无机材料学报 ›› 2023, Vol. 38 ›› Issue (9): 1103-1109.DOI: 10.15541/jim20230002 CSTR: 32189.14.10.15541/jim20230002

所属专题: 【能源环境】钙钛矿(202506); 【能源环境】太阳能电池(202506)

方万丽1,2( ), 沈黎丽2, 李海艳2, 陈薪羽2, 陈宗琦2, 寿春晖3, 赵斌1(

), 沈黎丽2, 李海艳2, 陈薪羽2, 陈宗琦2, 寿春晖3, 赵斌1( ), 杨松旺1,2,4(

), 杨松旺1,2,4( )

)

收稿日期:2023-01-01

修回日期:2023-04-11

出版日期:2023-09-20

网络出版日期:2023-05-04

通讯作者:

赵 斌, 教授. E-mail: zhaobin@usst.edu.cn;作者简介:方万丽(1997-), 女, 硕士研究生. E-mail: fangwl08@163.com

FANG Wanli1,2( ), SHEN Lili2, LI Haiyan2, CHEN Xinyu2, CHEN Zongqi2, SHOU Chunhui3, ZHAO Bin1(

), SHEN Lili2, LI Haiyan2, CHEN Xinyu2, CHEN Zongqi2, SHOU Chunhui3, ZHAO Bin1( ), YANG Songwang1,2,4(

), YANG Songwang1,2,4( )

)

Received:2023-01-01

Revised:2023-04-11

Published:2023-09-20

Online:2023-05-04

Contact:

ZHAO Bin, professor. E-mail: zhaobin@usst.edu.cn;About author:FANG Wanli (1997-), female, Master candidate. E-mail: fangwl08@163.com

Supported by:摘要:

碳基钙钛矿太阳能电池(C-PSCs)具有稳定性好且成本低的优势, 展现出广阔的应用前景。本研究基于MAPbI3材料, 选择高质量的NiOx介孔层作为空穴传输层(HTL), 对比了NiOx介孔层不同制备方法对电池性能的影响, 并对NiOx介孔层的厚度进行优化。研究发现, 与旋涂工艺制备的NiOx介孔层相比, 丝网印刷工艺制备的介孔层的孔径分布均匀, 可改善钙钛矿(PVK)前体溶液填充在介孔支架中的填充状态。最终得到含HTL的高效率和低滞后的钙钛矿太阳能电池, 其开路电压(VOC)为910 mV, 光电转换效率(PCE)为14.63%, 认证效率达14.88%。此外, 在空气中储存近900 h, 其PCE没有明显衰减。

中图分类号:

方万丽, 沈黎丽, 李海艳, 陈薪羽, 陈宗琦, 寿春晖, 赵斌, 杨松旺. NiOx介孔层的成膜过程对碳电极钙钛矿太阳能电池性能的影响[J]. 无机材料学报, 2023, 38(9): 1103-1109.

FANG Wanli, SHEN Lili, LI Haiyan, CHEN Xinyu, CHEN Zongqi, SHOU Chunhui, ZHAO Bin, YANG Songwang. Effect of Film Formation Processes of NiOx Mesoporous Layer on Performance of Perovskite Solar Cells with Carbon Electrodes[J]. Journal of Inorganic Materials, 2023, 38(9): 1103-1109.

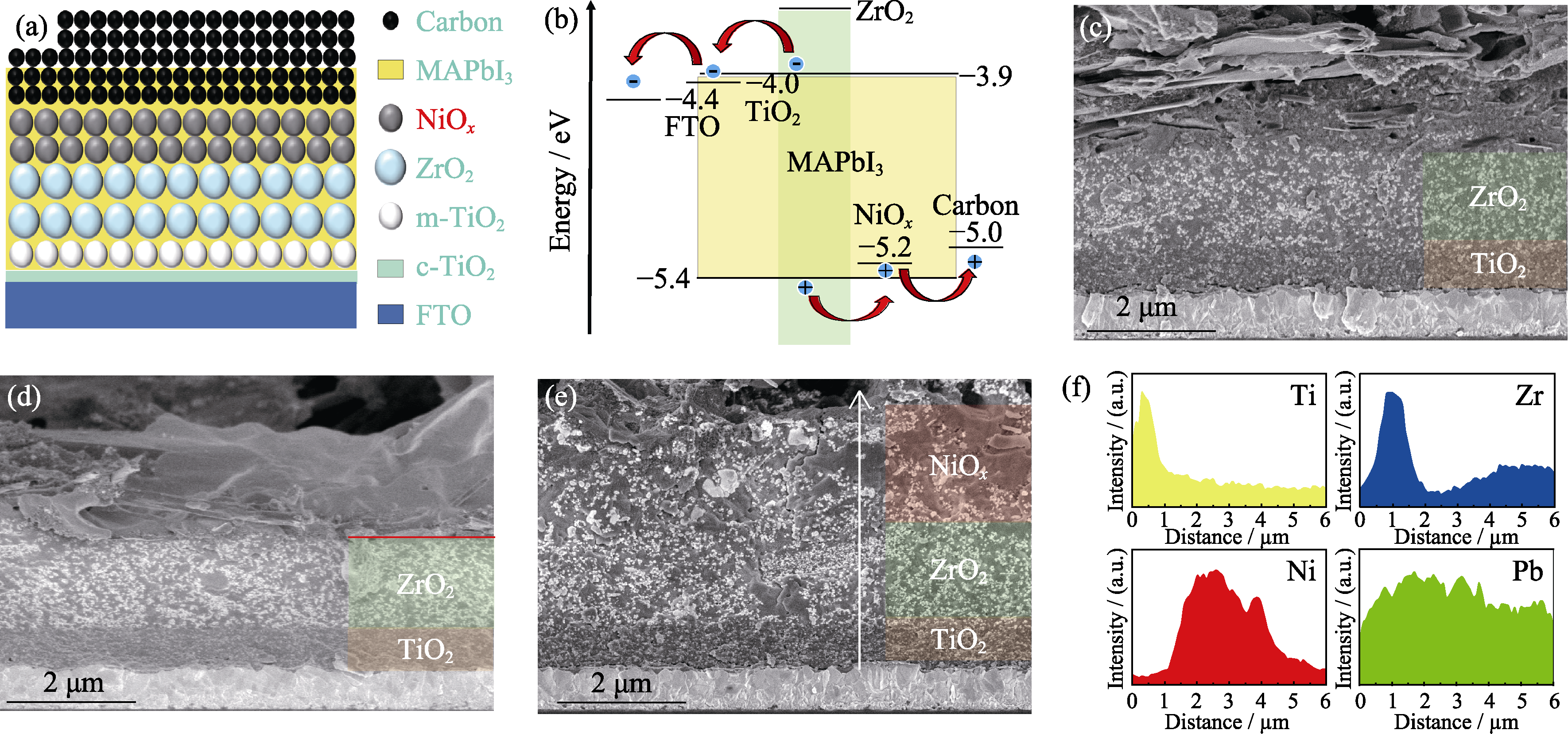

Fig. 1 (a) Schematic illustration and (b) work function of the device, cross-sectional SEM images of C-PSCs: (c) device A, (d) device B and (e) device C, and (f) element distribution in the direction of the white arrow in (e)

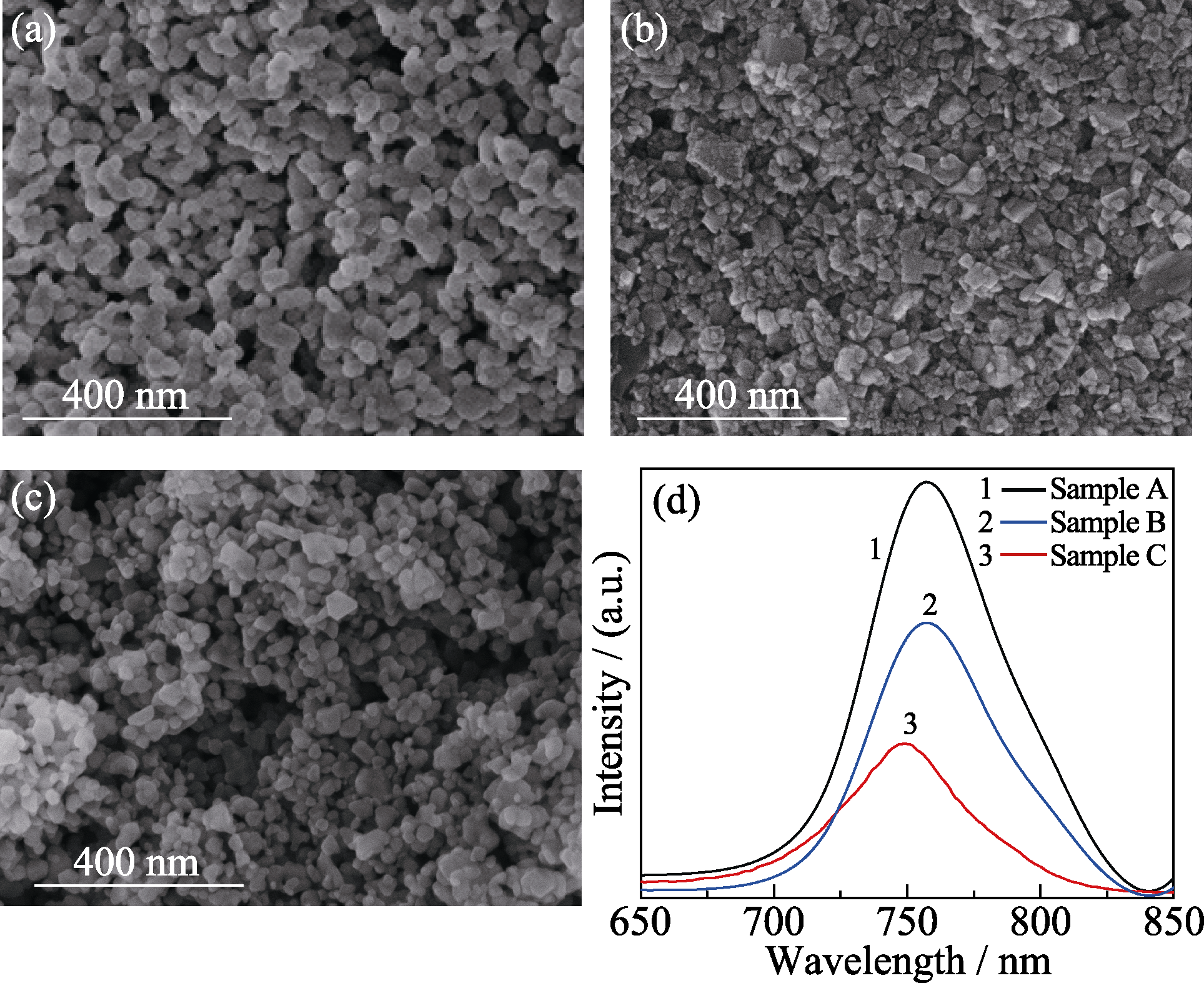

Fig. 3 SEM images of (a) ZrO2 mesoporous film, (b) spin- coated and (c) screen-printed NiOx films, and (d) PL spectra for sample A (ZrO2/MAPbI3), sample B (ZrO2/NiOx (spin-coated)/ MAPbI3), and sample C (ZrO2/NiOx(screen-printed)/MAPbI3)

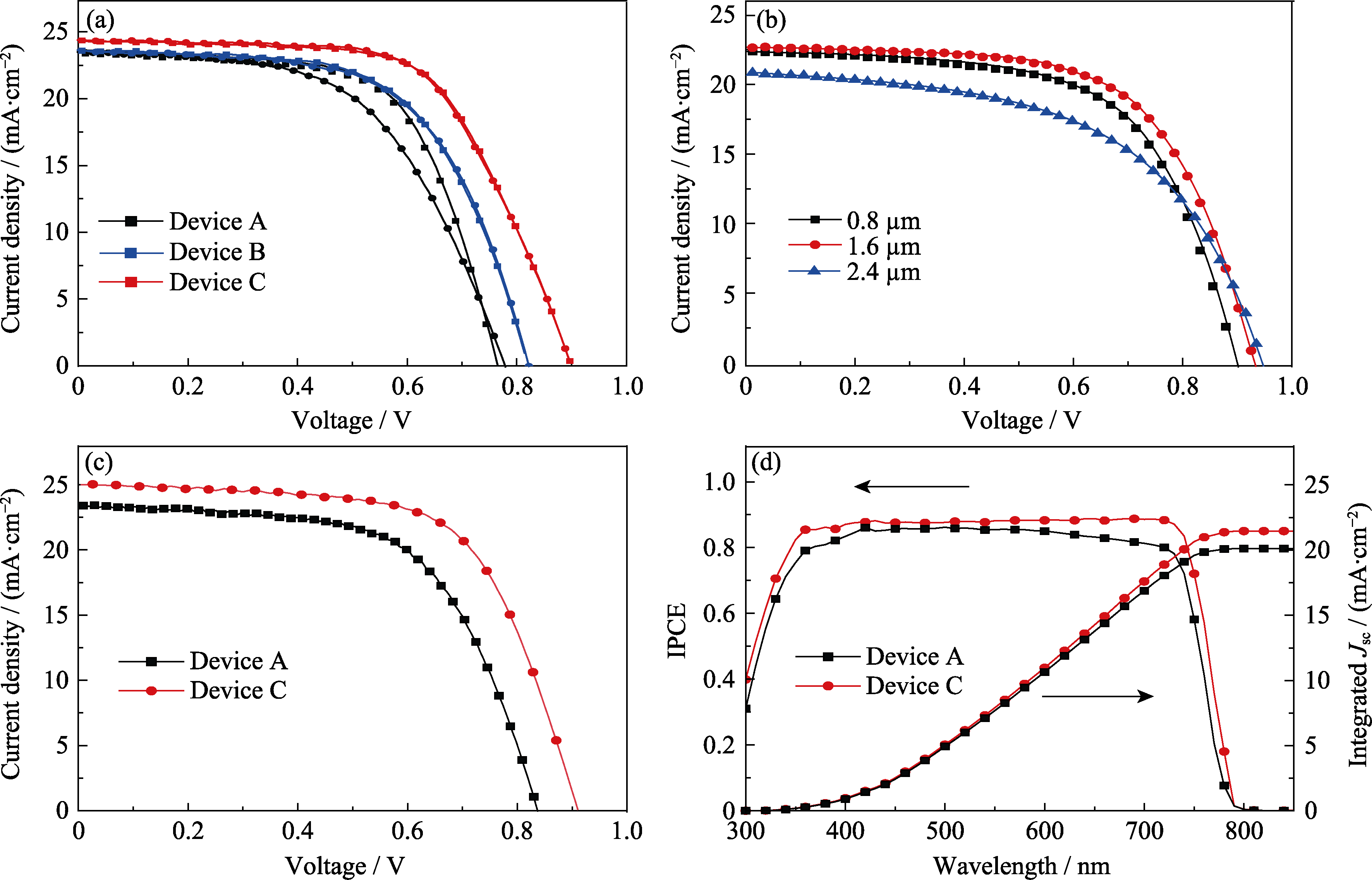

Fig. 5 (a-c) J-V curves and (d) incident photon-to-electron conversion efficiency (IPCE) spectra and the integrated current density curves of different devices (a) Forward and reverse scans of device A, B and C; (b) Different thicknesses of NiOx layer; (c) The optimum cells of device A and device C; Colorful figures are available on website

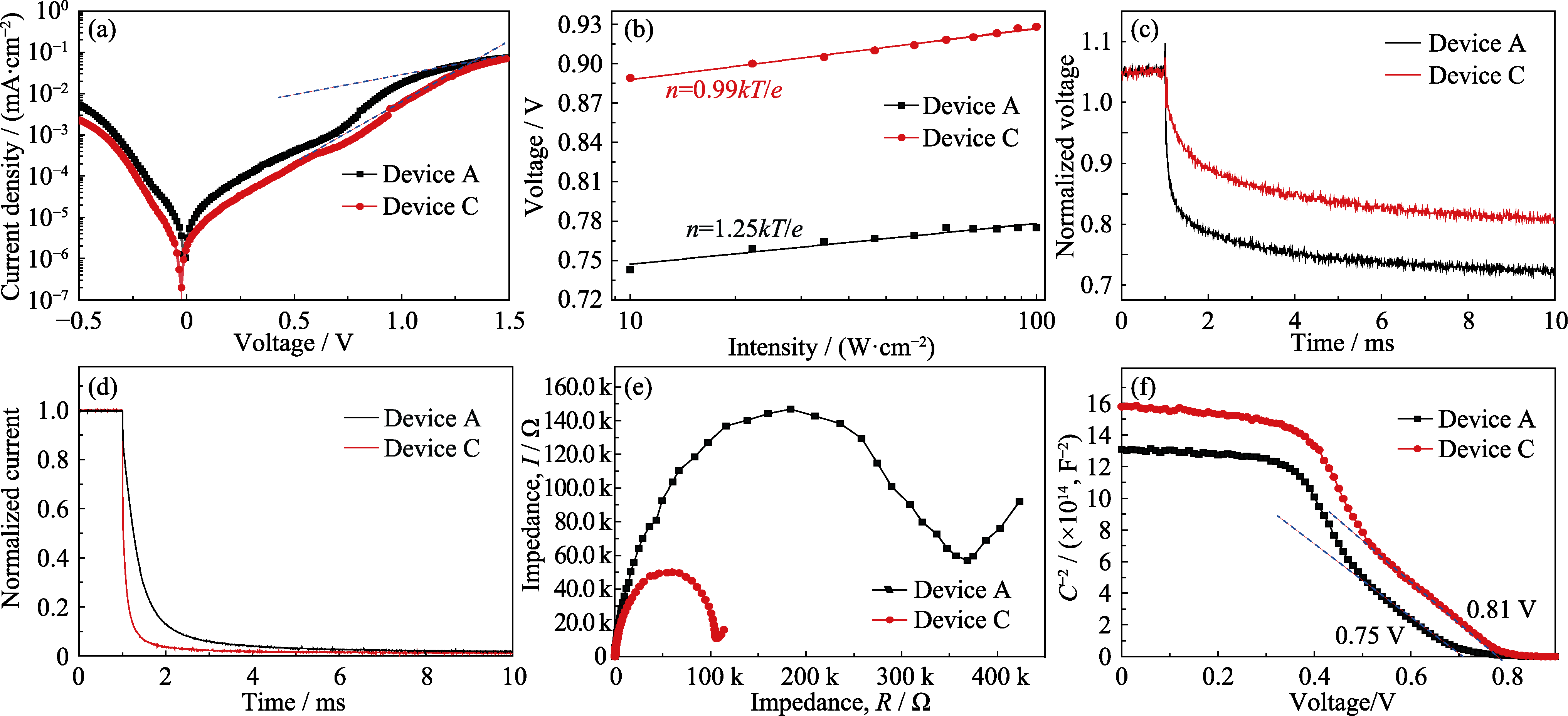

Fig. 6 (a) J-V curves under dark conditions, (b) light-intensity dependence of VOC (solid line: linear fitting), (c) transient photovoltage (TPV) decay curves, (d) transient photocurrent (TPC) decay curves, (e) Nyquist plots measured in the dark, and (f) Mott-Schottky plots for device A and device C; Colorful figures are available on website

| Sample | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | ||||

|---|---|---|---|---|---|---|---|---|

| Reverse | Forward | Reverse | Forward | Reverse | Forward | Reverse | Forward | |

| Device A | 0.779 | 0.764 | 23.45 | 23.38 | 63.60 | 55.47 | 11.62 | 9.91 |

| Device B | 0.822 | 0.820 | 23.62 | 23.56 | 60.66 | 60.26 | 11.78 | 11.64 |

| Device C | 0.904 | 0.903 | 23.57 | 23.56 | 63.29 | 62.98 | 13.49 | 13.40 |

Table S1 Photovoltaic parameters for different devices with an aperture area of 0.07 cm2 under 1 sun (100 mW·cm-2) illumination

| Sample | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | ||||

|---|---|---|---|---|---|---|---|---|

| Reverse | Forward | Reverse | Forward | Reverse | Forward | Reverse | Forward | |

| Device A | 0.779 | 0.764 | 23.45 | 23.38 | 63.60 | 55.47 | 11.62 | 9.91 |

| Device B | 0.822 | 0.820 | 23.62 | 23.56 | 60.66 | 60.26 | 11.78 | 11.64 |

| Device C | 0.904 | 0.903 | 23.57 | 23.56 | 63.29 | 62.98 | 13.49 | 13.40 |

| Sample | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% |

|---|---|---|---|---|

| NiOx (0.8 μm) | 0.898 | 22.36 | 61.66 | 12.38 |

| NiOx (1.6 μm) | 0.932 | 22.68 | 62.87 | 13.28 |

| NiOx (2.4 μm) | 0.939 | 20.86 | 54.43 | 10.66 |

Table S2 Photovoltaic parameters of devices with different thicknesses of screen-printed NiOx layer

| Sample | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% |

|---|---|---|---|---|

| NiOx (0.8 μm) | 0.898 | 22.36 | 61.66 | 12.38 |

| NiOx (1.6 μm) | 0.932 | 22.68 | 62.87 | 13.28 |

| NiOx (2.4 μm) | 0.939 | 20.86 | 54.43 | 10.66 |

| Device | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% |

|---|---|---|---|---|

| Device A | 0.840 | 23.39 | 61.00 | 11.95 |

| Device C | 0.910 | 25.04 | 64.13 | 14.63 |

Table S3 Photovoltaic parameters of device A and C

| Device | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% |

|---|---|---|---|---|

| Device A | 0.840 | 23.39 | 61.00 | 11.95 |

| Device C | 0.910 | 25.04 | 64.13 | 14.63 |

| [1] |

KIM M, JEONG J, LU H, et al. Conformal quantum dot-SnO2 layers as electron transporters for efficient perovskite solar cells. Science, 2022, 375(6578): 302.

DOI URL |

| [2] |

SAMANTARAY M R, RANA N K, KUMAR A, et al. Stability study of large-area perovskite solar cells fabricated with copper as low-cost metal contact. J. Energy Res., 2022, 46(2): 1250.

DOI URL |

| [3] |

YUE M, YUE H, ANYI M, et al. Application of lead acetate additive for printable perovskite solar cell. J. Inorg. Mater., 2022, 37(2): 197.

DOI |

| [4] |

LAURA M G, DANIEL R, FRANKLIN J. Current status and trends of carbon-based electrodes for fully solution-processed perovskite solar cells. J. Energy Chem., 2021, 68: 222.

DOI URL |

| [5] |

LIU S, HUANG W, LIAO P, et al. 17% efficient printable mesoscopic PIN metal oxide framework perovskite solar cells using cesium-containing triple cation perovskite. J. Mater. Chem. A, 2017, 5(44): 22952.

DOI URL |

| [6] |

JAYAN K D, SEBASTIAN V. Comprehensive device modelling and performance analysis of MASnI3 based perovskite solar cells with diverse ETM, HTM and back metal contacts. Sol. Energy, 2021, 217: 40.

DOI URL |

| [7] |

WANG J, ZHENG Z, ZU Y, et al. A tandem organic photovoltaic cell with 19.6% efficiency enabled by light distribution control. Adv. Mater., 2021, 33(39): 2102787.

DOI URL |

| [8] |

WANG H, HUANG Z, XIAO S, et al. An in situ bifacial passivation strategy for flexible perovskite solar module with mechanical robustness by roll-to-roll fabrication. J. Mater. Chem. A, 2021, 9(9): 5759.

DOI URL |

| [9] |

XU X, LIU Z, ZUO Z, et al. Hole selective NiO contact for efficient perovskite solar cells with carbon electrode. Nano Lett., 2015, 15(4): 2402.

DOI PMID |

| [10] |

CAO K, ZUO Z, CUI J, et al. Efficient screen printed perovskite solar cells based on mesoscopic TiO2/Al2O3/NiO/carbon architecture. Nano Energy, 2015, 17: 171.

DOI URL |

| [11] |

LIU X, REN S, LI Z, et al. Flexible transparent high-efficiency photoelectric perovskite resistive switching memory. Adv. Funct. Mater., 2022, 32(38): 2202951.

DOI URL |

| [12] |

TAO L, ZHANG Y, CHEN H, et al. Printable commercial carbon based mesoscopic perovskite solar cell using NiO/graphene as hole-transport materials. ECS J. Solid State Sci. Technol., 2021, 10(10): 105003.

DOI |

| [13] |

BHANDARI S, ROY A, ALI M S, et al. Cotton soot derived carbon nanoparticles for NiO supported processing temperature tuned ambient perovskite solar cells. Sci. Rep., 2021, 11: 23388.

DOI PMID |

| [14] |

JIANG F, CHOY W C H, LI X, et al. Post-treatment-free solution-processed non-stoichiometric NiOx nanoparticles for efficient hole-transport layers of organic optoelectronic devices. Adv. Mater., 2015, 27(18): 2930.

DOI URL |

| [15] |

LEE J H, JIN I S, JUNG J W. Binary-mixed organic electron transport layers for planar heterojunction perovskite solar cells with high efficiency and thermal reliability. Chem. Eng. J., 2021, 420: 129678.

DOI URL |

| [16] |

HOU X M, HU Y, LIU H W, et al. Effect of guanidinium on mesoscopic perovskite solar cells. J. Mater. Chem. A, 2017, 5(1): 73.

DOI URL |

| [17] |

ZHAO J J, SU X, MI Z, et al. Trivalent Ni oxidation controlled through regulating lithium content to minimize perovskite interfacial recombination. Rare Metals, 2022, 41(1): 96.

DOI |

| [18] | LIU Z, SUN B, LIU X, et al. Efficient carbon-based CsPbBr3 inorganic perovskite solar cells by using Cu-phthalocyanine as hole transport material. Nano-Micro Lett., 2018, 10(2): 34. |

| [19] |

TSUJI R, BOGACHUK D, LUO B, et al. Activation of weak monochromic photocurrents by white light irradiation for accurate IPCE measurements of carbon-based multi-porous-layered-electrode perovskite solar cells. Electrochemistry, 2020, 88(5): 418.

DOI URL |

| [20] |

LIU X, CHENG Y, LIU C, et al. 20.7% highly reproducible inverted planar perovskite solar cells with enhanced fill factor and eliminated hysteresis. Energy Environ. Sci., 2019, 12(5): 1622.

DOI URL |

| [21] |

LIAO P, ZHAO X, LI G, et al. A new method for fitting current-voltage curves of planar heterojunction perovskite solar cells. Nano-Micro Lett., 2018, 10: 5.

DOI PMID |

| [22] |

KE W, FANG G, WAN J, et al. Efficient hole-blocking layer-free planar halide perovskite thin-film solar cells. Nat. Commun., 2015, 6: 6700.

DOI PMID |

| [23] |

WANG Y, MAHMOUDI T, HAHN Y B. Highly stable and efficient perovskite solar cells based on FAMA-perovskite-Cu:NiO composites with 20.7% efficiency and 80.5% fill factor. Adv. Energy Mater., 2020, 10(27): 2000967.

DOI URL |

| [24] |

LEGUY A M A, FROST J M, MCMAHON A P, et al. The dynamics of methylammonium ions in hybrid organic-inorganic perovskite solar cells. Nat. Commun., 2015, 6: 7124.

DOI PMID |

| [25] |

CAI C, ZHOU K, GUO H, et al. Enhanced hole extraction by NiO nanoparticles in carbon-based perovskite solar cells. Electrochim. Acta, 2019, 312: 100.

DOI URL |

| [26] |

LIU S, LI S, WU J, et al. Amide additives induced a Fermi level shift to improve the performance of hole-conductor-free, printable mesoscopic perovskite solar cells. J. Phy. Chem. Lett., 2019, 10(21): 6865.

DOI URL |

| [27] |

LI X, ZHANG W, GUO X, et al. Constructing heterojunctions by surface sulfidation for efficient inverted perovskite solar cells. Science, 2022, 375(6579): 434.

DOI PMID |

| [28] |

ZHOU Y, ZHANG X, LU X, et al. Promoting the hole extraction with Co3O4 nanomaterials for efficient carbon-based CsPbI2Br perovskite solar cells. Solar RRL, 2019, 3(4): 1800315.

DOI URL |

| [29] |

CHEN X, LU L, GU D, et al. Chlorine management of a carbon counter electrode for high performance printable perovskite solar cells. J. Mater. Chem. C, 2021, 9(27): 8615.

DOI URL |

| [1] | 江宗玉, 黄红花, 清江, 王红宁, 姚超, 陈若愚. 铝离子掺杂MIL-101(Cr)的制备及其VOCs吸附性能研究[J]. 无机材料学报, 2025, 40(7): 747-753. |

| [2] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [3] | 瞿牡静, 张淑兰, 朱梦梦, 丁浩杰, 段嘉欣, 代恒龙, 周国红, 李会利. CsPbBr3@MIL-53纳米复合荧光粉的合成、性能及其白光LEDs应用[J]. 无机材料学报, 2024, 39(9): 1035-1043. |

| [4] | 潘建隆, 马官军, 宋乐美, 郇宇, 魏涛. 燃料还原法原位制备高稳定性/催化活性SOFC钴基钙钛矿阳极[J]. 无机材料学报, 2024, 39(8): 911-919. |

| [5] | 苗鑫, 闫世强, 韦金豆, 吴超, 樊文浩, 陈少平. Te基热电器件反常界面层生长行为及界面稳定性研究[J]. 无机材料学报, 2024, 39(8): 903-910. |

| [6] | 陈甜, 罗媛, 朱刘, 郭学益, 杨英. 有机-无机共添加增强柔性钙钛矿太阳能电池机械弯曲及环境稳定性能[J]. 无机材料学报, 2024, 39(5): 477-484. |

| [7] | 杨博, 吕功煊, 马建泰. 镍铁氢氧化物-磷化钴复合电极电催化分解水研究[J]. 无机材料学报, 2024, 39(4): 374-382. |

| [8] | 张宇晨, 陆知遥, 赫晓东, 宋广平, 朱春城, 郑永挺, 柏跃磊. 硫族MAX相硼化物的物相稳定性和性能预测[J]. 无机材料学报, 2024, 39(2): 225-232. |

| [9] | 王煜, 熊浩, 黄孝坤, 江琳沁, 吴波, 黎健生, 杨爱军. 低剂量异辛酸亚锡调控两步法制备Sn-Pb混合钙钛矿太阳能电池[J]. 无机材料学报, 2024, 39(12): 1339-1347. |

| [10] | 周云凯, 刁亚琪, 王明磊, 张宴会, 王利民. 聚苯胺改性Ti3C2(OH)2抗氧化性的第一性原理计算研究[J]. 无机材料学报, 2024, 39(10): 1151-1158. |

| [11] | 陈雨, 林埔安, 蔡冰, 张文华. 钙钛矿太阳能电池无机空穴传输材料的研究进展[J]. 无机材料学报, 2023, 38(9): 991-1004. |

| [12] | 胡忠良, 傅赟天, 蒋蒙, 王连军, 江莞. Nb/Mg3SbBi界面层热稳定性研究[J]. 无机材料学报, 2023, 38(8): 931-937. |

| [13] | 刘建, 王凌坤, 许保亮, 赵倩, 王耀萱, 丁艺, 张胜泰, 段涛. 熔盐法低温合成掺钕ZrSiO4陶瓷的物相演变和化学稳定性[J]. 无机材料学报, 2023, 38(8): 910-916. |

| [14] | 肖娅妮, 吕嘉南, 李振明, 刘铭扬, 刘伟, 任志刚, 刘弘景, 杨东旺, 鄢永高. Bi2Te3基热电材料的湿热稳定性研究[J]. 无机材料学报, 2023, 38(7): 800-806. |

| [15] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||