Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 944-956.DOI: 10.15541/jim20240473

Special Issue: 【制备方法】3D打印(202512); 【结构材料】超高温结构陶瓷(202512)

• REVIEW • Previous Articles Next Articles

YU Shengyang( ), SU Haijun(

), SU Haijun( ), JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin

), JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin

Received:2024-11-11

Revised:2025-01-07

Published:2025-09-20

Online:2025-01-09

Contact:

SU Haijun, professor. E-mail: shjnpu@nwpu.edu.cnAbout author:YU Shengyang (2001-), male, Master candidate. E-mail: yushengyangabc@163.com

Supported by:CLC Number:

YU Shengyang, SU Haijun, JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin. A Review of Pore Defects in Ultra-high Temperature Oxide Ceramics by Laser Additive Manufacturing: Formation and Suppression[J]. Journal of Inorganic Materials, 2025, 40(9): 944-956.

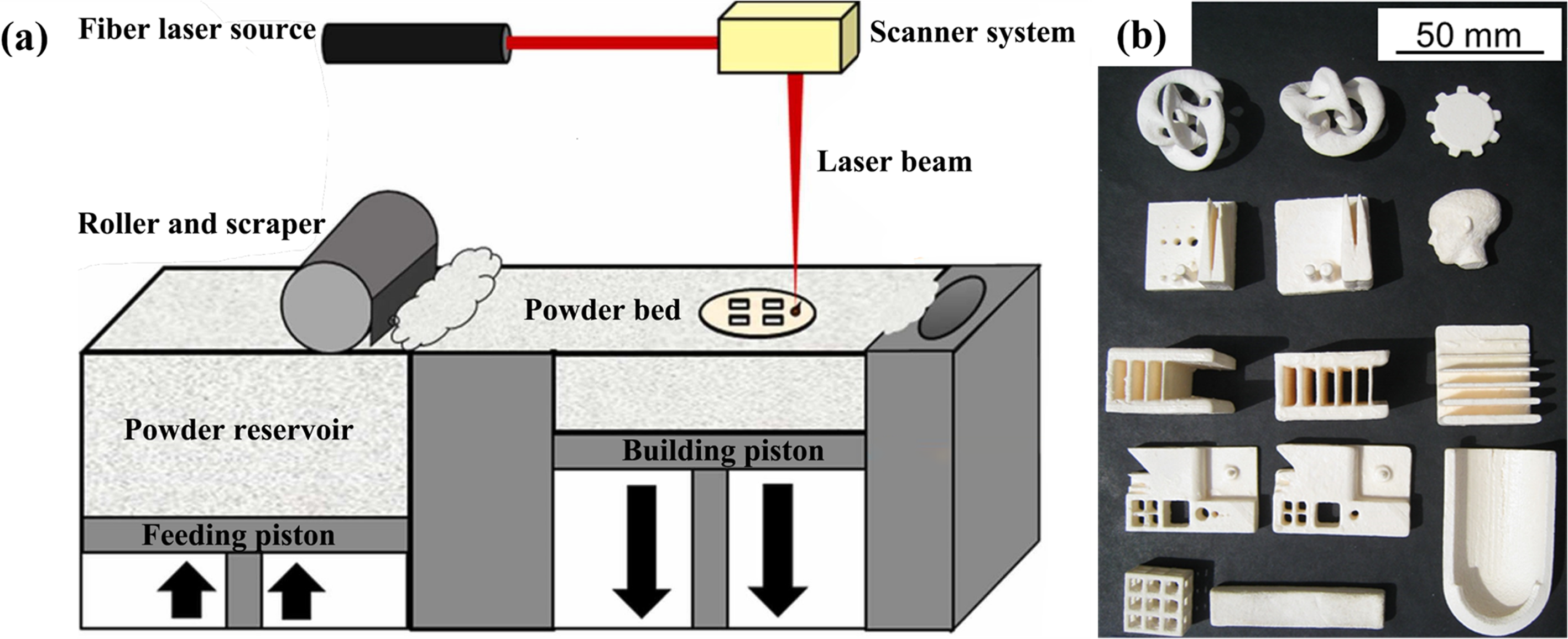

Fig. 1 Schematic diagram of SLS and pictures of fabricated ceramic samples[30,32] (a) Schematic diagram[30]; (b) Complicated Al2O3 ceramics fabricated by SLS[32]

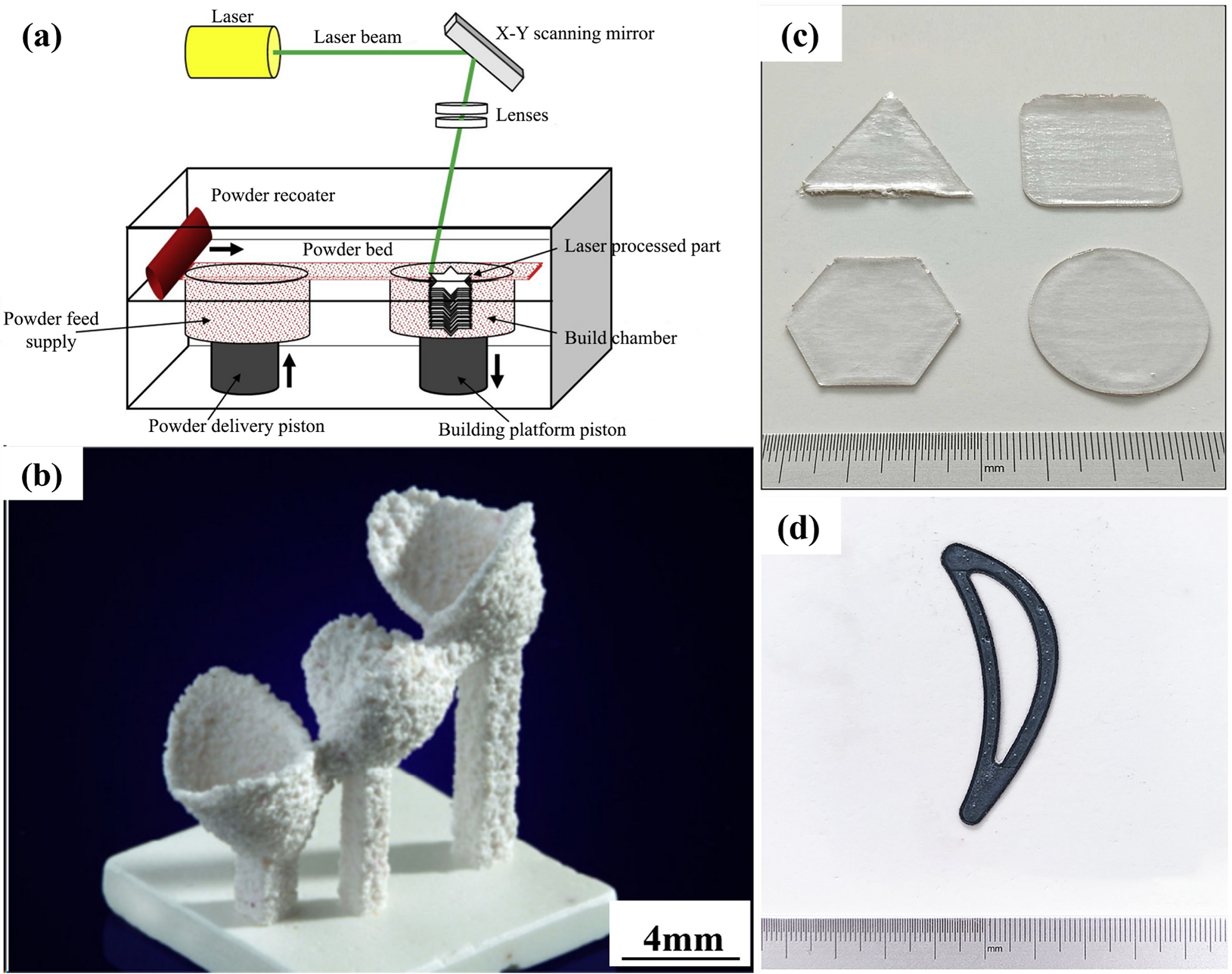

Fig. 2 Schematic diagram of LPBF and pictures of fabricated ceramic samples[34,36-38] (a) Schematic diagram[34]; (b) Al2O3/ZrO2 composite ceramics[36]; (c) Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics of different shapes[37]; (d) Al2O3/GdAlO3/ZrO2 eutectic ceramic[38]

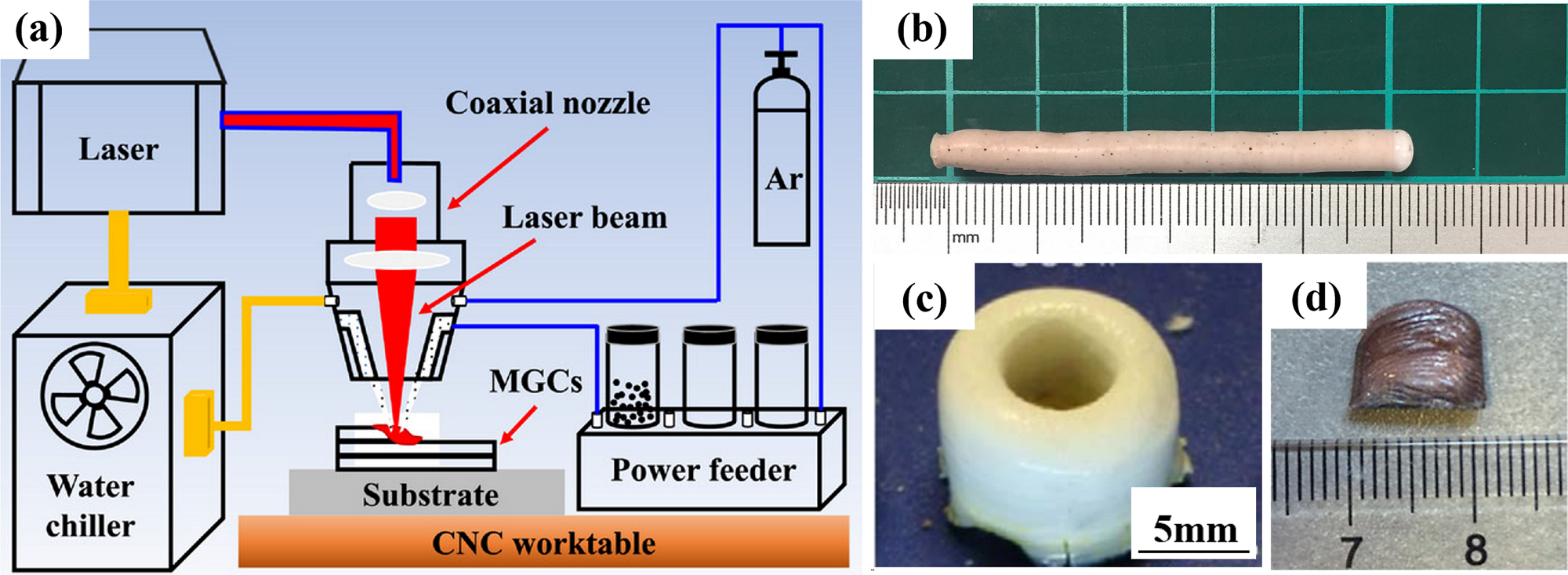

Fig. 3 Schematic diagram of LDED and pictures of fabricated ceramic samples[39,42-44] (a) Schematic diagram[39]; (b) Rod-shaped Al2O3/GAP ceramics[42]; (c) Hollow cylindrical Al2O3/YAG ceramics[43]; (d) Thin-walled Al2O3/YAG/ZrO2 eutectic ceramics[44]

| Technology | Powder feeding method | Applied material | Power/W | Manufacturing precision | Features |

|---|---|---|---|---|---|

| SLS | Powder bed melting | Polymers, metals, ceramics, wax, precoated sand | 10-200 | Low | Rough surface, low geometrical accuracy, macro-porous structure |

| LPBF | Powder bed melting | Metals, polymers, ceramics | 50-1000 | High | Being limited to manufacture small objects, very fine resolution |

| LDED | Blow powder by gas | Metals, polymers, ceramics | 100-3000 | Low | Large-scale components, low powder utilization rate |

Table 1 Comparative analysis of three representative LAM technologies[45-46]

| Technology | Powder feeding method | Applied material | Power/W | Manufacturing precision | Features |

|---|---|---|---|---|---|

| SLS | Powder bed melting | Polymers, metals, ceramics, wax, precoated sand | 10-200 | Low | Rough surface, low geometrical accuracy, macro-porous structure |

| LPBF | Powder bed melting | Metals, polymers, ceramics | 50-1000 | High | Being limited to manufacture small objects, very fine resolution |

| LDED | Blow powder by gas | Metals, polymers, ceramics | 100-3000 | Low | Large-scale components, low powder utilization rate |

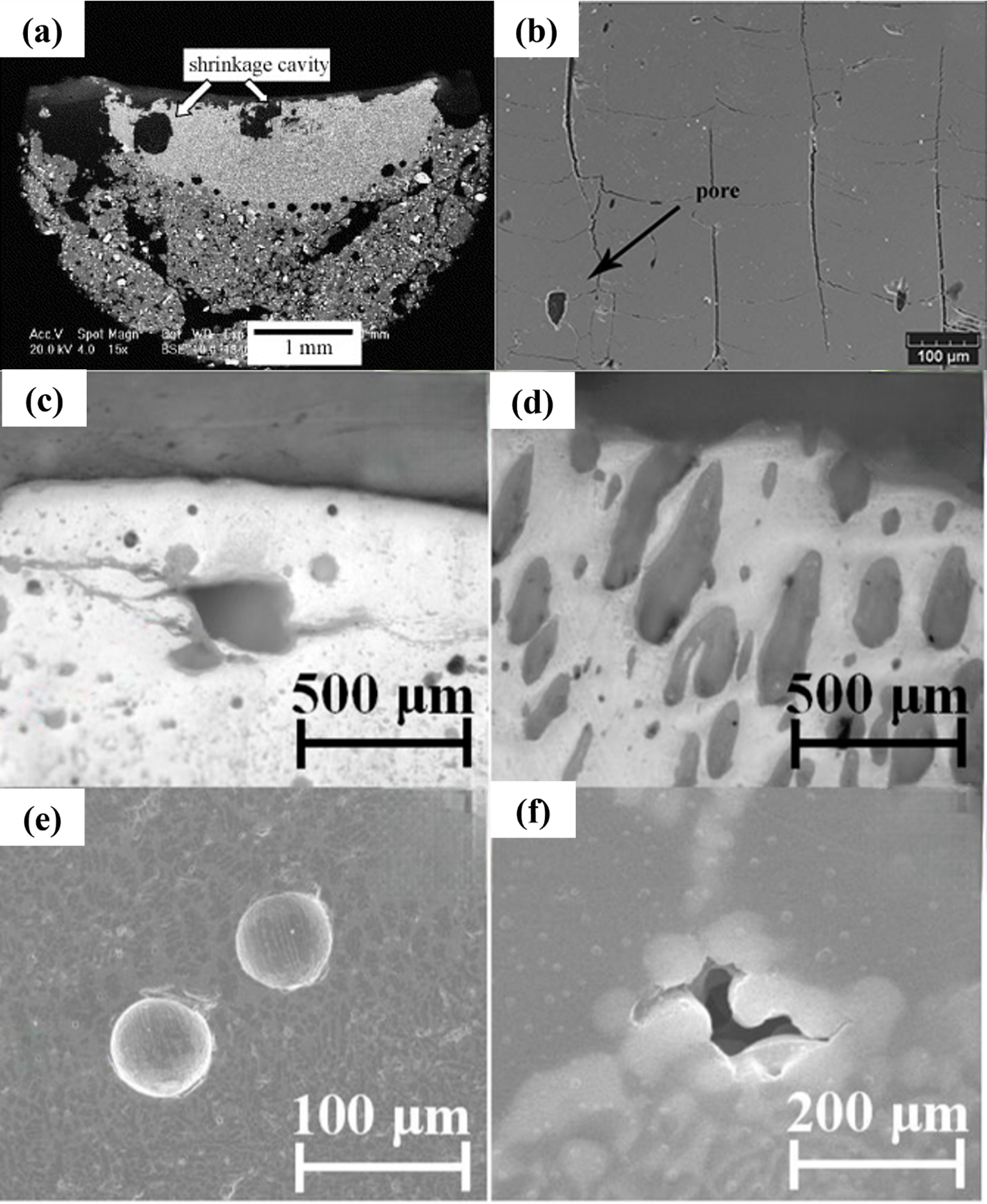

Fig. 4 Pore defects during LAM preparation[49-50,53] (a) Round-like pores and irregular shrinkage[49]; (b) Ellipsoidal pores[50]; (c) Shrinkage cavities on top[53]; (d) Elongated gas holes on top[53]; (e) Internal round gas holes[53]; (f) Internal shrinkage cavities[53]

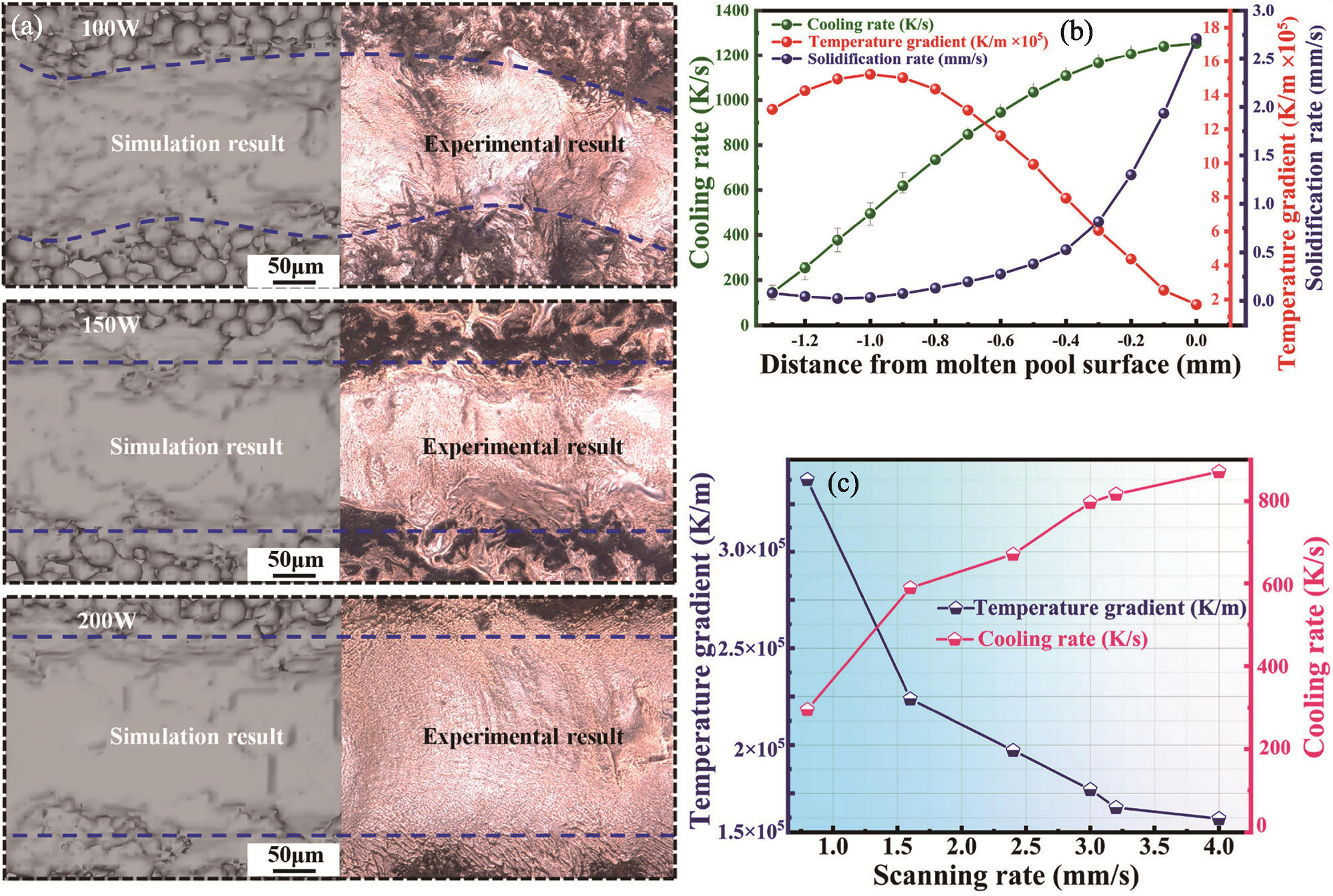

Fig. 7 Influence of molten pool temperature distribution and laser energy density on the molten pool[42,57] (a) Comparison between the experimental and the simulation results of the single melt track morphology[57];(b) Temperature gradient, cooling and solidification rates at vertical distances from the molten pool surface center[42]; (c) Temperature gradient and cooling rate at different scanning rates[42]

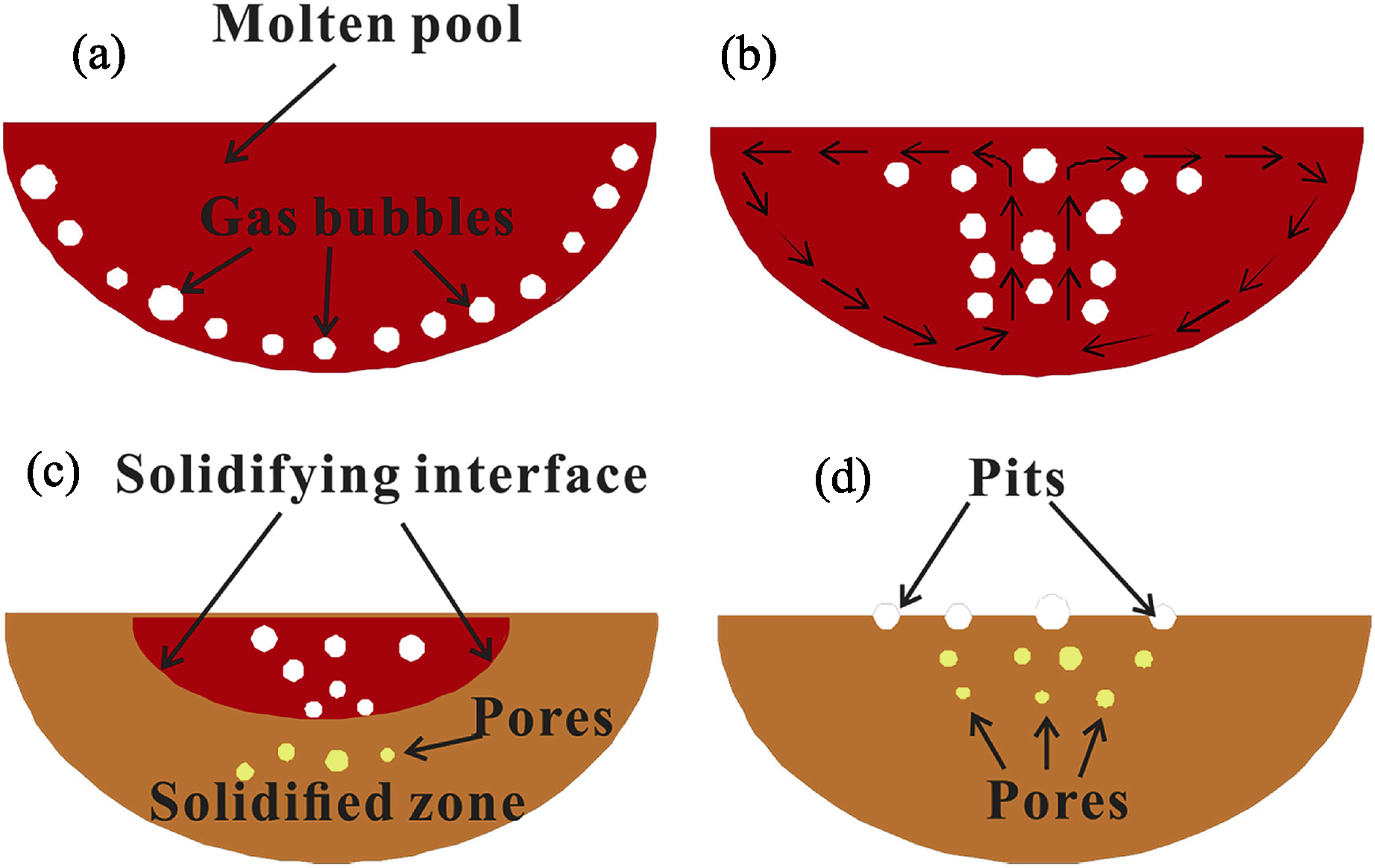

Fig. 8 Schematic diagrams of the formation of pores[61] (a) Formation of bubbles at the solid-liquid interface; (b) Upward movement of bubbles under the Marangoni force; (c) Formation of pores by bubbles trapped at the front of the solidification interface; (d) Formation of pits by some bubbles trapped at the solid-liquid interface

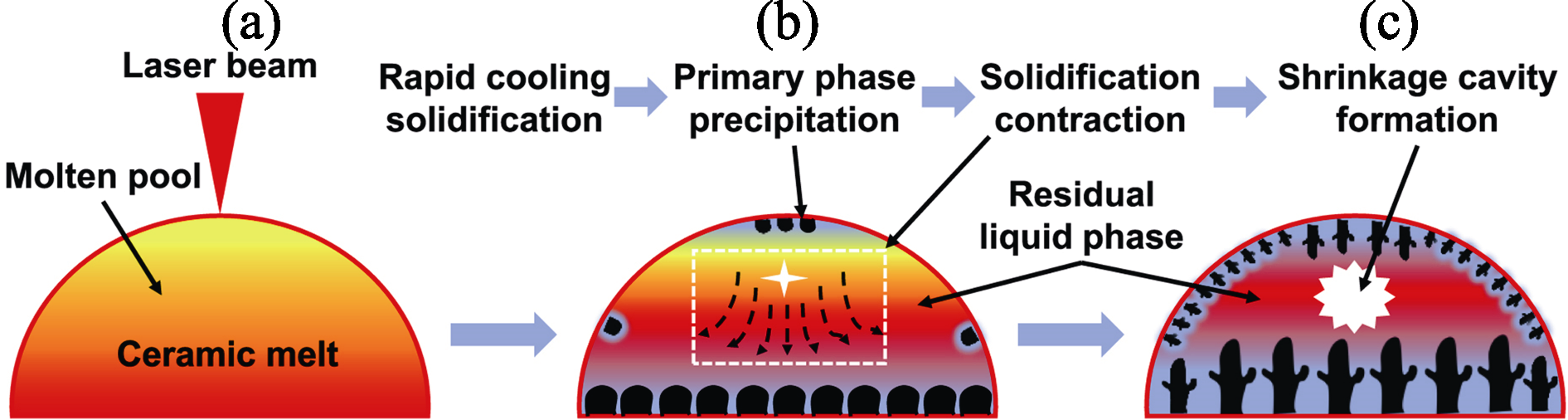

Fig. 9 Schematic diagrams of the formation of shrinkage cavity[68] (a) Laser beam scanning ceramic powder to form molten pool; (b) Nucleation and growth of the primary phase while solidification and contraction of the surrounding residual liquid phase; (c) Gradual enlargement of holes produced by solidification and contraction into shrinkage cavity

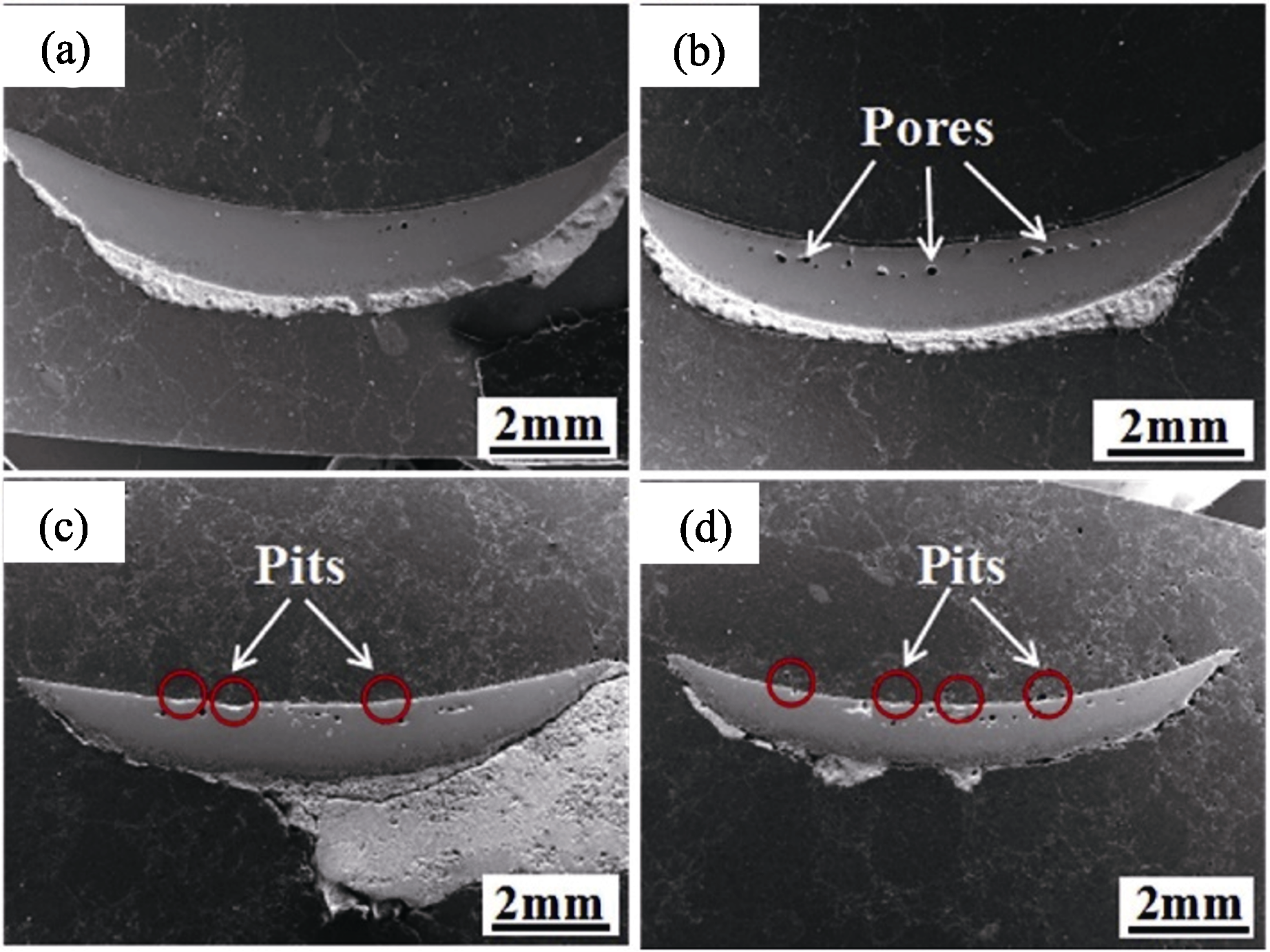

Fig. 10 SEM images of transverse sections of eutectic ceramics prepared with different scanning speeds[61] (a) 12 mm/min; (b) 18 mm/min; (c) 24 mm/min; (d) 30 mm/min

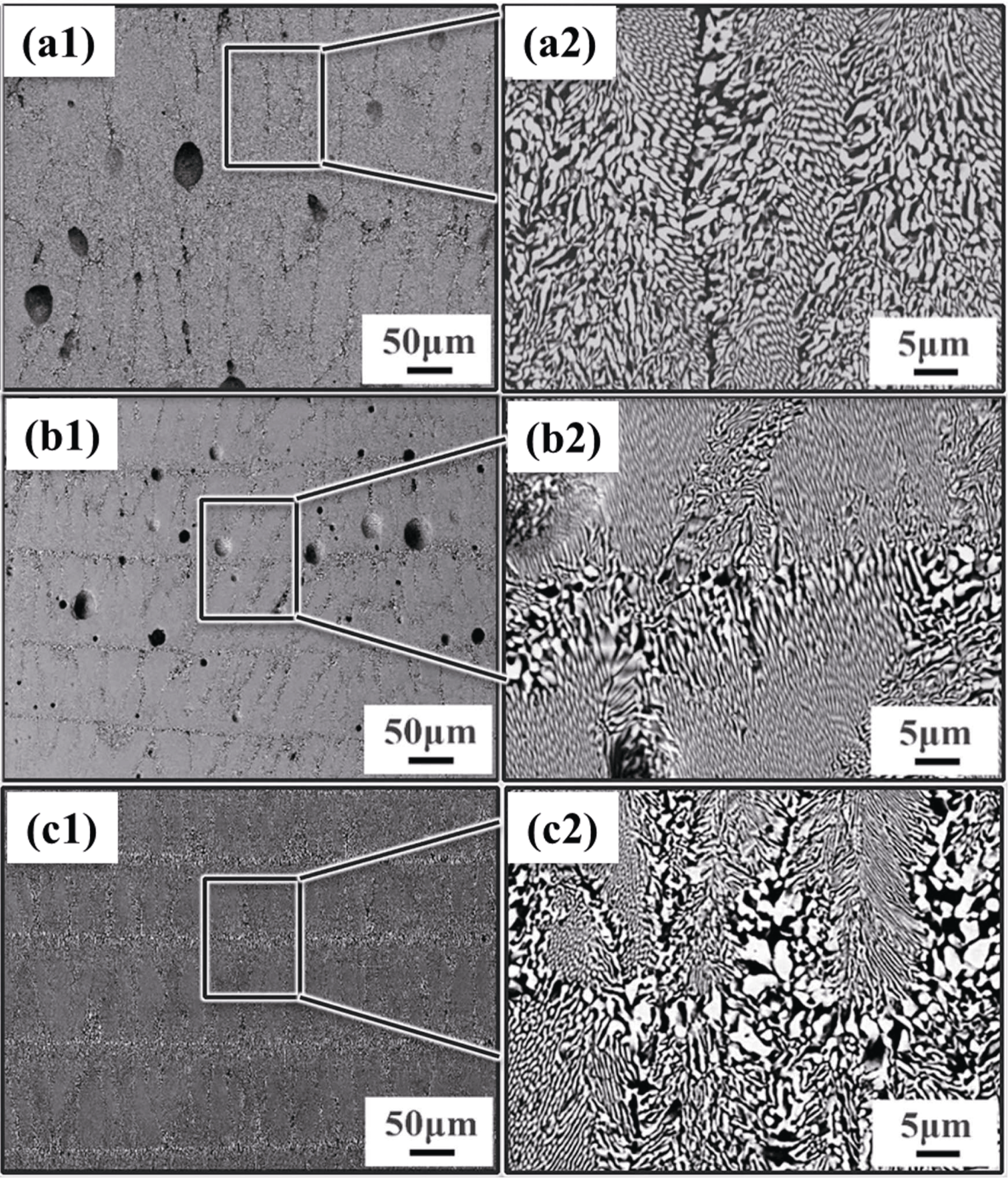

Fig. 12 Microstructures of the longitudinal sections of the specimens at different powder feeding rates (c>b>a)[78] (a2-c2) Corresponding magnified microstructures

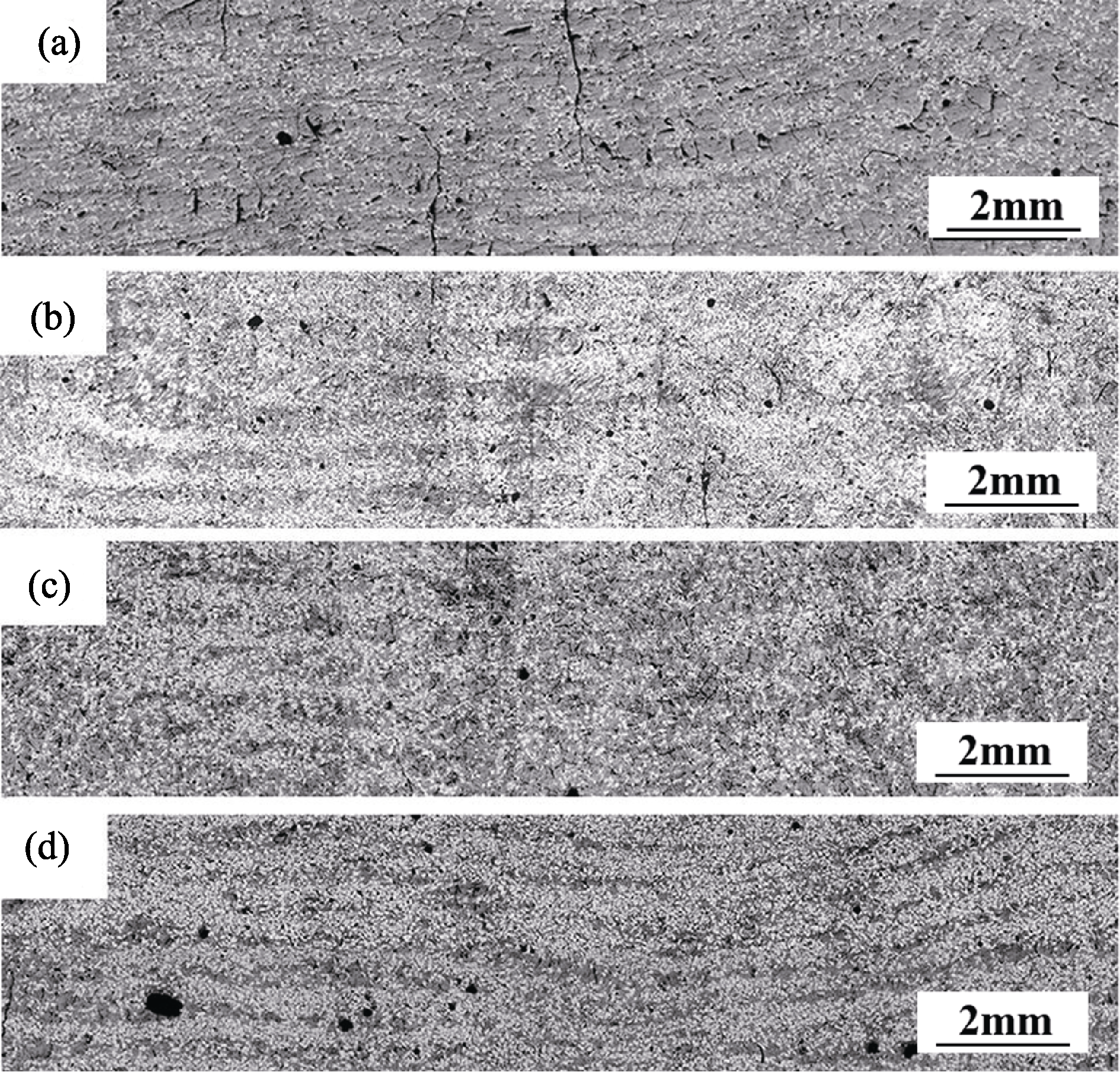

Fig. 15 SEM images of longitudinal sections of Al2O3/ZrO2 ceramic specimens with different SiC particle contents (mass fraction)[88] (a) 10%; (b) 15%; (c) 20%; (d) 25%

| [1] | 傅恒志. 未来航空发动机材料面临的挑战与发展趋向. 航空材料学报, 1998, 18(4): 52. |

| [2] |

张健, 王莉, 王栋, 等. 镍基单晶高温合金的研发进展. 金属学报, 2019, 55(9): 1077.

DOI |

| [3] | WINDHORST T, BLOUNT G. Carbon-carbon composites: a summary of recent developments and applications. Materials & Design, 1997, 18(1): 11. |

| [4] | MONTEVERDE F, SAVINO R. Stability of ultra-high-temperature ZrB2-SiC ceramics under simulated atmospheric re-entry conditions. Journal of the European Ceramic Society, 2007, 27(16): 4797. |

| [5] | TAN M, CHEN X W, YANG J S, et al. Microstructure and oxidation behavior of ZrB2-SiC ceramics fabricated by tape casting and reactive melt infiltration. Journal of Inorganic Materials, 2024, 39(8): 955. |

| [6] | TANG S, DENG J, WANG S, et al. Ablation behaviors of ultra- high temperature ceramic composites. Materials Science and Engineering: A, 2007, 465(1/2): 1. |

| [7] | ZHANG X H, WANG Y M, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [8] |

LIU H F, SU H J, SHEN Z L, et al. Research progress on ultrahigh temperature oxide eutectic ceramics by laser additive manufacturing. Journal of Inorganic Materials, 2022, 37(3): 255.

DOI |

| [9] | WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. A ductile ceramic eutectic composite with high strength at 1873 K. Nature, 1997, 389(6646): 49. |

| [10] | SU H, SHEN Z, MA W, et al. Comprehensive microstructure regularization mechanism and microstructure-property stability at 1773 K of directionally solidified Al2O3/GdAlO3 eutectic ceramic composite. Composites Part B: Engineering, 2023, 256: 110647. |

| [11] | NAKAGAWA N, OHTSUBO H, MITANI A, et al. High temperature strength and thermal stability for melt growth composite. Journal of the European Ceramic Society, 2005, 25(8): 1251. |

| [12] | BORODIN V A, STAROSTIN M Y, YALOVETS T N. Structure and related mechanical properties of shaped eutectic Al2O3-ZrO2(Y2O3) composites. Journal of Crystal Growth, 1990, 104(1): 148. |

| [13] | WAKU Y. A new ceramic eutectic composite with high strength at 1873 K. Advanced Materials, 1998, 10(8): 615. |

| [14] | LIU Y, SU H, TAN X, et al. Unveiling crystallographic texture in laser floating zone melted Al2O3/YAG eutectic ceramic by seed- crystal inducing. Ceramics International, 2024, 50(20): 40185. |

| [15] | ZHAO D, SU H, HAO S, et al. Insight into faceted-nonfaceted transition of directionally solidified eutectic ceramic composites by laser floating zone melting and infrared imaging. Composites Part B: Engineering, 2024, 277: 111372. |

| [16] | CHEN J, SU R, ZHAI X, et al. Improving the accuracy of stereolithography 3D printed Al2O3 microcomponents by adding photoabsorber: fundamentals and experiments. Journal of Materials Research and Technology, 2023, 27: 757. |

| [17] | ZHAI X, CHEN J, SU R, et al. Vat photopolymerization 3D printing of Al2O3 ceramic cores with strip-shaped pores by using polyamide 6 fiber template. Journal of the American Ceramic Society, 2024, 107(8): 5400. |

| [18] |

WANG L K, FENG J Z, JIANG Y G, et al. Direct-ink-writing 3D printing of ceramic-based porous structures: a review. Journal of Inorganic Materials, 2023, 38(10): 1133.

DOI |

| [19] | 申仲琳, 苏海军, 刘海方, 等. 超高温氧化物陶瓷激光增材制造技术与缺陷控制研究进展. 复合材料学报, 2021, 38(3): 668. |

| [20] | DONG X, WU J, ZHOU Q, et al. Mechanical and dielectric properties of Si3N4-SiO2 ceramics prepared by digital light processing based 3D printing and oxidation sintering. Ceramics International, 2023, 49(18): 29699. |

| [21] | 王华明, 张述泉, 王向明. 大型钛合金结构件激光直接制造的进展与挑战(邀请论文). 中国激光, 2009, 36(12): 3204. |

| [22] | 林鑫, 黄卫东. 高性能金属构件的激光增材制造. 中国科学: 信息科学, 2015, 45(9): 1111. |

| [23] | WOOD S. 3D printing in outer space NASA 3D prints first full-scale copper rocket engine part. Materials Australia, 2015, 48(2): 42. |

| [24] | THIELE M, KUTLU Y, DOBBELSTEIN H, et al. Direct generation of 3D structures by laser polymer deposition. Journal of Laser Applications, 2021, 33(2): 022002. |

| [25] | LIU H, JIANG H, CHEN Q, et al. Insights into the applicability of laser energy density in directly preparing Al2O3-based eutectic ceramics by laser additive manufacturing. Ceramics International, 2024, 50(2): 3381. |

| [26] | LIU H, SU H, SHEN Z, et al. Insights into high thermal stability of laser additively manufactured Al2O3/GdAlO3/ZrO2 eutectic ceramics under high temperatures. Additive Manufacturing, 2021, 48: 102425. |

| [27] | JIANG H, SU H, YU M, et al. Insights into the influence of powder particle shape on forming process and mechanical properties of Al2O3 ceramic fabricated by laser directed energy deposition. Additive Manufacturing, 2024, 81: 103984. |

| [28] | HU Y, NING F, WANG X, et al. Laser deposition-additive manufacturing of in situ TiB reinforced titanium matrix composites: TiB growth and part performance. The International Journal of Advanced Manufacturing Technology, 2017, 93(9): 3409. |

| [29] | NIU F, WU D, MA G, et al. Additive manufacturing of ceramic structures by laser engineered net shaping. Chinese Journal of Mechanical Engineering, 2015, 28(6): 1117. |

| [30] | NAVARRETE-SEGADO P, FRANCES C, TOURBIN M, et al. Powder bed selective laser process (sintering/melting) applied to tailored calcium phosphate-based powders. Additive Manufacturing, 2022, 50: 102542. |

| [31] | 郭洪飞, 高文海, 郝新, 等. 选择性激光烧结原理及实例应用. 新技术新工艺, 2007(6): 60. |

| [32] | DECKERS J P, SHAHZAD K, CARDON L, et al. Shaping ceramics through indirect selective laser sintering. Rapid Prototyping Journal, 2016, 22(3): 544. |

| [33] | CHEN Q, SU H K, JIANG H, et al. Progress of ultra-high temperature oxide ceramics: laser additive manufacturing and microstructure evolution. Journal of Inorganic Materials, 2024, 39(7): 741. |

| [34] | LU Y, ZHOU Y, WEN P, et al. Effect of laser power on microstructure and mechanical properties of K418 nickel-based alloy prepared by selective laser melting. Journal of Materials Research and Technology, 2023, 27: 2964. |

| [35] | MULLEN L, STAMP R C, BROOKS W K, et al. Selective Laser Melting: a regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2009, 89B(2): 325. |

| [36] | YVES-CHRISTIAN H, JAN W, WILHELM M, et al. Net shaped high performance oxide ceramic parts by selective laser melting. Physics Procedia, 2010, 5: 587. |

| [37] | SHEN Z, SU H, YU M, et al. Large-size complex-structure ternary eutectic ceramic fabricated using laser powder bed fusion assisted with finite element analysis. Additive Manufacturing, 2023, 72: 103627. |

| [38] | SHEN Z, SU H, YU M, et al. Enhanced 3D printing and crack control in melt-grown eutectic ceramic composites with high- entropy alloy doping. Journal of Materials Science & Technology, 2025, 209: 64. |

| [39] | HUANG Y F, WU D J, YU X X, et al. Cracking mechanism in laser directed energy deposition of melt growth alumina/aluminum titanate ceramics. Journal of the American Ceramic Society, 2023, 106(7): 4358. |

| [40] | WU D, SHI J, NIU F, et al. Direct additive manufacturing of melt growth Al2O3-ZrO2 functionally graded ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2022, 42(6): 2957. |

| [41] | WU D K, YU X X, ZHAO Z Y, et al. Direct additive manufacturing of TiCp reinforced Al2O3-ZrO2 eutectic functionally graded ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2023, 43(6): 2718. |

| [42] | SHEN Z, SU H, JIANG H, et al. Predicting rapid growth behavior in solidified eutectic ceramic composites using infrared thermal imaging and thermal field simulation during laser directed energy deposition. Composites Part B: Engineering, 2024, 283: 111619. |

| [43] | NIU F, WU D, MA G, et al. Rapid fabrication of eutectic ceramic structures by laser engineered net shaping. Procedia CIRP, 2016, 42: 91. |

| [44] | FAN Z, ZHAO Y, TAN Q, et al. Nanostructured Al2O3-YAG-ZrO2 ternary eutectic components prepared by laser engineered net shaping. Acta Materialia, 2019, 170: 24. |

| [45] | GU D, SHI X, POPRAWE R, et al. Material-structure-performance integrated laser-metal additive manufacturing. Science, 2021, 372(6545): eabg1487. |

| [46] | DADKHAH M, TULLIANI J M, SABOORI A, et al. Additive manufacturing of ceramics: advances, challenges, and outlook. Journal of the European Ceramic Society, 2023, 43(15): 6635. |

| [47] | SU H, LIU H, JIANG H, et al. One-step preparation of melt-grown Al2O3/GdAlO3/ZrO2 eutectic ceramics with large size and irregular shape by directed energy deposition. Additive Manufacturing, 2023, 70: 103563. |

| [48] | ZHANG K, MENG Q, QU Z, et al. A review of defects in vat photopolymerization additive-manufactured ceramics: characterization, control, and challenges. Journal of the European Ceramic Society, 2024, 44(3): 1361. |

| [49] | WANG A H, WANG W Y, XIE C S, et al. Microstructural characteristics of Al2O3-based refractory containing ZrO2 induced by CO2 laser melting. Applied Surface Science, 2004, 221: 293. |

| [50] | LIU Q, SONG B, LIAO H. Microstructure study on selective laser melting yttria stabilized zirconia ceramic with near IR fiber laser. Rapid Prototyping Journal, 2014, 20(5): 346. |

| [51] | NIU F, WU D, LU F, et al. Microstructure and macro properties of Al2O3 ceramics prepared by laser engineered net shaping. Ceramics International, 2018, 44(12): 14303. |

| [52] | YAN S, WU D, NIU F, et al. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceramics International, 2018, 44(1): 1120. |

| [53] | YAN S, HUANG Y, ZHAO D, et al. 3D printing of nano-scale Al2O3-ZrO2 eutectic ceramic: principle analysis and process optimization of pores. Additive Manufacturing, 2019, 28: 120. |

| [54] | QU M, GUO Q, ESCANO L I, et al. Mitigating keyhole pore formation by nanoparticles during laser powder bed fusion additive manufacturing. Additive Manufacturing Letters, 2022, 3: 100068. |

| [55] | XIONG Z, ZHANG K, ZHU Z, et al. Effect of laser focus shift on the forming quality, microstructure and mechanical properties of additively manufactured Al2O3-ZrO2 eutectic ceramics. Ceramics International, 2023, 49(22): 35948. |

| [56] | RAZAVYKIA A, BRUSA E, DELPRETE C, et al. An overview of additive manufacturing technologies—a review to technical synthesis in numerical study of selective laser melting. Materials, 2020, 13(17): 3895. |

| [57] | LI S, LIU D, MI H, et al. Numerical simulation on evolution process of molten pool and solidification characteristics of melt track in selective laser melting of ceramic powder. Ceramics International, 2022, 48(13): 18302. |

| [58] | LI F, LIU Z, LI B, et al. Pore formation model for direct laser deposition of Al2O3-ZrO2 ceramic. Journal of the European Ceramic Society, 2022, 42(1): 207. |

| [59] | LIANG Z, LIAO Z, ZHANG H, et al. Improving process stability of electron beam directed energy deposition by closed-loop control of molten pool. Additive Manufacturing, 2023, 72: 103638. |

| [60] | LIU Z, MA C, CHANG Z, et al. Formation mechanism and quantitative analysis of pores in Al2O3-ZrO2 ceramic different structures by laser additive manufacturing. Ceramics International, 2023, 49(10): 16099. |

| [61] | LIU H, SU H, SHEN Z, et al. Effect of scanning speed on the solidification process of Al2O3/GdAlO3/ZrO2 eutectic ceramics in a single track by selective laser melting. Ceramics International, 2019, 45(14): 17252. |

| [62] | TRIANTAFYLLIDIS D, LI L, STOTT F H. Mechanisms of porosity formation along the solid/liquid interface during laser melting of ceramics. Applied Surface Science, 2003, 208: 458. |

| [63] | OLIETE P B, PEÑA J I. Study of the gas inclusions in Al2O3/ Y3Al5O12 and Al2O3/Y3Al5O12/ZrO2 eutectic fibers grown by laser floating zone. Journal of Crystal Growth, 2007, 304(2): 514. |

| [64] | SUSAN D F, PUSKAR J D, BROOKS J A, et al. Quantitative characterization of porosity in stainless steel LENS powders and deposits. Materials Characterization, 2006, 57(1): 36. |

| [65] | ZHAO D K, BI G J, CHEN J, et al. Melt-grown behaviour of heat treated high-purity alumina ceramics prepared by laser directed energy deposition. Ceramics International, 2024, 50(1): 1777. |

| [66] | WILCOX W R, KUO V H S. Gas bubble nucleation during crystallization. Journal of Crystal Growth, 1973, 19(4): 221. |

| [67] | WU D, YU X, ZHAO Z, et al. One-step additive manufacturing of TiCp reinforced Al2O3-ZrO2 eutectic ceramics composites by laser directed energy deposition. Ceramics International, 2023, 49(8): 12758. |

| [68] | HUANG Y, WU D, ZHAO D, et al. Investigation of melt-growth alumina/aluminum titanate composite ceramics prepared by directed energy deposition. International Journal of Extreme Manufacturing, 2021, 3(3): 035101. |

| [69] | ZHANG K, MENG Q, ZHANG X, et al. Quantitative characterization of defects in stereolithographic additive manufactured ceramic using X-ray computed tomography. Journal of Materials Science & Technology, 2022, 118: 144. |

| [70] |

姚佳彤, 苏海军, 姜浩, 等. 氧化物共晶陶瓷激光增材制造裂纹缺陷形成及抑制研究进展. 材料工程, 2024, 52(5): 34.

DOI |

| [71] | HUANG Y, WU D, ZHAO D, et al. Process optimization of melt growth alumina/aluminum titanate composites directed energy deposition: effects of scanning speed. Additive Manufacturing, 2020, 35: 101210. |

| [72] | ZHAO J, SUN L, JI P, et al. The effect of scanning strategies on the microstructure and mechanical properties of M2052 alloy manufactured by selective laser melting. Journal of Materials Research and Technology, 2023, 27: 7084. |

| [73] | DAS T, KUMAR B R, SAHOO B K, et al. Implementation of different scanning strategy to improve the mechanical and wear properties of 15-5 PH stainless steel fabricated by laser-directed energy deposition. Materials Today Communications, 2024, 38: 108533. |

| [74] | GAO L, BHATTACHARYYA J, LIN W, et al. Tailoring material microstructure and property in wire-laser directed energy deposition through a wiggle deposition strategy. Additive Manufacturing, 2023, 77: 103801. |

| [75] | DOS SANTOS PAES L E, PEREIRA M, XAVIER F A, et al. Understanding the behavior of laser surface remelting after directed energy deposition additive manufacturing through comparing the use of iron and inconel powders. Journal of Manufacturing Processes, 2021, 70: 494. |

| [76] | MISHRA G K, PAUL C P, RAI A K, et al. Experimental investigation on laser directed energy deposition based additive manufacturing of Al2O3 bulk structures. Ceramics International, 2021, 47(4): 5708. |

| [77] | WILKES J, HAGEDORN Y C, MEINERS W, et al. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyping Journal, 2013, 19(1): 51. |

| [78] | SHEN Z, SU H, LIU Y, et al. Laser additive manufacturing of melt-grown Al2O3/GdAlO3 eutectic ceramic composite: powder designs and crack analysis with thermo-mechanical simulation. Journal of the European Ceramic Society, 2022, 42(14): 6583. |

| [79] | LIU Q, DANLOS Y, SONG B, et al. Effect of high-temperature preheating on the selective laser melting of yttria-stabilized zirconia ceramic. Journal of Materials Processing Technology, 2015, 222: 61. |

| [80] | LIU H, SU H, SHEN Z, et al. Preparation of large-size Al2O3/ GdAlO3/ZrO2 ternary eutectic ceramic rod by laser directed energy deposition and its microstructure homogenization mechanism. Journal of Materials Science & Technology, 2021, 85: 218. |

| [81] | WU D, LIU H, LU F, et al. Al2O3-YAG eutectic ceramic prepared by laser additive manufacturing with water-cooled substrate. Ceramics International, 2019, 45(3): 4119. |

| [82] | HU Y, NING F, CONG W, et al. Ultrasonic vibration-assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties. Ceramics International, 2018, 44(3): 2752. |

| [83] | YAN S, WU D, NIU F, et al. Al2O3-ZrO2 eutectic ceramic via ultrasonic-assisted laser engineered net shaping. Ceramics International, 2017, 43(17): 15905. |

| [84] |

牛方勇, 于学鑫, 赵紫渊, 等. 熔体自生陶瓷激光直接能量沉积增材制造研究进展. 材料工程, 2022, 50(7): 1.

DOI |

| [85] | PFEIFFER S, MAKOWSKA M, FLORIO K, et al. Selective laser melting of thermal pre-treated metal oxide doped aluminum oxide granules. Open Ceramics, 2020, 2: 100007. |

| [86] | VERGA F, BORLAF M, CONTI L, et al. Laser-based powder bed fusion of alumina toughened zirconia. Additive Manufacturing, 2020, 31: 100959. |

| [87] | 吴东江, 杨策, 吴楠, 等. SiC颗粒掺杂对激光直接成形Al2O3陶瓷裂纹敏感性的影响. 光学精密工程, 2012, 20(7): 1551. |

| [88] | WU D J, LU F, ZHAO D K, et al. Effect of doping SiC particles on cracks and pores of Al2O3-ZrO2 eutectic ceramics fabricated by directed laser deposition. Journal of Materials Science, 2019, 54(13): 9321. |

| [89] | YAN S, WU D, HUANG Y, et al. C fiber toughening Al2O3-ZrO2 eutectic via ultrasonic-assisted directed laser deposition. Materials Letters, 2019, 235: 228. |

| [90] | NIU F, WU D, HUANG Y, et al. Direct additive manufacturing of large-sized crack-free alumina/aluminum titanate composite ceramics by directed laser deposition. Rapid Prototyping Journal, 2019, 25(8): 1370. |

| [1] | FAN Yuzhu, WANG Yuan, WANG Linyan, XIANG Meiling, YAN Yuting, LI Benhui, LI Min, WEN Zhidong, WANG Haichao, CHEN Yongfu, QIU Huidong, ZHAO Bo, ZHOU Chengyu. Graphene Oxide-based Adsorbents for Pb(II) Removing in Water: Progresses on Synthesis, Performance and Mechanism [J]. Journal of Inorganic Materials, 2026, 41(1): 12-26. |

| [2] | XU Jintao, GAO Pan, HE Weiyi, JIANG Shengnan, PAN Xiuhong, TANG Meibo, CHEN Kun, LIU Xuechao. Recent Progress on Preparation of 3C-SiC Single Crystal [J]. Journal of Inorganic Materials, 2026, 41(1): 1-11. |

| [3] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [4] | XIAO Xiaolin, WANG Yuxiang, GU Peiyang, ZHU Zhenrong, SUN Yong. Advances in Regulation of Damaged Skin Regeneration by Two-dimensional Inorganic Materials [J]. Journal of Inorganic Materials, 2025, 40(8): 860-870. |

| [5] | MA Jingge, WU Chengtie. Application of Inorganic Bioceramics in Promoting Hair Follicle Regeneration and Hair Growth [J]. Journal of Inorganic Materials, 2025, 40(8): 901-910. |

| [6] | ZHANG Hongjian, ZHAO Ziyi, WU Chengtie. Inorganic Biomaterials on Regulating Neural Cell Function and Innervated Tissue Regeneration: A Review [J]. Journal of Inorganic Materials, 2025, 40(8): 849-859. |

| [7] | AI Minhui, LEI Bo. Micro-nanoscale Bioactive Glass: Functionalized Design and Angiogenic Skin Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 921-932. |

| [8] | WANG Yutong, CHANG Jiang, XU He, WU Chengtie. Advances in Silicate Bioceramic/Bioglass for Wound Healing: Effects, Mechanisms and Application Ways [J]. Journal of Inorganic Materials, 2025, 40(8): 911-920. |

| [9] | MA Wenping, HAN Yahui, WU Chengtie, LÜ Hongxu. Application of Inorganic Bioactive Materials in Organoid Research [J]. Journal of Inorganic Materials, 2025, 40(8): 888-900. |

| [10] | LUO Xiaomin, QIAO Zhilong, LIU Ying, YANG Chen, CHANG Jiang. Inorganic Bioactive Materials Regulating Myocardial Regeneration [J]. Journal of Inorganic Materials, 2025, 40(8): 871-887. |

| [11] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [12] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [13] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [14] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [15] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||