Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (5): 554-560.DOI: 10.15541/jim20230524

Special Issue: 【信息功能】功能晶体(202506)

• RESEARCH LETTER • Previous Articles Next Articles

JIN Min1( ), MA Yupeng2, WEI Tianran2, LIN Siqi1, BAI Xudong3, SHI Xun4, LIU Xuechao4(

), MA Yupeng2, WEI Tianran2, LIN Siqi1, BAI Xudong3, SHI Xun4, LIU Xuechao4( )

)

Received:2023-11-09

Published:2024-05-20

Online:2024-03-08

Contact:

LIU Xuechao, professor. E-mail: xcliu@mail.sic.ac.cnAbout author:JIN Min (1982-), male, professor. E-mail: jmaish@aliyun.com

Supported by:CLC Number:

JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method[J]. Journal of Inorganic Materials, 2024, 39(5): 554-560.

Fig. 1 Crystal growth design (a) Dependence of weight percentage of In/Se elements on temperature; (b) Schematic diagram of zone melting method for InSe crystal growth

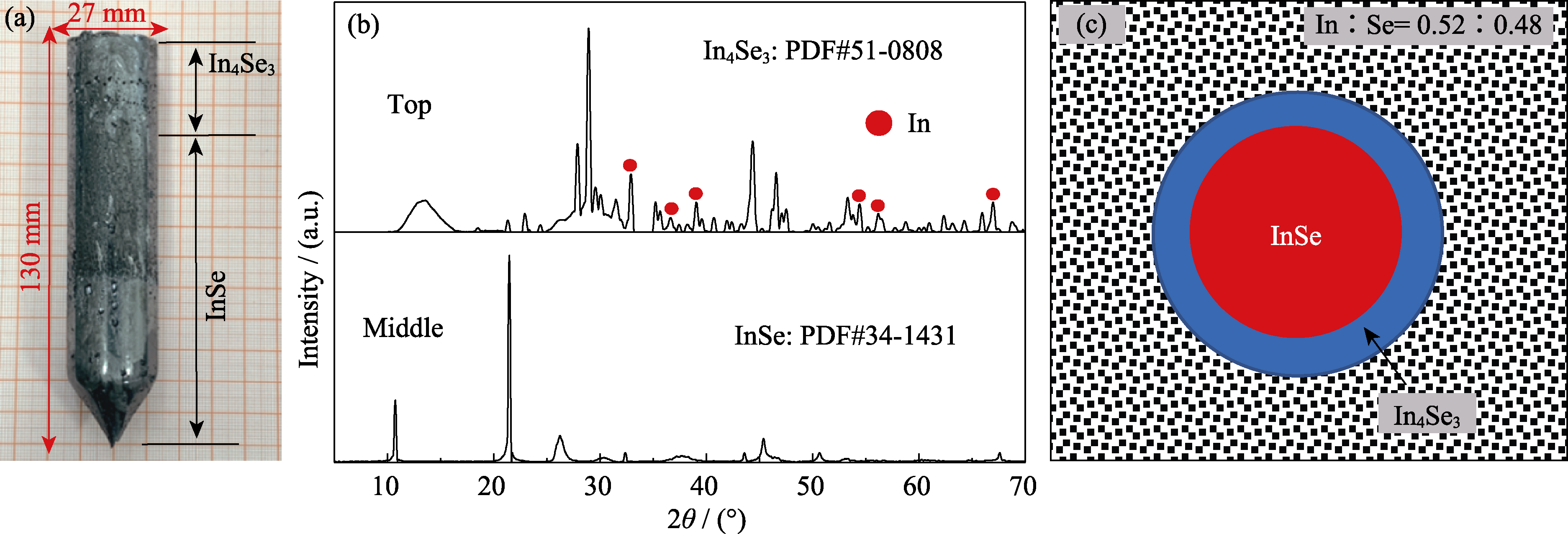

Fig. 3 Results of as-grown ingot (a) Photo of as-grown ingot; (b) Powder XRD patterns of the middle and top parts of the ingot; (c) Transfer relationship between InSe and In4Se3 phases

| Author | Year | Country | Method | n(In) : n(Se) | Crystal size | Ref. |

|---|---|---|---|---|---|---|

| Damon R W et al. | 1954 | USA | Stockbarger | 1 : 1 | ϕ10 mm×20 mm | [ |

| Andriyashik M V et al. | 1968 | Ukraine | Czochralski | 1 : 1 | ϕ20 mm×(40-50) mm | [ |

| Chevy A et al. | 1977 | France | Vertical Bridgman | 0.56 : 0.44 | ϕ14 mm×30 mm | [ |

| Chevy A et al. | 1978 | France | Czochralski | 0.56 : 0.44 | 1 mm×25 mm×65 mm | [ |

| Chevy A | 1981 | France | Chemical transport | 1 : 1 | 0.3 mm×0.3 mm×0.1 mm | [ |

| Imai K et al. | 1981 | Japan | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm×50 mm | [ |

| Blasi C D et al. | 1982 | Italy | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm | [ |

| Chevy A | 1984 | France | Modified Bridgman | 0.56 : 0.44 | ϕ10 mm | [ |

| Tribloulet R et al. | 1986 | France | Travelling heater | 0.52 : 0.48 | ϕ15 mm×60 mm | [ |

| Ishii T | 1988 | Japan | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm | [ |

| Gurbulak B | 1999 | Turkey | Freezing method | 1 : 1 | ϕ12 mm×60 mm | [ |

| Icelli O et al. | 2004 | Turkey | Stockbarger | 1 : 1 | ϕ12 mm×60 mm | [ |

| Gurbulak B et al. | 2014 | Turkey | Bridgman-Stockbarger | 1 : 1 | ϕ10 mm×60 mm | [ |

| Wei T R et al. | 2020 | China | Vertical Bridgman | 0.52 : 0.48 | ϕ25 mm×75 mm | [ |

| Zhang B et al. | 2021 | China | Vertical Bridgman | 1 : 1 | ϕ14 mm×40 mm | [ |

| Shi H et al. | 2021 | China | Vertical Bridgman | 1 : 1 | ϕ12.7 mm×12 mm | [ |

| Jin M et al. | 2023 | China | Zone melting method | 0.52 : 0.48 | ϕ27 mm×130 mm | This work |

Table 1 Growth results of InSe crystals by different methods in the past years

| Author | Year | Country | Method | n(In) : n(Se) | Crystal size | Ref. |

|---|---|---|---|---|---|---|

| Damon R W et al. | 1954 | USA | Stockbarger | 1 : 1 | ϕ10 mm×20 mm | [ |

| Andriyashik M V et al. | 1968 | Ukraine | Czochralski | 1 : 1 | ϕ20 mm×(40-50) mm | [ |

| Chevy A et al. | 1977 | France | Vertical Bridgman | 0.56 : 0.44 | ϕ14 mm×30 mm | [ |

| Chevy A et al. | 1978 | France | Czochralski | 0.56 : 0.44 | 1 mm×25 mm×65 mm | [ |

| Chevy A | 1981 | France | Chemical transport | 1 : 1 | 0.3 mm×0.3 mm×0.1 mm | [ |

| Imai K et al. | 1981 | Japan | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm×50 mm | [ |

| Blasi C D et al. | 1982 | Italy | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm | [ |

| Chevy A | 1984 | France | Modified Bridgman | 0.56 : 0.44 | ϕ10 mm | [ |

| Tribloulet R et al. | 1986 | France | Travelling heater | 0.52 : 0.48 | ϕ15 mm×60 mm | [ |

| Ishii T | 1988 | Japan | Vertical Bridgman | 0.52 : 0.48 | ϕ10 mm | [ |

| Gurbulak B | 1999 | Turkey | Freezing method | 1 : 1 | ϕ12 mm×60 mm | [ |

| Icelli O et al. | 2004 | Turkey | Stockbarger | 1 : 1 | ϕ12 mm×60 mm | [ |

| Gurbulak B et al. | 2014 | Turkey | Bridgman-Stockbarger | 1 : 1 | ϕ10 mm×60 mm | [ |

| Wei T R et al. | 2020 | China | Vertical Bridgman | 0.52 : 0.48 | ϕ25 mm×75 mm | [ |

| Zhang B et al. | 2021 | China | Vertical Bridgman | 1 : 1 | ϕ14 mm×40 mm | [ |

| Shi H et al. | 2021 | China | Vertical Bridgman | 1 : 1 | ϕ12.7 mm×12 mm | [ |

| Jin M et al. | 2023 | China | Zone melting method | 0.52 : 0.48 | ϕ27 mm×130 mm | This work |

Fig. 4 Characteriation of obtained single crystals (a) Large area slab-like InSe crystal cleaved from the ingot; (b) XRD pattern of (001) cleavage plane; (c) Fresh flake disclosed by tweezers; (d) SEM image of (001) plane; (e) Area scan and (f) line scan by EDS

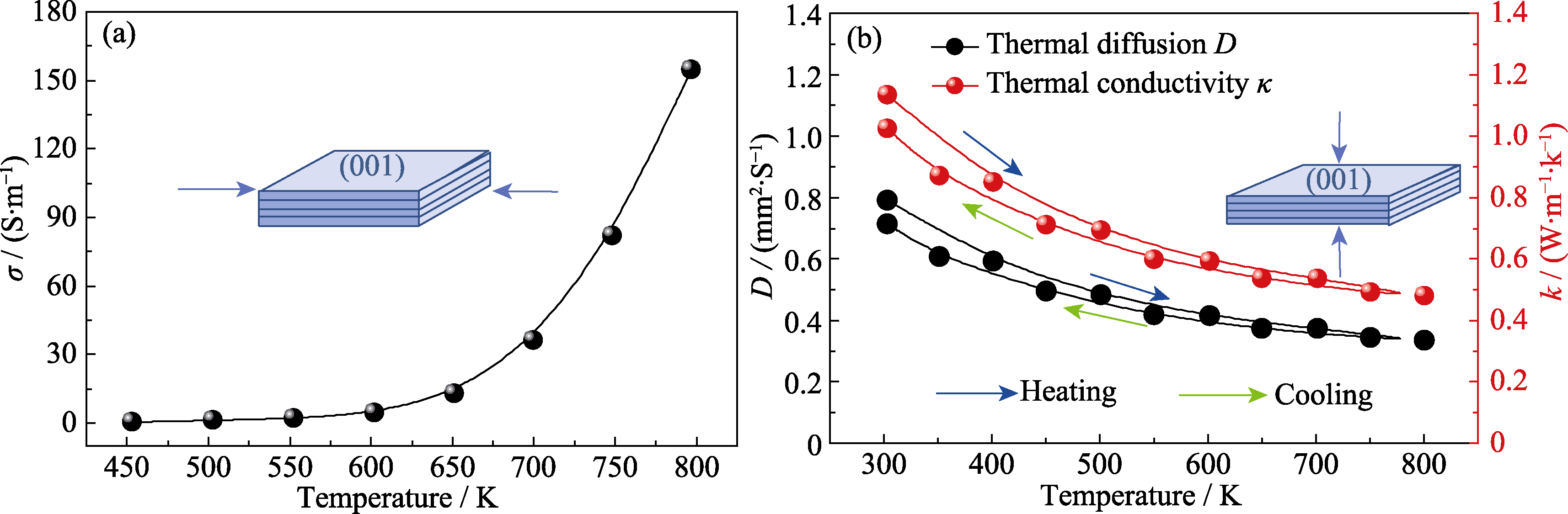

Fig. 6 Transport properties under different temperatures (a) Electrical conductivity σ; (b) Thermal diffusion D and thermal conductivity κ Colorful figures are available on website

| [1] | JIANG J F, LI J X, LI Y T, et al. Stable InSe transistors with high-field effect mobility for reliable nerve signal sensing. npj 2D Mater. Appl., 2019, 3(1): 29. |

| [2] | BANDURIN D A, TYURNINA A V, YU G L, et al. High electron mobility, quantum Hall effect and anomalous optical response in atomically thin InSe. Nat. Nanotechnol., 2016, 12(3): 223. |

| [3] | YU M M, HU Y X, GAO F, et al. High-performance devices based on InSe-In1-xGaxSe van der Waals heterojunctions. ACS Appl. Mater. Interf., 2020, 12(22): 24978. |

| [4] | HOU X J, CHEN S P, DU Z L, et al. Improvement of the thermoelectric performance of InSe-based alloys doped with Sn. RSC Adv., 2015, 5(124): 102856. |

| [5] | HE F, BAI X D, LU X Y, et al. Research progress of Ⅲ-Ⅵ group InSe semiconductor crystal growth. J. Synth. Cryst., 2022, 51(9/10): 1722. |

| [6] | ZHAO Q H, ZHENG D, CHEN P, et al. Research progress on indium selenide crystals and optoelectronic devices. J. Synth. Cryst., 2022, 51(9/10): 1704. |

| [7] | GUO Z, CAO R, WANG H, et al. High-performance polarization- sensitive photodetectors on two-dimensional beta-InSe. Natl. Sci. Rev., 2022, 9(5): nwab098. |

| [8] |

PASQUALE G, LOPRIORE E, SUN Z, et al. Electrical detection of the flat-band dispersion in van der Waals field-effect structures. Nat. Nanotechnol., 2023, 18(12): 1416.

DOI PMID |

| [9] | SUI F, JIN M, ZHANG Y, et al. Sliding ferroelectricity in van der Waals layered gamma-InSe semiconductor. Nat. Commun., 2023, 14: 36. |

| [10] | WEI T R, JIN M, WANG Y, et al. Exceptional plasticity in the bulk single-crystalline van der Waals semiconductor InSe. Science, 2020, 369(6503): 542. |

| [11] |

HAN X. Ductile van der Waals materials. Science, 2020, 369(6503): 509.

DOI PMID |

| [12] | MA Y P, HUANG H R, LIU Y F, et al. Remarkable plasticity and softness of polymorphic InSe van der Waals crystals. J. Materiomics, 2023, 9: 709. |

| [13] | CHEVY A. GOUSKOV A, BESSON J M. Growth of crystalline slabs of layered InSe by the Czochralski method. J. Cryst. Growth, 1978, 43(6): 756. |

| [14] | TANG C, SATO Y, TANABE T, et al. Low temperature liquid phase growth of crystalline InSe grown by the temperature difference method under controlled vapor pressure. J. Cryst. Growth, 2018, 495: 54. |

| [15] | MEDVEDEVA Z S, GULIEV T N. Growing single crystals of the indium selenide from the gas phase. Inorg. Mater., 1965, 1(6): 848. |

| [16] | ZHANG B, WU H, PENG K L, et al. Super deformability and thermoelectricity of bulk γ-InSe single crystals. Chin. Phys. B, 2021, 30(7): 078101. |

| [17] | JIN M, SHEN H, FAN S J, et al. Industrial growth and characterization of Si-doped GaAs crystal by a novel multi-crucible Bridgman method. Cryst. Res. Technol., 2017, 52(6): 1700052. |

| [18] | JIN M, LIN S Q, LI W, et al. Nearly isotropic transport properties in anisotropically structured n-type single-crystalline Mg3Sb2. Mater. Today Phys., 2021, 21: 100508. |

| [19] | JIN M, YANG W H, WANG X H, et al. Growth and characterization of ZnTe single crystal via a novel Te flux vertical Bridgman method. Rare Met., 2020, 40(4): 858. |

| [20] | JIN M, TANG Z Q, ZHANG R L, et al. Growth of large size SnSe crystal via directional solidification and evaluation of its properties. J. Alloys Compd., 2020, 824: 153869. |

| [21] | IMAI K, SUZUKI K, HAGA T, et al. Phase diagram of In-Se system and crystal growth of indium monoselenide. J. Cryst. Growth, 1981, 54(3): 501. |

| [22] | JIN M, BAI X D, TANG Z Q, et al. Fabrication of InSb crystal via horizontal Bridgman method and investigation on its thermoelectric properties. Mater. Res. Bull., 2021, 142: 111411. |

| [23] | JIN M, TANG Z Q, ZHANG R L, et al. Growth of GaSb crystal and evaluation of its thermoelectric properties along (111) plane. Cryst. Res. Technol., 2019, 55(1): 1900156. |

| [24] | SHI H, WANG D, XIAO Y, et al. Dynamic carrier transports and low thermal conductivity in n-type layered InSe thermoelectrics. Aggregate, 2021, 2(4): e92. |

| [25] | WANG W Y, CHEN X L, NI D Q, et al. Growth of near stoichiometric LiNbO3crystals by a modified zone melting method. J. Alloys Compd., 2005, 402(1/2): 224. |

| [26] | LIU Y, AI F, PAN X H, et al. Effects of rotating magnetic field on Bi12SiO20 crystal growth by vertical zone-melting technique. J. Cryst. Growth, 2010, 312(9): 1622. |

| [27] | ISHII T. High quality single crystal growth of layered InSe semiconductor by Bridgman technique. J. Cryst. Growth, 1988, 89(4): 459. |

| [28] | DAMON R W, REDINGTON R W. Electrical and optical properties of indium selenide. Phys. Rev., 1954, 96(6): 1498. |

| [29] | ANDRIYASHIK M V, SAKHNOVSKII M Y, TIMOFEEV V B, et al. Optical transitions in the spectra of the fundamental absorption and reflection of InSe single crystals. Phys. Stat. Sol. (B), 1968, 28(1): 277. |

| [30] | CHEVY A, KUHN A, MARTIN M S. Large InSe monocrystals grown from a non-stoichiometric melt. J. Cryst. Growth, 1977, 38(1): 118. |

| [31] | CHEVY A. Growth of indium selenides by vapour phase chemical transport; polytypism of indium monoselenide. J. Cryst. Growth, 1981, 51(2): 157. |

| [32] | BLASI C D, MICOCCI G, MONGELLI S, et al. Large InSe single crystals grown from stoichiometric and non-stoichiometric melts. J. Cryst. Growth, 1982, 57(3): 482. |

| [33] | CHEVY A. Improvement of growth parameters for Bridgman- grown InSe crystals. J. Cryst. Growth, 1984, 67(1): 119. |

| [34] | TRIBLOULET R, CLEMENT C L, THEYS B, et al. Growth of InSe single crystals by the travelling heater method. J. Cryst. Growth, 1986, 79(1/2/3): 984. |

| [35] | GURBULAK B. Growth and optical properties of Dy doped and undoped n-type InSe single crystal. Solid State Commun., 1999, 109(10): 665. |

| [36] | İCELLI Q, ERZENEOGLU S, GURBULAK B. Mass attenuation coefficients for n-type InSe, InSe:Gd, InSe:Ho and InSe:Er single crystals. J. Quant. Spectrosc. Radiat. Transf., 2004, 90(3/4): 399. |

| [37] | GURBULAK B, ŞATA M, DOGAN S, et al. Structural characterizations and optical properties of InSe and InSe:Ag semiconductors grown by Bridgman/Stockbarger technique. Physica E, 2014, 64: 106. |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [3] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [4] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [5] | JIANG Runlu, WU Xin, GUO Haocheng, ZHENG Qi, WANG Lianjun, JIANG Wan. UiO-67 Based Conductive Composites: Preparation and Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(11): 1338-1344. |

| [6] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [7] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [8] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [9] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [10] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [11] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [12] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [13] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [14] | ZHANG Keyi, ZHENG Qi, WANG Lianjun, JIANG Wan. Preparation and Characterization of Ag2Se-based Ink Used for Inkjet Printing [J]. Journal of Inorganic Materials, 2022, 37(10): 1109-1115. |

| [15] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||