Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (5): 561-568.DOI: 10.15541/jim20220555

Special Issue: 【结构材料】陶瓷基复合材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Shuo( ), FU Qiangang(

), FU Qiangang( ), ZHANG Pei, FEI Jie, LI Wei

), ZHANG Pei, FEI Jie, LI Wei

Received:2022-09-22

Revised:2022-11-21

Published:2022-12-09

Online:2022-12-09

Contact:

FU Qiangang, professor. E-mail: fuqiangang@nwpu.edu.cnAbout author:ZHANG Shuo (1994-), female, PhD candidate. E-mail: shuozhang@mail.nwpu.edu.cn

Supported by:CLC Number:

ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites[J]. Journal of Inorganic Materials, 2023, 38(5): 561-568.

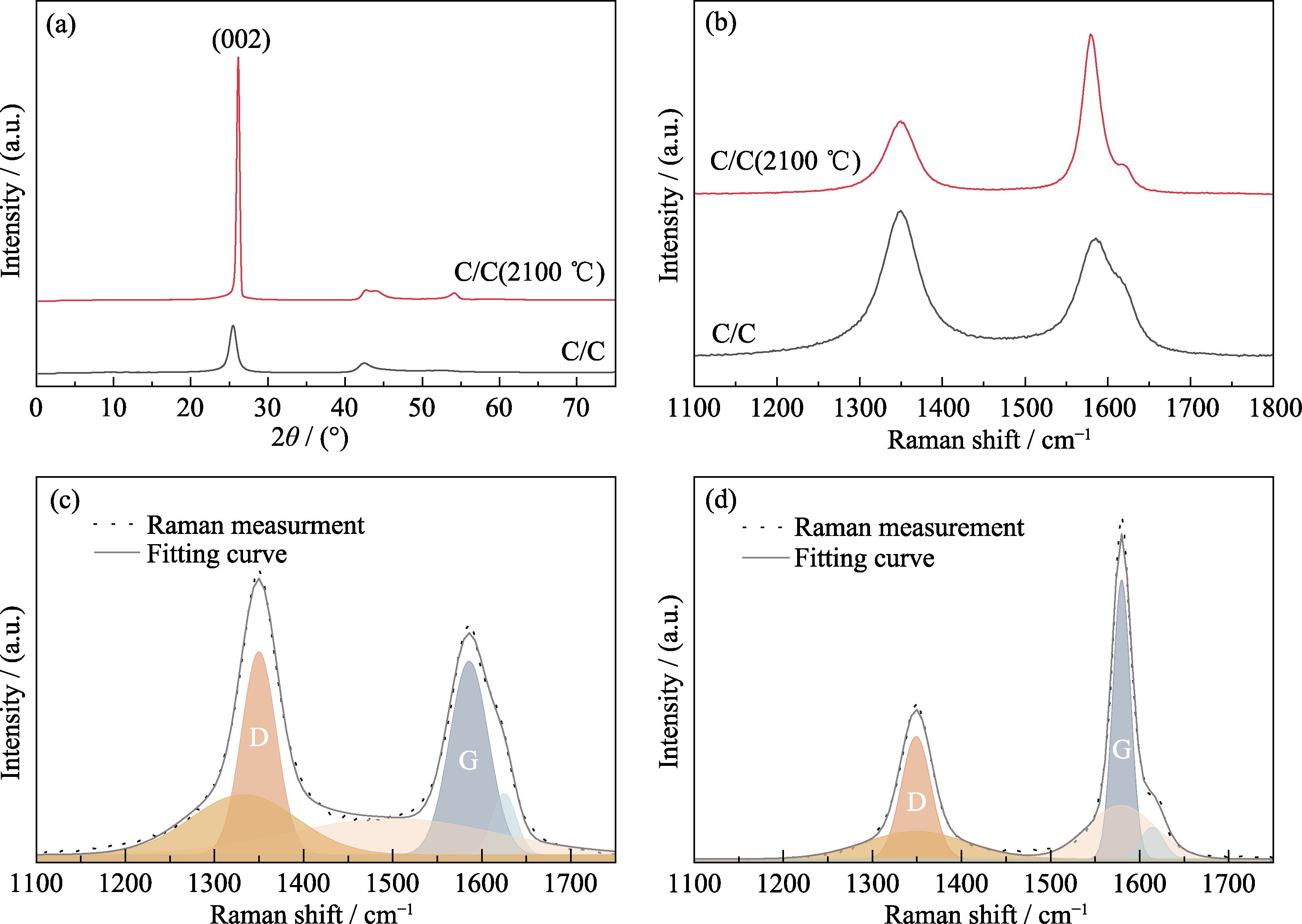

Fig. 2 Analysis of PyC crystal in porous C/C preform (a) XRD patterns; (b) Raman spectra; (c, d) Raman fitting spectra of (c) sample C/C and (d) sample C/C (2100 ℃)

| Sample | 2θC(002)/(°) | g/% | ID/IG | AG/AT |

|---|---|---|---|---|

| C/C | 25.501 | -60.93 | 1.19 | 0.20 |

| C/C(2100 ℃) | 26.162 | 41.74 | 0.44 | 0.31 |

Table 1 XRD diffraction peaks, graphitization degrees, and Raman spectral fitting results of porous C/C preform

| Sample | 2θC(002)/(°) | g/% | ID/IG | AG/AT |

|---|---|---|---|---|

| C/C | 25.501 | -60.93 | 1.19 | 0.20 |

| C/C(2100 ℃) | 26.162 | 41.74 | 0.44 | 0.31 |

| Sample | Density/(g·cm-3) | Porosity /% |

|---|---|---|

| C/C | 1.45 | 18.9 |

| C/C(2100 ℃) | 1.41 | 21.9 |

| C/C-SiC | 2.13 | 5.1 |

| C/C(2100 ℃)-SiC | 2.22 | 3.4 |

Table 2 Densities and porosities of the C/C and C/C-SiC composites

| Sample | Density/(g·cm-3) | Porosity /% |

|---|---|---|

| C/C | 1.45 | 18.9 |

| C/C(2100 ℃) | 1.41 | 21.9 |

| C/C-SiC | 2.13 | 5.1 |

| C/C(2100 ℃)-SiC | 2.22 | 3.4 |

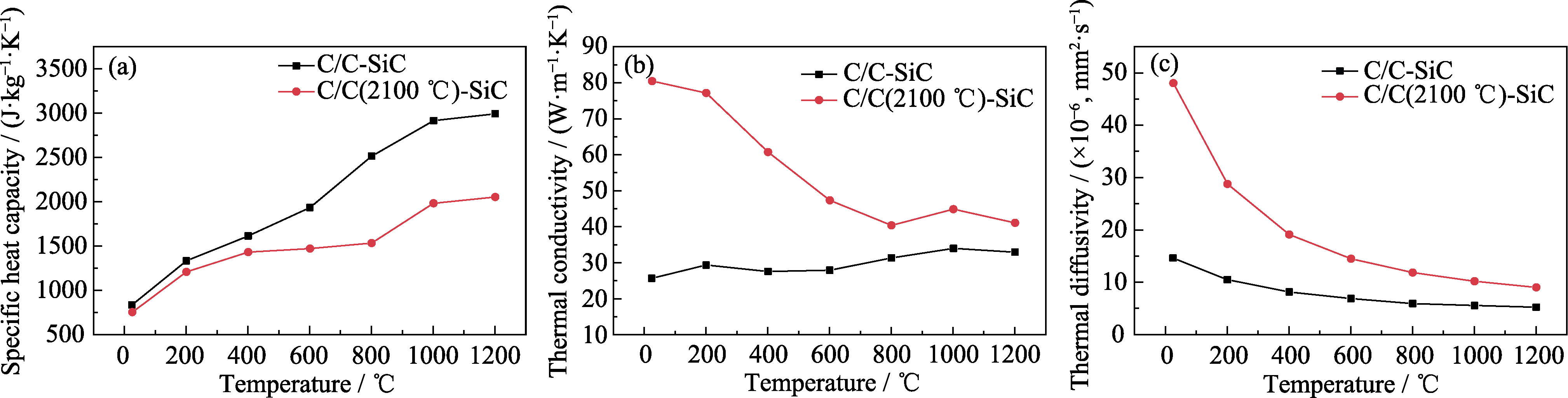

Fig. 5 Relations of thermal properties to temperature of C/C-SiC composites on Z direction (a) Specific heat capacity; (b) Thermal conductivity; (c) Thermal diffusivity

Fig. 7 SEM images of C/C-SiC composites grinding defect under different loads (a-c) Sample C/C-SiC under (a) 3 N, (b) 6 N, (c) 9 N loads; (d-f) Sample C/C(2100 ℃)-SiC under (d) 3 N, (e) 6 N, (f) 9 N loads

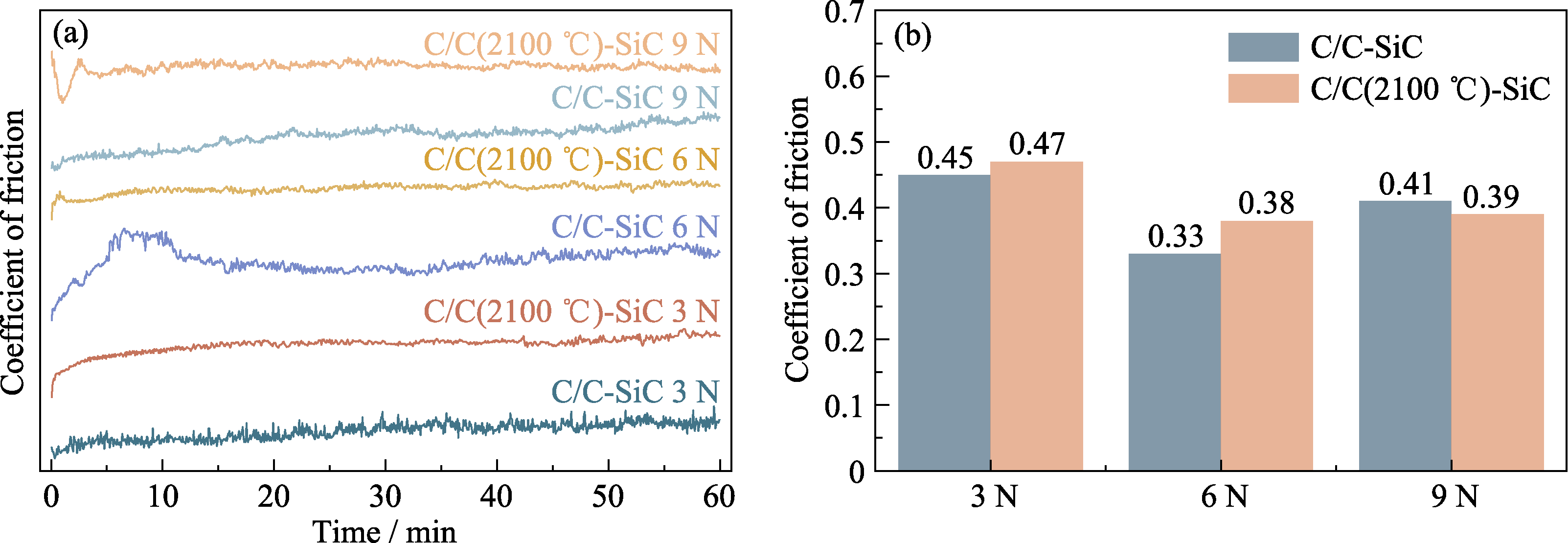

Fig. 6 Friction coefficient of C/C-SiC composites (a) Variation of friction coefficient with time under different loads; (b) Average coefficient of friction under different loads

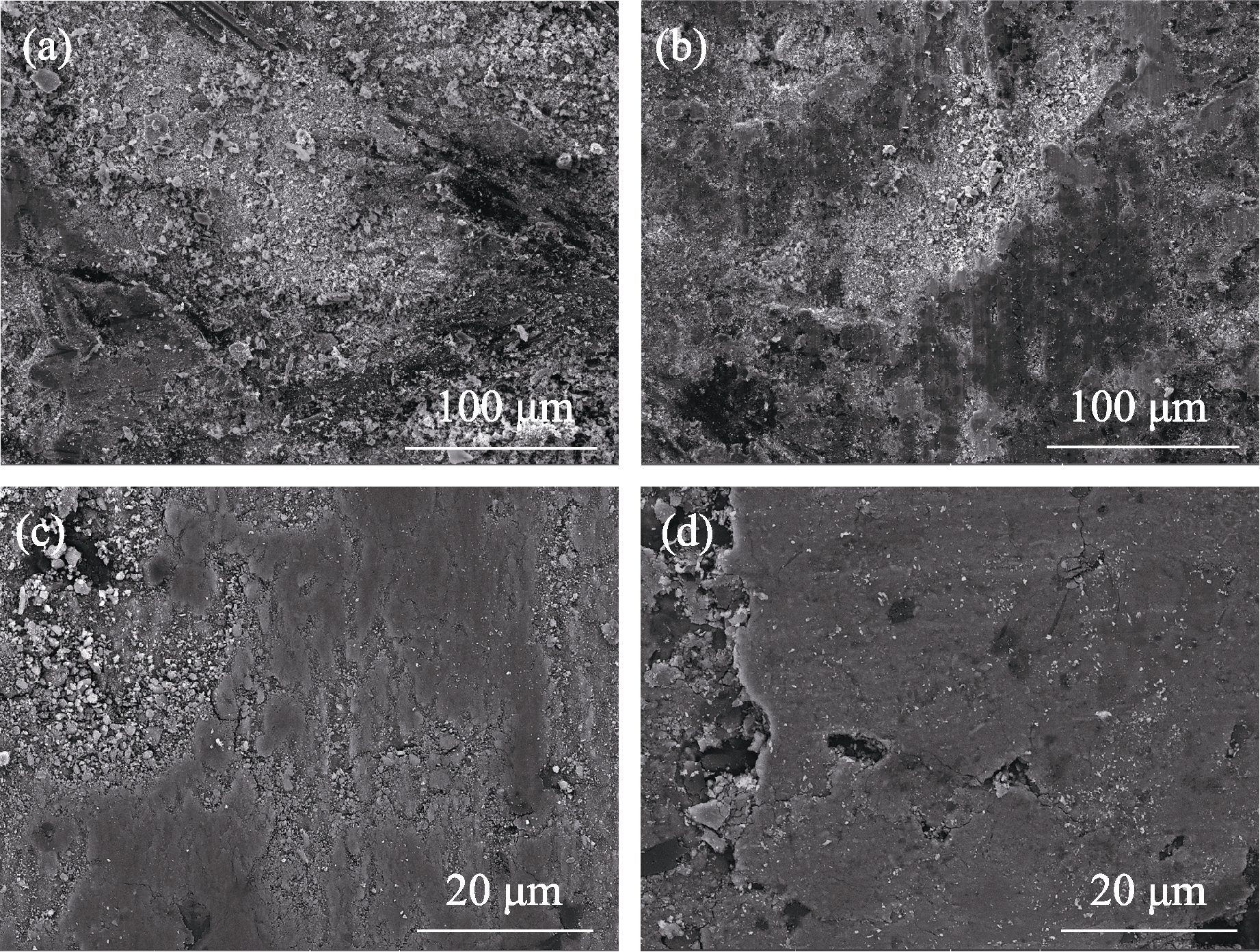

Fig. 9 SEM images of C/C-SiC composites grinding defect under different loads (a, b) Sample C/C-SiC under (a) 3 N, (b) 9 N loads; (c, d) Sample C/C(2100 ℃)-SiC under (c) 3 N, (d) 9 N loads

| [1] |

DUAN J, ZHANG M, CHEN P, et al. Tribological behavior and applications of carbon fiber reinforced ceramic composites as high-performance frictional materials. Ceramics International, 2021, 47(14): 19271.

DOI URL |

| [2] |

WANG Z, HAN J, DOMBLESKY J P, et al. Crack propagation and microstructural transformation on the friction surface of a high-speed railway brake disc. Wear, 2019, 428-429: 45.

DOI URL |

| [3] |

LI Z, XIAO P, ZHANG B G, et al. Preparation and tribological properties of C/C-SiC brake composites modified by in situ grown carbon nanofibers. Ceramics International, 2015, 41(9): 11733.

DOI URL |

| [4] |

XU J, GUO L, WANG H, et al. Influence of graphitization temperature on microstructure and mechanical property of C/C-SiC composites with highly textured pyrolytic carbon. Journal of the European Ceramic Society, 2022, 42(5): 1893.

DOI URL |

| [5] |

FU Q G, ZHNAG P, ZHUANG L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science and Technology, 2021, 96: 31.

DOI URL |

| [6] |

KRENKEL W, HEIDENREICH B, RENZ R. C/C-SiC composites for advanced friction systems. Advanced Engineering Materials, 2009, 4(7): 427.

DOI URL |

| [7] |

ZHOU H J, DONG S M, HE P, et al. Tribological behaviors and anti-wear mechanisms of carbon/carbon-silicon carbide composites. Journal of Inorganic Materials, 2013, 28(10): 1057.

DOI URL |

| [8] |

BERNDT W K. C/C-SiC composites for space applications and advanced friction systems. Materials Science and Engineering: A, 2005, 412: 177.

DOI URL |

| [9] |

KUMAR P, SRIVASTAVA V K. Tribological behaviour of C/C-SiC composites-a review. Journal of Advanced Ceramics, 2016, 5(1): 1.

DOI URL |

| [10] |

ALMEIDA R, LI Y, BSESER B, et al. Damage analysis of 2.5D C/C-SiC composites subjected to fatigue loadings. Journal of the European Ceramic Society, 2019, 39(7): 2244.

DOI |

| [11] |

REN J J, LI K Z, ZHANG S Y, et al. Preparation of carbon/carbon composite by pyrolysis of ethanol and methane. Materials and Design, 2015, 65: 174.

DOI URL |

| [12] | 李贺军, 史小红, 沈庆凉, 等. 国内C/C复合材料研究进展. 中国有色金属学报, 2019, 29(9): 13. |

| [13] | SUN J J, LI H J, HAN L Y, et al. Enhancing both strength and toughness of carbon/carbon composites by heat-treated interface modification. Journal of Materials Science & Technology, 2019, 35(3): 383. |

| [14] | 王静. 近零膨胀C/C-SiC复合材料的反应烧结法制备及性能研究. 长沙: 国防科学技术大学硕士学位论文, 2013. |

| [15] |

LI W, LI H J, WANG J, et al. Preparation and mechanical properties of carbon/carbon composites with high textured pyrolytic carbon matrix. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 2129.

DOI URL |

| [16] | 虎琳, 李崇俊, 张永辉. C/C多孔体热处理温度对C/C-SiC复合材料微观结构和热学性能的影响. 炭素, 2018(1): 18. |

| [17] |

周蕊, 韩文静, 施伟伟. 高温热处理对C/C复合刹车材料摩擦磨损性能影响的研究. 复合材料科学与工程, 2021(3): 112.

DOI |

| [18] |

WANG T, LI H, ZHANG S, et al. The effect of microstructural evolution on micromechanical behavior of pyrolytic carbon after heat treatment. Diamond and Related Materials, 2020, 103: 107729.

DOI URL |

| [19] |

DENG P, LI P, XIAO P, et al. Oxidation behaviour of C/C-SiC brake discs tested on full-scale bench rig. Ceramics International, 2021, 47(24): 34783.

DOI URL |

| [20] |

PIAO Y, TONDARE V N, DAVIS C S, et al. Comparative study of multiwall carbon nanotube nanocomposites by Raman, SEM, and XPS measurement techniques. Composites Science and Technology, 2021, 208(80): 108753.

DOI URL |

| [21] | RONG X A, ZW A, ZZ A, et al. Anisotropic tribological behavior of LSI based 2.5D needle-punched carbon fiber reinforced Cf/C-SiC composites. Ceramics International, 2022, 48(15): 21324. |

| [22] | 曾志伟. C/C-SiC复合材料的制备及摩擦性能研究. 长沙: 中南大学硕士学位论文, 2013. |

| [23] |

ZHANG Y H, XIAO Z C, WANG J P, et al. Effect of pyrocarbon content on thermal and frictional properties in C/C preforms of C/C-SiC composites. Wear, 2010, 269(1): 132.

DOI URL |

| [24] | 李专, 肖鹏, 熊翔, 等. C/C-SiC复合材料的导热性能及其影响因素. 中南大学学报: 自然科学版, 2013, 44(1): 6. |

| [25] |

KUMAR P, SRIVASTAVA V K. Reciprocating sliding tribology of ceramic fiber composites with variation of laminate orientation and surface conformity. Ceramics International, 2017, 44(5): 5365.

DOI URL |

| [26] |

FOUQUET S, ROLLIN M, PAILLER R, et al. Tribological behaviour of composites made of carbon fibres and ceramic matrix in the Si-C system. Wear, 2008, 264(9/10): 850.

DOI URL |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| [3] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [4] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [5] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [6] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [7] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [8] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [9] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [10] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [11] | CHENG Weijie, WANG Minglei, LIN Guoqiang. Composition, Structure and Properties of CrAlN-DLC Hard Composite Films Deposited by Arc Ion Plating [J]. Journal of Inorganic Materials, 2022, 37(7): 764-772. |

| [12] | CHEN Junyun, SUN Lei, JIN Tianye, LUO Kun, ZHAO Zhisheng, TIAN Yongjun. Binderless Layered BN Toughened cBN for Ultra-precision Cutting [J]. Journal of Inorganic Materials, 2022, 37(6): 623-628. |

| [13] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [14] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [15] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||