

|

3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties

ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng

2021 Vol. 36 (4): 436–442

Abstract

Abstract(

1019 )

HTML

HTML(

44)

PDF

PDF(11811KB)(

1874

)

Dense and porous zirconia ceramics were 3D printed with granular feedstock and screw extrusion mechanism on the basis of the traditional fused deposition method. The printability of granular feedstock, microstructure of the body and mechanical properties of ceramic materials were studied. The unsupported structure with maximum inclination 165° and span 5.5 mm were obtained. Effects of the two filling modes of printing on the flexural strength and Weibull modulus of the dense zirconia ceramics were compared. The results showed that the “single line+rectangle” filling mode was more conducive to achieve higher density and better mechanical properties than the traditional single line filling mode. Materials with bending strength of 637.8 MPa and Weibull modulus of 9.1 were obtained. The compressive behavior of porous zirconia ceramics prepared with different porosities were studied, showing an exponential law between compressive strength and porosity. There was only elasticity stage on the stress-strain curve for the samples with high porosity, while collapse stage may appear for the samples with low porosity. There was no collapse stage for both samples.

|

|

|

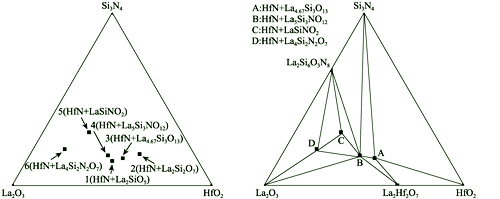

HfN Formation and Phase Relationships in the Hf-Si-La-O-N System

LIU Yang, LU Youjun, LI Yanrui, LIN Liqun, YUAN Zhenxia, HUANG Zhenkun

2021 Vol. 36 (4): 443–448

Abstract

Abstract(

880 )

HTML

HTML(

9)

PDF

PDF(1030KB)(

2564

)

In this study, the synthesis is feasibility and formulation design of HfN composite lanthanum silicate ceramics were explored. The feasibility of HfN synthesis by ternary reaction of HfO2-Si3N4-La2O3 system was verified by experiments, and the relationship between reaction pathway of HfO2-Si3N4 binary system and Hf-Si-La-O-N was studied. Considering that the lanthanum silicate salt in the reaction of HfO2-SiO2-La2O3 ternary system was contained in the Si3N4-SiO2-La2O3 system, lanthanum silicate was extended to the HfO2-Si3N4-La2O3-SiO2-HfN (Hf-Si-La-O-N) system, which clarified the coexistence of HfN and the lanthanum salt phases in the system. Experimental phase diagrams of HfO2-SiO2-La2O3 ternary system and Hf-Si-La-O-N system at 1500 ℃ were proposed. The results show that intermediate product Hf7O8N4 formed in the synthesis of HfN at high temperature in HfO2-Si3N4 binary system. Introduction of La2O3 promoted the system to generate HfN which was beneficial to reduce the burning loss rate of ceramics. There existed HfN and La4.67Si3O13, La5Si3NO12, LaSiNO2, La4Si2N2O7, La2Hf2O7 five lanthanum salt phases in the Hf-Si-La-O-N system.

|

|