Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (4): 459-466.DOI: 10.15541/jim20210230

• RESEARCH LETTER • Previous Articles Next Articles

RUAN Jing1,2,3( ), YANG Jinshan1,2(

), YANG Jinshan1,2( ), YAN Jingyi1,2,4, YOU Xiao1,2,4, WANG Mengmeng1,2,4, HU Jianbao1,2, ZHANG Xiangyu1,2, DING Yusheng1,2, DONG Shaoming1,2,5(

), YAN Jingyi1,2,4, YOU Xiao1,2,4, WANG Mengmeng1,2,4, HU Jianbao1,2, ZHANG Xiangyu1,2, DING Yusheng1,2, DONG Shaoming1,2,5( )

)

Received:2021-04-07

Revised:2021-06-27

Published:2022-04-20

Online:2021-06-30

Contact:

YANG Jinshan, professor. E-mail: jyang@mail.sic.ac.cn;About author:RUAN Jing (1993–), male, PhD candidate. E-mail: ruanjing@shanghaitech.edu.cn

Supported by:CLC Number:

RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity[J]. Journal of Inorganic Materials, 2022, 37(4): 459-466.

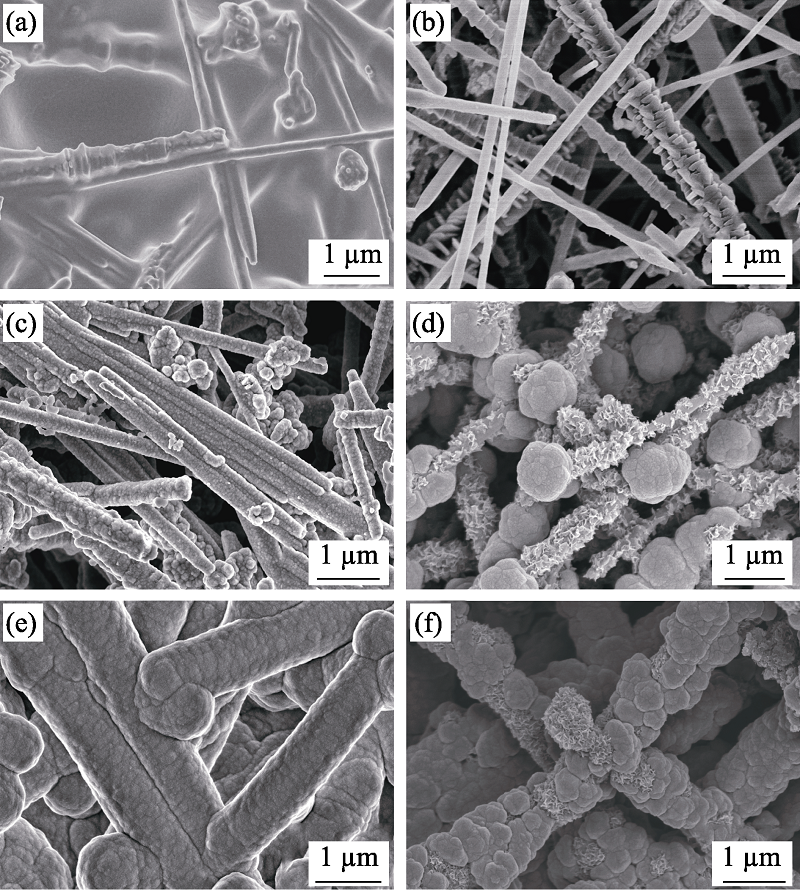

Fig. 1 Surface morphologies of the SiCNWs/PVA film (a), SiCNWs network without PyC and SiC deposition (b), surface morphologies of sample without (c) and with (d) PyC interphase after short time CVI process, and without (e) and with (f) PyC interphase after a long time CVI process

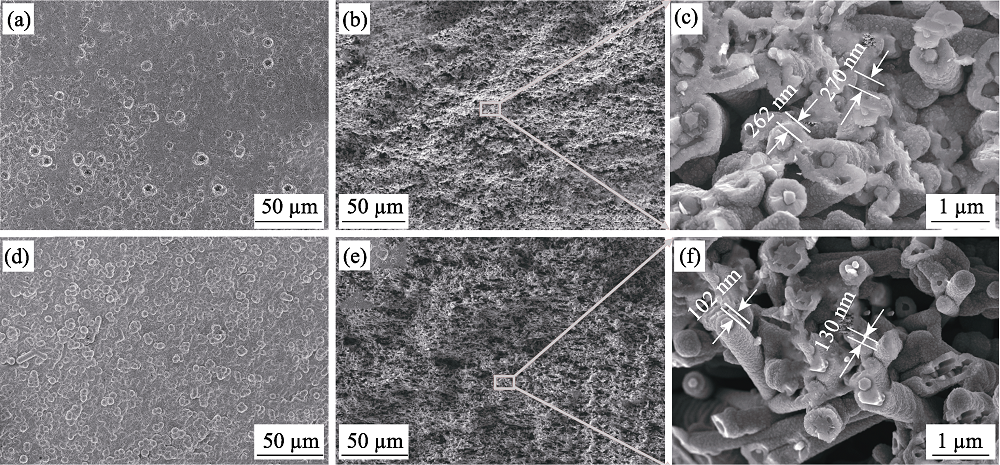

Fig. 3 SEM images of the prepared SiCNWs/SiC ceramic matrix composites (a) External surface view of the sample under 8 h CVI process at 1030 ℃; (b) Fracture surface view and (c) corresponding enlarged region of the sample under 8 h CVI process at 1030 ℃; (d) External surface view of the sample under 8 h CVI process at 1100 ℃; (e) Fracture surface view and (f) corresponding enlarged region of the sample under 8 h CVI process at 1100 ℃

| Materials | Porosity/% | Strength /MPa | Thermal conductivity/(W·m-1·K-1) | Ref. |

|---|---|---|---|---|

| Porous SiC-SiO2 ceramic | ~72 | ~2.7 | 0.066 | [ |

| Sc-doped porous SiC ceramic | ~61% | 10.5 | 7.700 | [ |

| Porous Al2O3-SiC | ~38 | 28.0 | - | [ |

| Porous ZrB2-SiC ceramics | ~59% | ~78.0 | - | [ |

| Porous SiC ceramic | ~40% | ~10.7 | 0.580 | [ |

| Porous SiCNWs/SiC ceramic matrix composite | ~39% | ~194.3 | 1.900 | This work |

| Porous SiCNWs/SiC ceramic matrix composite | ~62% | ~49.0 | 1.600 | This work |

Table 1 Strength and thermal conductivity of different materials

| Materials | Porosity/% | Strength /MPa | Thermal conductivity/(W·m-1·K-1) | Ref. |

|---|---|---|---|---|

| Porous SiC-SiO2 ceramic | ~72 | ~2.7 | 0.066 | [ |

| Sc-doped porous SiC ceramic | ~61% | 10.5 | 7.700 | [ |

| Porous Al2O3-SiC | ~38 | 28.0 | - | [ |

| Porous ZrB2-SiC ceramics | ~59% | ~78.0 | - | [ |

| Porous SiC ceramic | ~40% | ~10.7 | 0.580 | [ |

| Porous SiCNWs/SiC ceramic matrix composite | ~39% | ~194.3 | 1.900 | This work |

| Porous SiCNWs/SiC ceramic matrix composite | ~62% | ~49.0 | 1.600 | This work |

| [1] |

LI S, ZENG X, CHEN H, et al. Porous hexagonal boron nitride nanosheets from g-C3N4 templates with a high specific surface area for CO2 adsorption. Ceramics International, 2020, 46(17): 27627-27633.

DOI URL |

| [2] | SARAVANAN S, CHIDAMBARAM R K, GEO V E. An experimental study to analyze influence of porous media combustor on performance and emission characteristics of a DI diesel engine. Fuel, 2020, 280: 118645-1-8. |

| [3] | BICY K, KALARIKKAL N, STEPHEN A M, et al. Facile fabrication of microporous polypropylene membrane separator for lithium-ion batteries. Materials Chemistry and Physics, 2020, 255: 123473-1-9. |

| [4] | PAN B, CHEN J, ZHANG F, et al. Porous TiO2 aerogel-modified SiC ceramic membrane supported MnOx catalyst for simultaneous removal of NO and dust. Journal of Membrane Science, 2020, 611: 118366-1-10. |

| [5] |

SONG X, JIAN B, JIN J. Preparation of porous ceramic membrane for gas-solid separation. Ceramics International, 2018, 44(16): 20361-20366.

DOI URL |

| [6] |

WANG Z, PAN Z. Preparation of hierarchical structured nano-sized/ porous poly (lactic acid) composite fibrous membranes for air filtration. Applied Surface Science, 2015, 356: 1168-1179.

DOI URL |

| [7] |

LIU X, MARTIN C L, BOUVARD D, et al. Strength of highly porous ceramic electrodes. Journal of the American Ceramic Society, 2011, 94(10): 3500-3508.

DOI URL |

| [8] |

HUO W, ZHANG X, CHEN Y, et al. Mechanical strength of highly porous ceramic foams with thin and lamellate cell wall from particle-stabilized foams. Ceramics International, 2018, 44(5): 5780-5784.

DOI URL |

| [9] |

SAUCEDO M L, LOWE T, ZHAO S, et al. In situ observation of mechanical damage within a SiC-SiC ceramic matrix composite. Journal of Nuclear Materials, 2016, 481: 13-23.

DOI URL |

| [10] |

SONG C, LIU X, YE F, et al. Mechanical and dielectric properties of SiCf/BN/SiBCN composites via different synthesis technologies. Journal of the European Ceramic Society, 2019, 39(14): 4417-4423.

DOI URL |

| [11] |

WANG H, ZHOU X, YU J, et al. Fabrication of SiCf/SiC composites by chemical vapor infiltration and vapor silicon infiltration. Materials Letters, 2010, 64(15): 1691-1693.

DOI URL |

| [12] |

WONG E W, SHEEHAN P E, LIEBER C M. Nanobeam mechanics: elasticity, strength, and toughness of nanorods and nanotubes. Science, 1997, 277(5334): 1971-1975.

DOI URL |

| [13] |

ZHANG Y, HAN X, ZHENG K, et al. Direct observation of super- plasticity of beta-SiC nanowires at low temperature. Advanced Functional Materials, 2007, 17(17): 3435-3440.

DOI URL |

| [14] |

VIVEKCHAND S R C, RAMAMURTY U, RAO C N R. Mechanical properties of inorganic nanowire reinforced polymer-matrix composites. Nanotechnology, 2006, 17(11):344-S350.

DOI URL |

| [15] |

XIN L, YANG W, ZHAO Q, et al. Strengthening behavior in SiC nanowires reinforced pure Al composite. Journal of Alloys and Compounds, 2017, 695: 2406-2412.

DOI URL |

| [16] | SHEN Q L, LI H J, LI L, et al. SiC nanowire reinforced carbon/ carbon composites with improved interlaminar strength. Materials Science and Engineering: A, 2016, 651: 583-589. |

| [17] | DONG L H, ZHANG H J, ZHANG J, et al. Carbon nanotube modified sepiolite porous ceramics for high-efficient oil/water separation. Journal of Inorganic Materials, 2020, 35(6): 689-696. |

| [18] |

ZHANG K J, YADAV A, KIM K H, et al. Thermal and electrical transport in ultralow density single-walled carbon nanotube networks. Advanced Materials, 2013, 25(21): 2926-2931.

DOI URL |

| [19] | ZHAO X, HUANG C, LIU Q, et al. Thermal conductivity model for nanofiber networks. Journal of Applied Physics, 2018, 123(8): 085103-1-10. |

| [20] |

MA R, CHENG X, YE W. SiC fiber and yttria-stabilized zirconia composite thick thermal barrier coatings fabricated by plasma spray. Applied Surface Science, 2015, 357: 407-412.

DOI URL |

| [21] |

ZHUANG L, FU Q G, LIU T Y, et al. In-situ PIP-SiC NWs- toughened SiC-CrSi2-Cr3C2-MoSi2-Mo2C coating for oxidation protection of carbon/carbon composites. Journal of Alloys and Compounds, 2016, 675: 348-354.

DOI URL |

| [22] |

CHU Y, LI H, FU Q, et al. Toughening by SiC nanowires in a dense SiC-Si ceramic coating for oxidation protection of C/C composites. Journal of the American Ceramic Society, 2012, 95(11): 3691-3697.

DOI URL |

| [23] |

WANG D, XUE C, BAI H, et al. Silicon carbide nanowires grown on graphene sheets. Ceramics International, 2015, 41(4): 5473-5477.

DOI URL |

| [24] |

NGUYEN V H, DELBARI S A, AHMADI Z, et al. Electron microscopy characterization of porous ZrB2-SiC-AlN composites prepared by pressureless sintering. Ceramics International, 2020, 46(16): 25415-25423.

DOI URL |

| [25] |

LI X, YAO D, ZUO K, et al. Microstructure and permeability of porous YSZ ceramics fabricated by freeze casting of oil-in-water suspension. Journal of the European Ceramic Society, 2020, 40(15): 5845-5851.

DOI URL |

| [26] | FITZER E, HEGEN D. Chemical vapor-deposition of silicon- carbide and silicon-nitride-chemistrys contribution to modern silicon ceramics. Angewandte ChemieInternational Edition, 1979, 18(4): 295-304. |

| [27] | NASLAIN R, ROSSGNOL J Y, HAGENMULLER P, et al. Synthesis and properties of new composite-materials for high-temperature applications based on carbon-fibers and C-SiC or C-TiC hybrid matrices. Revue De ChimieMinerale, 1981, 18(5): 544-564. |

| [28] |

RUAN J, YANG J S, DONG S M, et al. Interfacial optimization of SiC nanocomposites reinforced by SiC nanowires with high volume fraction. Journal of the American Ceramic Society, 2019, 102(9): 5033-5037.

DOI URL |

| [29] | ZHU Y, ZHANG Y, YAN L S. Interface between multi-layered CVD SiC coating and its graphite substrate. Equipment Environmetal Engineering, 2019, 16(10): 59-63. |

| [30] |

CHIN J, GANTZEL P K, HUDSON R G. The structure of chemical vapor deposition sillicon carbide. Thin Solid Films, 1977, 40: 57-72.

DOI URL |

| [31] |

MASLOV M M, OPENOV L A, PODILIVAEV A I. On the vineyard formula for the pre-exponential factor in the Arrhenius law. Physics of the Solid State, 2014, 56(6): 1239-1244.

DOI URL |

| [32] |

TIEGS T N. Fission product Pd-SiC interaction in irradiated coated-particle fuels. Nuclear Technology, 2017, 57(3): 389-398.

DOI URL |

| [33] |

KINGON A I, LUTZ L J, LIAW P, et al. Thermodynamic calculations for the chemical vapor deposition of silicon carbide. Journal of the American Ceramic Society, 1983, 66(8): 558-566.

DOI URL |

| [34] |

KAZUO M, KOUSAKU F. Structure of chemically vapour deposited silicon carbide for coated fuel particles. Journal of Materials Science, 1998, 23: 699-706.

DOI URL |

| [35] |

BYUNG J C, DONG W P, DAI R K. Chemical vapour deposition of silicon carbide by pyrolysis of methylchlorosilanes. Journal of Materials Science Letters, 1997, 16: 33-36.

DOI URL |

| [36] |

HAN D Y, MEI H, XIAO S S, et al. Porous SiCnw/SiC ceramics with unidirectionally aligned channels produced by freeze-drying and chemical vapor infiltration. Journal of the European Ceramic Society, 2017, 37(3): 915-921.

DOI URL |

| [37] |

KANG E S, KIM Y W, NAM H. Multiple thermal resistance induced extremely low thermal conductivity in porous SiC-SiO2 ceramics with hierarchical porosity. Journal of the European Ceramic Society, 2021, 41(2): 1171-1180.

DOI URL |

| [38] |

KULTAYEVA S, KIM Y W, SONG I H. Effects of dopants on electrical, thermal, and mechanical properties of porous SiC ceramics. Journal of the European Ceramic Society, 2021, 41(7): 4006-4015.

DOI URL |

| [39] | DEY A, KAYAL N, CHAKRABARTI O, et al. Studies on processing of layered oxide-bonded porous SiC ceramic filter materials. International Journal of Applied Ceramic Technology, 2021, 18(3): 869-879. |

| [40] |

QI Y S, JIANG K, ZHOU C L, et al. Preparation and properties of high-porosity ZrB2-SiC ceramics by water-based freeze casting. Journal of the European Ceramic Society, 2021, 41(4): 2239-2246.

DOI URL |

| [41] |

RAJPOOT S, HA J H, KIMY W. Effects of initial particle size on mechanical, thermal, and electrical properties of porous SiC ceramics. Ceramics International, 2021, 47(6): 8668-8676.

DOI URL |

| [1] | MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing. Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching [J]. Journal of Inorganic Materials, 2024, 39(8): 929-936. |

| [2] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [3] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [4] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [5] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [6] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [7] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [8] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [9] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [10] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [11] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [12] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [13] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [14] | WANG Haoxuan, LIU Qiaomu, WANG Yiguang. Research Progress of High Entropy Transition Metal Carbide Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 355-364. |

| [15] | SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun. Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic [J]. Journal of Inorganic Materials, 2021, 36(4): 405-410. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||