Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (3): 267-273.DOI: 10.15541/jim20230259

Special Issue: 【结构材料】陶瓷基复合材料(202506); 【信息功能】MAX、MXene及其他二维材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

SUN Chuan1( ), HE Pengfei1, HU Zhenfeng1, WANG Rong1, XING Yue1, ZHANG Zhibin1, LI Jinglong1, WAN Chunlei2, LIANG Xiubing1(

), HE Pengfei1, HU Zhenfeng1, WANG Rong1, XING Yue1, ZHANG Zhibin1, LI Jinglong1, WAN Chunlei2, LIANG Xiubing1( )

)

Received:2023-06-02

Revised:2023-07-28

Published:2024-03-20

Online:2023-08-31

Contact:

LIANG Xiubing, professor. E-mail: liangxb_d@163.comAbout author:SUN Chuan (1986-), male, PhD. E-mail: sunchuanyeah@163.com

Supported by:CLC Number:

SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization[J]. Journal of Inorganic Materials, 2024, 39(3): 267-273.

| No. | GNPs content/(%, in vol) | Relative density/% | GNPs average layer spacing/μm | KIC/(MPa·m1/2) | Bending strength/MPa |

|---|---|---|---|---|---|

| G0 | 0 | 99.2 | - | 4.05 | 395 |

| G1 | ~1 | 99.0 | 7.5 | 5.18 | 410 |

| G3 | ~3 | 98.5 | 5.2 | 5.67 | 445 |

| G5 | ~5 | 97.4 | 3.4 | 4.37 | 370 |

Table 1 Basic physical properties of SiC/GNPs composites

| No. | GNPs content/(%, in vol) | Relative density/% | GNPs average layer spacing/μm | KIC/(MPa·m1/2) | Bending strength/MPa |

|---|---|---|---|---|---|

| G0 | 0 | 99.2 | - | 4.05 | 395 |

| G1 | ~1 | 99.0 | 7.5 | 5.18 | 410 |

| G3 | ~3 | 98.5 | 5.2 | 5.67 | 445 |

| G5 | ~5 | 97.4 | 3.4 | 4.37 | 370 |

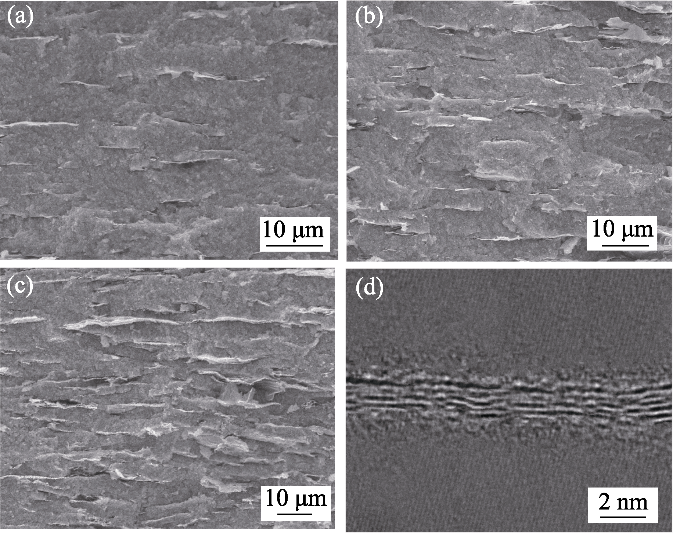

Fig. 4 SEM and TEM images of the fractured surface of SiC/GNPs bulks (a) SEM image of sample G1; (b) SEM image of sample G3; (c) SEM image of sample G5; (d) TEM image of GNP in SiC matrix

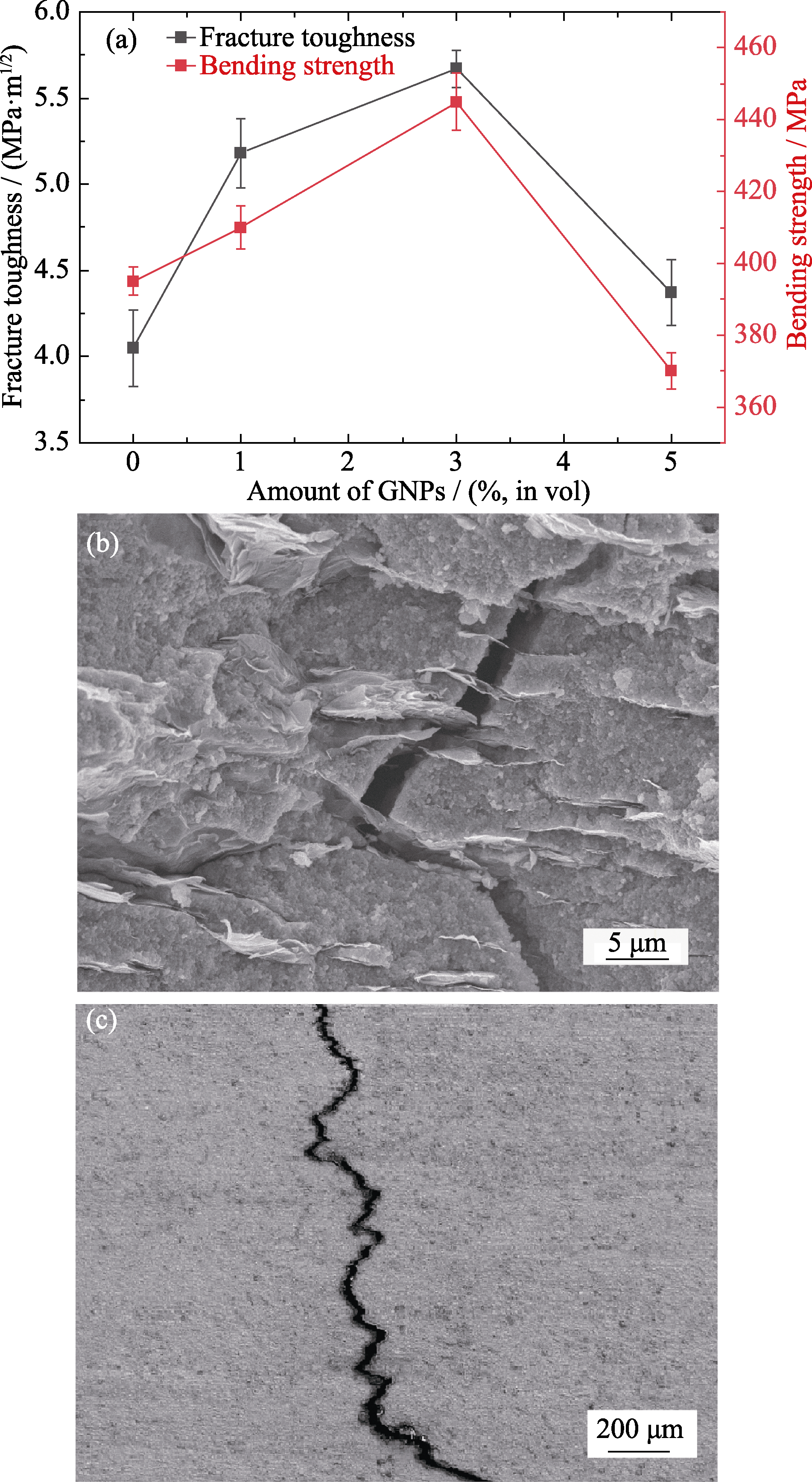

Fig. 7 Fracture properties of SiC/GNPs sample (a) Changing curves of fracture toughness and bending strength of SiC/GNPs with GNPs content; (b) SEM image of sample showing crack bridging; (c) SEM image of sample showing crack deflection

| [1] |

ZABELINA A A, SHCHERBAKOVA G I, FAIKOV P P, et al. SiC composites containing carbon nanotubes and oxide additives based on organoelementoxanes. Preparation by spark plasma sintering. Ceramics International, 2020, 46(3): 2786.

DOI URL |

| [2] |

OUYANG Q, WANG Y F, XU J, et al. Research progress of SiC fiber reinforced SiC composites for nuclear application. Journal of Inorganic Materials, 2022, 37(8): 821.

DOI |

| [3] |

KOYANAGI T, KATOH Y, NOZAWA T, et al. Recent progress in the development of SiC composites for nuclear fusion applications. Journal of Nuclear Materials, 2018, 511(1): 544.

DOI URL |

| [4] |

YAO X Y, LI K Z, REN J J, et al. Microstructure and fatigue behavior of high texture three-dimensional C/C composites prepared by mixed precursors. Journal of Inorganic Materials, 2020, 35(5): 589.

DOI |

| [5] | 李辰冉, 谢志鹏, 赵林. 碳化硅陶瓷材料烧结技术的研究与应用进展. 陶瓷学报, 2020, 41(2): 13. |

| [6] |

LIAO L, CHEN Z, XU X H, et al. Effects of oxidation curing and sintering temperature on the microstructure formation and heat transfer performance of freestanding polymer-derived SiC films for high-power LEDs. Ceramics International, 2018, 44(6): 6072.

DOI URL |

| [7] | 乔玉林, 薛胤昌, 刘军, 等. 聚合物先驱体材料体系的陶瓷化研究进展与展望. 材料导报, 2016, 30(11): 6. |

| [8] |

BALANDIN A A, GHOSH S, BAO W, et al. Superior thermal conductivity of single-layer graphene. Nano Letters, 2008, 8(3): 902.

DOI PMID |

| [9] |

BOLOTIN K I, SIKES K J, JIANG Z, et al. Ultrahigh electron mobility in suspended graphene. Solid State Communications, 2008, 146(9/10): 351.

DOI URL |

| [10] |

CHAE H K, SIBERIO-PÉREZ D Y, KIM J, et al. A route to high surface area, porosity and inclusion of large molecules in crystals. Nature, 2004, 427(6974): 523.

DOI |

| [11] |

MULLER S E, SANTHAPURAM R R, NAIR A K. Failure mechanisms in pre-cracked Ni-graphene nanocomposites. Computational Materials Science, 2018, 152: 341.

DOI URL |

| [12] |

LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science, 2008, 321(5887): 385.

DOI PMID |

| [13] |

WANG Y, HUANG Y, SONG Y, et al. Room-temperature ferromagnetism of graphene. Nano Letters, 2009, 9(1): 220.

DOI PMID |

| [14] | HAN T, HE P, WANG J, et al. The effect of vacancy defects on the tensile mechanical properties of single graphene sheets. Journal of Tongji University (Natural Science), 2010, 38(8): 1210. |

| [15] |

ZHANG B, HOU C Y, WANG H P, et al. Preparation and performance of reduced graphene oxide functionalized flexible and multicolor electrothermal chromatic films. Journal of Inorganic Materials, 2018, 33(11): 1232.

DOI |

| [16] |

YU Y, XIA F, HUANG Q, et al. Electrical conductivity of silicon carbonitride-reduced graphene oxide composites. Journal of the American Ceramic Society, 2017, 100(11): 5113.

DOI URL |

| [17] |

LEE B, KOO M Y, JIN S H, et al. Simultaneous strengthening and toughening of reduced graphene oxide/alumina composites fabricated by molecular-level mixing process. Carbon, 2014, 78: 212.

DOI URL |

| [18] |

SUN C, HUANG Y, SHEN Q, et al. Embedding two-dimensional graphene array in ceramic matrix. Science Advances, 2020, 6(39): eabb1338.

DOI URL |

| [19] | FAN Y, WANG L, LI J, et al. Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Materials Science, 2010, 48(6): 1743. |

| [20] |

FAN Y, SONG Y, TUFAIL, et al. Liquid-phase assisted engineering of highly strong SiC composite reinforced by multiwalled carbon nanotubes. Advanced Science, 2020, 7(21): 2002225

DOI URL |

| [21] |

GAO J, DING Q, YAN P, et al. Highly improved microwave absorbing and mechanical properties in cold sintered ZnO by incorporating graphene oxide. Journal of the European Ceramic Society, 2022, 42(3): 993.

DOI URL |

| [22] |

YANG Y F, ZHU T B, DAN J N, et al. Mechanical and tribological properties of SiC-GNPs composites prepared by oscillatory pressure sintering. Ceramics International, 2022, 48(23): 34769.

DOI URL |

| [23] |

HANZEL O, TATARKO P. Preparation and properties of layered SiC-graphene composites for EDM. Materials, 2021, 14(11): 2916.

DOI URL |

| [24] |

HUANG Y H, JIANG D L, CHEN Z M, et al. Fabrication and property of rGO/SiC composite. Journal of Inorganic Materials, 2018, 33(11): 1147.

DOI URL |

| [25] |

RAZMJOO A, BAHARVANDI H R, EHSANI N. αSiC-βSiC- graphene composites. Scientific Reports, 2023, 13: 4306.

DOI |

| [26] |

FAN Y C, WANG L J, JIANG W. Graphene based oxide ceramic composites with high mechanical and functional performance: from preparation to property. Journal of Inorganic Materials, 2018, 33(2): 138.

DOI URL |

| [27] |

TANG J, LIU M, WEI Y, et al. An efficient and low-cost liquid silicon infiltration method to prepare SiC-coated carbon short fiber for fiber protection of Cf/SiC ceramic matrix composites. Ceramics International, 2021, 47(9): 13235.

DOI URL |

| [28] |

LIN B, WEI J, SUI T, et al. Effects of the surface processing on the tribological performance of C/SiCs under dry friction. Scientific Reports, 2020, 10: 5990.

DOI PMID |

| [29] |

HU X, HUANG M, KONG N, et al. Enhancing the electrical insulation of highly thermally conductive carbon fiber powders by SiC ceramic coating for efficient thermal interface materials. Composites Part B Engineering, 2021, 227(2): 109398.

DOI URL |

| [30] |

WANG X, SONG Z, CHENG Z, et al. Tensile creep properties and damage mechanisms of 2D-SiCf/SiC composites reinforced with low-oxygen high-carbon type SiC fiber. Journal of the European Ceramic Society, 2020, 40(14): 4872.

DOI URL |

| [31] | 邓卫斌, 李铁虎, 李昊, 等. 石墨烯/陶瓷复合材料的研究进展. 固体火箭技术, 2022, 45(1): 13. |

| [32] | 侯保江, 水涌涛, 孙向春, 等. 碳化硅陶瓷超声波辅助磨削表面完整性研究. 兵器装备工程学报, 2019(7): 3. |

| [33] | 徐广平, 何江荣, 刘鹏程, 等. 振荡压力烧结技术制备高性能碳化硅陶瓷. 中国陶瓷, 2022(3): 58. |

| [34] |

YIN Z, ZHANG X, HUANG Z, et al. Paraffin/expanded graphite phase change composites with enhanced thermal conductivity prepared by implanted β-SiC nanowires with chemical vapor deposition method. Materials Research Express, 2018, 5(2): 25503.

DOI URL |

| [35] | 贺国旭, 曹测祥, 韩永军, 等. 反应烧结制备碳化硅陶瓷及其性能研究. 耐火材料, 2022(2): 056. |

| [36] | 李红伟, 王瑶琪, 高莹, 等. 工业级石墨烯纳米片对碳化硅陶瓷摩擦磨损性能影响的研究. 中国陶瓷, 2021, 57(5): 7. |

| [37] |

PAPAGEORGIOU D G, KINLOCH I A, YOUNG R J. Mechanical properties of graphene and graphene-based nanocomposites. Progress in Materials science. 2017, 90(10): 75.

DOI URL |

| [38] |

RAMIRE Z, VEGA-DIAZ S M, MORELOS-GÓMEZ A, et al. Synthesis of conducting graphene/Si3N4 composites by spark plasma sintering. Carbon, 2013, 57: 425.

DOI URL |

| [39] |

COLEMAN J N, LOTYA M, O'NEILL A, et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science, 2011, 331(6017): 568.

DOI PMID |

| [40] |

TAN Y, LUO H, ZHANG H, et al. Lightweight graphene nanoplatelet/boron carbide composite with high EMI shielding effectiveness. AIP Advances, 2016, 6(3): 35208.

DOI URL |

| [1] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [2] | YANG Mingkai, HUANG Zeai, ZHOU Yunxiao, LIU Tong, ZHANG Kuikui, TAN Hao, LIU Mengying, ZHAN Junjie, CHEN Guoxing, ZHOU Ying. Co-production of Few-layer Graphene and Hydrogen from Methane Pyrolysis Based on Cu and Metal Oxide-KCl Molten Medium [J]. Journal of Inorganic Materials, 2025, 40(5): 473-480. |

| [3] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [4] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [5] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [6] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [7] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [10] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [11] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [12] | LI Honglan, ZHANG Junmiao, SONG Erhong, YANG Xinglin. Mo/S Co-doped Graphene for Ammonia Synthesis: a Density Functional Theory Study [J]. Journal of Inorganic Materials, 2024, 39(5): 561-568. |

| [13] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [14] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [15] | WANG Yanli, QIAN Xinyi, SHEN Chunyin, ZHAN Liang. Graphene Based Mesoporous Manganese-Cerium Oxides Catalysts: Preparation and Low-temperature Catalytic Reduction of NO [J]. Journal of Inorganic Materials, 2024, 39(1): 81-89. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||