Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 393-398.DOI: 10.15541/jim20200391

• RESEARCH PAPER • Previous Articles Next Articles

SUN Yanan1( ), YE Li1, ZHAO Wenying1, CHEN Fenghua1, QIU Wenfeng2, HAN Weijian1, LIU Wei3, ZHAO Tong1(

), YE Li1, ZHAO Wenying1, CHEN Fenghua1, QIU Wenfeng2, HAN Weijian1, LIU Wei3, ZHAO Tong1( )

)

Received:2020-07-13

Revised:2020-10-27

Published:2021-04-20

Online:2020-11-05

Contact:

ZHAO Tong, professor. E-mail: tzhao@iccas.ac.cn

About author:SUN Yanan(1989-), female, PhD candidate. E-mail: sunyanan@iccas.ac.cn

Supported by:CLC Number:

SUN Yanan, YE Li, ZHAO Wenying, CHEN Fenghua, QIU Wenfeng, HAN Weijian, LIU Wei, ZHAO Tong. Synthesis of High Entropy Carbide Nano Powders via Liquid Polymer Precursor Route[J]. Journal of Inorganic Materials, 2021, 36(4): 393-398.

| Item | Metal content/wt% | Yield/ wt% | Viscosity/(mPa∙s) | |

|---|---|---|---|---|

| 1 | 2 | |||

| (Ti, Zr, Hf, Ta)C | 28 | 28.6 | 150 | 162 |

Table 1 Metal content, yield and viscosity of PHEC

| Item | Metal content/wt% | Yield/ wt% | Viscosity/(mPa∙s) | |

|---|---|---|---|---|

| 1 | 2 | |||

| (Ti, Zr, Hf, Ta)C | 28 | 28.6 | 150 | 162 |

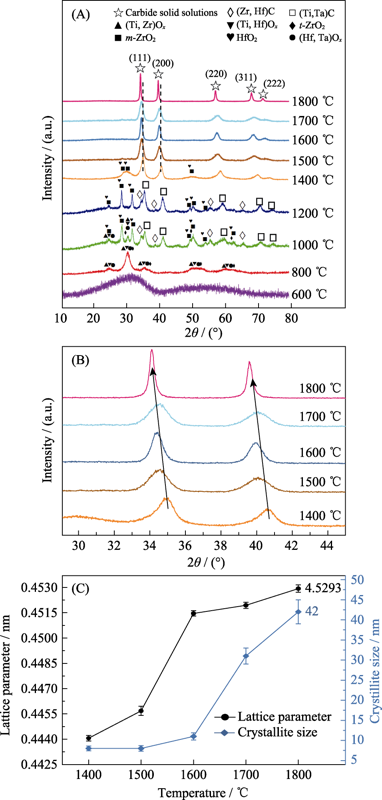

Fig. 5 Characterization of pyrolysis process for PHEC (A) XRD patterns of products pyrolyzed at different temperatures; (B) Enlarged images of XRD patterns of products pyrolyzed at 1400~ 1800 ℃; (C) Lattice parameter and crystallite size of samples pyrolyzed at 1400-1800 ℃

| [1] | YEH JIEN-WEI, CHEN SWE-KAI, LIN SU-JIEN, et al. Nanostructured high-entropy alloys with multiple principal elements:novel alloydesign concepts andoutcomes. Advanced Engineering Materials, 2004,6:299-303. |

| [2] | CANTOR B, CHANG ITH, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A, 2004,377:213-218. |

| [3] | CHEN LEI, WANG KAI, SU WEN-TAO, et al. Research progress of transition metal non-oxide high-entropy ceramics. Journal of Inorganic Materials, 2020,35(7):748-758. |

| [4] | OSES C, TOHER C, CURTAROLO S. High-entropy ceramics. Nature Reviews Materials, 2020,5(4):295-309. |

| [5] | GILD J, ZHANG YUAN-YAO, HARRINGTON T, et al. High- entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 2016,6(1):37946. |

| [6] | ZHANG RUI-ZHI, REECE M J. Review of high entropy ceramics: design, synthesis, structure and properties. Journal of Materials Chemistry A, 2019,7(39):22148-22162. |

| [7] |

SARKER P, HARRINGTON T, TOHER C, et al. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nature Communications, 2018,9(1):4980.

URL PMID |

| [8] | 顾俊峰, 邹冀, 张帆, 等. 高熵陶瓷材料研究进展. 中国材料进展, 2019,38(9):855-886. |

| [9] | YE BEI-LIN, WEN TONG-QI, CHU YAN-HUI. High-temperature oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics in air. Journal of the American Ceramic Society, 2019,103(1):500-507. |

| [10] | YAN XUE-LIANG, CONSTANTIN L, LU YONG-FENG, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491. |

| [11] | ROST C M, BORMAN T, HOSSAIN M D, et al. Electron and phonon thermal conductivity in high entropy carbides with variable carbon content. Acta Materialia, 2020,196:231-239. |

| [12] | CHEN HENG, XIANG HUI-MIN, DAI FU-ZHI, et al. High porosity and low thermal conductivity high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C. Journal of Materials Science & Technology, 2019,35(8):1700-1705. |

| [13] | CSANÁDI T, VOJTKO M, DANKHÁZI Z, et al. Small scale fracture and strength of high-entropy carbide grains during microcantilever bending experiments. Journal of the European Ceramic Society, 2020,40(14):4774-4782. |

| [14] | WEI XIAO-FENG, LIU JI-XUAN, LI FEI, et al. High entropy carbide ceramics from different starting materials. Journal of the European Ceramic Society, 2019,39(10):2989-2994. |

| [15] | PENG CHONG, GAO XIANG, WANG MING-ZHI, et al. Diffusion- controlled alloying of single-phase multi-principal transition metal carbides with high toughness and low thermal diffusivity. Applied Physics Letters, 2019,114(1):011905-1-5. |

| [16] | MOSKOVSKIKH D O, VOROTILO S, SEDEGOV A S, et al. High- entropy (HfTaTiNbZr)C and (HfTaTiNbMo)C carbides fabricated through reactive high-energy ball milling and spark plasma sintering. Ceramics International, 2020,46(11):19008-19014. |

| [17] |

SURE J, SRI MAHA VISHNU D, KIM H K, et al. Facile electrochemical synthesis of nanoscale (TiNbTaZrHf)C high-entropy carbide powder. Angewandte Chemie International Edition, 2020,59(29):11830-11835.

URL PMID |

| [18] | WANG KAI, CHEN LEI, XU CHEN-GUANG, et al. Microstructure and mechanical properties of (TiZrNbTaMo)C high-entropy ceramic. Journal of Materials Science & Technology, 2020,39:99-105. |

| [19] | CHICARDI E, GARCÍA-GARRIDO C, GOTOR F J. Low temperature synthesis of an equiatomic (TiZrHfVNb)C5 high entropy carbide by a mechanically-induced carbon diffusion route. Ceramics International, 2019,45(17):21858-21863. |

| [20] |

CHICARDI E, GARCÍA-GARRIDO C, HERNÁNDEZ-SAZ J, et al. Synthesis of all equiatomic five-transition metals high entropy carbides of the IVB (Ti, Zr, Hf) and VB (V, Nb, Ta) groups by a low temperature route. Ceramics International, 2020,46(13):21421-21430.

DOI URL |

| [21] | GILD J, KAUFMANN K, VECCHIO K, et al. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scripta Materialia, 2019,170:106-110. |

| [22] |

CASTLE E, CSANADI T, GRASSO S, et al. Processing and properties of high-entropy ultra-high temperature carbides. Scientific Reports, 2018,8(1):8609.

URL PMID |

| [23] | FENG LUN, FAHRENHOLTZ W G, HILMAS G E, et al. Synthesis of single-phase high-entropy carbide powders. Scripta Materialia, 2019,162:90-93. |

| [24] | YE BEI-LIN, NING SHAN-SHAN, LIU DA, et al. One-step synthesis of coral-like high-entropy metal carbide powders. Journal of the American Ceramic Society, 2019,102(10):6372-6378. |

| [25] | ZHOU JIE-YANG, ZHANG JIN-YONG, ZHANG FAN, et al. High-entropy carbide: a novel class of multicomponent ceramics. Ceramics International, 2018,44(17):22014-22018. |

| [26] | LU YAN, SUN YA-NAN, ZHANG TU-ZI, et al. Polymer-derived Ta4HfC5 nanoscale ultrahigh-temperature ceramics: synthesis, microstructure and properties. Journal of the European Ceramic Society, 2019,39(2/3):205-211. |

| [27] | SUN YA-NAN, YANG CHUN-MING, LU YAN, et al. Transformation of metallic polymer precursor into nanosized HfTaC2 ceramics. Ceramics International, 2020,46(5):6022-6028. |

| [28] | LI FEI, LU YING, WANG XIN-GANG, et al. Liquid precursor- derived high-entropy carbide nanopowders. Ceramics International, 2019,45(17):22437-22441. |

| [29] | LIU HONG-HUA, DU BIN, CHU YAN-HUI. Synthesis of the ternary metal carbide solid-solution ceramics by polymer-derived- ceramic route. Journal of the American Ceramic Society, 2020,103(5):2970-2974. |

| [30] | DU BIN, LIU HONG-HUA, CHU YAN-HUI. Fabrication and characterization of polymer-derived high-entropy carbide ceramic powders. Journal of the American Ceramic Society, 2020,103(8):4063-4068. |

| [31] | LU YAN, YE LI, HAN WEI-JIAN, et al. Synthesis, characterization and microstructure of tantalum carbide-based ceramics by liquid polymeric precursor method. Ceramics International, 2015,41(9):12475-12479. |

| [32] | LIU DAN, CAI TAO, QIU WEN-FENG, et al. Synthesis, characterization, and microstructure of ZrC/SiC composite ceramics via liquid precursor conversion method. Journal of the American Ceramic Society, 2014,97(4):1242-1247. |

| [1] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [2] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | BAO Weichao, GUO Xiaojie, XIN Xiaoting, PENG Pai, WANG Xingang, LIU Jixuan, ZHANG Guojun, XU Fangfang. Establishment of Symbiotic Structure with Metal Atomic-layer Phase-separation in Carbide Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 17-22. |

| [6] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| [7] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [8] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [9] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [10] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [11] | XU Hao, QIAN Wei, HUA Yinqun, YE Yunxia, DAI Fengze, CAI Jie. Effects of Micro Texture Processed by Picosecond Laser on Hydrophobicity of Silicon Carbide [J]. Journal of Inorganic Materials, 2023, 38(8): 923-930. |

| [12] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [13] | GU Xuesu, YIN Jie, WANG Kanglong, CUI Chong, MEI Hui, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics by Binder Jetting Printing [J]. Journal of Inorganic Materials, 2023, 38(12): 1373-1378. |

| [14] | OUYANG Qin, WANG Yanfei, XU Jian, LI Yinsheng, PEI Xueliang, MO Gaoming, LI Mian, LI Peng, ZHOU Xiaobing, GE Fangfang, ZHANG Chonghong, HE Liu, YANG Lei, HUANG Zhengren, CHAI Zhifang, ZHAN Wenlong, HUANG Qing. Research Progress of SiC Fiber Reinforced SiC Composites for Nuclear Application [J]. Journal of Inorganic Materials, 2022, 37(8): 821-840. |

| [15] | CHEN Junyun, SUN Lei, JIN Tianye, LUO Kun, ZHAO Zhisheng, TIAN Yongjun. Binderless Layered BN Toughened cBN for Ultra-precision Cutting [J]. Journal of Inorganic Materials, 2022, 37(6): 623-628. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||