无机材料学报 ›› 2023, Vol. 38 ›› Issue (9): 1089-1096.DOI: 10.15541/jim20220710 CSTR: 32189.14.10.15541/jim20220710

所属专题: 【能源环境】钙钛矿(202506); 【能源环境】太阳能电池(202506)

代晓栋1,2( ), 张露伟2, 钱奕成2, 任智鑫2, 曹焕奇2(

), 张露伟2, 钱奕成2, 任智鑫2, 曹焕奇2( ), 印寿根2

), 印寿根2

收稿日期:2022-11-28

修回日期:2023-01-27

出版日期:2023-09-20

网络出版日期:2023-04-15

通讯作者:

曹焕奇, 教授. E-mail: caoh@tjut.edu.cn作者简介:代晓栋(1996-), 男, 硕士研究生. E-mail: 1021385583@qq.com

基金资助:

DAI Xiaodong1,2( ), ZHANG Luwei2, QIAN Yicheng2, REN Zhixin2, CAO Huanqi2(

), ZHANG Luwei2, QIAN Yicheng2, REN Zhixin2, CAO Huanqi2( ), YIN Shougen2

), YIN Shougen2

Received:2022-11-28

Revised:2023-01-27

Published:2023-09-20

Online:2023-04-15

Contact:

CAO Huanqi, professor. E-mail: caoh@tjut.edu.cnAbout author:DAI Xiaodong (1996-), male, Master candidate. E-mail: 1021385583@qq.com

Supported by:摘要:

带隙1.1~1.4 eV的锡铅混合卤化物钙钛矿是单结太阳能电池光电转换效率(PCE)接近Shockley-Queisser (S-Q)理论效率极限值的理想材料。钙钛矿薄膜垂直方向上的化学组分梯度会通过影响能带结构影响载流子的传输和分离, 因此对锡铅混合钙钛矿薄膜的结晶过程进行控制十分重要。本研究发现使用不同剂量的反溶剂制备锡铅混合钙钛矿会形成不同的垂直组分梯度, 并且随反溶剂用量增大薄膜表面铅含量增加。调整溶剂组分可以控制锡铅混合钙钛矿的垂直组分梯度, 增大溶剂中V(DMSO):V(DMF)可以形成底部富铅而表面富锡的垂直组分梯度。当铅基前驱液溶剂中V(DMSO):V(DMF)最优化为1 : 2时, 相比于1 : 4的对照组, 器件在标准光照条件下的开路电压从0.725 V提高到0.769 V, 短路电流密度从30.95 mA·cm-2提高到31.65 mA·cm-2, PCE从16.22%提升到接近18%。利用SCAPS软件数值模拟进一步证明了垂直组分梯度的必要性, 当钙钛矿薄膜底部富铅、顶部富锡时, 载流子在空穴传输层界面区域的复合有所减少, 因而电池性能得到提升。

中图分类号:

代晓栋, 张露伟, 钱奕成, 任智鑫, 曹焕奇, 印寿根. 锡铅混合钙钛矿太阳能电池垂直组分梯度的溶剂工程调控[J]. 无机材料学报, 2023, 38(9): 1089-1096.

DAI Xiaodong, ZHANG Luwei, QIAN Yicheng, REN Zhixin, CAO Huanqi, YIN Shougen. Controlling Vertical Composition Gradients in Sn-Pb Mixed Perovskite Solar Cells via Solvent Engineering[J]. Journal of Inorganic Materials, 2023, 38(9): 1089-1096.

图1 不同反溶剂乙酸乙酯用量制备钙钛矿薄膜的晶体结构

Fig. 1 Crystal structures of perovskite films prepared with different amounts of antisolvent (a) XRD patterns of perovskite films prepared with different amounts of antisolvent; (b) Magnified XRD patterns of (100) lattice plane diffraction peaks; (c) Half-peak width of (100) lattice plane diffraction peaks of thin films at different antisolvent dosages; (d-f) Top-down SEM images of films prepared by 100, 300 and 500 μL antisolvents and statistics of grain sizes

图2 (a) PF-DMSO0.25正面和背面的PL谱图; (b) PF-DMSO0.25对应的PSCs的横截面SEM照片及EDS面扫分析区域; (c) PF-DMSO0.25或PF-DMSO0.50的SEM截面照片中不同深度区域的铅锡元素比

Fig. 2 (a) PL spectra from the front and back sides of PF-DMSO0.25; (b) Cross-sectional SEM images of PSCs of PF-DMSO0.25 and EDS scanning areas; (c) Lead/tin elemental ratios in different depth regions of the cross-sectional SEM images of PF-DMSO0.25 or PF-DMSO0.50; Colorful figures are available on website

图3 PF-DMSOx的物相结构和光电性能

Fig. 3 Phase structure and photoelectric properties of perovskites films PF-DMSOx (a) XRD patterns of films and (b) PCE statistics of devices; (c) Time-resolved photoluminescence spectra; (d) Tauc plots of ultraviolet-visible absorption spectra and (e) ultraviolet photoelectron spectra of PF-DMSO0.50 and PF-DMSO0.25; (f) Energy level relationship, (g) J-V curves, (h) external quantum efficiency and integrated current density, (i) Urbach band edge absorption obtained from EQE spectra and fitted electroluminescence spectra of devices fabricated with PF-DMSO0.50 and PF-DMSO0.25; Colorful figures are available on website

| Ingredient | Thickness/μm | Eg/eV | χ/eV | εr | Nc/cm-3 | Nv/cm-3 | μn/(cm2∙ V-1∙s-1) | μp/(cm2∙ V-1∙s-1) | Nd/cm-3 | Na/cm-3 | Nt/cm-3 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PEDOT: PSS | 0.03 | 2.2 | 3 | 3 | 2.2×1015 | 1.8×1018 | 0.02 | 0.0002 | - | 3.17×1014 | 1×1015 | [ |

| Perovskite | 0.6 | 1.25-1.23 | 4.15-4.2 | 100 | 1.0×1018 | 1.0×1018 | 2 | 2 | - | 1.0×1018 | 2.5×1016 | [ |

| PCBM | 0.05 | 2.0 | 3.9 | 3.9 | 2.5×1021 | 2.5×1020 | 0.2 | 0.2 | 2.93×1017 | - | 1×1015 | [ |

| BCP | 0.01 | 3.5 | 3.7 | 10 | 1.8×1018 | 2.2×1018 | 0.02 | 0.002 | 1×1021 | 1×1010 | 1×10 | [ |

表1 钙钛矿太阳能电池各层结构主要模拟参数

Table 1 Main simulation parameters of perovskite solar cell structures

| Ingredient | Thickness/μm | Eg/eV | χ/eV | εr | Nc/cm-3 | Nv/cm-3 | μn/(cm2∙ V-1∙s-1) | μp/(cm2∙ V-1∙s-1) | Nd/cm-3 | Na/cm-3 | Nt/cm-3 | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PEDOT: PSS | 0.03 | 2.2 | 3 | 3 | 2.2×1015 | 1.8×1018 | 0.02 | 0.0002 | - | 3.17×1014 | 1×1015 | [ |

| Perovskite | 0.6 | 1.25-1.23 | 4.15-4.2 | 100 | 1.0×1018 | 1.0×1018 | 2 | 2 | - | 1.0×1018 | 2.5×1016 | [ |

| PCBM | 0.05 | 2.0 | 3.9 | 3.9 | 2.5×1021 | 2.5×1020 | 0.2 | 0.2 | 2.93×1017 | - | 1×1015 | [ |

| BCP | 0.01 | 3.5 | 3.7 | 10 | 1.8×1018 | 2.2×1018 | 0.02 | 0.002 | 1×1021 | 1×1010 | 1×10 | [ |

图4 数值模拟顺梯度(NG)、无梯度(WO)和逆梯度(IG)异质结结构器件性能

Fig. 4 Numerical simulation of devices with NG, WO, IG heterojunctions (a) Schematic diagram of the solar cell structures with different vertical composition gradients; (b) Positions of the conduction band, valence band, electron and hole quasi-Fermi levels, (c) electron and hole carrier concentrations, (d) J-V curves and (e) EQE curves; (f) Hole deep-level defect trapping probabilities of normal or inverted gradient devices; Colorful figures are available on website

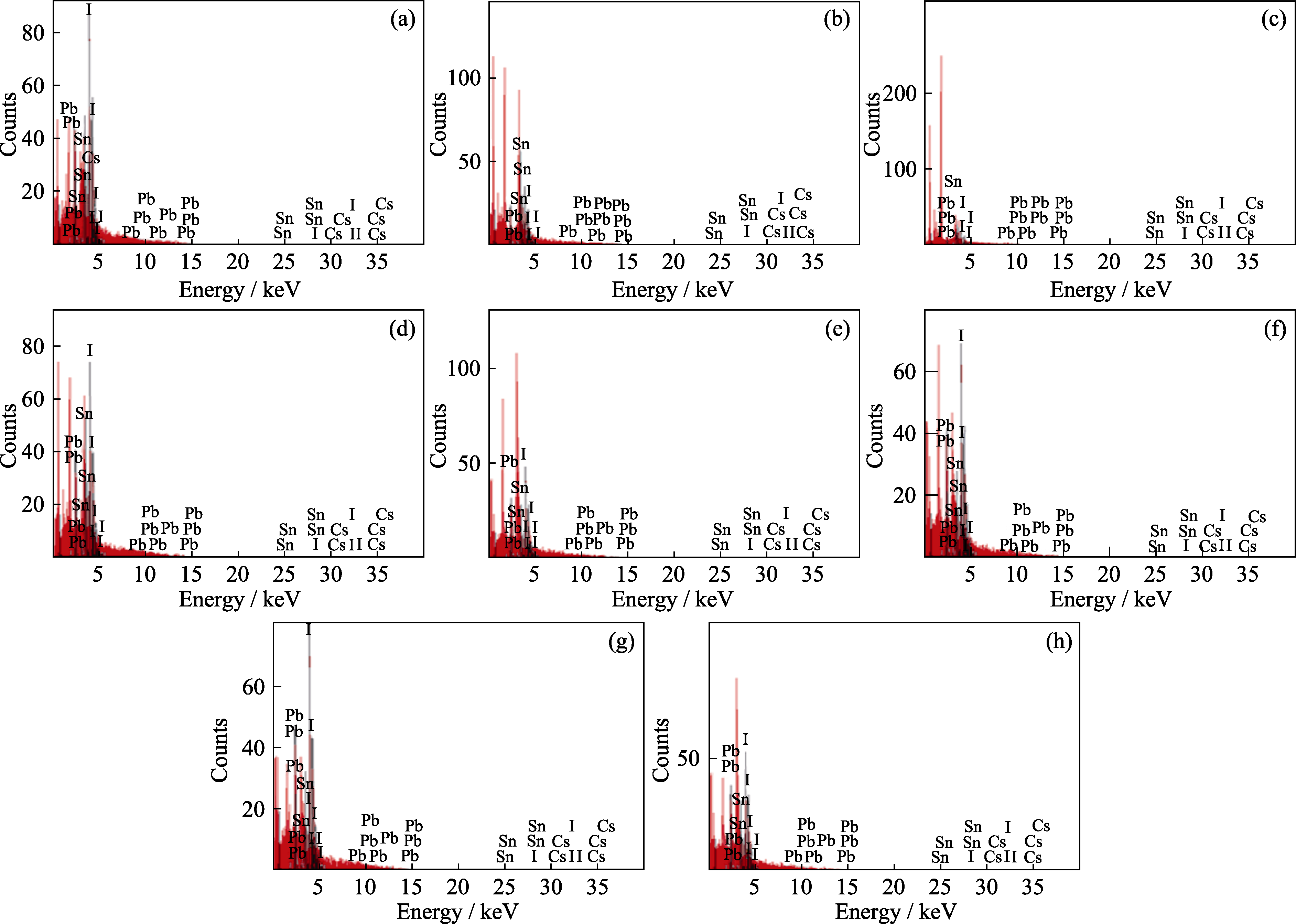

图S2 (a~d) PF-DMSO0.50薄膜中, 区域1~4的EDS能谱图; (e~h) PF-DMSO0.25薄膜中, 区域1~4的EDS能谱图

Fig. S2 (a-d) EDS spectra of regions 1-4 of PF-DMSO0.50 film and (e-h) EDS spectra of regions 1-4 of PF-DMSO0.25 film

图S3 PF-DMSOx (x=0.20,0.25,0.33,0.50,1.00)对应器件的(a)开路电压, (b)填充因子和(c)短路电流密度统计图

Fig. S3 Statistical charts of (a) open-circuit voltage, (b) fill factor and (c) short-circuit current density for devices of PF-DMSOx (x=0.20,0.25,0.33,0.50,1.00)

| [1] |

KOJIMA A, TESHIMA K, SHIRAI Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. Journal of the American Chemical Society, 2009, 131(17): 6050.

DOI PMID |

| [2] |

XIAO J W, LIU L, ZHANG D, et al. The emergence of the mixed perovskites and their applications as solar cells. Advanced Energy Materials, 2017, 7(20): 1700491.

DOI URL |

| [3] |

NING W, GAO F. Structural and functional diversity in lead-free halide perovskite materials. Advanced Materials, 2019, 31(22): 1900326.

DOI URL |

| [4] |

ZHAO J, WEI L, JIA C, et al. Metallic tin substitution of organic lead perovskite films for efficient solar cells. Journal of Materials Chemistry A, 2018, 6(41): 20224.

DOI URL |

| [5] |

MING Y, HU Y, MEI A, et al. Application of lead acetate additive for printable perovskite solar cell. Journal of Inorganic Materials, 2022, 37(2): 197.

DOI |

| [6] | ZANG Z, LI H, JIANG X, et al. Progress and perspective of tin perovskite solar cells. Acta Physico-Chimica Sinica, 2021, 37(4): 2007090. |

| [7] |

ZHAO J J, SU X, MI Z, et al. Trivalent Ni oxidation controlled through regulating lithiumcontent to minimize perovskite interfacial recombination. Rare Metals, 2022, 41(1): 96.

DOI |

| [8] | The National Renewable Energy Laboratory. Best research-cell effi- ciency chart[2022-11-04]. https://www.nrel.gov/pv/cell-efficiency.html. |

| [9] |

SHA W E I, REN X, CHEN L, et al. The efficiency limit of CH3NH3PbI3 perovskite solar cells. Applied Physics Letters, 2015, 106(22): 221104.

DOI URL |

| [10] |

SHOCKLEY W, QUEISSER H J. Detailed balance limit of efficiency of p-n junction solar cells. Journal of Applied Physics, 1961, 32(3): 510.

DOI URL |

| [11] |

EPERON G E, HÖRANTNER M T, SNAITH H J. Metal halide perovskite tandem and multiple-junction photovoltaics. Nature Reviews Chemistry, 2017, 1(12): 0095.

DOI URL |

| [12] |

LIAO W, ZHAO D, YU Y, et al. Fabrication of efficient low- bandgap perovskite solar cells by combining formamidinium tin iodide with methylammonium lead iodide. Journal of the American Chemical Society, 2016, 138(38): 12360.

DOI URL |

| [13] |

HU S, OTSUKA K, MURDEY R, et al. Optimized carrier extraction at interfaces for 23.6% efficient tin-lead perovskite solar cells. Energy and Environmental Science, 2022, 15: 2096.

DOI URL |

| [14] |

LIN R, XU J, WEI M, et al. All-perovskite tandem solar cells with improved grain surface passivation. Nature, 2022, 603(7899): 73.

DOI |

| [15] |

WEI M, XIAO K, WALTERS G, et al. Combining efficiency and stability in mixed tin-lead perovskite solar cells by capping grains with an ultrathin 2D layer. Advanced Materials, 2020, 32(12): 1907058.

DOI URL |

| [16] |

ZHU H L, XIAO J, MAO J, et al. Controllable crystallization of CH3NH3Sn0.25Pb0.75I3 perovskites for hysteresis-free solar cells with efficiency reaching 15.2%. Advanced Functional Materials, 2017, 27(11): 1605469.

DOI URL |

| [17] |

ZHANG T, BAN H, SUN Q, et al. Preventing inhomogeneous elemental distribution and phase segregation in mixed Pb-Sn inorganic perovskites via incorporating PbS quantum dots. Journal of Energy Chemistry, 2022, 65: 179.

DOI URL |

| [18] |

ZHU H L, CHOY W C H. Crystallization, properties, and challenges of low-bandgap Sn-Pb binary perovskites. Solar RRL, 2018, 2(10): 1800146.

DOI URL |

| [19] |

KANG H, YOON W. Microstructural morphology changes of the lead-tin eutectic alloy by different undercooling levels. Materials Transactions, 2004, 45(10): 2956.

DOI URL |

| [20] |

ZHANG Z, LIANG J, ZHENG Y, et al. Balancing crystallization rate in a mixed Sn-Pb perovskite film for efficient and stable perovskite solar cells of more than 20% efficiency. Journal of Materials Chemistry A, 2021, 9(33): 17830.

DOI URL |

| [21] |

LEE S J, SHIN S S, KIM Y C, et al. Fabrication of efficient formamidinium tin iodide perovskite solar cells through SnF2- pyrazine complex. Journal of the American Chemical Society, 2016, 138(12): 3974.

DOI URL |

| [22] |

ZHU Z, CHUEH C C, LI N, et al. Realizing efficient lead-free formamidinium tin triiodide perovskite solar cells via a sequential deposition route. Advanced Materials, 2018, 30(6): 1703800.

DOI URL |

| [23] |

SAVILL K J, ULATOWSKI A M, FARRAR M D, et al. Impact of tin fluoride additive on the properties of mixed tin-lead iodide perovskite semiconductors. Advanced Functional Materials, 2020, 30(52): 2005594.

DOI URL |

| [24] |

SHAO S, DONG J, DUIM H, et al. Enhancing the crystallinity and perfecting the orientation of formamidinium tin iodide for highly efficient Sn-based perovskite solar cells. Nano Energy, 2019, 60: 810.

DOI URL |

| [25] | HU H, ZHOU X, CHEN J, et al. Crystallization regulation and morphological evolution for HTM-free tin-lead (1.28 eV) alloyed perovskite solar cells. Energy and Environmental Materials, 2023, 6(2): e12322. |

| [26] |

CAO D H, STOUMPOS C C, YOKOYAMA T, et al. Thin films and solar cells based on semiconducting two-dimensional ruddlesden-popper (CH3(CH2)3NH3)2(CH3NH3)n-1SnnI3n+1 perovskites. ACS Energy Letters, 2017, 2(5): 982.

DOI URL |

| [27] |

LIAO Y, LIU H, ZHOU W, et al. Highly oriented low-dimensional tin halide perovskites with enhanced stability and photovoltaic performance. Journal of the American Chemical Society, 2017, 139(19): 6693.

DOI PMID |

| [28] |

LIAN X, CHEN J, ZHANG Y, et al. Highly efficient Sn/Pb binary perovskite solar cell via precursor engineering: a two-step fabrication process. Advanced Functional Materials, 2019, 29(5): 1807024.

DOI URL |

| [29] |

XIAO K, LIN R, HAN Q, et al. All-perovskite tandem solar cells with 24.2% certified efficiency and area over 1 cm2 using surface- anchoring zwitterionic antioxidant. Nature Energy, 2020, 5(11): 870.

DOI |

| [30] |

JIANG X, LI H, ZHOU Q, et al. One-step synthesis of SnI2·(DMSO)x adducts for high-performance tin perovskite solar cells. Journal of the American Chemical Society, 2021, 143(29): 10970.

DOI URL |

| [31] |

CAO J, LOI H L, XU Y, et al. High-performance tin-lead mixed- perovskite solar cells with vertical compositional gradient. Advanced Materials, 2022, 34(6): 2107729.

DOI URL |

| [32] |

WU T, LIU X, LUO X, et al. Heterogeneous FASnI3 absorber with enhanced electric field for high-performance lead-free perovskite solar cells. Nano-Micro Letters, 2022, 14(1): 99.

DOI |

| [33] |

CHEN P, BAI Y, WANG S, et al. In situ growth of 2D perovskite capping layer for stable and efficient perovskite solar cells. Advanced Functional Materials, 2018, 28(17): 1706923.

DOI URL |

| [34] |

JIAO B, LIU X, QUAN Z, et al. Performance of perovskite solar cells doped with L-arginine. Journal of Inorganic Materials, 2022, 37(6): 669.

DOI URL |

| [35] |

ZHANG W, HUANG L, ZHENG W, et al. Revealing key factors of efficient narrow-bandgap mixed lead-tin perovskite solar cells via numerical simulations and experiments. Nano Energy, 2022, 96: 107078.

DOI URL |

| [36] |

RAOUI Y, EZ-ZAHRAOUY H, KAZIM S, et al. Energy level engineering of charge selective contact and halide perovskite by modulating band offset: mechanistic insights. Journal of Energy Chemistry, 2021, 54: 822.

DOI |

| [37] | BURGELMAN M, NOLLET P, DEGRAVE S. Modelling polycrystalline semiconductor solar cells. Thin Solid Films, 2000, 361: 527. |

| [38] |

CHANG J, ZHU H, LI B, et al. Boosting the performance of planar heterojunction perovskite solar cell by controlling the precursor purity of perovskite materials. Journal of Materials Chemistry A, 2016, 4(3): 887.

DOI URL |

| [39] |

ZHAO P, LIU Z, LIN Z, et al. Device simulation of inverted CH3NH3PbI3-xClx perovskite solar cells based on PCBM electron transport layer and NiO hole transport layer. Solar Energy, 2018, 169: 11.

DOI URL |

| [40] |

WANG A, GAN X, YU J. Simulation of narrow-bandgap mixed Pb-Sn perovskite solar cells with inverted p-i-n structure. Optical Materials, 2021, 112: 110751.

DOI URL |

| [41] |

PANDEY R, SHARMA S, MADAN J, et al. Numerical simulations of 22% efficient all-perovskite tandem solar cell utilizing lead-free and low lead content halide perovskites. Journal of Micromechanics and Microengineering, 2022, 32(1): 014004.

DOI |

| [42] |

MINEMOTO T, KAWANO Y, NISHIMURA T, et al. Theoretical analysis of band alignment at back junction in Sn-Ge perovskite solar cells with inverted p-i-n structure. Solar Energy Materials and Solar Cells, 2020, 206: 110268.

DOI URL |

| [43] |

GHIMIRE K, ZHAO D, YAN Y, et al. Optical response of mixed methylammonium lead iodide and formamidinium tin iodide perovskite thin films. AIP Advances, 2017, 7(7): 075108.

DOI URL |

| [44] |

GOYAL A, MCKECHNIE S, PASHOV D, et al. Origin of pronounced nonlinear band gap behavior in lead-tin hybrid perovskite alloys. Chemistry of Materials, 2018, 30(11): 3920.

DOI URL |

| [45] |

RAJAGOPAL A, STODDARD R J, HILLHOUSE H W, et al. On understanding bandgap bowing and optoelectronic quality in Pb-Sn alloy hybrid perovskites. Journal of Materials Chemistry A, 2019, 7(27): 16285.

DOI URL |

| [46] |

MOIZ S A, ALAHMADI A N M. Design of dopant and lead-free novel perovskite solar cell for 16.85% efficiency. Polymers, 2021, 13(13): 2110.

DOI URL |

| [1] | 倪晓萌, 许方贤, 刘静静, 张帅, 郭华飞, 袁宁一. 甲脒亚磺酸添加剂提升Sb2(S,Se)3薄膜质量及其光伏性能[J]. 无机材料学报, 2025, 40(4): 372-378. |

| [2] | 肖梓晨, 何世豪, 邱诚远, 邓攀, 张威, 戴维德仁, 缑炎卓, 李金华, 尤俊, 王贤保, 林俍佑. 钙钛矿太阳能电池纳米纤维改性电子传输层研究[J]. 无机材料学报, 2024, 39(7): 828-834. |

| [3] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [4] | 陈甜, 罗媛, 朱刘, 郭学益, 杨英. 有机-无机共添加增强柔性钙钛矿太阳能电池机械弯曲及环境稳定性能[J]. 无机材料学报, 2024, 39(5): 477-484. |

| [5] | 于嫚, 高荣耀, 秦玉军, 艾希成. 上转换发光纳米材料对钙钛矿太阳能电池迟滞效应和离子迁移动力学的影响[J]. 无机材料学报, 2024, 39(4): 359-366. |

| [6] | 费玲, 雷蕾, 汪德高. 二维MXene材料在新型薄膜太阳能电池技术中的研究进展[J]. 无机材料学报, 2024, 39(2): 215-224. |

| [7] | 刘锁兰, 栾福园, 吴子华, 寿春晖, 谢华清, 杨松旺. 原位生长钙钛矿太阳能电池共形氧化锡薄膜[J]. 无机材料学报, 2024, 39(12): 1397-1403. |

| [8] | 王煜, 熊浩, 黄孝坤, 江琳沁, 吴波, 黎健生, 杨爱军. 低剂量异辛酸亚锡调控两步法制备Sn-Pb混合钙钛矿太阳能电池[J]. 无机材料学报, 2024, 39(12): 1339-1347. |

| [9] | 周泽铸, 梁子辉, 李静, 吴聪聪. 基于挥发性溶剂制备MAPbI3钙钛矿太阳能电池/模组[J]. 无机材料学报, 2024, 39(11): 1197-1204. |

| [10] | 厉佥元, 李纪伟, 张钰涵, 刘焱康, 孟阳, 储余, 朱一佳, 徐诺言, 朱亮, 张传香, 陶海军. PbTiO3修饰和极化处理提升钙钛矿太阳能电池性能[J]. 无机材料学报, 2024, 39(11): 1205-1211. |

| [11] | 韩旭, 姚恒大, 吕梅, 陆红波, 朱俊. 单分子液晶添加剂在甲脒铅碘钙钛矿太阳能电池中的应用[J]. 无机材料学报, 2023, 38(9): 1097-1102. |

| [12] | 方万丽, 沈黎丽, 李海艳, 陈薪羽, 陈宗琦, 寿春晖, 赵斌, 杨松旺. NiOx介孔层的成膜过程对碳电极钙钛矿太阳能电池性能的影响[J]. 无机材料学报, 2023, 38(9): 1103-1109. |

| [13] | 丁统顺, 丰平, 孙学文, 单沪生, 李琪, 宋健. Fmoc-FF-OH钝化钙钛矿薄膜及其太阳能电池性能研究[J]. 无机材料学报, 2023, 38(9): 1076-1082. |

| [14] | 张伦, 吕梅, 朱俊. Cs2AgBiBr6钙钛矿太阳能电池研究进展[J]. 无机材料学报, 2023, 38(9): 1044-1054. |

| [15] | 陈雨, 林埔安, 蔡冰, 张文华. 钙钛矿太阳能电池无机空穴传输材料的研究进展[J]. 无机材料学报, 2023, 38(9): 991-1004. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||