|

|

Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds

LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming

2025 Vol. 40 (9): 933–943

Abstract

Abstract(

697 )

HTML

HTML(

30)

PDF

PDF(1836KB)(

811

)

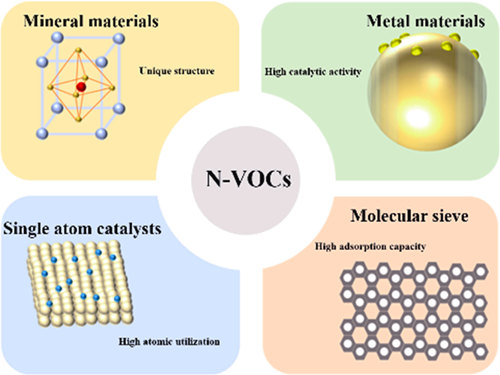

Volatile organic compounds (VOCs) and NOx are important precursors of PM2.5 and O3, and their excessive emissions have significant negative impacts on environmental quality and human health. Compared with ordinary VOCs, nitrogen-containing volatile organic compounds (N-VOCs) need more complex environmental control strategies due to their nitrogen heteroatoms. Therefore, development and application of control technologies for N-VOCs have become a current research hotspot. In order to achieve the two key objectives of low-temperature high catalytic activity and high N2 selectivity in catalytic oxidation system of N-VOCs, there is an urgent need to design efficient and low-cost catalysts. This paper systematically summarizes the research progress of mineral materials, metal materials, single atom catalysts (SACs) and molecular sieves in catalytic oxidation of common N-VOCs (N,N-dimethylformamide, acrylonitrile, acetonitrile, n-butylamine, triethylamine, etc.), and describes the sources and hazards of N-VOCs. The key factors affecting catalytic oxidation of amines, nitriles and other typical N-VOCs are summarized, including catalytic activity, catalyst physicochemical properties, catalytic constitutive relationship and reaction mechanism. It is proposed that secondary pollutants should be avoided from deep oxidation of intermediate products in catalytic oxidation of N-VOCs. Finally, the prospects and challenges on catalytic oxidation of N-VOCs are discussed, aiming to provide theoretical guidance and practical cases for clearing N-VOCs in the future.

|

|

|

A Review of Pore Defects in Ultra-high Temperature Oxide Ceramics by Laser Additive Manufacturing: Formation and Suppression

YU Shengyang, SU Haijun, JIANG Hao, YU Minghui, YAO Jiatong, YANG Peixin

2025 Vol. 40 (9): 944–956

Abstract

Abstract(

498 )

HTML

HTML(

29)

PDF

PDF(9545KB)(

222

)

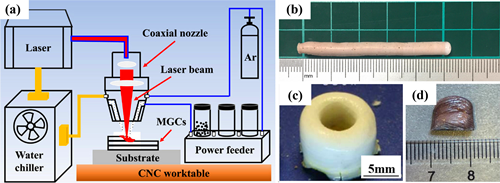

Ultra-high temperature oxide ceramics, known for their outstanding high-temperature strength, microstructural stability, oxidation and corrosion resistance, are anticipated to serve as the next generation of ultra-high temperature structural materials, suitable for prolonged use in high-temperature oxidizing environments, and are expected to have broad application potential in the aerospace sector. In recent years, laser additive manufacturing (LAM) technology has emerged as a prominent method for the preparation of ultra-high temperature oxide ceramics, characterized by advantages such as rapid near-net shaping, mold-free production, and high flexibility for fabricating complex-shaped parts, thereby establishing itself as a significant research hotspot. However, ceramics are highly prone to pore defects during LAM process, which not only hinders the subsequent deposition of samples but also leads to deterioration in the surface quality and mechanical properties of formed parts. This review firstly provides an overview of the basic principles and process characteristics of three LAM techniques, including selective laser sintering (SLS), laser powder bed fusion (LPBF), and laser directed energy deposition (LDED). It focuses on characteristics of pore defects, flow characteristics of molten pool, and formation mechanism of pore defects in the LAM of ultra-high temperature oxide ceramics. Furthermore, their research progress in suppressing pore defects is detailed from three aspects: optimization of process parameters, outfield assistance, and second-phase doping. Finally, their challenges associated with achieving practical engineering applications are summarized, along with prospective development trends and breakthrough points in the field, focusing on suppression of forming defects, powder characteristics and subsequent heat treatment.

|

|

|

Flash Joining of Metal Cu with 5YSZ Ceramics

LI Wenjin, LOU Chengguang, ZHANG Shuai, SU Xinghua

2025 Vol. 40 (9): 957–963

Abstract

Abstract(

487 )

HTML

HTML(

5)

PDF

PDF(3455KB)(

269

)

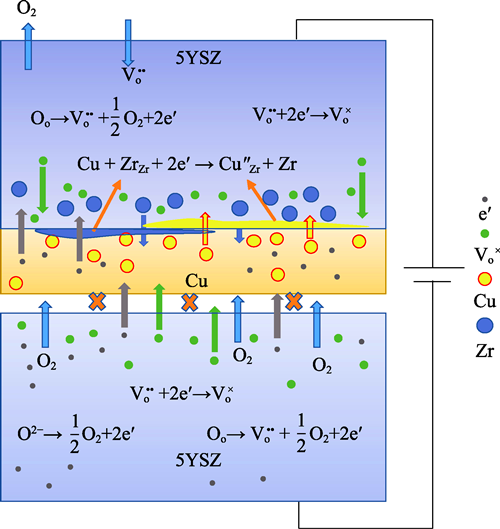

Joining of ceramic and metal meets the engineering needs for high-performance structural components. However, the significant difference in thermal expansion coefficients between metals and ceramics, as well as the poor wettability of metals on ceramic surfaces, makes the joining of ceramics and metals face many challenges. In this study, “flash joining” technology was used to achieve the rapid connection of metal Cu and 5YSZ (5% yttria stabilized zirconia, molar fraction) ceramics at a relatively low temperature under the assistance of electric field/current. The effects of electric field, current density, and joining time on the “flash joining” behavior and the degree of bonding between Cu and 5YSZ were investigated. Moreover, the mechanism of “flash joining” between Cu and 5YSZ was discussed. The results showed that the densest joint between Cu and 5YSZ was obtained at a temperature of 753 ℃, a current density of 10 A/cm2 and a joining time of 3 min. However, the joint began to deteriorate and even fracture when the temperature, current and joining time were further increased. Electrochemical reactions occurred during the “flash joining” process, introducing oxygen vacancy defects. Phase and microstructural analyses indicated that atomic diffusion driven by electrochemical reactions facilitated the joining of Cu and 5YSZ, with Cu atoms diffusing into the 5YSZ lattice and reduced Zr atoms diffusing into the Cu lattice. In addition, the direction of the electric field had a significant impact on the bonding between Cu and 5YSZ. A good bond was achieved when the electric field was oriented from 5YSZ to Cu, while the bonding did not occur when the electric field direction was from Cu to 5YSZ.

|

|

|

Effect of Oscillatory Pressure Amplitude on Microstructures and Wear Resistance of Tungsten Carbide

ZHONG Weimin, ZHAO Ke, WANG Kewei, LIU Dianguang, LIU Jinling, AN Linan

2025 Vol. 40 (9): 964–970

Abstract

Abstract(

370 )

HTML

HTML(

10)

PDF

PDF(6827KB)(

242

)

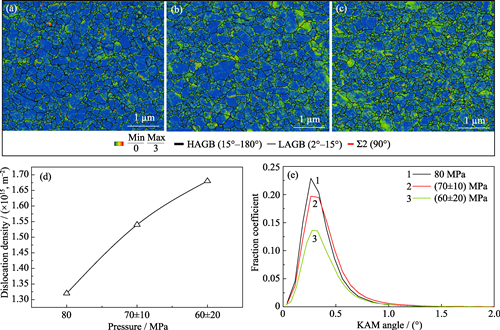

Achieving complete densification of ultrafine-grained tungsten carbide (WC) without inducing grain growth has long been a challenge, which limits industrial applications of WC. The dynamic sinter forging process, which involves forging of incompletely dense materials under oscillatory pressure, facilitates densification while suppressing grain growth. This study explores effects of oscillatory pressure amplitude during dynamic sinter forging on microstructure and tribological properties of WC. The results show that increasing pressure amplitude leads to higher relative density of WC, accompanied by a reduction in grain size, an increase in proportion of low angle grain boundaries and special grain boundaries Σ2, as well as an enhancement of dislocation density. At a pressure amplitude of 20 MPa, the relative density, average grain size and dislocation density of WC reach 99.6%, 203 nm and 1.68×1015 m-2, respectively. With an increase in pressure amplitude, both the friction coefficient and the wear rate gradually decrease. Under this condition, the adhesive wear and ploughing were identified as the dominant wear mechanisms. The reduction in wear rate is attributed to complete densification, finer grains and higher dislocation density, which result from the increased pressure amplitude. Grain refinement and high dislocation density enhance plastic deformation capacity and hardening ability during the wear, thereby increasing hardness of worn surface while mitigating crack initiation and propagation. Furthermore, special grain boundaries Σ2 also effectively impede motion of dislocation, thereby improving strain hardening capability and enhancing hardness of worn surface.

|

|

|

Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time

CHEN Bin, REN Ke, WANG Yiguang

2025 Vol. 40 (9): 971–980

Abstract

Abstract(

544 )

HTML

HTML(

20)

PDF

PDF(2956KB)(

338

)

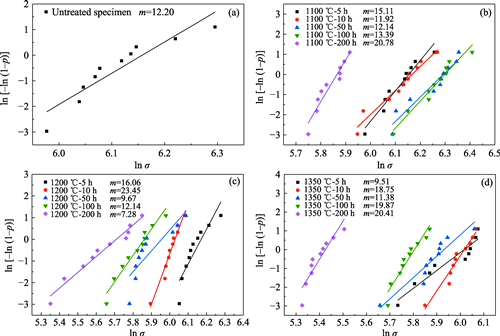

Continuous silicon carbide fiber reinforced silicon carbide (SiCf/SiC) composites are widely utilized in the hot-end components of aero engines due to their exceptional properties and high-temperature resistance. To ensure the safety and reliability of SiCf/SiC composite parts during service, it is crucial to investigate the evolution of their mechanical properties under prolonged high-temperature exposure. In this study, mini-SiCf/SiC composites with a BN interface were fabricated using Cansas-II SiC fibers. These mini-SiCf/SiC composites underwent heat treatment at 1100, 1200, and 1350 ℃ for durations of 5, 10, 50, 100, and 200 h, respectively, to examine the effects of high-temperature and long-term heat treatment on their mechanical properties and microstructure. The results show that at 1100 ℃, heat treatment has no significant impact on the mini-SiCf/SiC composites. The mechanical properties remain largely unchanged, and the contribution fractions of each stage to the overall mechanical performance remain consistent. At 1200 ℃, short-term heat treatment shows minimal effects on the mini-SiCf/SiC composites without notable change in tensile strength. However, prolonged heat treatment leads to damage in the SiC fibers, thereby decreasing their tensile strength. At 1350 ℃, heat treatment significantly improves the properties of the BN interface but causes severe damage to the SiC fibers, resulting in a marked decline in the mechanical properties of the mini composites. As the heat treatment duration increases, the extent of fiber damage intensifies, leading to a continuous deterioration in the mechanical performance of the composites.

|

|

|

Compressive Resilience Mechanism of SiO2 Nanofibre Aerogels

LI Fuping, CHU Jiabao, QIU Haibo, DANG Wei, LI Chenxi, ZHAO Kang, TANG Yufei

2025 Vol. 40 (9): 981–988

Abstract

Abstract(

422 )

HTML

HTML(

6)

PDF

PDF(7800KB)(

125

)

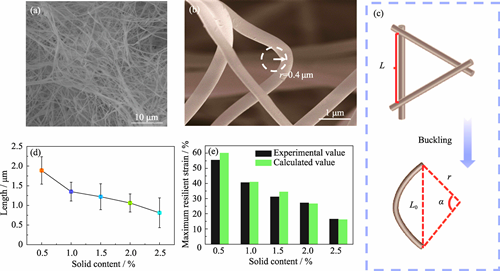

SiO2 aerogels possess low density, ultralow thermal conductivity and excellent chemical stability, endowing them suitable for wide application in the fields of aviation/aerospace, building energy conservation, and energy chemical industry. Traditional SiO2 nanoparticle aerogels have large brittleness and poor resilience due to their pearl necklace-like particle structure. Using nanofibers as construction units to fabricate SiO2 nanofiber aerogels can overcome these shortcomings to some extent. However, the resilience mechanism of SiO2 nanofiber aerogels is still unclear, which limits further improvement in their mechanical properties. Here, flexible SiO2 nanofibers were prepared by electrospinning to investigate the effect of calcination temperature on phase microstructure to elucidate flexibility mechanism. Subsequently, SiO2 nanofiber aerogels were fabricated by freeze drying. The influence of solid content on the pore structure, strength and resilience of aerogels was studied. A buckling deformation model based on effective nanofiber length was established to explain the compressive resilience mechanism. The findings show that calcination temperature affects the amorphous structure and flexibility of SiO2 nanofibers. Degree of short-range order in SiO2 increases with the increase in calcination temperature, leading to poor flexibility of nanofibers, while resilience of SiO2 nanofiber aerogels is related to solid content. The energy loss coefficient and resilient rate of the aerogels fabricated with 0.5% (in mass) solid content are 0.6 and 55.2%, respectively. Further data shows that the resilience of SiO2 nanofiber aerogels is dominated by effective nanofiber length and the curvature radius of nanofibers. Based on the above results, a relationship of resilience model is established and proved through nanofiber buckling theory. With a reduction in curvature radius, achievable through enhancement of nanofiber flexibility and increase in effective nanofiber length, the compressive resilient rate of aerogels increases. The present study provides theoretical guidance for the design of SiO2 nanofiber aerogels with high resilience.

|

|

|

Nanocrystalline CeO2-ZrO2 Solid Solution: One-step Alcohothermal Synthesis and Arsenic Removal Performance

LI Ronghui, QIAN Jun

2025 Vol. 40 (9): 989–996

Abstract

Abstract(

300 )

HTML

HTML(

8)

PDF

PDF(1365KB)(

269

)

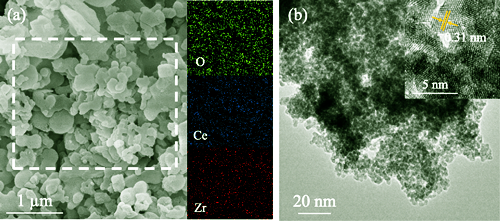

CeO2-ZrO2 solid solution is generally synthesized through chemical precipitation, followed by high-temperature calcination. However, their grains under high-temperature calcination are prone to aggregate and grow, resulting in lower specific surface area, weaker adsorption and poorer catalytic performance. In this study, nanocrystalline CeO2-ZrO2 solid solutions were prepared by a simple one-step alcohothermal method, avoiding effects of high-temperature calcination on grain growth and specific surface area reduction. Crystal structure, morphologies and thermal stability of the synthesized CeO2-ZrO2 solid solutions were characterized, and arsenic removal performance was determined. The results show that the grains in nanocrystalline CeO2-ZrO2 solid solutions grow sufficiently with large specific surface areas, high particle purity and good dispersibility, leading to improved adsorption effect on As(III) in water. The arsenic adsorption results show that maximum adsorption capacity of Ce0.8Zr0.2O2 sample can reach 160 mg/g at an As(III) equilibrium solubility of 95 mg/L, which is much higher than pure CeO2 and ZrO2 samples, as well as CeO2-ZrO2 solid solution prepared by traditional calcination method. In addition, the prepared Ce0.8Zr0.2O2 solid solution maintains a high As(III) removal rate and good acid-alkali resistance within pH range of 3-9. The arsenic adsorption mechanisms indicate that As(III) ions in the solution form coordination bonds with metal ions on the surface of Ce0.8Zr0.2O2 solid solution, which belongs to the chemical adsorption process.

|

|

|

Optimization of Thermoelectric Transport Properties in Nanocomposite MgAgSb-based Alloys

WU Huaxin, ZHANG Qihao, YAN Haixue, WANG Lianjun, JIANG Wan

2025 Vol. 40 (9): 997–1004

Abstract

Abstract(

332 )

HTML

HTML(

6)

PDF

PDF(2595KB)(

104

)

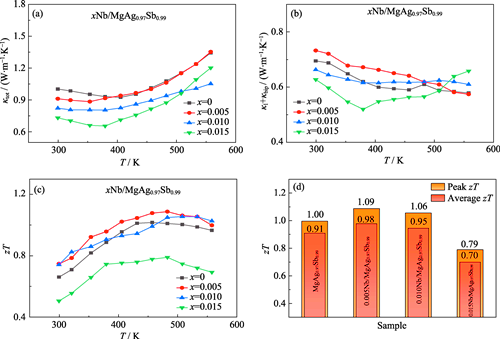

MgAgSb exhibits excellent thermoelectric performance in the near-room temperature range of 300-573 K, making it a key research focus for p-type materials in recent years. Due to the low level of atomic doping, the improvement of thermoelectric performance through carrier concentration optimization via doping alone is limited. In this study, Nb and Ta nano-secondary phases were introduced into the MgAg0.97Sb0.99 matrix, and two series of alloys, xNb/MgAg0.97Sb0.99 and yTa/MgAg0.97Sb0.99, were prepared using high-energy ball milling mechanical alloying. The introduction of Nb nano-secondary phase significantly altered carrier and phonon transport properties of the material. It was the presence of nano-secondary phase Nb in the 0.005Nb/MgAg0.97Sb0.99 alloy that optimized its unique microstructure and electrical performance, achieving a maximum power factor of 24.1 μW·cm-1·K-2 at 533 K. Additionally, the introduction of secondary phase enhanced phonon scattering, significantly reducing thermal conductivity. As a result, the 0.005Nb/MgAg0.97Sb0.99 sample achieved an optimal zT of 1.09 at 483 K, improved by 9.0% compared to MgAg0.97Sb0.99 at the same temperature. Furthermore, the introduction of Ta, a homologue of Nb, into the MgAg0.97Sb0.99 sample showed a similar trend, with 0.005Ta/MgAg0.97Sb0.99 achieving zT of 1.02 at 483 K. This study demonstrates an effective nanocomposite strategy for optimizing thermoelectric transport properties and enhancing thermoelectric performance of p-type MgAg0.97Sb0.99.

|

|

|

Al-doped P2-type Na0.8Ni0.33Mn0.67-xAlxO2 as Cathode for Sodium-ion Batteries: Synthesis and Electrochemical Properties

YAN Gongqin, WANG Chen, LAN Chunbo, HONG Yuxin, YE Weichao, FU Xianghui

2025 Vol. 40 (9): 1005–1012

Abstract

Abstract(

610 )

HTML

HTML(

16)

PDF

PDF(1752KB)(

264

)

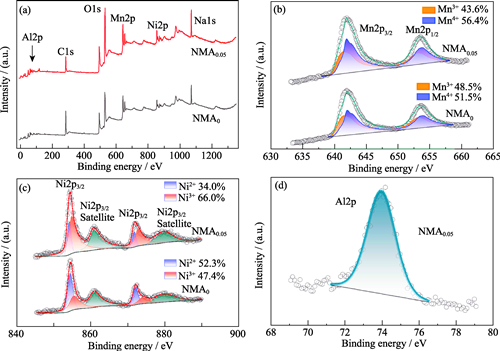

Sodium-ion batteries (SIBs) have emerged as a significant alternative to lithium-ion batteries, offering a cost-effective and safe solution with promising potential in energy storage. Among these, P2-type Ni/Mn based oxides possess the advantages of high theoretical capacity and wide operating voltage. However, the P2-O2 phase transition under high voltage and Jahn-Teller aberration significantly impact the cycling reversibility and structural stability. To address the above issues, here, P2-type Na0.8Ni0.33Mn0.67-xAlxO2 materials with different doping contents of Al using a high-temperature solid-phase method were prepared, and employed as cathodes for sodium-ion batteries. It was observed that Al doping resulted in strengthening of their metal-oxygen bonds (M-O bonds) and expansion of the distance of Na layer, thereby facilitating Na+ diffusion and enhancing structural stability. The electrochemical properties demonstrated that Al doping could impede the high-voltage phase transition, stimulate the electrochemical activity of Mn, and diminish the charge transfer resistance, leading to enhanced electrochemical properties of the materials. Among these P2-type Na0.8Ni0.33Mn0.67-xAlxO2 materials, Na0.8Ni0.33Mn0.62Al0.05O2 cathode displayed the optimal cycling performance with a capacity retention of 87.3% after 200 cycles at 0.1C (1C=200 mA·g-1) in the range of 2.0-4.2 V, and the superior rate performance with a discharge specific capacity of 100.9 mAh·g-1 at 2C in the range of 2.0-4.2 V.

|

|

|

Interface Engineering for the Anode in Solid-state Lithium Batteries Based on LLZTO Electrolyte

WEN Shenhao, PENG Dezhao, LIN Zheyu, GUO Xia, HUANG Peixin, ZHANG Zhizhen

2025 Vol. 40 (9): 1013–1021

Abstract

Abstract(

582 )

HTML

HTML(

9)

PDF

PDF(4291KB)(

537

)

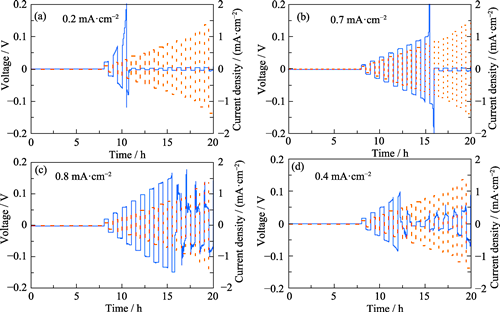

Garnet-type solid electrolytes (LLZTO) have attracted tremendous attention in the past few years, owing to their high ionic conductivity and wide electrochemical stability window. However, the poor wettability with lithium metal and severe lithium dendrite formation during cycling greatly hindered their application in large-scale devices. In this study, a composite anode (LAF) was prepared by melting Li metal and AlF3, which eventually formed fluorides (LiF, AlF3) and Li-Al alloys. Elemental distribution analysis revealed that a fluoride layer was formed at LLZTO|LAF interface upon contact with LLZTO. Compared to metallic lithium, the composite anode formed a significantly smaller interface contact angle with LLZTO, notably improving the interfacial wettability. As a result, the modified LAF3|LLZTO interface (a mass ratio of Li to AlF3 is 3 : 1) exhibits an ultralow interfacial resistance of 3.9 Ω/cm2, which is much lower than that of the lithium anode with LLZTO (138.6 Ω/cm²). Meanwhile, the critical current density of the composite anode with LLZTO increases from 0.2 mA/cm² to 0.8 mA/cm². LAF|LLZTO|LAF symmetric cells demonstrate stable plating/stripping for 3500 h under a current density of 0.2 mA/cm2, illustrating the good stability of lithium-ion plating/stripping process. LiFePO4|LLZTO|LAF quasi-solid-state battery delivers a high discharge capacity of 151.1 mAh/g at 0.1C rate (1C=170 mA/g) and retains 96.5% of its initial capacity after 240 cycles at 1C rate. The LAF composite anode demonstrated in this study effectively decreases the interfacial resistance between LLZTO and anode, and stabilizes lithium-ion plating/stripping process, offering a promising approach for designing high-performance LLZTO-based lithium metal batteries.

|

|

|

Cu-Mn-I Solid Solution Thin Films: Preparation and Control of p-type Transparent Conductive Properties

WANG Liangjun, OUYANG Yuzhao, ZHAO Junliang, YANG Chang

2025 Vol. 40 (9): 1022–1028

Abstract

Abstract(

287 )

HTML

HTML(

7)

PDF

PDF(1909KB)(

223

)

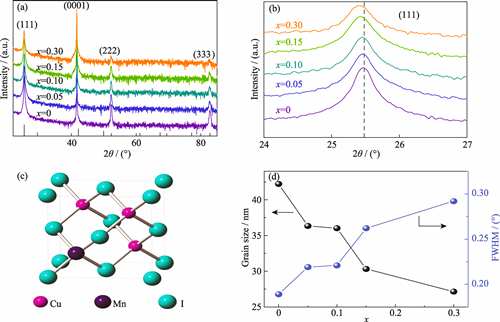

In the field of optoelectronic devices, p-type transparent semiconductor materials with controllable electrical properties hold significant application value. CuI, as a representative material, still faces considerable technical challenges in terms of preparation processes and doping control. This study successfully developed a new p-type transparent semiconductor material with adjustable electrical properties through manganese cation doping, offering a new approach for the advancement of transparent electronics. The Cu1-xMnxI solid solution film, prepared via reactive magnetron sputtering, exhibits unique performance advantages. Firstly, the material can be fabricated at room temperature while maintaining excellent visible light transparency. Secondly, as the manganese doping concentration (x) increases, the grain size of the film gradually decreases, and pronounced crystal cluster aggregation is observed at higher doping concentrations. X-ray photoelectron spectroscopy analysis reveals that manganese ions in the film exist in a mixed valence state of Mn2+ and Mn3+. Electrical performance characterization shows that the resistivity of the film can be tuned over two orders of magnitude, ranging from 0.017 to 2.5 Ω·cm, while the hole carrier concentration remains stable at a high order of magnitude of 1018-1019 cm-3. Unlike the n-type doping behavior observed in traditional semiconductors, introduction of high-valent manganese ions does not significantly affect the p-type conductivity of the material. This is likely due to the partially localized electronic state formed when manganese replaces cuprous ions. This discovery suggests that the hole conductivity of CuI semiconductors is not easily affected by high-valent manganese ion doping, enabling a wide range of compositional adjustments while maintaining stable p-type conductivity. This study provides a valuable material basis for the development of CuI-based multifunctional transparent electronic devices.

|

|

|

Rare Earth Oxide Surface Modification of Porous SiO2 Film Prepared by Atomic Layer Deposition

JIN Jianfei, LÜ Lin, LI Ying, YAN Lu, CAO Yunzhen, LI Wei

2025 Vol. 40 (9): 1029–1036

Abstract

Abstract(

497 )

HTML

HTML(

19)

PDF

PDF(3833KB)(

173

)

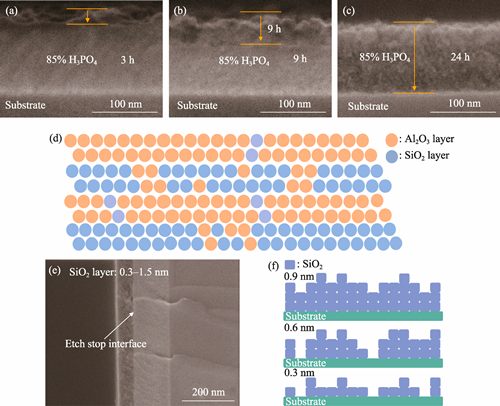

Broadband transparent films play a pivotal role in various applications such as lenses and solar cells, particularly porous structured transparent films exhibit significant potential. This study investigates a porous SiO2 refractive index gradient anti-reflective film prepared by atomic layer deposition (ALD). A porous SiO2 film with gradual porosity was obtained by phosphoric acid etching of Al2O3/SiO2 multilayers with gradient Al2O3 ratios, achieving a gradual decrease in refractive index from the substrate to the surface. The film exhibited an average transmittance as high as 97.8% within the wavelength range from 320 nm to 1200 nm. The environmental adaptability was further enhanced by surface modification using rare earth oxide (REO) La2O3, resulting in formation of a lotus leaf-like structure and achieving a water contact angle of 100.0°. These data proved that the modification significantly improved hydrophobic self-cleaning capability while maintaining exceptional transparency of the film. The surface structure of the modified film remained undamaged even after undergoing wipe testing, demonstrating its excellent surface durability.

|

|

|

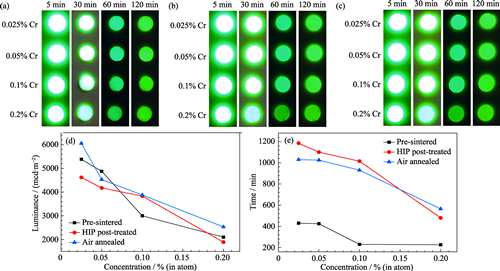

Influence of Cr3+ Doping Concentration on the Persistent Performance of YAGG:Ce3+,Cr3+ Luminescent Ceramics

LI Tingsong, WANG Wenli, LIU Qiang, WANG Yanbin, ZHOU Zhenzhen, HU Chen, LI Jiang

2025 Vol. 40 (9): 1037–1044

Abstract

Abstract(

360 )

HTML

HTML(

11)

PDF

PDF(4521KB)(

200

)

Y3Al2Ga3O12:Ce3+,Cr3+ (YAGG:Ce3+,Cr3+), as a persistent luminescent material, has advantages of high initial luminescence intensity and long persistent time, which is promising in persistent luminescent material applications. At present, YAGG:Ce3+,Cr3+ powders exhibit good persistent performance, but their persistent performance of ceramics still needs to be further improved to meet the new requirements. In this work, (Y0.998Ce0.002)3(Al1-xCrx)2Ga3O12 ceramics with different Cr3+ doping concentrations were prepared by solid-state reaction, including air pre-sintering, hot isostatic pressing (HIP) post-treatment and air annealing, to investigate the effects of Cr3+ doping concentration on the microstructure, optical properties and persistent performance of the ceramics. The results showed that as the doping concentration of Cr3+ increased from 0.025% to 0.2% (in atom), no significant effect of Cr3+ concentration on the morphology of pre-sintered ceramics or HIP post-treatment ceramics was observed, but the in-line transmittance gradually increased while the persistent performance gradually decreased. Among them, YAGG:Ce3+,Cr3+ ceramics doped with 0.025% Cr3+ showed the strongest initial luminescence intensity exceeding 6055 mcd/m2 and a persistent time of 1030 min after air pre-sintering combined with HIP post-treatment and air annealing. By optimizing the Cr3+ doping concentration and the fabrication process, the persistent luminescence (PersL) performance of the YAGG:Ce3+,Cr3+ ceramics was obviously improved.

|

|