Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (8): 923-930.DOI: 10.15541/jim20230073

• RESEARCH ARTICLE • Previous Articles Next Articles

XU Hao1( ), QIAN Wei2,3, HUA Yinqun1,2,3(

), QIAN Wei2,3, HUA Yinqun1,2,3( ), YE Yunxia3,4, DAI Fengze3, CAI Jie2,3

), YE Yunxia3,4, DAI Fengze3, CAI Jie2,3

Received:2023-02-14

Revised:2023-04-05

Published:2023-08-20

Online:2023-05-04

Contact:

HUA Yinqun, professor. E-mail: huayq@ujs.edu.cnAbout author:XU Hao (1997-), male, Master candidate. E-mail: 1574686698@qq.com

Supported by:CLC Number:

XU Hao, QIAN Wei, HUA Yinqun, YE Yunxia, DAI Fengze, CAI Jie. Effects of Micro Texture Processed by Picosecond Laser on Hydrophobicity of Silicon Carbide[J]. Journal of Inorganic Materials, 2023, 38(8): 923-930.

| Serial number | Power/ W | Speed/ (mm·s-1) | Interval/ μm |

|---|---|---|---|

| A-1~A-10 | 9 | 125 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| B-1~B-10 | 6 | 100 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| C-1~C-10 | 3 | 50 | 64/80/100/125/150/ |

| 200/250/300/400/500 |

Table 1 Processing parameters of laser processing

| Serial number | Power/ W | Speed/ (mm·s-1) | Interval/ μm |

|---|---|---|---|

| A-1~A-10 | 9 | 125 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| B-1~B-10 | 6 | 100 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| C-1~C-10 | 3 | 50 | 64/80/100/125/150/ |

| 200/250/300/400/500 |

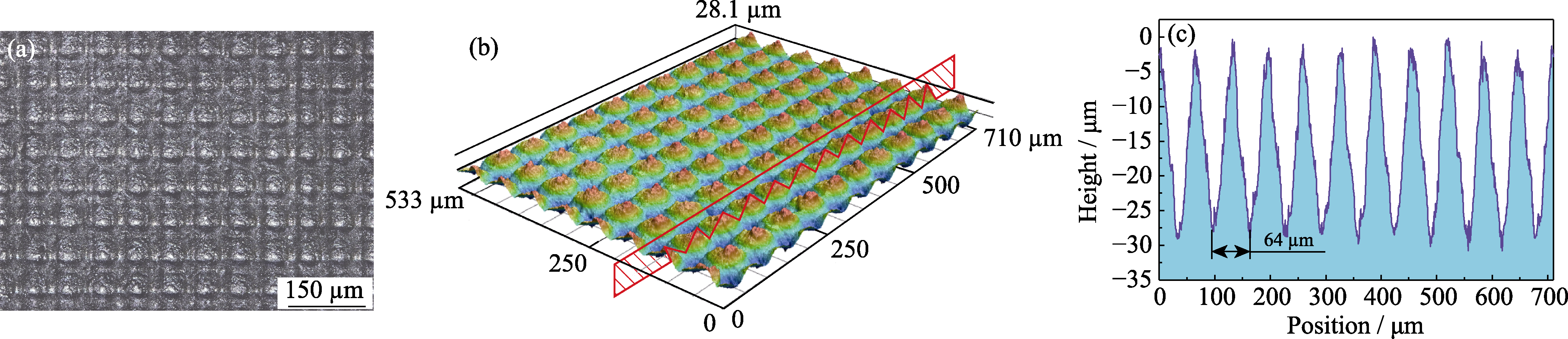

Fig. 6 Surface morphologies of A-1 (a) Photograph of laser machined reticular micro-texture; (b) Laser confocal 3D model; (c) Cross-sectional shape of (b)

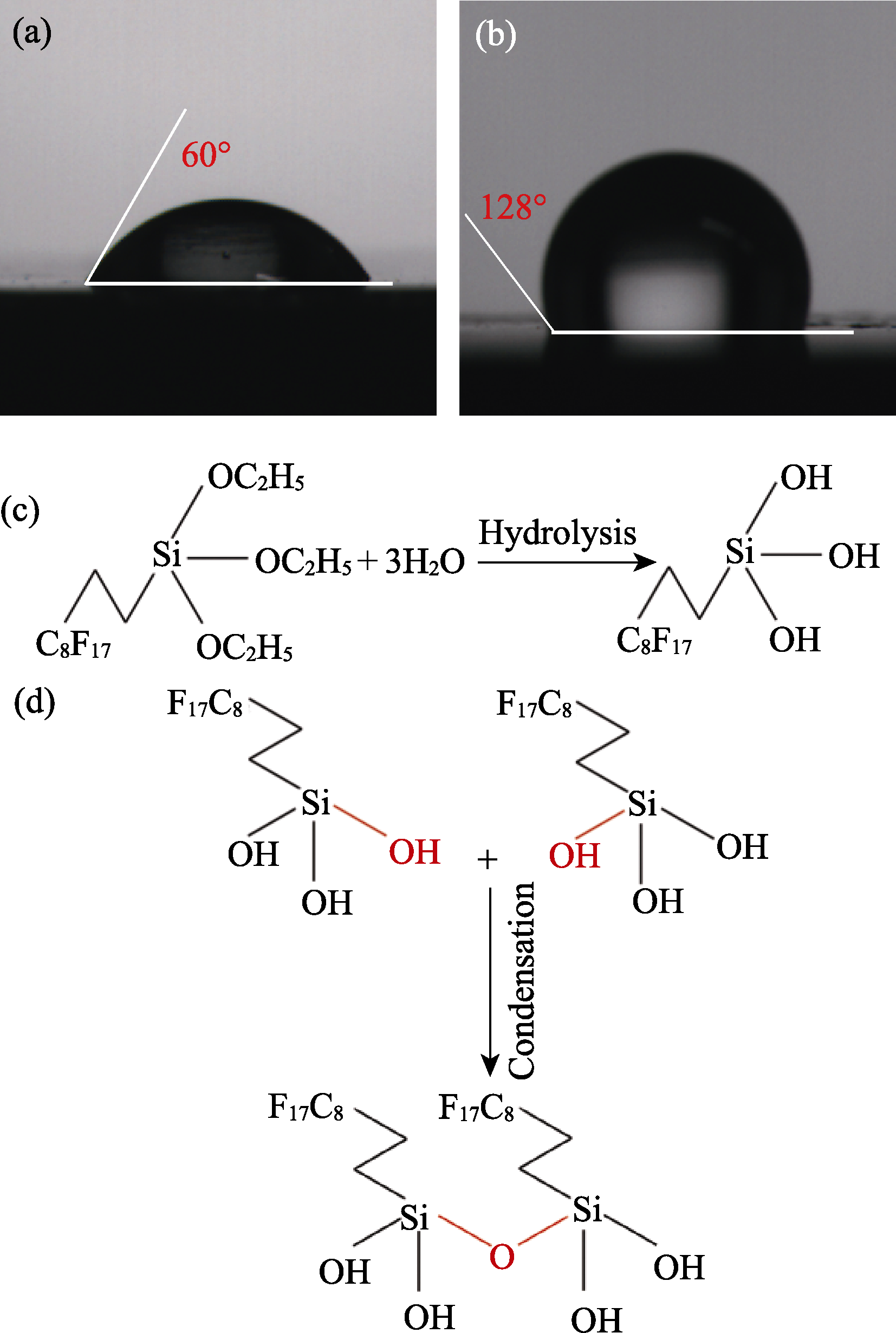

Fig. 7 Effect of modification on contact angle and its modification principle (a) Contact angle of R-0; (b) Contact angle of R-1; (c) Hydrolysis of FAS; (d) Dehydration condensation

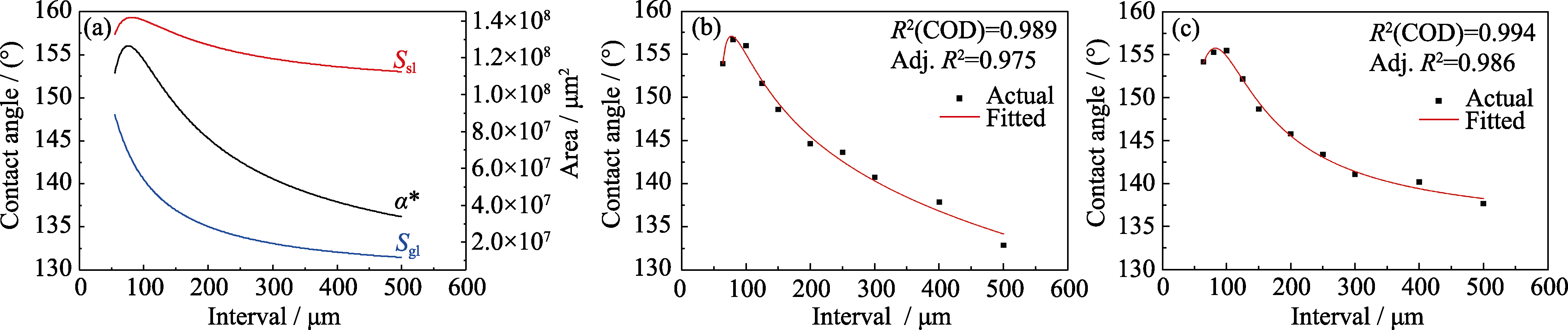

Fig. 8 Statistics and photographs of contact angle for samples (a) Contact angles of three groups with processing intervals; (b) Contact angle photographs of three groups

Fig. 11 Theoretical contact angle variation and fitted curves (a) Theoretical variation of contact angle; (b) Fitted curve of variation of contact angle of group B; (c) Fitted curve of variation of contact angle of group C

| [1] |

KHADER I, KOPLIN C, SCHRÖDER C, et al. Characterization of a silicon nitride ceramic material for ceramic springs. Journal of the European Ceramic Society, 2020, 40(10): 3541.

DOI URL |

| [2] |

KHADER I, RENZ A, KAILER A, et al. Thermal and corrosion properties of silicon nitride for copper die casting components. Journal of the European Ceramic Society, 2013, 33(3): 593.

DOI URL |

| [3] | BREYSSE J, CASTEL D, LAVIRON B, et al. All-SiC telescope technology: recent progress and achievements. International Conference on Space Optics — ICSO 2004, 2019: 201. |

| [4] |

SPITSBERG I, STEIBEL J. Thermal and environmental barrier coatings for SiC/SiC CMCs in aircraft engine applications. International Journal of Applied Ceramic Technology, 2005, 1(4): 291.

DOI URL |

| [5] |

KOUCHAKI S, ROSHANI H, PROZZI J A, et al. Evaluation of aggregates surface micro-texture using spectral analysis. Construction and Building Materials, 2017, 156: 944.

DOI URL |

| [6] | TIEJUN Z, NAN W. Analysis of the research status of surface texture technology. Mechanical & Electrical Engineering Technology, 2020, 49(11): 116. |

| [7] |

NEINHUIS C, BARTHLOTT W. Characterization and distribution of water-repellent, self-cleaning plant surfaces. Annals of Botany, 1997, 79(6): 667.

DOI URL |

| [8] | DAVIS A, YEONG Y H, STEELE A, et al. Superhydrophobic nanocomposite surface topography and ice adhesion. ACS Applied Materials & Interfaces, 2014, 6(12): 9272. |

| [9] |

QU N, CHEN X, LI H, et al. Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist. Chinese Journal of Aeronautics, 2014, 27(4): 1030.

DOI URL |

| [10] |

SUN Y, JIN L, GONG Y, et al. Experimental evaluation of surface generation and force time-varying characteristics of curvilinear grooved micro end mills fabricated by EDM. Journal of Manufacturing Processes, 2022, 73: 799.

DOI URL |

| [11] |

NAKANO M, KORENAGA A, KORENAGA A, et al. Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions. Tribology Letters, 2007, 28(2): 131.

DOI URL |

| [12] |

OBIKAWA T, KAMIO A, TAKAOKA H, et al. Micro-texture at the coated tool face for high performance cutting. International Journal of Machine Tools and Manufacture, 2011, 51(12): 966.

DOI URL |

| [13] |

SCARAGGI M, MEZZAPESA F P, CARBONE G, et al. Friction properties of lubricated laser-microtextured-surfaces: an experimental study from boundary-to hydrodynamic-lubrication. Tribology Letters, 2012, 49(1): 117.

DOI URL |

| [14] | ZHAO B, LI P, ZHAO C, et al. Fractal characterization of surface microtexture of Ti6Al4V subjected to ultrasonic vibration assisted milling. Ultrasonics, 2020, 102: 106052. |

| [15] |

MA C, BAI S, PENG X, et al. Improving hydrophobicity of laser textured SiC surface with micro-square convexes. Applied Surface Science, 2013, 266: 51.

DOI URL |

| [16] | ZHAO M, HE Q, LEI B, et al. Preparation of ceramic superhydrophobic surface based on laser engraving technology. Journal of China Three Gorges University (Natural Sciences), 2021, 43(1): 107. |

| [17] |

WANG S, JIANG L. Definition of superhydrophobic states. Advanced Materials, 2007, 19(21): 3423.

DOI URL |

| [18] |

BICO J, THIELE U, QUÉRÉ D. Wetting of textured surfaces. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2002, 206(1): 41.

DOI URL |

| [19] |

KANG C, LU H, YUAN S, et al. Superhydrophilicity/superhydrophobicity of nickel micro-arrays fabricated by electroless deposition on an etched porous aluminum template. Chemical Engineering Journal, 2012, 203: 1.

DOI URL |

| [20] | ZHAI Z, WEI C, ZHANG Y, et al. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser. Applied Surface Science, 2020, 502:144131. |

| [21] |

FU C, YANG Y, HUANG Z, et al. Investigation on the laser ablation of SiC ceramics using micro-Raman mapping technique. Journal of Advanced Ceramics, 2016, 5(3): 253.

DOI URL |

| [22] |

DENG D, XIE Y, CHEN L, et al. Experimental investigation on laser micromilling of SiC microchannels. The International Journal of Advanced Manufacturing Technology, 2019, 101(1): 9.

DOI |

| [23] | TEMMLER A, KÜPPER M, WALOCHNIK M A, et al. Surface structuring by laser remelting of metals. Journal of Laser Applications, 2017, 29(1): 012015. |

| [24] |

ZHAI Z, WANG W, ZHAO J, et al. Influence of surface morphology on processing of C/SiC composites via femtosecond laser. Composites Part A: Applied Science and Manufacturing, 2017, 102: 117.

DOI URL |

| [25] |

ZHANG M, ZHU H, XI B, et al. Surface hydrophobic modification of biochar by silane coupling agent KH-570. Processes, 2022, 10(301): 301.

DOI URL |

| [26] |

WU X L, XIONG S J, ZHU J, et al. Identification of surface structures on 3C-SiC nanocrystals with hydrogen and hydroxyl bonding by photoluminescence. Nano Letters, 2009, 9(12): 4053.

DOI URL |

| [27] |

SONG J, ROJAS O J. Approaching super-hydrophobicity from cellulosic materials: a review. Nordic Pulp and Paper Research Journal, 2013, 28(2): 216.

DOI URL |

| [28] |

LAW K Y. Definitions for hydrophilicity, hydrophobicity, and superhydrophobicity: getting the basics right. Journal of Physical Chemistry Letters, 2014, 5(4): 686.

DOI URL |

| [29] |

SEDEV R. Surface tension, interfacial tension and contact angles of ionic liquids. Current Opinion in Colloid & Interface Science, 2011, 16(4): 310.

DOI URL |

| [30] | CRICK C R, PARKIN I P. Preparation and characterisation of super-hydrophobic surfaces. Chemistry, 2010, 16(12): 3568. |

| [31] |

HAN T Y, SHR J F, WU C F, et al. A modified Wenzel model for hydrophobic behavior of nanostructured surfaces. Thin Solid Films, 2007, 515(11): 4666.

DOI URL |

| [32] |

WOLANSKY G, MARMUR A. Apparent contact angles on rough surfaces: the Wenzel equation revisited. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1999, 156(1): 381.

DOI URL |

| [33] |

YEN T H, SOONG C Y. Hybrid Cassie-Wenzel model for droplets on surfaces with nanoscale roughness. Physical Review E, 2016, 93(2): 22805.

DOI URL |

| [34] |

XU X, WANG X. Derivation of the Wenzel and Cassie equations from a phase field model for two phase flow on rough surface. SIAM Journal on Applied Mathematics, 2010, 70(8): 2929.

DOI URL |

| [35] | NAKAYAMA Y. Introduction to Fluid Mechanics(2nd Edition). Britain: Butterworth-Heinemann, 2018: 25. |

| [1] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [2] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [3] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [4] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [5] | ZHAO Yawen, QU Fajin, WANG Yanyi, WANG Zhiwen, CHEN Chusheng. Preparation and Properties of Aluminum Silicate Fiber Supported PtTFPP-PDMS Flexible Oxygen Sensing Components [J]. Journal of Inorganic Materials, 2024, 39(10): 1084-1090. |

| [6] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [7] | GU Xuesu, YIN Jie, WANG Kanglong, CUI Chong, MEI Hui, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics by Binder Jetting Printing [J]. Journal of Inorganic Materials, 2023, 38(12): 1373-1378. |

| [8] | OUYANG Qin, WANG Yanfei, XU Jian, LI Yinsheng, PEI Xueliang, MO Gaoming, LI Mian, LI Peng, ZHOU Xiaobing, GE Fangfang, ZHANG Chonghong, HE Liu, YANG Lei, HUANG Zhengren, CHAI Zhifang, ZHAN Wenlong, HUANG Qing. Research Progress of SiC Fiber Reinforced SiC Composites for Nuclear Application [J]. Journal of Inorganic Materials, 2022, 37(8): 821-840. |

| [9] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [10] | MENG Qing, LI Jiangtao. Hydrophobic BN Powders by Combustion Synthesis and Its Super-hydrophobic Coatings: Preparation and Property [J]. Journal of Inorganic Materials, 2022, 37(10): 1037-1042. |

| [11] | CHEN Jun,MA Pei-Hua,ZHANG Cheng,Laurent RUHLMANN,LYU Yao-Kang. Preparation and Electrochemical Property of New Multifunctional Inorganic/Organic Composite Film [J]. Journal of Inorganic Materials, 2020, 35(2): 217-223. |

| [12] | LUO Qing,YUAN Qing,JIANG Qian-Qin,YU Nai-Sen. Cu-SSZ-13/SiC-waste Composite: Synthesis and Application for NH3-SCR [J]. Journal of Inorganic Materials, 2019, 34(9): 953-960. |

| [13] | HE Fei, LI Ya, LUO Jin, FANG Min-Han, HE Xiao-Dong. Development of SiO2/C and SiC/C Composites Featuring Aerogel Structures [J]. Journal of Inorganic Materials, 2017, 32(5): 449-458. |

| [14] | YU Jie-Yi, HUANG Hao, GAO Jian, ZHOU Lei, GAO Song, DONG Xing-Long, QUAN Xie. Synthesis and Catalytic Performances of SiC Nanoparticles by DC Arc-discharge Plasma [J]. Journal of Inorganic Materials, 2017, 32(4): 351-356. |

| [15] | ZHUO Shi-Yi, LIU Xi, GAO Pan, YAN Cheng-Feng, SHI Er-Wei. Luminescence of Donor-acceptor-pair in Fluorescent 4H-SiC Doped with Nitrogen, Boron and Aluminum [J]. Journal of Inorganic Materials, 2017, 32(1): 51-55. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||