Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (9): 947-953.DOI: 10.15541/jim20220101

• RESEARCH ARTICLE • Previous Articles Next Articles

FU Shi1,2( ), YANG Zengchao1, LI Honghua1(

), YANG Zengchao1, LI Honghua1( ), WANG Liang1, LI Jiangtao1,2(

), WANG Liang1, LI Jiangtao1,2( )

)

Received:2022-03-02

Revised:2022-04-29

Published:2022-09-20

Online:2022-05-27

Contact:

LI Jiangtao, professor. E-mail: lijiangtao@mail.ipc.ac.cn;About author:FU Shi, male, PhD candidate. E-mail: fushi18@mails.ucas.ac.cn

Supported by:CLC Number:

FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives[J]. Journal of Inorganic Materials, 2022, 37(9): 947-953.

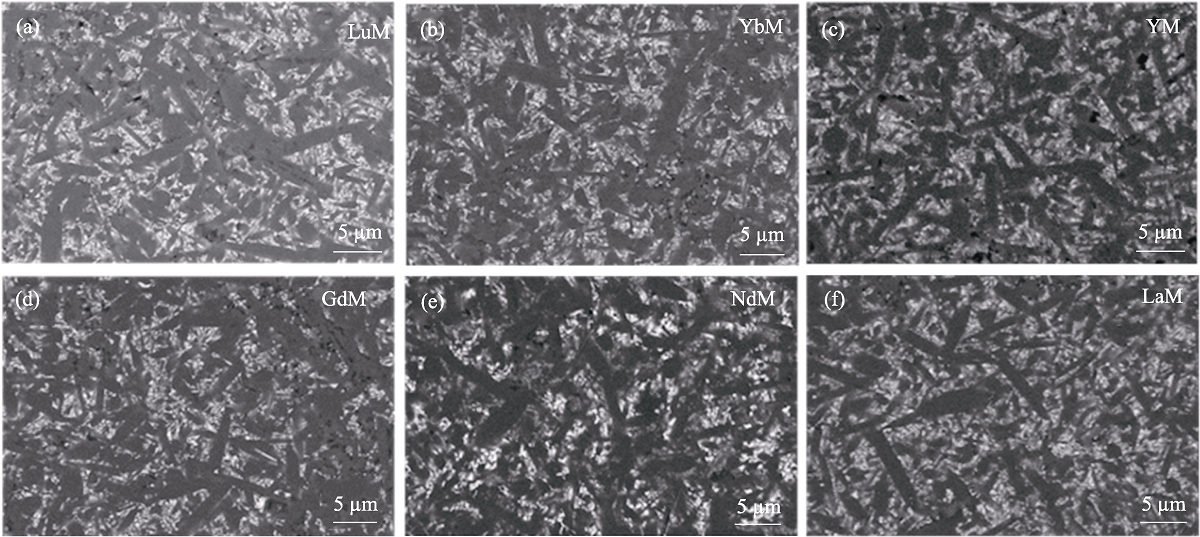

Fig. 2 SEM images of the polished surfaces of Si3N4 ceramics with different additive systems prepared by hot pressing sintering (a) LuM; (b) YbM; (c) YM; (d) GdM; (e) NdM; (f) LaM

| Sample | Ionic radius/nm | Relative density/% | Grain size/μm | Vickers’ hardness/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Thermal conductivity/ (W·m-1·K-1) |

|---|---|---|---|---|---|---|---|

| ScM | 0.073 | 99.36 | 0.72±0.32 | 14.58±0.25 | 905±36 | 8.21±0.09 | 54.7 |

| LuM | 0.085 | 99.53 | 0.9±0.40 | 14.75±0.20 | 785±25 | 8.01±0.12 | 49.6 |

| YbM | 0.086 | 99.49 | 0.97±0.47 | 14.75±0.27 | 759±20 | 8.03±0.16 | 49.7 |

| YM | 0.089 | 99.73 | 1.03±0.46 | 14.64±0.29 | 819±10 | 8.65±0.11 | 51.1 |

| GdM | 0.094 | 99.89 | 1.01±0.48 | 14.57±0.22 | 792±34 | 7.62±0.47 | 54.6 |

| NdM | 0.100 | 99.37 | 0.95±0.42 | 14.79±0.27 | 1115±49 | 7.19±0.10 | 53.9 |

| LaM | 0.106 | 99.21 | 0.9±0.41 | 15.37±0.33 | 978±39 | 7.25±0.10 | 52.8 |

Table 1 Properties of Si3N4 ceramic samples prepared by hot pressing sintering

| Sample | Ionic radius/nm | Relative density/% | Grain size/μm | Vickers’ hardness/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Thermal conductivity/ (W·m-1·K-1) |

|---|---|---|---|---|---|---|---|

| ScM | 0.073 | 99.36 | 0.72±0.32 | 14.58±0.25 | 905±36 | 8.21±0.09 | 54.7 |

| LuM | 0.085 | 99.53 | 0.9±0.40 | 14.75±0.20 | 785±25 | 8.01±0.12 | 49.6 |

| YbM | 0.086 | 99.49 | 0.97±0.47 | 14.75±0.27 | 759±20 | 8.03±0.16 | 49.7 |

| YM | 0.089 | 99.73 | 1.03±0.46 | 14.64±0.29 | 819±10 | 8.65±0.11 | 51.1 |

| GdM | 0.094 | 99.89 | 1.01±0.48 | 14.57±0.22 | 792±34 | 7.62±0.47 | 54.6 |

| NdM | 0.100 | 99.37 | 0.95±0.42 | 14.79±0.27 | 1115±49 | 7.19±0.10 | 53.9 |

| LaM | 0.106 | 99.21 | 0.9±0.41 | 15.37±0.33 | 978±39 | 7.25±0.10 | 52.8 |

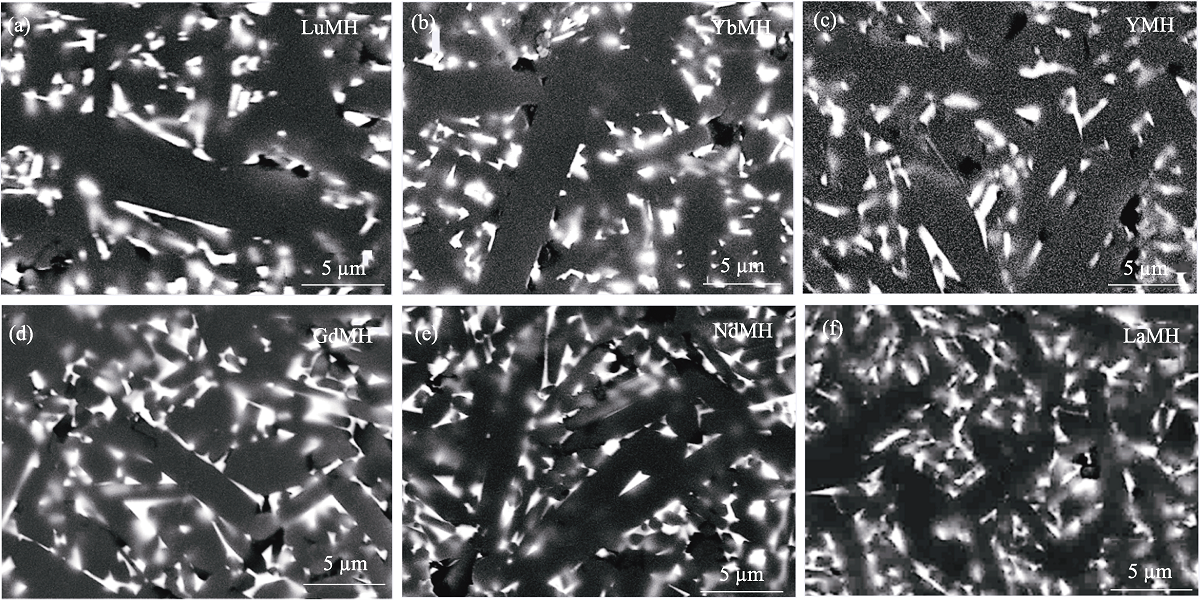

Fig. 4 SEM images of the polished surfaces of Si3N4 ceramics with different additive systems after annealing (a) LuMH; (b) YbMH; (c) YMH; (d) GdMH; (e) NdMH; (f) LaMH

Fig. 5 (a) Average grain size, (b) bending strength, (c) fracture toughness, and (d) thermal conductivity changing with radius of rare earth ion of Si3N4 ceramics before and after annealing

Fig. 6 Microstructures of Si3N4 ceramic samples before and after annealing (a) ScM and (d) ScMH etched by molten NaOH; Fracture surfaces of (b) YM, (e) YMH, (c) YbM and (f) YbMH

| [1] | CHOI U M, BLAABJERG F, JORGENSEN S, et al. Power cycling test and failure analysis of molded intelligent power IGBT module under different temperature swing durations. Microelectronics Reliability, 2016, 64: 403-408. |

| [2] |

EDDY C R, GASKILL D K. Silicon carbide as a platform for power electronics. Science, 2009, 324(5933): 1398-1400.

DOI URL |

| [3] |

RILEY F L. Silicon nitride and related materials. Journal of the American Ceramic Society, 2000, 83(2): 245-265.

DOI URL |

| [4] | HAGGERTY J S, LIGHTFOOT A. Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing. Ceramic Engineering and Science Proceeding, 1995: 475-487. |

| [5] |

ZHOU Y, HYUGA H, KUSANO D, et al. Development of high- thermal-conductivity silicon nitride ceramics. Journal of Asian Ceramic Societies, 2018, 3(3): 221-229.

DOI URL |

| [6] | KITAYAMA M. High thermal conductivity ceramics. Encyclopedia of Materials: Technical Ceramics and Glasses, 2021: 165-181. |

| [7] |

ZHOU Y, HYUGA H, KUSANO D, et al. A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39): 4563-4567.

DOI URL |

| [8] |

KITAYAMA M, HIRAO K, TORIYAMA M, et al. Thermal conductivity of β-Si3N4: I, effects of various microstructural factors. Journal of the American Ceramic Society, 1999, 82(11): 3105-3112.

DOI URL |

| [9] |

KITAYAMA M, HIRAO K, TSUGE A, et al. Thermal conductivity of β-Si3N4: II, effect of lattice oxygen. Journal of the American Ceramic Society, 2000, 83(8): 1985-1992.

DOI URL |

| [10] |

LEE H M, LEE E B, KIM D L, et al. Comparative study of oxide and non-oxide additives in high thermal conductive and high strength Si3N4 ceramics. Ceramics International, 2016, 42(15): 17466-17471.

DOI URL |

| [11] | LI Y, KIM H-N, WU H, et al. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: the effects of Y2O3 additive content. Journal of the European Ceramic Society, 2021, 41(1): 274-283. |

| [12] |

ZHU X, HAYASHI H, ZHOU Y, et al. Influence of additive composition on thermal and mechanical properties of β-Si3N4 ceramics. Journal of Materials Research, 2004, 19(11): 3270-3278.

DOI URL |

| [13] |

LIU W, TONG W, HE R, et al. Effect of the Y2O3 additive concentration on the properties of a silicon nitride ceramic substrate. Ceramics International, 2016, 42(16): 18641-18647.

DOI URL |

| [14] |

ZHANG J, CUI W, LI F, et al. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceramics International, 2020, 46(10): 15719-15722.

DOI URL |

| [15] |

HAYASHI H, HIRAO K, TORIYAMA M, et al. MgSiN2 Addition as a means of increasing the thermal conductivity of β-silicon nitride. Journal of the American Ceramic Society, 2001, 84(12): 3060-3062.

DOI URL |

| [16] |

ZHU X W, SAKKA Y, ZHOU Y, et al. Effect of MgSiN2 addition on gas pressure sintering and thermal conductivity of silicon nitride with Y2O3. Journal of the Ceramic Society of Japan, 2008, 116(1354): 706-711.

DOI URL |

| [17] |

ZHU X W, ZHOU Y, HIRAO K. Effect of sintering additive composition on the processing and thermal conductivity of sintered reaction-bonded Si3N4. Journal of the American Ceramic Society, 2004, 87(7): 1398-1400.

DOI URL |

| [18] |

BECHER P F, PAINTER G S, SHIBATA N, et al. Effects of rare-earth (RE) intergranular adsorption on the phase transformation, microstructure evolution, and mechanical properties in silicon nitride with RE2O3+MgO additives: RE=La, Gd, and Lu. Journal of the American Ceramic Society, 2008, 91(7): 2328-2336.

DOI URL |

| [19] |

SATET R L, HOFFMANN M J. Influence of the rare-earth element on the mechanical properties of RE-Mg-bearing silicon nitride. Journal of the American Ceramic Society, 2005, 88(9): 2485-2490.

DOI URL |

| [20] |

KITAYAMA M, HIRAO K, WATARI K, et al. Thermal conductivity of β-Si3N4: III, effect of rare-earth (RE = La, Nd, Gd, Y, Yb, and Sc) oxide additives. Journal of the American Ceramic Society, 2001, 84(2): 353-358.

DOI URL |

| [21] |

LIANG H, WANG W, ZUO K, et al. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceramics International, 2020, 46(11): 17776-17783.

DOI URL |

| [22] | WATARI K. High thermal conductivity non-oxide ceramics. Journal of the Ceramic Society of Japan, 2001, 109(1): S7-S16. |

| [23] |

HIRAO K, WATARI K, HAYASHI H, et al. High thermal conductivity silicon nitride ceramic. MRS Bulletin, 2001, 26(6): 451-455.

DOI URL |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [3] | LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(3): 291-298. |

| [4] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [5] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [6] | ZHANG Shouchao, CHEN Hongyu, LIU Hongfei, YANG Yu, LI Xin, LIU Defeng. High Temperature Recovery of Neutron Irradiation-induced Swelling and Optical Property of 6H-SiC [J]. Journal of Inorganic Materials, 2023, 38(6): 678-686. |

| [7] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [8] | YU Ruixian, WANG Guodong, WANG Shouzhi, HU Xiaobo, XU Xiangang, ZHANG Lei. Effect of High-temperature Annealing on AlN Crystal Grown by PVT Method [J]. Journal of Inorganic Materials, 2023, 38(3): 343-349. |

| [9] | SHANGGUAN Li, NIE Xiaoshuang, YE Kuicai, CUI Yuanyuan, QIAO Yuqin. Effects of Surface Wettability of Titanium Oxide Coatings on Osteoimmunomodulatory Properties [J]. Journal of Inorganic Materials, 2023, 38(12): 1457-1565. |

| [10] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [11] | LI Honghua, DONG Wanru, WANG Liang, YANG Zengchao, LI Jiangtao. Consistency of Silicon Nitride Powders Produced by Combustion Synthesis: Evaluation and Application [J]. Journal of Inorganic Materials, 2023, 38(10): 1169-1175. |

| [12] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [13] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [14] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [15] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||