Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (10): 1223-1229.DOI: 10.15541/jim20230091

Special Issue: 【结构材料】高导热陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

• RESEARCH LETTER • Previous Articles Next Articles

SUN Xiaofan1,2( ), CHEN Xiaowu1,2, JIN Xihai1,2(

), CHEN Xiaowu1,2, JIN Xihai1,2( ), KAN Yanmei1,2, HU Jianbao1,2, DONG Shaoming1,2(

), KAN Yanmei1,2, HU Jianbao1,2, DONG Shaoming1,2( )

)

Received:2023-02-22

Revised:2023-04-20

Published:2023-10-20

Online:2023-05-15

Contact:

JIN Xihai, professor. E-mail: jinxihai@hotmail.com;About author:SUN Xiaofan (1998-), male, Master candidate. E-mail: 2487801767@qq.com

Supported by:CLC Number:

SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration[J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229.

| Material | Mass percent of LCP/% | Mass percent of HCP/% |

|---|---|---|

| α-Si3N4 | 20.17 | 15.66 |

| Carbon black | 8.65 | 6.71 |

| Phenolic resin | 17.29 | 26.85 |

| Dibutyl phthalate (DBP) | 5.76 | 4.47 |

| Polyvinyl butyral (PVB) | 7.20 | 5.59 |

| Castor oil | 0.58 | 0.45 |

| Ethanol absolute | 40.35 | 40.27 |

Table 1 Chemical composition of the slurries used for different types of C-Si3N4 infiltration preform preparation

| Material | Mass percent of LCP/% | Mass percent of HCP/% |

|---|---|---|

| α-Si3N4 | 20.17 | 15.66 |

| Carbon black | 8.65 | 6.71 |

| Phenolic resin | 17.29 | 26.85 |

| Dibutyl phthalate (DBP) | 5.76 | 4.47 |

| Polyvinyl butyral (PVB) | 7.20 | 5.59 |

| Castor oil | 0.58 | 0.45 |

| Ethanol absolute | 40.35 | 40.27 |

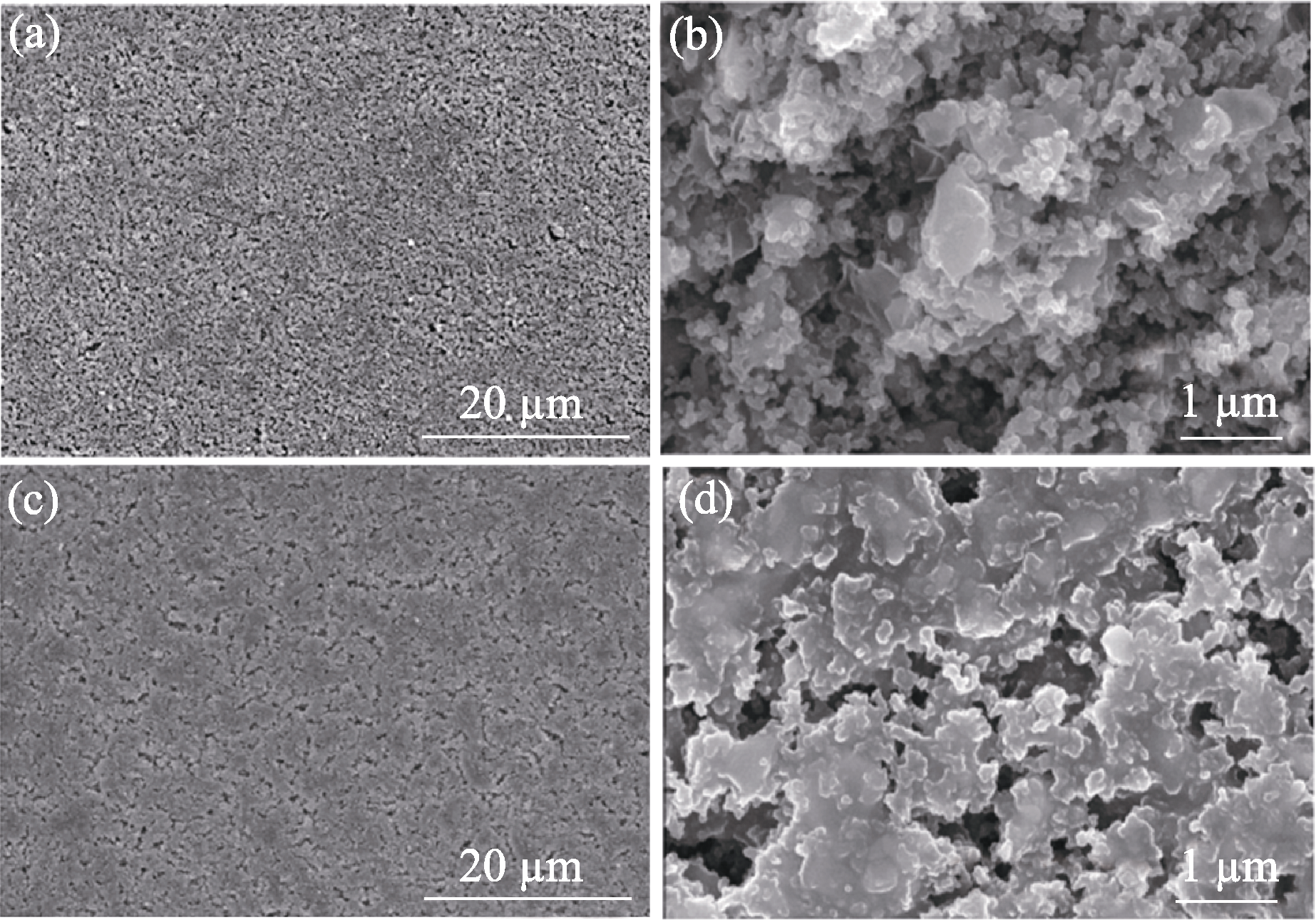

Fig. 1 SEM images of porous C-Si3N4 infiltration preforms with different carbon contents (a, b) Low carbon content preform (LCP); (c, d) High carbon content preform (HCP)

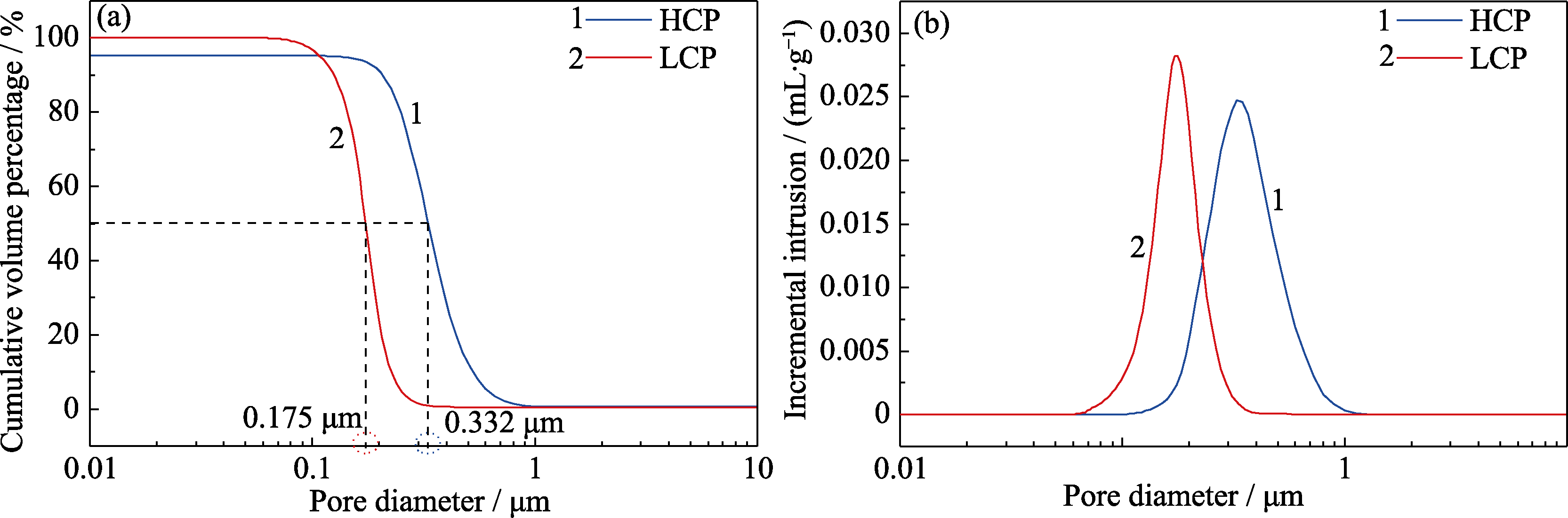

Fig. 2 Mercury porosimetry curves of the C-Si3N4 infiltration preforms with different carbon contents (a) Cumulative volume percentage vs pore diameter; (b) Incremental intrusion vs pore diameter

Fig. 3 SEM image and EDS line scanning of the melt/preform interface region in the post melt infiltrated Si-Al/C-Si3N4 system, using (a, b) Si-Al ingot and (c, d) Si-Al powder as infiltration medium Colorful figures are available on the website

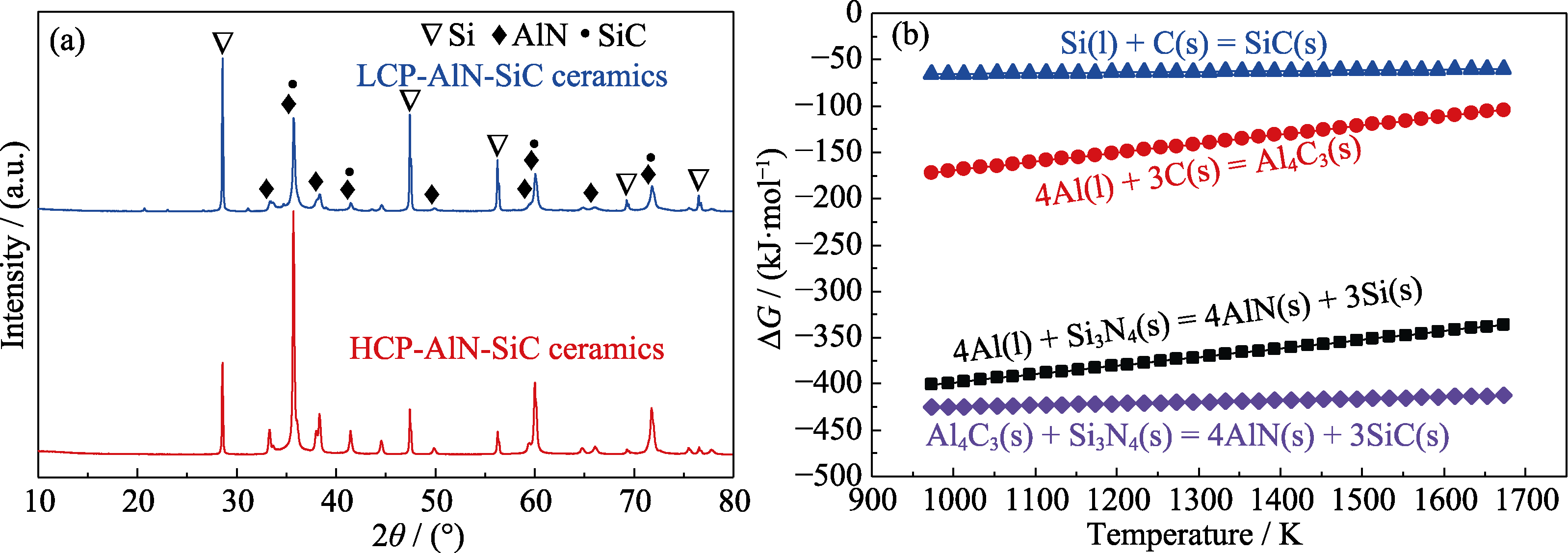

Fig. 4 (a) XRD patterns of AlN-SiC multiphase ceramics prepared from different types of C-Si3N4 preform, and (b) changes of standard Gibbs free energy of reaction (3-6) as a function of temperatures calculated with HSC 6.0 software

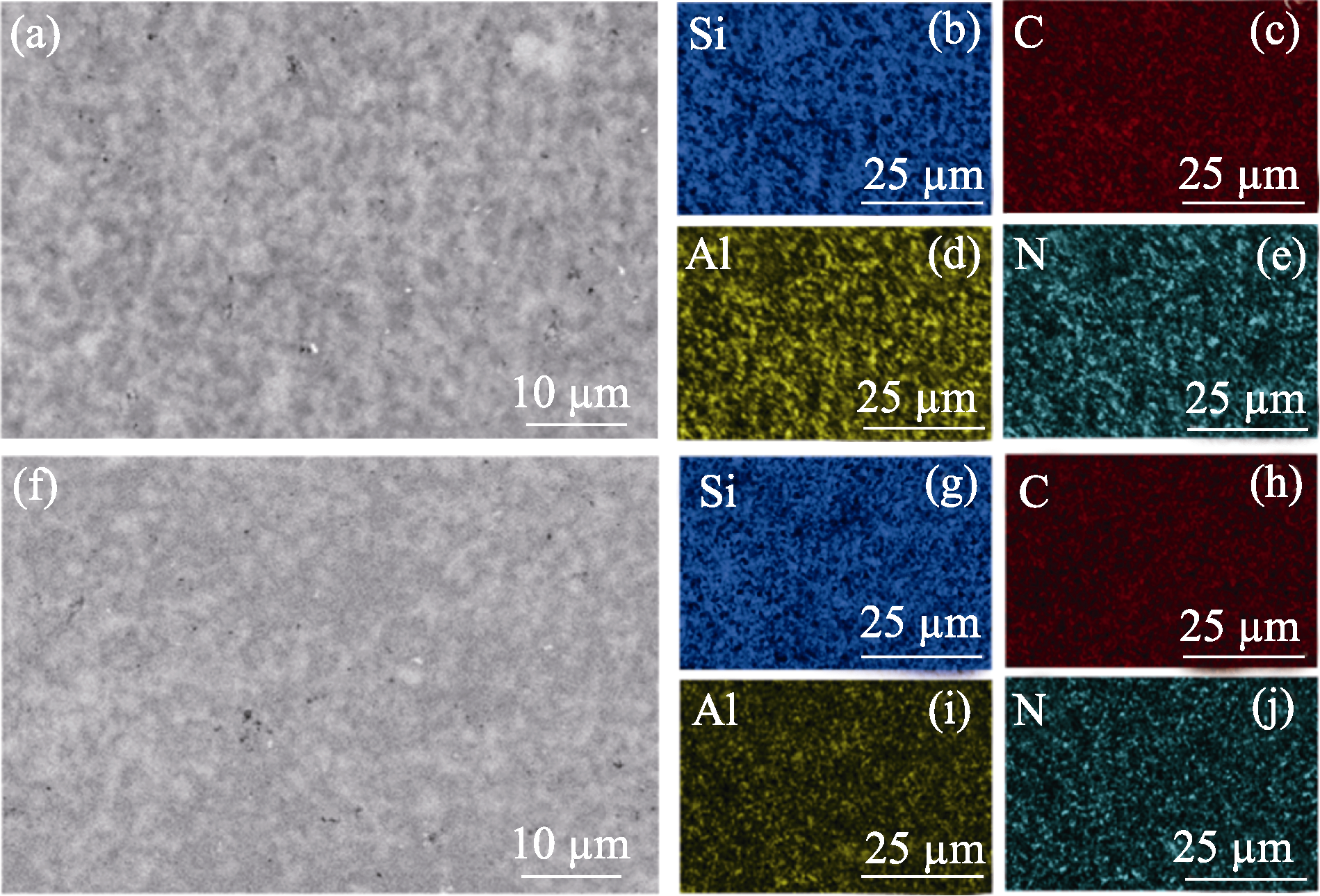

Fig. 5 SEM images of AlN-SiC multiphase ceramics prepared from different C-Si3N4 preforms and their corresponding EDS mapping (a-e) Low carbon content preform; (f-j) High carbon content preform

| Preform type | Bulk density/ (g·cm-3) | Hardness/GPa | Bending strength/MPa |

|---|---|---|---|

| LCP | 2.83 | 12.8±0.2 | 198.3±4.6 |

| HCP | 2.95 | 16.9±0.4 | 320.1±25.1 |

Table 2 Density and mechanical properties of AlN-SiC multiphase ceramics prepared from different types of C-Si3N4 preform

| Preform type | Bulk density/ (g·cm-3) | Hardness/GPa | Bending strength/MPa |

|---|---|---|---|

| LCP | 2.83 | 12.8±0.2 | 198.3±4.6 |

| HCP | 2.95 | 16.9±0.4 | 320.1±25.1 |

| [1] |

SHEN X, LI M, DAI Y, et al. The effects of preparation temperature on the SiCf/SiC 3D4d woven composite. Ceramics International, 2020, 46(9): 13088.

DOI URL |

| [2] |

LIU Y, CHAI N, QIN H, et al. Tensile fracture behavior and strength distribution of SiCf/SiC composites with different SiBN interface thicknesses. Ceramics International, 2015, 41(1): 1609.

DOI URL |

| [3] |

YANG B, ZHOU X, CHAI Y. Mechanical properties of SiCf/SiC composites with PyC and the BN interface. Ceramics International, 2015, 41(5): 7185.

DOI URL |

| [4] |

ZHONG Q, ZHANG X, DONG S, et al. Reactive melt infiltrated Cf/SiC composites with robust matrix derived from novel engineered pyrolytic carbon structure. Ceramics International, 2017, 43(7): 5832.

DOI URL |

| [5] |

CHEN B W, NI D W, WANG J X, et al. Ablation behavior of Cf/ZrC-SiC-based composites fabricated by an improved reactive melt infiltration. Journal of the European Ceramic Society, 2019, 39(15): 4617.

DOI URL |

| [6] | MU Y, ZHOU W, WANG H, et al. Mechanical and dielectric properties of 2.5D SiCf/SiC-Al2O3composites prepared via precursor infiltration and pyrolysis. Materials Science and Engineering: A, 2014, 596: 64. |

| [7] |

SUN X, LIU H, LI J, et al. Effects of CVD SiBCN interphases on mechanical and dielectric properties of SiCf/SiC composites fabricated via a PIP process. Ceramics International, 2016, 42(1): 82.

DOI URL |

| [8] |

WU P, LIU Y, XU S, et al. Mechanical properties and strengthening mechanism of SiCf/SiC mini-composites modified by SiC nanowires. Ceramics International, 2021, 47(2): 1819.

DOI URL |

| [9] | SANTORO U, NOVITSKAYA E, KARANDIKAR K, et al. Phase stability of SiC/SiC fiber reinforced composites: the effect of processing on the formation of α and β phases. Materials Letters, 2019, 241: 123. |

| [10] |

CHEN X, FENG Q, GAO L, et al. Interphase degradation of three-dimensional Cf/SiC-ZrC-ZrB2composites fabricated via reactive melt infiltration. Journal of the American Ceramic Society, 2017, 100(10): 4816.

DOI URL |

| [11] |

CAO X, YIN X, MA X, et al. The microstructure and properties of SiC/SiC-based composites fabricated by low-temperature melt infiltration of Al-Si alloy. Ceramics International, 2016, 42(8): 10144.

DOI URL |

| [12] |

TAO P, WANG Y. Improved thermal conductivity of silicon carbide fibers-reinforced silicon carbide matrix composites by chemical vapor infiltration method. Ceramics International, 2019, 45(2): 2207.

DOI URL |

| [13] | AOKI T, OGASAWARA T, OKUBO Y, et al. Fabrication and properties of Si-Hf alloy melt-infiltrated Tyranno ZMI fiber/SiC- based matrix composites. Composites Part A: Applied Science and Manufacturing, 2014, 66: 155. |

| [14] | AOKI T, OGASAWARA T. Tyranno ZMI fiber/TiSi2-Si matrix composites for high-temperature structural applications. Composites Part A: Applied Science and Manufacturing, 2015, 76: 102. |

| [15] |

GAO Y, LIU Y, WANG J, et al. Formation mechanism of Si-Y-C ceramic matrix by reactive melt infiltration using Si-Y alloy and properties of C/Si-Y-C composites. Ceramics International, 2020, 46(11): 18976.

DOI URL |

| [16] |

LI Z, GUO R, LI L, et al. Improvement in high-temperature oxidation resistance of SiC nanocrystalline ceramics by doping AlN. Ceramics International, 2021, 47(21): 30999.

DOI URL |

| [17] |

FUJII H, NAKAE H, OKADA K. Interfacial reaction wetting in the boron nitride/molten aluminum system. Acta Metallurgica et Materialia, 1993, 41(10): 2963.

DOI URL |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [10] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [11] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [12] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [13] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [14] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [15] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||