无机材料学报 ›› 2025, Vol. 40 ›› Issue (4): 372-378.DOI: 10.15541/jim20240319 CSTR: 32189.14.10.15541/jim20240319

所属专题: 【能源环境】太阳能电池(202506)

倪晓萌1( ), 许方贤1, 刘静静1, 张帅1,3(

), 许方贤1, 刘静静1, 张帅1,3( ), 郭华飞2,3(

), 郭华飞2,3( ), 袁宁一1,3

), 袁宁一1,3

收稿日期:2024-07-05

修回日期:2024-10-23

出版日期:2025-04-20

网络出版日期:2024-11-15

通讯作者:

张 帅, 副教授. E-mail: shuaizhang@cczu.edu.cn;作者简介:倪晓萌(1999-), 女, 硕士研究生. E-mail: 1102604931@qq.com

基金资助:

NI Xiaomeng1( ), XU Fangxian1, LIU Jingjing1, ZHANG Shuai1,3(

), XU Fangxian1, LIU Jingjing1, ZHANG Shuai1,3( ), GUO Huafei2,3(

), GUO Huafei2,3( ), YUAN Ningyi1,3

), YUAN Ningyi1,3

Received:2024-07-05

Revised:2024-10-23

Published:2025-04-20

Online:2024-11-15

Contact:

ZHANG Shuai, associate professor. E-mail: shuaizhang@cczu.edu.cn;About author:NI Xiaomeng (1999-), female, Master candidate. E-mail: 1102604931@qq.com

Supported by:摘要:

硒硫化锑(Sb2(S,Se)3)具有优异的光电特性, 是一种很有前景的光伏材料。然而, 目前Sb2(S,Se)3太阳能电池的最高光电转换效率(PCE)仍与理论极限有较大差距, 这部分归因于Sb2(S,Se)3薄膜中存在严重的载流子复合。本研究采用水热沉积法制备Sb2(S,Se)3薄膜, 在前驱体溶液中引入过程性添加剂甲脒亚磺酸(FSA), 不仅优化了Sb2(S,Se)3薄膜的(211)、(221)晶面取向和Se/S原子比例, 还控制了薄膜中载流子复合中心Sb2O3的含量。添加了FSA的太阳能电池的暗饱和电流密度(J0)和复合阻抗(Rrec)分别为1.10×10−5 mA·cm−2和3147 Ω·cm−2, 明显优于参照器件(J0=5.17×10−5 mA·cm−2, Rrec=974.3 Ω·cm−2), 表明FSA显著抑制了Sb2(S,Se)3太阳能电池的载流子复合。在AM 1.5G太阳光模拟器照射下, 添加了FSA的太阳能电池的开路电压(VOC)、短路电流密度(JSC)、填充因子(FF)和PCE的平均值分别为0.69 V、18.46 mA·cm−2、63.60%和8.04%, 较参照器件(0.67 V、17.82 mA·cm−2、62.27%和7.70%)均明显提升, 最优未封装器件PCE达8.21%, 在空气中老化120 d仍保持初始PCE的82.1%。

中图分类号:

倪晓萌, 许方贤, 刘静静, 张帅, 郭华飞, 袁宁一. 甲脒亚磺酸添加剂提升Sb2(S,Se)3薄膜质量及其光伏性能[J]. 无机材料学报, 2025, 40(4): 372-378.

NI Xiaomeng, XU Fangxian, LIU Jingjing, ZHANG Shuai, GUO Huafei, YUAN Ningyi. Photovoltaic Performance of Sb2(S,Se)3 Film Enhanced by Addition of Formamidinesulfinic Acid[J]. Journal of Inorganic Materials, 2025, 40(4): 372-378.

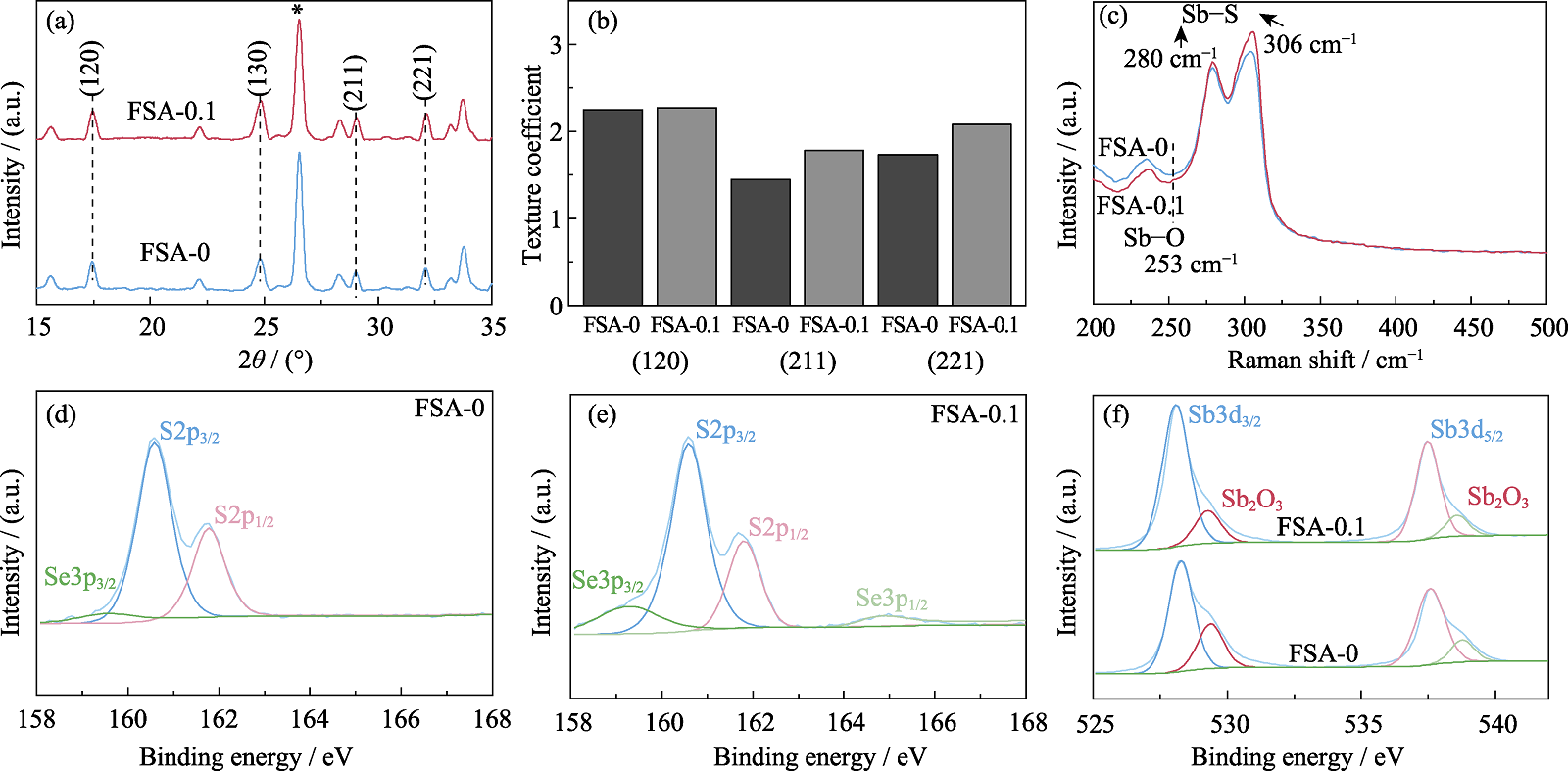

图1 Sb2(S,Se)3薄膜的晶体结构和化学状态表征

Fig. 1 Crystal structure and chemical states of Sb2(S,Se)3 films (a) XRD spectra; (b) Texture coefficients; (c) Raman spectra; (d-f) XPS spectra. Colorful figures are available on website

图3 Sb2(S,Se)3薄膜的能级表征

Fig. 3 Energy-level characterizations of Sb2(S,Se)3 films (a) UPS spectra; (b) Schematic diagram of energy levels. Colorful figures are available on website

图4 FSA-0与FSA-0.1太阳能电池的光伏性能

Fig. 4 Photovoltaic properties of FSA-0 and FSA-0.1 solar cells (a-d) Statistical distributions of photovoltaic parameters; (e) Schematic diagram of the device structure; (f) Normalized PCE. Colorful figures are available on website

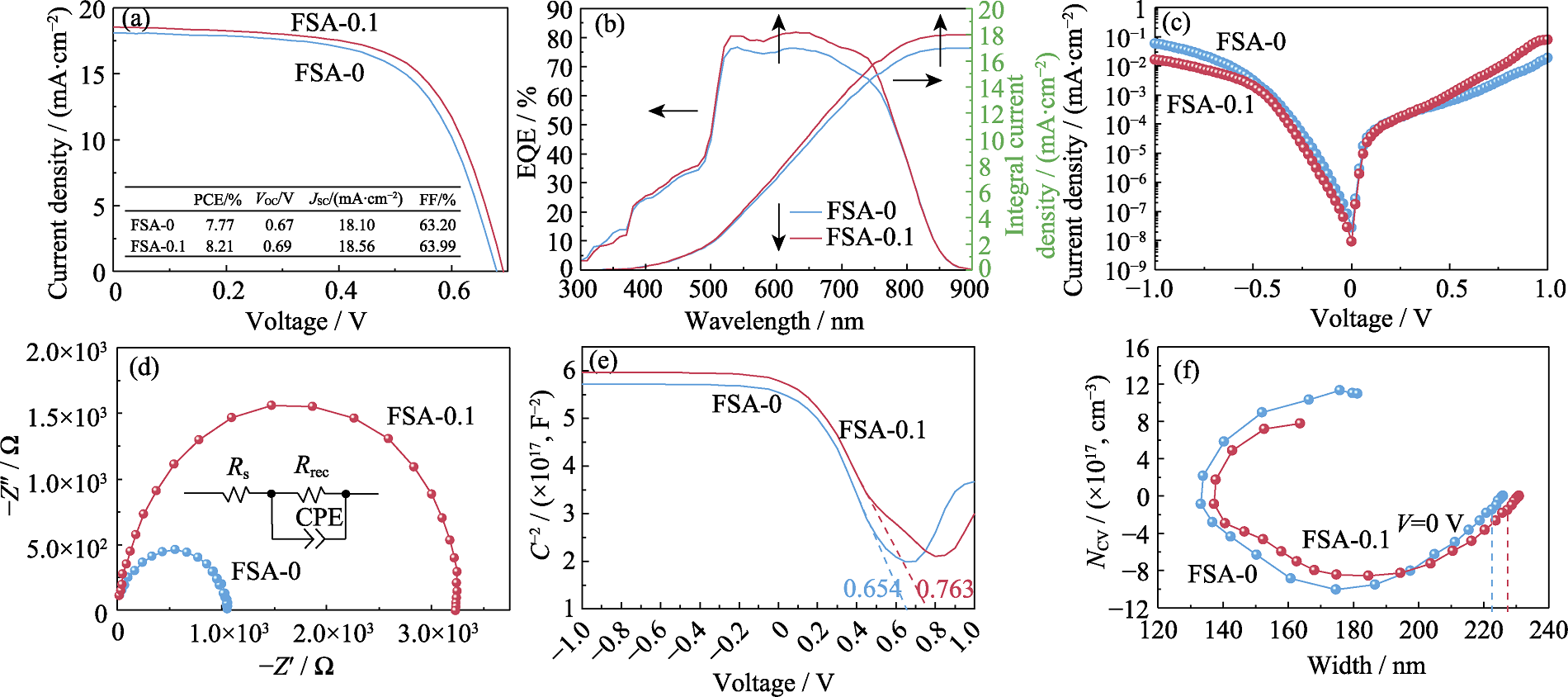

图5 FSA-0和FSA-0.1最优器件的光电性能和缺陷分析

Fig. 5 Photovoltaic properties and defect analysis for the best devices of FSA-0 and FSA-0.1 (a) J-V curves; (b) EQE spectra; (c) Dark J-V curves; (d) EIS plots; (e) C-V curves; (f) NCV curves

| Sample | Rs | Rrec | CPE |

|---|---|---|---|

| FSA-0 | 50.77 | 974.3 | 1.08×10−8 |

| FSA-0.1 | 49.08 | 3147 | 1.44×10−9 |

表1 Sb2(S,Se)3太阳能电池的EIS谱图拟合数据(Ω·cm−2)

Table 1 Fitting data of EIS plots for Sb2(S,Se)3 solar cells (Ω·cm−2)

| Sample | Rs | Rrec | CPE |

|---|---|---|---|

| FSA-0 | 50.77 | 974.3 | 1.08×10−8 |

| FSA-0.1 | 49.08 | 3147 | 1.44×10−9 |

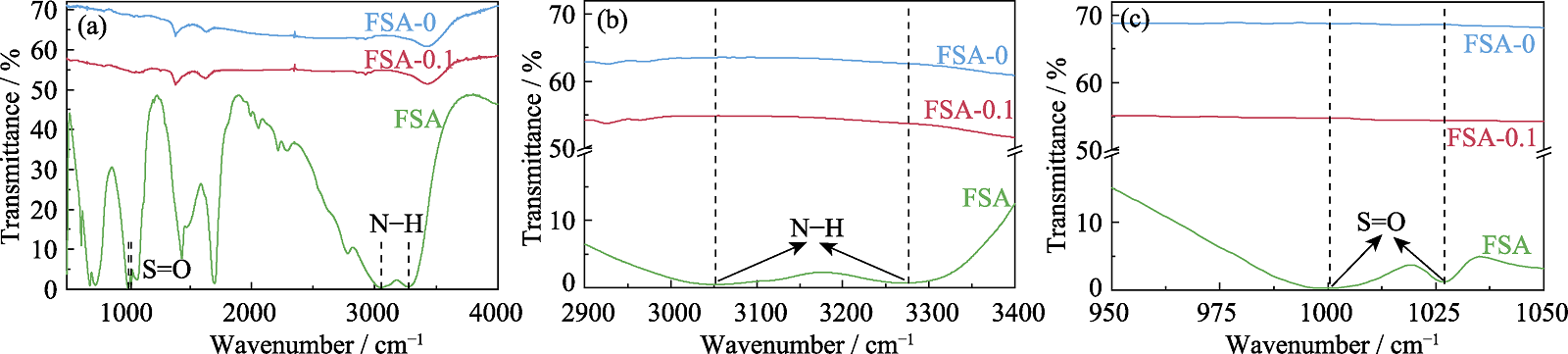

图S1 Sb2(S,Se)3薄膜(FSA-0与FSA-0.1样品)和FSA粉末的傅里叶变换红外光谱图

Fig. S1 Fourier transform infrared spectra of Sb2(S,Se)3 thin films (FSA-0 and FSA-0.1) and FSA powder Partial enlargements of (b) N-H and (c) S=O characteristic peaks

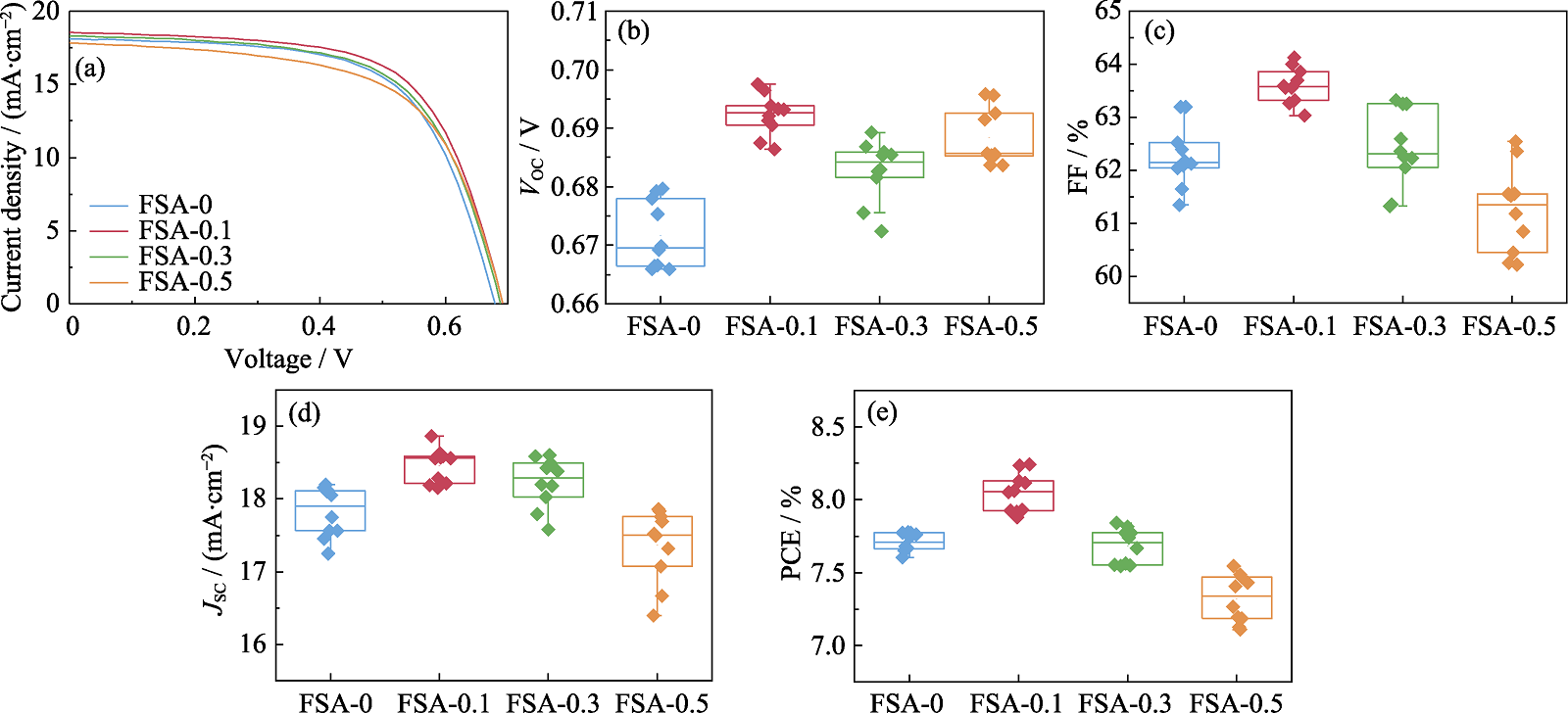

图S5 不同浓度FSA添加剂所制备器件的光电性能

Fig. S5 Photovoltaic properties of devices prepared with different concentrations of FSA (a) J-V curves; (b-e) Photovoltaic parameter statistical distribution

| [1] | TANG R, WANG X, LIAN W, et al. Hydrothermal deposition of antimony selenosulfide thin films enables solar cells with 10% efficiency. Nature Energy, 2020, 5(8):587. |

| [2] | PAN Y, HU X, GUO Y, et al. Vapor transport deposition of highly efficient Sb2(S,Se)3 solar cells via controllable orientation growth. Advanced Functional Materials, 2021, 31(28):2101476. |

| [3] | GAO J, CHE B, CAI H, et al. Single-source thermal evaporation converts anion controllable Sb2(S,Se)3 film for fabricating high- efficiency solar cell. Science China Materials, 2023, 66(9):3415. |

| [4] | CALIXTO-RODRIGUEZ M, GACIA H M, NAIR M T S, et al. Antimony chalcogenide/lead selenide thin film solar cell with 2.5% conversion efficiency prepared by chemical deposition. ECS Journal of Solid State Science and Technology, 2013, 2(4):Q69. |

| [5] | ZHANG L, ZHENG J, LIU C, et al. Over 10% efficient Sb2(S,Se)3 solar cells enabled by CsI-doping strategy. Small, 2024, 20(27):2310418. |

| [6] | ZHAO Y, WANG S, JIANG C, et al. Regulating energy band alignment via alkaline metal fluoride assisted solution post-treatment enabling Sb2(S,Se)3solar cells with 10.7% efficiency. Advanced Energy Materials, 2021, 12(1):2103015. |

| [7] | NICOLAS-MARIN M M, GONZALEX-CASTILLO J R, VIGIL- GALAN O, et al. The state of the art of Sb2(S, Se)3 thin film solar cells: current progress and future prospect. Journal of Physics D: Applied Physics, 2022, 55(30):303001. |

| [8] | LI J, ZHAO Y, LI C, et al. Hydrazine hydrate-induced surface modification of CdS electron transport layer enables 10.30%- efficient Sb2(S,Se)3 planar solar cells. Advanced Science, 2022, 9(25):2202356. |

| [9] | YAO L, LIN L, LIU H, et al. Front and back contact engineering for high-efficient and low-cost hydrothermal derived Sb2(S, Se)3 solar cells by using FTO/SnO2 and carbon. Journal of Materials Science & Technology, 2020, 58: 130. |

| [10] | XING Y, GUO H, LIU J, et al. High-efficiency Sb2(S,Se)3 solar cells with MoO3 as a hole-transport layer. Journal of Alloys and Compounds, 2022, 927: 166842. |

| [11] | ZHAO Y, LI C, NIU J, et al. Zinc-based electron transport materials for over 9.6%-efficient S-rich Sb2(S,Se)3 solar cells. Journal of Materials Chemistry A, 2021, 9(21):12644. |

| [12] | LIU J, NI X, XU F, et al. Optimizing the Se/S atom ratio and suppressing Sb2O3 impurities in hydrothermal deposition of Sb2(S,Se)3 films via Na plus doping. Physica B: Condensed Matter, 2023, 668: 415221. |

| [13] | GUO H, HUANG S, ZHU H, et al. Enhancement in the efficiency of Sb2Se3 solar cells by triple function of lithium hydroxide modified at the back contact interface. Advanced Science, 2023, 10(31):2304246. |

| [14] | LI J, GAO Z, HU X, et al. Defects passivation via potassium iodide post-treatment for antimony selenosulfide solar cells with improved performance. Advanced Functional Materials, 2022, 33(10):2211657. |

| [15] | TANG R, CHEN S, ZHENG Z, et al. Heterojunction annealing enabling record open-circuit voltage in antimony triselenide solar cells. Advanced Materials, 2022, 34(14):2109078. |

| [16] | WANG W, WANG X, CHEN G, et al. Over 6% certified Sb2(S,Se)3 solar cells fabricated via in situ hydrothermal growth and postselenization. Advanced Electronic Materials, 2019, 5(2):1800683. |

| [17] | ABDEL-SHAKOUR M, MAUSUISHI K, CHOWDHURY T H, et al. Regulated oxidation and moisture permeation via sulfinic acid based additive enables highly efficient and stable tin-based perovskite solar cells. Solar Energy Materials and Solar Cells, 2023, 254: 112241. |

| [18] | XIAO K, LIN R, HAN Q, et al. All-perovskite tandem solar cells with 24.2% certified efficiency and area over 1 cm2 using surface- anchoring zwitterionic antioxidant. Nature Energy, 2020, 5(11):870. |

| [19] | LI H, LIN L, YAO L, et al. High-efficiency Sb2(S,Se)3 solar cells with new hole transport layer-free back architecture via 2D titanium- carbide MXene. Advanced Functional Materials, 2022, 32(10):2110335. |

| [20] |

ZHANG F, HAN B, ZENG H. Perovskite quantum dot photovoltaic and luminescent concentrator cells: current status and challenges. Journal of Inorganic Materials, 2022, 37(2):117.

DOI |

| [21] | CHEN C, LI K, CHEN S, et al. Efficiency improvement of Sb2Se3 solar cells via grain boundary inversion. ACS Energy Letters, 2018, 3(10):2335. |

| [22] | WU F, ZHAO Y, YAO L, et al. Manipulating back contact enables over 8%-efficient carbon-based Sb2(S,Se)3 solar cells. Chemical Engineering Journal, 2022, 440: 135872. |

| [23] | CHEN X, CHE B, ZHAO Y, et al. Solvent-assisted hydrothermal deposition approach for highly-efficient Sb2(S,Se)3 thin-film solar cells. Advanced Energy Materials, 2023, 13(21):2300391. |

| [24] | MAO X, BIAN M, WANG C, et al. Ultrathin SnO2 buffer layer aids in interface and band engineering for Sb2(S,Se)3 solar cells with over 8% efficiency. ACS Applied Energy Materials, 2022, 5(3):3022. |

| [25] | WANG Y, JIAO Y, GUO J, et al. Optimization of interfacial engineering of perovskite solar cells. Journal of Inorganic Materials, 2023, 38(11):1323. |

| [26] | XIA Z, ZHANG W, CHEN C, et al. Improving performance of Cs2AgBiBr6 solar cell through constructing gradient energy level with deep-level hole transport material. Rare Metals, 2023, 42(9):3004. |

| [27] | WU J, LV Y, WANG J, et al. Performance improvement of Sb2Se3 thin-film solar cells through ultraviolet ozone treatment. Rare Metals, 2022, 41(8):2671. |

| [28] | CHEN T, LUO Y, ZHU L, et al. Organic-inorganic co-addition to improve mechanical bending and environmental stability of flexible perovskite solar cells. Journal of Inorganic Materials, 2024, 39(5):477. |

| [29] | SHIEL H, HOBSON T, HUTTER O, et al. Band alignment of Sb2O3 and Sb2Se3. Journal of Applied Physics, 2021, 129: 235301. |

| [30] | ZHANG S, LU Y, LIN B, et al. PVDF-HFP additive for visible- light-semitransparent perovskite films yielding enhanced photovoltaic performance. Solar Energy Materials and Solar Cells, 2017, 170: 178. |

| [31] | WAGEH S, Al-GHAMDI A A, ZHAO L. Insights into mechanism of CsPbBr3 nanocrystal interfacial modifier in perovskite solar cells. Acta Physico Chimica Sinica, 2022, 38(7):2111009. |

| [32] | ZHANG S, DONG G, LIN B, et al. A polymer gel electrolyte with an inverse opal structure and its effects on the performance of quasi-solid-state dye-sensitized solar cells. Journal of Power Sources, 2015, 277: 52. |

| [33] | ZHAO J, LI X, LIN J, et al. Unveiling the influence of absorber thickness on efficient Sb2(S, Se)3 solar cells through controlled chemical bath deposition. Surfaces and Interfaces, 2023, 42: 103411. |

| [34] | LIU J, CAO M, FENG Z, et al. Thermal evaporation-deposited hexagonal CdS buffer layer with improved quality, enlarged band gap, and reduced band gap offset to boost performance of Sb2(S,Se)3solar cells. Journal of Alloys and Compounds, 2022, 920: 165885. |

| [35] | GUO H, JIA X, LIU J, et al. Classification of lattice defects and the microscopic origin of p-type conductivity of Sb2Se3 solar cell absorber with varying Al2O3-layer thicknesses. Physica B: Condensed Matter, 2023, 648: 414394. |

| [36] | ZHANG S, HU Z, ZHANG J, et al. Interface engineering via phthalocyanine decoration of perovskite solar cells with high efficiency and stability. Journal of Power Sources, 2019, 438: 226987. |

| [1] | 胡清豪, 刘兴翀, 彭永珊, 侯孟君, 何堂贵, 汤安民. 安赛蜜修饰SnO2电子传输层对钙钛矿太阳能电池性能的影响[J]. 无机材料学报, 2025, 40(11): 1261-1267. |

| [2] | 肖梓晨, 何世豪, 邱诚远, 邓攀, 张威, 戴维德仁, 缑炎卓, 李金华, 尤俊, 王贤保, 林俍佑. 钙钛矿太阳能电池纳米纤维改性电子传输层研究[J]. 无机材料学报, 2024, 39(7): 828-834. |

| [3] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [4] | 陈甜, 罗媛, 朱刘, 郭学益, 杨英. 有机-无机共添加增强柔性钙钛矿太阳能电池机械弯曲及环境稳定性能[J]. 无机材料学报, 2024, 39(5): 477-484. |

| [5] | 于嫚, 高荣耀, 秦玉军, 艾希成. 上转换发光纳米材料对钙钛矿太阳能电池迟滞效应和离子迁移动力学的影响[J]. 无机材料学报, 2024, 39(4): 359-366. |

| [6] | 费玲, 雷蕾, 汪德高. 二维MXene材料在新型薄膜太阳能电池技术中的研究进展[J]. 无机材料学报, 2024, 39(2): 215-224. |

| [7] | 刘锁兰, 栾福园, 吴子华, 寿春晖, 谢华清, 杨松旺. 原位生长钙钛矿太阳能电池共形氧化锡薄膜[J]. 无机材料学报, 2024, 39(12): 1397-1403. |

| [8] | 王煜, 熊浩, 黄孝坤, 江琳沁, 吴波, 黎健生, 杨爱军. 低剂量异辛酸亚锡调控两步法制备Sn-Pb混合钙钛矿太阳能电池[J]. 无机材料学报, 2024, 39(12): 1339-1347. |

| [9] | 周泽铸, 梁子辉, 李静, 吴聪聪. 基于挥发性溶剂制备MAPbI3钙钛矿太阳能电池/模组[J]. 无机材料学报, 2024, 39(11): 1197-1204. |

| [10] | 厉佥元, 李纪伟, 张钰涵, 刘焱康, 孟阳, 储余, 朱一佳, 徐诺言, 朱亮, 张传香, 陶海军. PbTiO3修饰和极化处理提升钙钛矿太阳能电池性能[J]. 无机材料学报, 2024, 39(11): 1205-1211. |

| [11] | 代晓栋, 张露伟, 钱奕成, 任智鑫, 曹焕奇, 印寿根. 锡铅混合钙钛矿太阳能电池垂直组分梯度的溶剂工程调控[J]. 无机材料学报, 2023, 38(9): 1089-1096. |

| [12] | 韩旭, 姚恒大, 吕梅, 陆红波, 朱俊. 单分子液晶添加剂在甲脒铅碘钙钛矿太阳能电池中的应用[J]. 无机材料学报, 2023, 38(9): 1097-1102. |

| [13] | 方万丽, 沈黎丽, 李海艳, 陈薪羽, 陈宗琦, 寿春晖, 赵斌, 杨松旺. NiOx介孔层的成膜过程对碳电极钙钛矿太阳能电池性能的影响[J]. 无机材料学报, 2023, 38(9): 1103-1109. |

| [14] | 丁统顺, 丰平, 孙学文, 单沪生, 李琪, 宋健. Fmoc-FF-OH钝化钙钛矿薄膜及其太阳能电池性能研究[J]. 无机材料学报, 2023, 38(9): 1076-1082. |

| [15] | 张伦, 吕梅, 朱俊. Cs2AgBiBr6钙钛矿太阳能电池研究进展[J]. 无机材料学报, 2023, 38(9): 1044-1054. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||