Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (9): 959-966.DOI: 10.15541/jim20200705

• RESEARCH ARTICLE • Previous Articles Next Articles

WANG Weide1,2( ), CHEN Huanbei3, LI Shishuai1,2, YAO Dongxu1(

), CHEN Huanbei3, LI Shishuai1,2, YAO Dongxu1( ), ZUO Kaihui1, ZENG Yuping1

), ZUO Kaihui1, ZENG Yuping1

Received:2020-12-08

Revised:2021-01-31

Published:2021-09-20

Online:2021-03-01

Contact:

YAO Dongxu, associate professor. E-mail: yaodongxu@mail.sic.ac.cn

About author:WANG Weide, PhD candidate. E-mail: wangweide@student.sic.ac.cn

Supported by:CLC Number:

WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive[J]. Journal of Inorganic Materials, 2021, 36(9): 959-966.

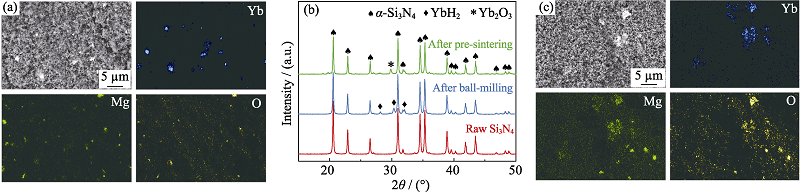

Fig. 1 (a) Elemental distributions of YbHM after ball milling, (b) XRD patterns of α-Si3N4 raw powder, YbHM after ball milling, and YbHM after pre-sintering, (c) elemental distributions of YbHM after pre-sintering

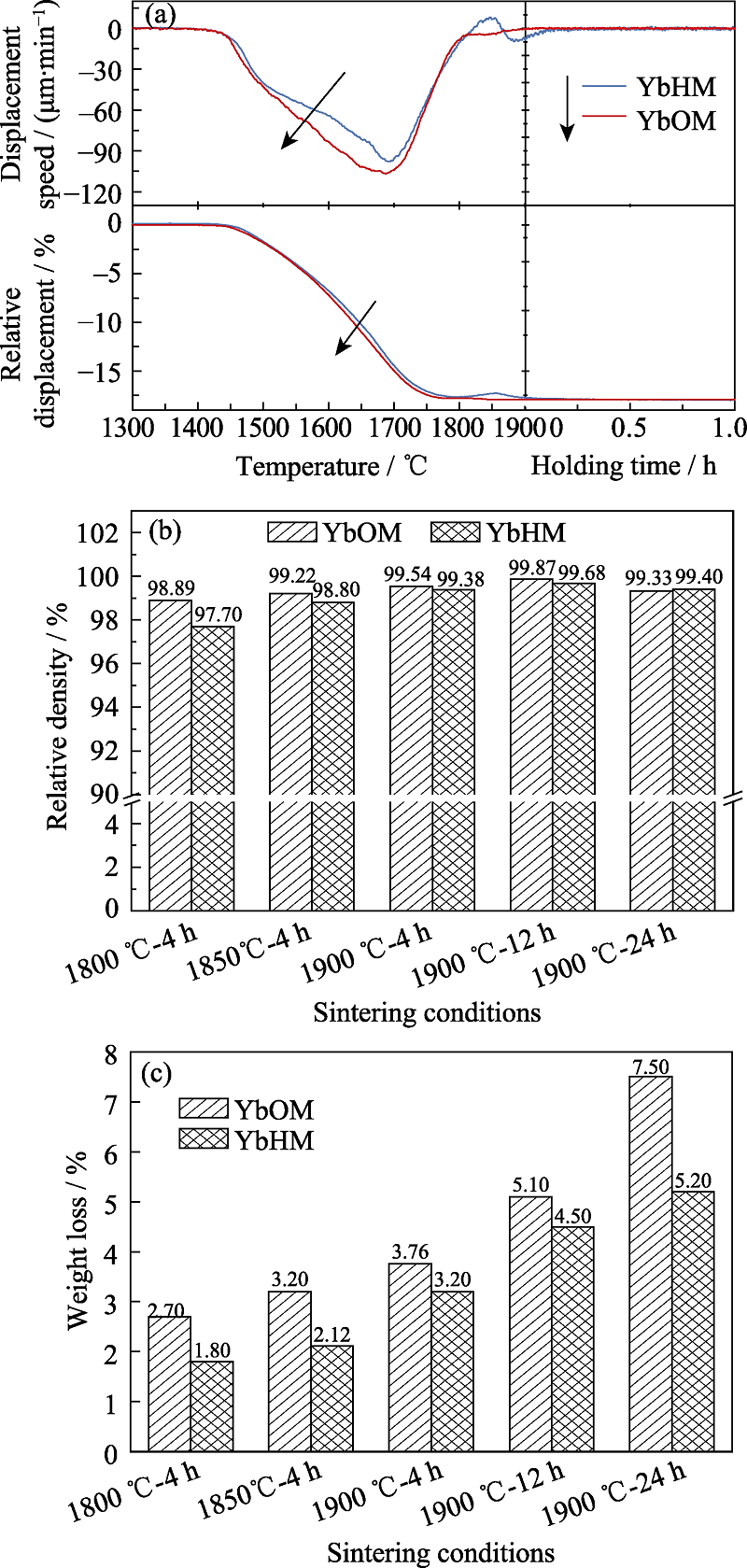

Fig. 3 (a) In-situ observation of shrinkage behaviors of the Si3N4 ceramics, (b) relative density after gas-pressure sintering, and (c) weight loss after gas-pressure sintering

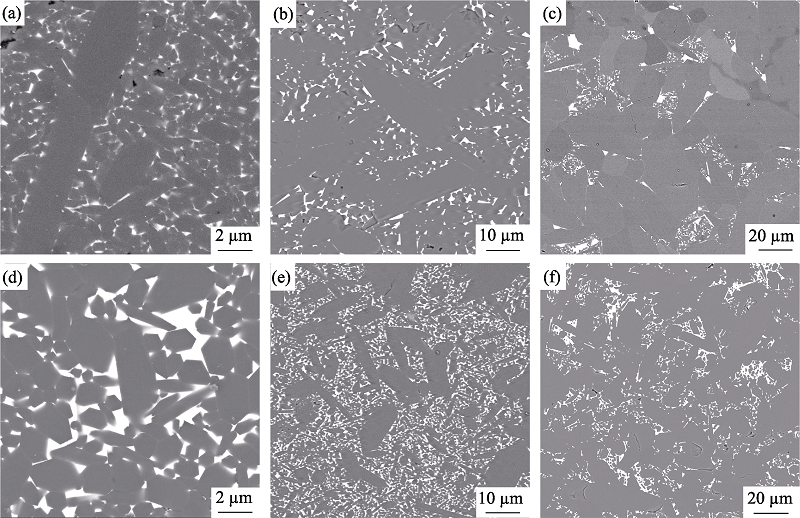

Fig. 6 SEM images of the polished surfaces (a) 1900 ℃-4 h-YbHM; (b) 1900 ℃-12 h-YbHM; (c) 1900 ℃-24 h-YbHM; (d) 1900 ℃-4 h-YbOM; (e) 1900 ℃-12 h-YbOM; (f) 1900 ℃-24 h-YbOM

| Additive | Ionic radius /nm | Annealing time at 1900 ℃/h | Thermal conductivity /(W·m-1·K-1) |

|---|---|---|---|

| GdH2 [ | 0.094 | 4 h | 98.07 |

| 12 h | 119.07 | ||

| 24 h | 134.90 | ||

| YH2 [ | 0.089 | 4 h | 101.80 |

| 12 h | 123.00 | ||

| 24 h | 131.60 | ||

| YbH2 | 0.086 | 4 h | 100.20 |

| 12 h | 118.90 | ||

| 24 h | 131.15 |

Table 1 Thermal conductivities of Si3N4 doped with different rare-earth hydride

| Additive | Ionic radius /nm | Annealing time at 1900 ℃/h | Thermal conductivity /(W·m-1·K-1) |

|---|---|---|---|

| GdH2 [ | 0.094 | 4 h | 98.07 |

| 12 h | 119.07 | ||

| 24 h | 134.90 | ||

| YH2 [ | 0.089 | 4 h | 101.80 |

| 12 h | 123.00 | ||

| 24 h | 131.60 | ||

| YbH2 | 0.086 | 4 h | 100.20 |

| 12 h | 118.90 | ||

| 24 h | 131.15 |

| [1] |

EDDY C, GASKILL D. Silicon carbide as a platform for power electronics. Science, 2009, 324(5933):1398-1400.

DOI URL |

| [2] | OKUMURA H. Present status and future prospect of widegap semiconductor high-power devices. Japanese Journal of Applied Physics Part 1-Regular Papers Brief Communications & Review Papers, 2006, 45(10A):7565-7586. |

| [3] |

RILEY F L. Silicon nitride and related materials. Journal of the American Ceramic Society, 2000, 83(2):245-265.

DOI URL |

| [4] |

KRSTIC Z, KRSTIC V D. Silicon nitride: the engineering material of the future. Journal of Materials Science, 2012, 47(2):535-552.

DOI URL |

| [5] | HAGGERTY J S, LIGHTFOOT A. Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing. Ceramic Engineering and Science Proceedings, 1995, 16(4):475-487. |

| [6] |

KITAYAMA M, HIRAO K, TORIYAMA M, et al. Thermal conductivity of β-Si3N4: I, effects of various microstructural factors. Journal of the American Ceramic Society, 1999, 82(11):3105-3112.

DOI URL |

| [7] |

KITAYAMA M, HIRAO K, TSUGE A, et al. Thermal conductivity of β-Si3N4: II, Effect of lattice oxygen. Journal of the American Ceramic Society, 2000, 83(8):1985-1992.

DOI URL |

| [8] |

ZHU X W, ZHOU Y, HIRAO K. Effects of processing method and additive composition on microstructure and thermal conductivity of Si3N4 ceramics. Journal of the European Ceramic Society, 2006, 26(4/5):711-718.

DOI URL |

| [9] |

ZHOU Y, HYUGA H, KUSANO D, et al. A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39):4563-4567.

DOI URL |

| [10] |

KIM H D, HAN B D, PARK D S, et al. Novel two-step sintering process to obtain a bimodal microstructure in silicon nitride. Journal of the American Ceramic Society, 2002, 85(1):245-252.

DOI URL |

| [11] |

LI Y S, KIM H N, WU H B, et al. Enhanced thermal conductivity in Si3N4 ceramic by addition of a small amount of carbon. Journal of the European Ceramic Society, 2019, 39(2/3):157-164.

DOI URL |

| [12] |

WANG W, YAO D, LIANG H, et al. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. Journal of the European Ceramic Society, 2020, 41(2):1735-1738.

DOI URL |

| [13] |

LIANG H, WANG W, ZUO K, et al. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceramics International, 2020, 46(11):17776-17783.

DOI URL |

| [14] |

LIANG H, WANG W, ZUO K, et al. YB2C2: a new additive for fabricating Si3N4 ceramics with superior mechanical properties and medium thermal conductivity. Ceramics International, 2020, 46(4):5239-5243.

DOI URL |

| [15] |

WANG W, YAO D, CHEN H, et al. ZrSi2-MgO as novel additives for high thermal conductivity of β-Si3N4 ceramics. Journal of the American Ceramic Society, 2020, 103(3):2090-2100.

DOI URL |

| [16] |

WANG W, YAO D, LIANG H, et al. Effect of the binary non-oxide additives on the densification behavior and thermal conductivity of Si3N4 ceramics. Journal of the American Ceramic Society, 2020, 103(10):5891-5899.

DOI URL |

| [17] |

LIANG H, ZENG Y, ZUO K, et al. Mechanical properties and thermal conductivity of Si3N4 ceramics with YF3 and MgO as sintering additives. Ceramics International, 2016, 42(14):15679-15686.

DOI URL |

| [18] |

LEE H M, LEE E B, KIM D L, et al. Comparative study of oxide and non-oxide additives in high thermal conductive and high strength Si3N4 ceramics. Ceramics International, 2016, 42(15):17466-17471.

DOI URL |

| [19] | HU F, ZHAO L, XIE Z P. Silicon nitride ceramics with high thermal conductivity and excellent mechanical properties fabriccated with MgF2 sintering aid and post-sintering heat treatment. Journal of Ceramic Science and Technology, 2016, 7(4):423-428. |

| [20] |

RATZKER B, SOKOL M, KALABUKHOV S, et al. High- pressure spark plasma sintering of silicon nitride with LiF additive. Journal of the European Ceramic Society, 2018, 38(4):1271-1277.

DOI URL |

| [21] |

ZHANG J, CUI W, LI F, et al. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceramics International, 2020, 46(10):15719-15722.

DOI URL |

| [22] |

LI Y, KIM H N, WU H, et al. Enhanced thermal conductivity in Si3N4 ceramic with the addition of Y2Si4N6C. Journal of the American Ceramic Society, 2018, 101(9):4128-4136.

DOI URL |

| [23] |

WANG W, YAO D, LIANG H, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. Journal of the European Ceramic Society, 2020, 40(15):5316-5323.

DOI URL |

| [24] |

WANG W, YAO D, LIANG H, et al. Improved thermal conductivity of β-Si3N4 ceramics by lowering SiO2/Y2O3 ratio using YH2 as sintering additive. Journal of the American Ceramic Society, 2020, 103(10):5567-5572.

DOI URL |

| [25] |

WANG W, YAO D, LIANG H, et al. Improved thermal conductivity of β-Si3N4 ceramics through the modification of the liquid phase by using GdH2 as a sintering additive. Ceramics International, 2020, 47(4):5631-5638.

DOI URL |

| [26] |

WANG W, YAO D, LIANG H, et al. Enhanced thermal conductivity in Si3N4 ceramics prepared by using ZrH2 as an oxygen getter. Journal of Alloys and Compounds, 855:157451.

DOI URL |

| [27] |

LIU Y, LIU Y B, WANG B, et al. Rare earth element: is it a necessity for PM Ti alloys? Key Engineering Materials, 2012, 520:41-48.

DOI URL |

| [28] |

ROBERTSON I, SCHAFFER G. Comparison of sintering of titanium and titanium hydride powders. Powder Metallurgy, 2010, 53(1):12-19.

DOI URL |

| [29] |

ZHU X W, ZHOU Y, HIRAO K. Effect of sintering additive composition on the processing and thermal conductivity of sintered reaction-bonded Si3N4. Journal of the American Ceramic Society, 2004, 87(7):1398-1400.

DOI URL |

| [30] |

LINDSAY R, MOYER R O, THOMPSON J S, et al. Preparation, structure, and properties of ytterbium ruthenium hydride. Inorganic Chemistry, 1976, 15(12):3050-3053.

DOI URL |

| [31] |

HAKEEM A S, DAUCÉ R, LEONOVA E, et al. Silicate glasses with unprecedented high nitrogen and electropositive metal contents obtained by using metals as precursors. Advanced Materials, 2005, 17(18):2214-2216.

DOI URL |

| [32] |

ZHU X W, HAYASHI H, ZHOU Y, et al. Influence of additive composition on thermal and mechanical properties of β-Si3N4 ceramics. Journal of Materials Research, 2004, 19(11):3270-3278.

DOI URL |

| [33] |

KITAYAMA M, HIRAO K, WATARI K, et al. Thermal conductivity of β-Si3N4: III, effect of rare-earth (RE = La, Nd, Cd, Y, Yb, and Sc) oxide additives. Journal of the American Ceramic Society, 2001, 84(2):353-358.

DOI URL |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | JIN Min, MA Yupeng, WEI Tianran, LIN Siqi, BAI Xudong, SHI Xun, LIU Xuechao. Growth and Characterization of Large-size InSe Crystal from Non-stoichiometric Solution via a Zone Melting Method [J]. Journal of Inorganic Materials, 2024, 39(5): 554-560. |

| [3] | WANG Shuling, JIANG Meng, WANG Lianjun, JIANG Wan. n-Type Pb-free AgBiSe2 Based Thermoelectric Materials with Stable Cubic Phase Structure [J]. Journal of Inorganic Materials, 2023, 38(7): 807-814. |

| [4] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [5] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [6] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [7] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [8] | LI Honghua, DONG Wanru, WANG Liang, YANG Zengchao, LI Jiangtao. Consistency of Silicon Nitride Powders Produced by Combustion Synthesis: Evaluation and Application [J]. Journal of Inorganic Materials, 2023, 38(10): 1169-1175. |

| [9] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [10] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [11] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [12] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [13] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [14] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [15] | LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating [J]. Journal of Inorganic Materials, 2022, 37(4): 467-472. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||