Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (9): 1003-1008.DOI: 10.15541/jim20140165

• Orginal Article • Previous Articles

WANG He-Yun1,2, LIU Qian1, ZHOU Yao1,2, ZHOU Zhen-Zhen1, LIU Guang-Hui1

Received:2014-04-02

Published:2014-09-17

Online:2014-08-21

Supported by:WANG He-Yun, LIU Qian, ZHOU Yao, ZHOU Zhen-Zhen, LIU Guang-Hui. Preparation and Properties of Carbon Fiber/Si3N4 Composites[J]. Journal of Inorganic Materials, 2014, 29(9): 1003-1008.

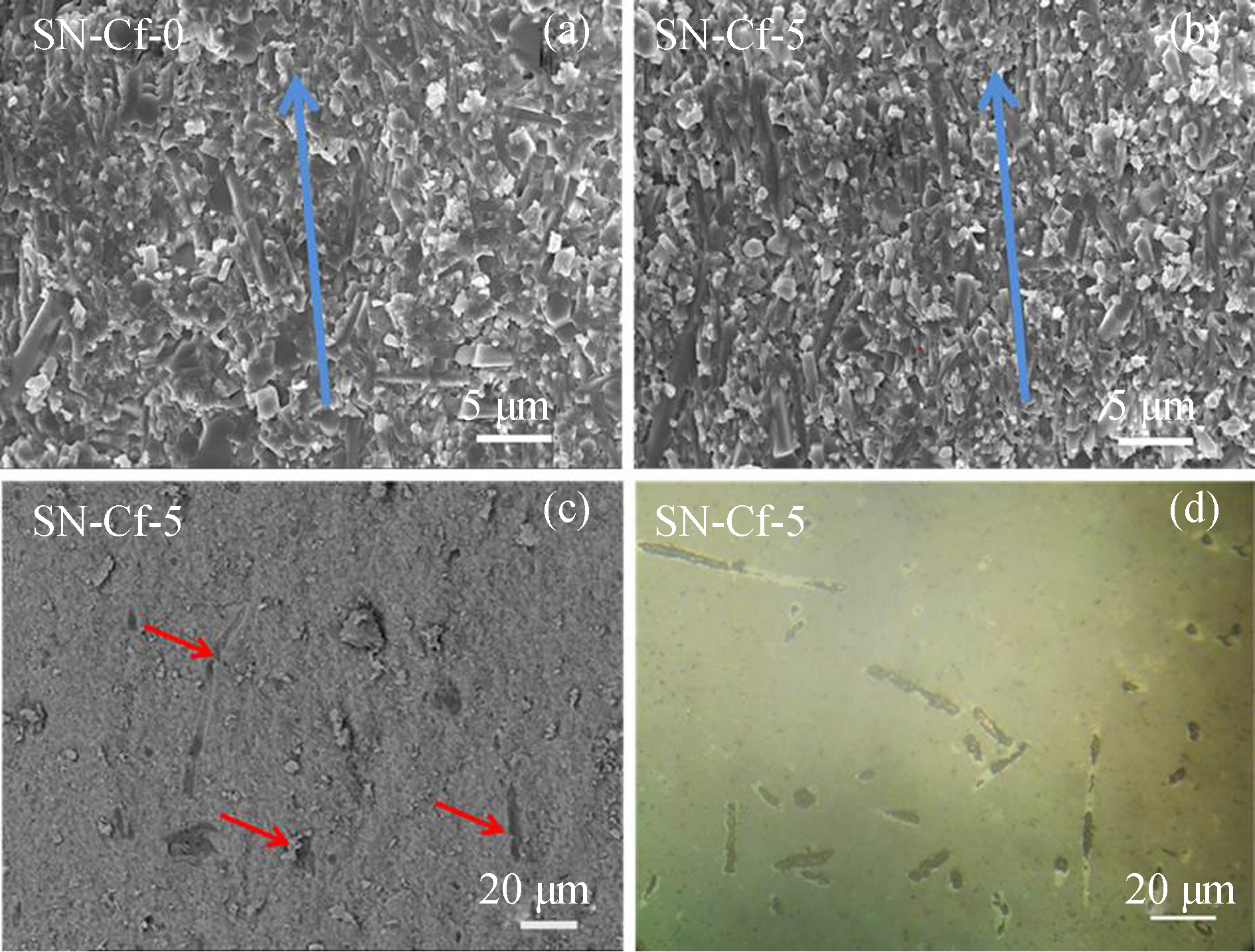

Fig. 3 SEM and optical microscopy images of Cf/Si3N4 Secondary electron image (SEI) of fracture surfaces of SN-Cf-0 (a) and SN-Cf-5 (b), back scattered electron image (BSEI) of fracture surface of SN-Cf-5 (c), and optical microscopy image of SN-Cf-5 surface (d)

| Composites | Cf/ wt% | ρ/ (g?cm-3) | Cp/ (mm2?s-1) | α/ (J?g-1?K-1) | k/ (W?m-1?K-1) |

|---|---|---|---|---|---|

| SN-Cf-0 | 0 | 3.27 | 17.98 | 0.59 | 37.12 |

| SN-Cf-2 | 2 | 3.31 | 19.99 | 0.61 | 45.84 |

| SN-Cf-5 | 5 | 3.28 | 15.12 | 0.58 | 33.43 |

Table 1 Thermal properties of Cf/Si3N4 composites measured at room temperature

| Composites | Cf/ wt% | ρ/ (g?cm-3) | Cp/ (mm2?s-1) | α/ (J?g-1?K-1) | k/ (W?m-1?K-1) |

|---|---|---|---|---|---|

| SN-Cf-0 | 0 | 3.27 | 17.98 | 0.59 | 37.12 |

| SN-Cf-2 | 2 | 3.31 | 19.99 | 0.61 | 45.84 |

| SN-Cf-5 | 5 | 3.28 | 15.12 | 0.58 | 33.43 |

| Composites | Cf /wt% | Hv/GPa | KIC/(MPa?m1/2) |

|---|---|---|---|

| SN-Cf-0 | 0 | 16.6 | 5.0 |

| SN-Cf-2 | 2 | 16.8 | 4.9 |

| SN-Cf-5 | 5 | 16.8 | 5.3 |

Table 2 Mechanical property of Cf/Si3N4 composites measured at room temperature

| Composites | Cf /wt% | Hv/GPa | KIC/(MPa?m1/2) |

|---|---|---|---|

| SN-Cf-0 | 0 | 16.6 | 5.0 |

| SN-Cf-2 | 2 | 16.8 | 4.9 |

| SN-Cf-5 | 5 | 16.8 | 5.3 |

| [1] | KRSTIC ZORAN, KRSTIC D. VLADIMIR. Silicon nitride: the engineering material of the future. Journal of Materials Science, 2011, 47(2): 535-552. |

| [2] | WATARI KOJI. High thermal conductivity non-oxide ceramics. Journal of the Ceramic Society of Japan, 2001, 109(1): S7-S16. |

| [3] | PENG MENG-MENG, NING XIAO-SHAN. Sintering of β-Si3N4 powder and thermal conductivity of the ceramic. Rare Metal Materials and Engineering, 2013, 42(1): 405-408. |

| [4] | ZHANG YING-WEI, YU JIAN-BO, XIA YONG-FENG, et al. Microstructure and mechanical performance of silicon nitride ceramic with seeds addition. Journal of Inorganic Materials, 2012, 27(8): 807-812. |

| [5] | ZHU XIN-WEN, ZHOU YOU, HIRAO KIYOSHI. Effects of processing method and additive composition on microstructure and thermal conductivity of Si3N4 ceramics. Journal of the European Ceramic Society, 2006, 26: 711-718. |

| [6] | ZHU XIN-WEN, ZHOU YOU, HIRAO KIYOSHI. Post-densification behavior of reaction-bonded silicon nitride (RBSN): effect of various characteristics of RBSN. Journal of Materials Science, 2004, 39(18): 5785-5797. |

| [7] | WARARI KOJI, HIRAO KIYOSHI, BRITO E MANUEL, et al. Hot isostatic pressing to increase thermal conductivity of Si3N4 ceramics. Journal of Materials Research, 1998, 14(4): 1538-1551. |

| [8] | WATARI KOJI, HIRSO KIYOSHI, TORIYAMA MOTOHIRO. Effect of grain size on the thermal conductivity of Si3N4. Journal of the American Ceramic Society, 1999, 82(3): 777-779. |

| [9] | ZHOU YOU, HYUGA HIDEKI, KUSANO DAI, et al. A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39): 4563-4567. |

| [10] | CHOI Stephen U S, ZHANG Z G, YU W, et al. Anomalous thermal conductivity enhancement in nanotube suspensions. Applied Physics Letters, 2001, 79(14): 2252-2254. |

| [11] | HAN SEUNGJIN, CHUNG D D L. Increasing thethrough-thickness thermal conductivity of carbon fiber polymer-matrix composite by curing pressure increase and filler incorporation. Composites Science and Technology, 2011, 71(16): 1944-1952. |

| [12] | BORRELL B, ROCHA V G, TORRECILLAS R, et al. Effect of carbon nanofibers content on thermal properties of ceramic nanocomposites. Journal of Composite Materials, 2011, 46(10): 1229-1234. |

| [13] | YAO DONG-XU, XIA YONG-FENG, ZOU KAI-HUI, et al. Porous Si3N4 ceramics prepared via partial nitridation and SHS. Journal of the European Ceramic Society, 2013, 33(2): 371-374. |

| [14] | YANG JIAN-FENG, ZHANG GUO-JUN, KONDO NAOKI, et al. Synthesis and properties of porous Si3N4/SiC nanocomposites by carbothermal reaction between Si3N4 and carbon. Acta Materialia, 2002, 50(19): 4831-4840. |

| [15] | WANG XIAO-YAN, ZHU DONG-MEI, LI PENG, et al. Behavior of short carbon fibers in Cfiber/Si3N4 composites by hot pressed sintering. Journal of Reinforced Plastics and Composites, 2009, 28(2): 167-173. |

| [16] | MAGNANT J, PAILLER R, PETITCORPS Y L, et al. Fiber-reinforced ceramic matrix composites processed by a hybrid technique based on chemical vapor infiltration, slurry impregnation and spark plasma sintering. Journal of the European Ceramic Society, 2013, 33(1): 181-190. |

| [17] | YANG JIAN-FENG, ZHANG GUO-JUN, KONDO NAOKI, et al. Porous 2H-silicon carbide ceramics fabricated by carbothermal reaction between silicon nitride and carbon. Journal of the American Ceramic Society, 2003, 86(6): 910-914. |

| [18] | CHOI JAE-YOUNG, KIM CHONG-HEE, KIM DO-KYUNG, et al. Carbothermic synthesis of monodispersed spherical Si3N4/SiC nanocomposite powder. Journal of the American Ceramic Society, 1999, 82(10): 2665-2671. |

| [19] | ELIMAT Z M, HUSSAIN W T, ZIHLIF A M. PAN-based carbon fibers/PMMA composites: thermal, dielectric, and DC electrical properties. Journal of Materials Science: Materials in Electronics, 2012, 23(12): 2117-2122. |

| [20] | KUMARI L, ZHANG T, DU G H, et al. Thermal properties of CNT-alumina nanocomposites. Composites Science and Technology, 2008, 68(9): 2178-2183. |

| [21] | BAKSHI SRINIVAS R, BALANI KANTESH, AGARWAL ARVIND. Thermal conductivity of plasma-sprayed aluminum oxide-multiwalled carbon nanotube composites. Journal of the American Ceramic Society, 2008, 91(3): 942-947. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [10] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [11] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [12] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [13] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [14] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [15] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||