Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (2): 145-152.DOI: 10.15541/jim20230425

Special Issue: 【结构材料】陶瓷基复合材料(202506); 【信息功能】MAX、MXene及其他二维材料(202506)

• PERSPECTIVE • Previous Articles Next Articles

LIU Yanyan1,2( ), XIE Xi1, LIU Zengqian1,2(

), XIE Xi1, LIU Zengqian1,2( ), ZHANG Zhefeng1,2(

), ZHANG Zhefeng1,2( )

)

Received:2023-09-19

Revised:2023-11-02

Published:2023-11-10

Online:2023-11-10

Contact:

LIU Zengqian, professor. E-mail: zengqianliu@imr.ac.cn;About author:LIU Yanyan (1994-), female, PhD candidate. E-mail: yyliu18s@imr.ac.cn

Supported by:CLC Number:

LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs[J]. Journal of Inorganic Materials, 2024, 39(2): 145-152.

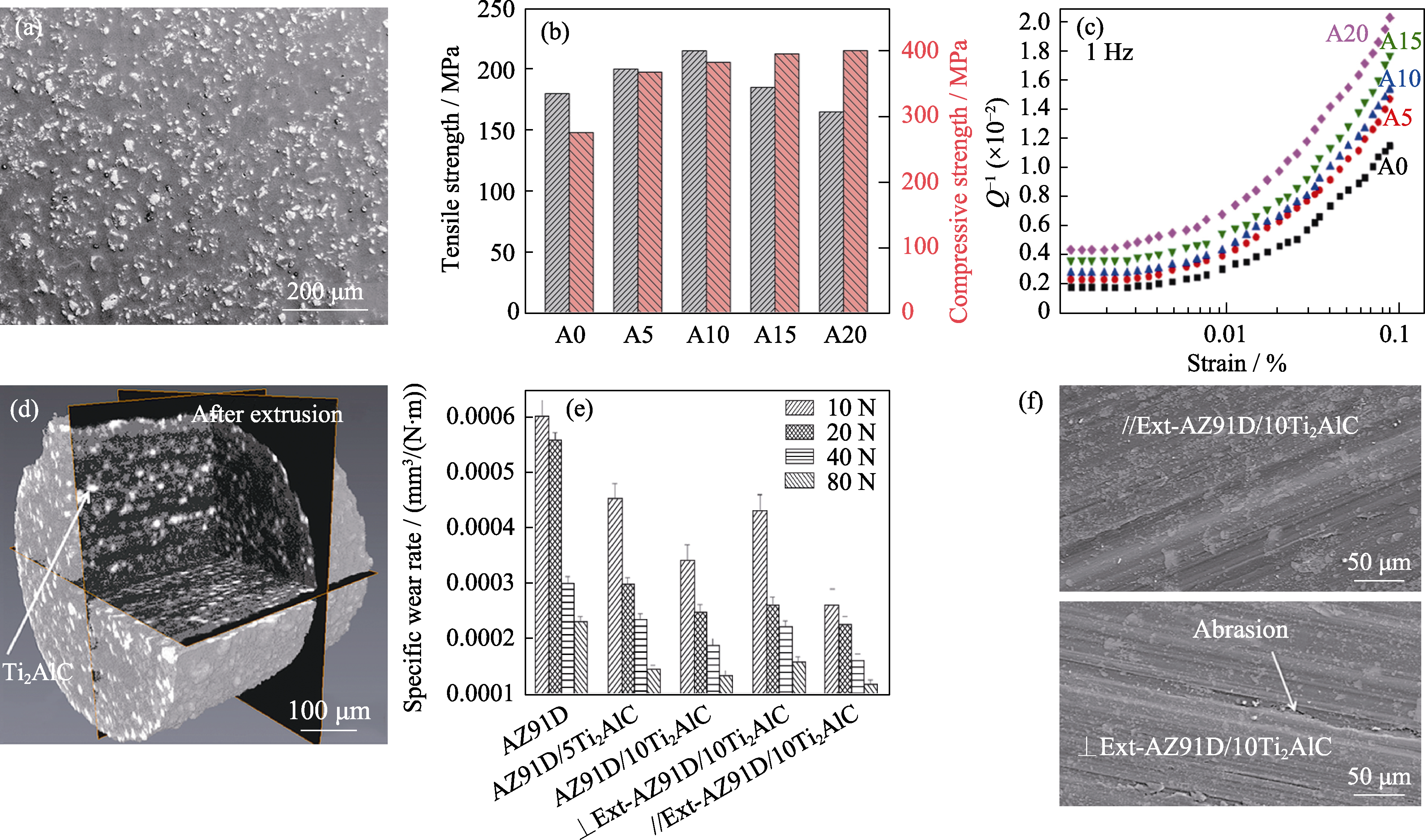

Fig. 2 Structure and mechanical, damping and friction properties of AZ91D-Ti2AlC composites fabricated by stir casting technique (a) Representative structure of as-cast AZ91D-Ti2AlC composite with white regions showing Ti2AlC phase[13]; (b) Tensile and compressive strengths of the as-cast composites with different Ti2AlC contents (A0‒A20 denoting the volume fraction of Ti2AlC from 0 to 20%)[13]; (c) Variations in the internal friction (Q-1) with strain amplitude[16]; (d) 3D structure of AZ91D-Ti2AlC composite after hot extrusion[14]; (e) Specific wear rates of as-cast and extruded composites compared to the AZ91D matrix under different applied loads[15]; (f) Wear morphologies of extruded composite after sliding along parallel (∥) and perpendicular (⊥) directions with respect to the extrusion axis[15] (a, b) Adapted with permission from Ref. [13] Copyright 2017, Elsevier; (c) Adapted with permission from Ref. [16] Copyright 2019, Elsevier; (d) Adapted with permission from Ref. [14] Copyright 2018, Elsevier; (e, f) Adapted with permission from Ref. [15] Copyright 2019, Elsevier

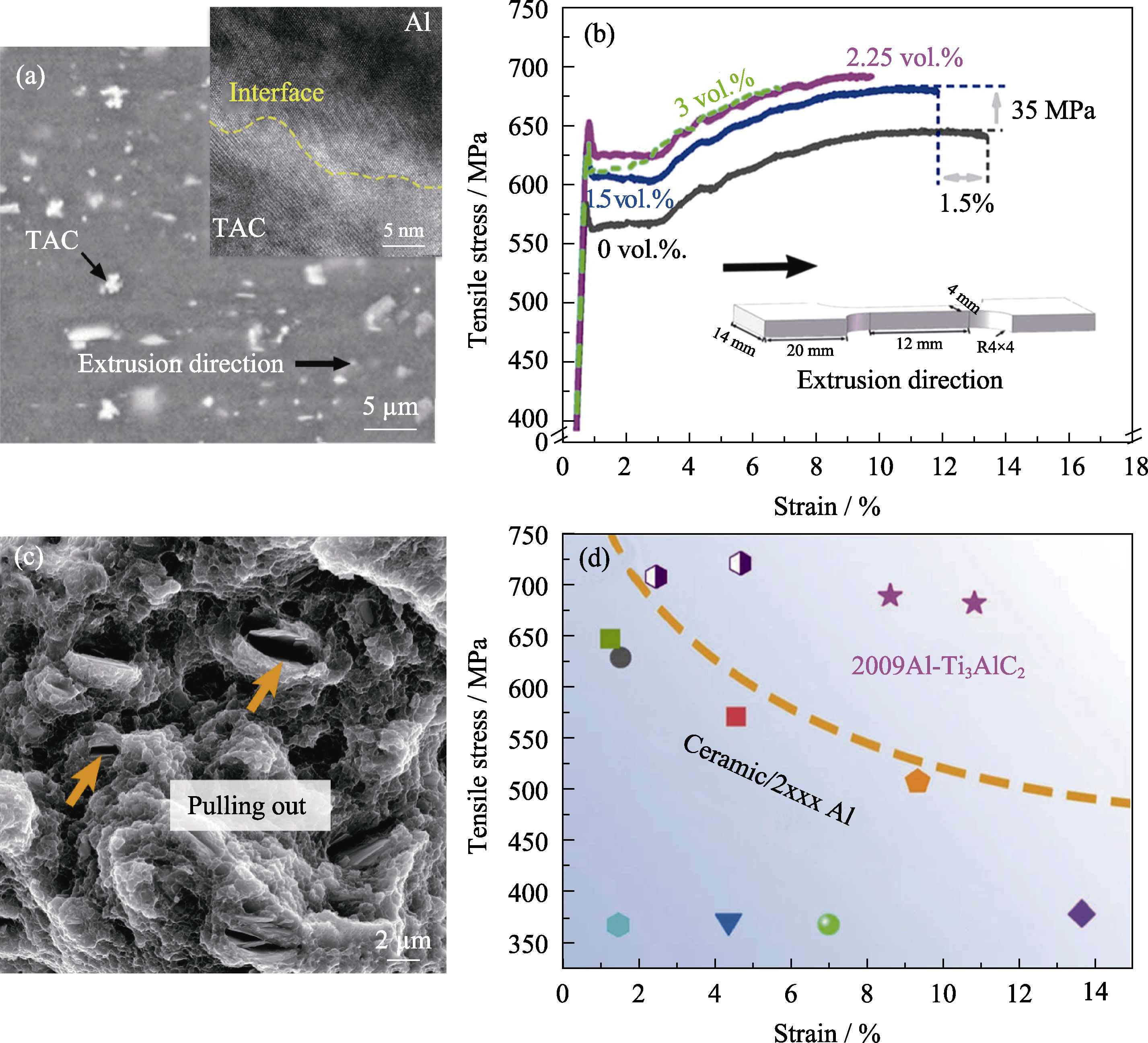

Fig. 3 Structure, mechanical properties, and fracture morphologies of 2009Al-Ti3AlC2 composites made by powder metallurgy technique[17] (a) Structure of 2009Al-Ti3AlC2 composite after extrusion and inverse fast Fourier transformation image of interface between Ti3AlC2 particle and Al alloy matrix. TAC: Ti3AlC2; (b) Tensile stress-strain curves of the composites with different Ti3AlC2 contents; (c) Fracture morphologies of composite after tensile fracture; (d) Comparison of tensile strength and ductility of 2009Al-Ti3AlC2 composites with other 2xxx Al alloy composites reinforced by ceramics. Adapted with permission from Ref. [17] Copyright 2023, Springer

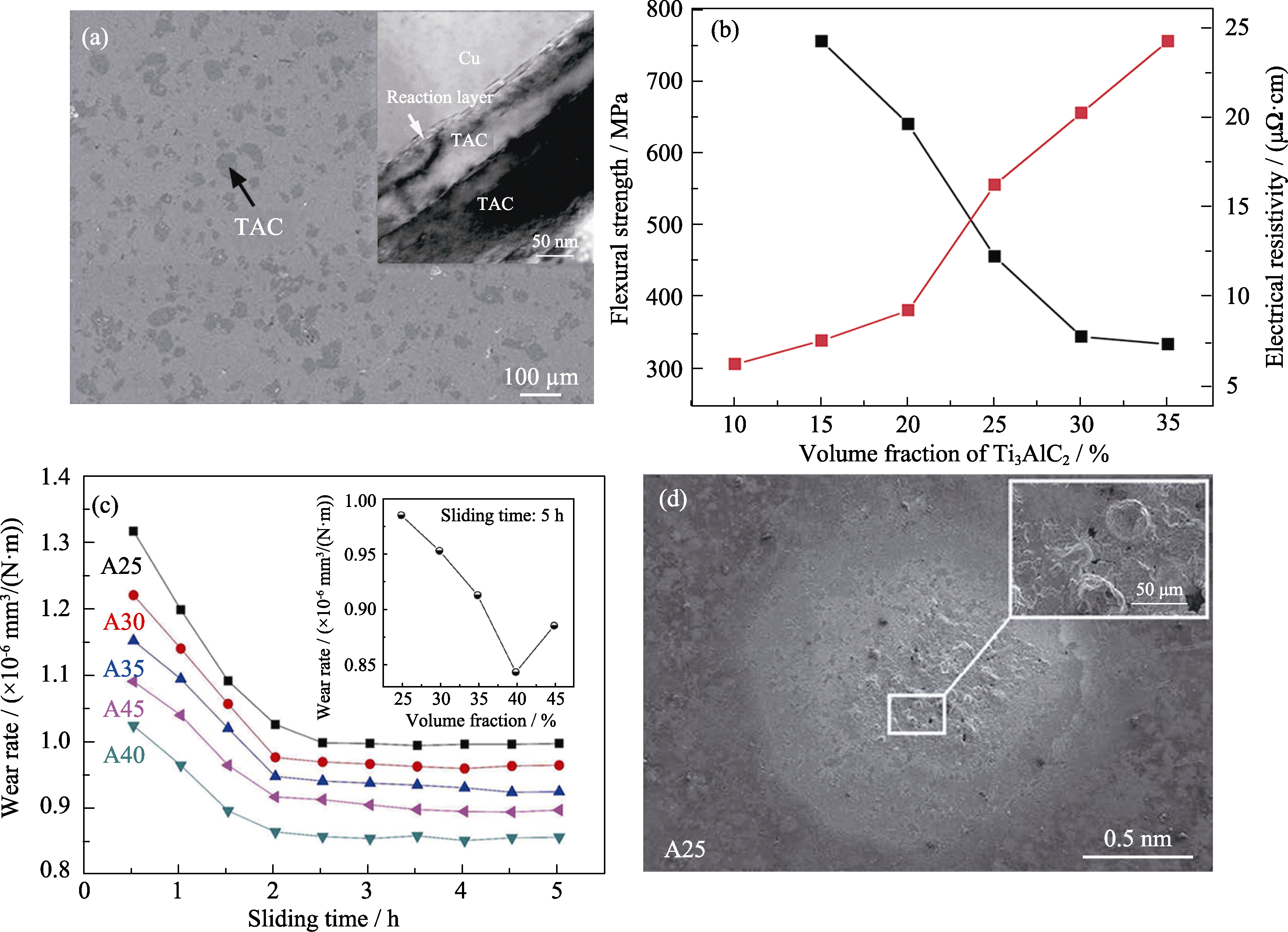

Fig. 4 Structural, mechanical and functional charateristics of Cu-Ti3AlC2 composites fabricated by powder metallurgy technique (a) Structure of Cu-Ti3AlC2 composite and its reaction layer between Ti3AlC2 (TAC) and Cu phases[20]; (b) Variations in the flexural strength and electrical resistivity of the composites as a function of the volume fraction of Ti3AlC2 phase[20]; (c) Wear rate of the composites against increasing sliding time with inset showing the dependence of wear rate on the volume fraction of Ti3AlC2 phase at a sliding time of 5 h[22]; (d) Surface morphology of Cu-25% Ti3AlC2 composite after arc erosion[20]. (a, b, d) Adapted with permission from Ref. [20] Copyright 2017, Taylor & Francis. The inset in (a) is adapted with permission from Ref. [21] Copyright 2007, Elsevier. (c) Adapted with permission from Ref. [22] Copyright 2019, Springer

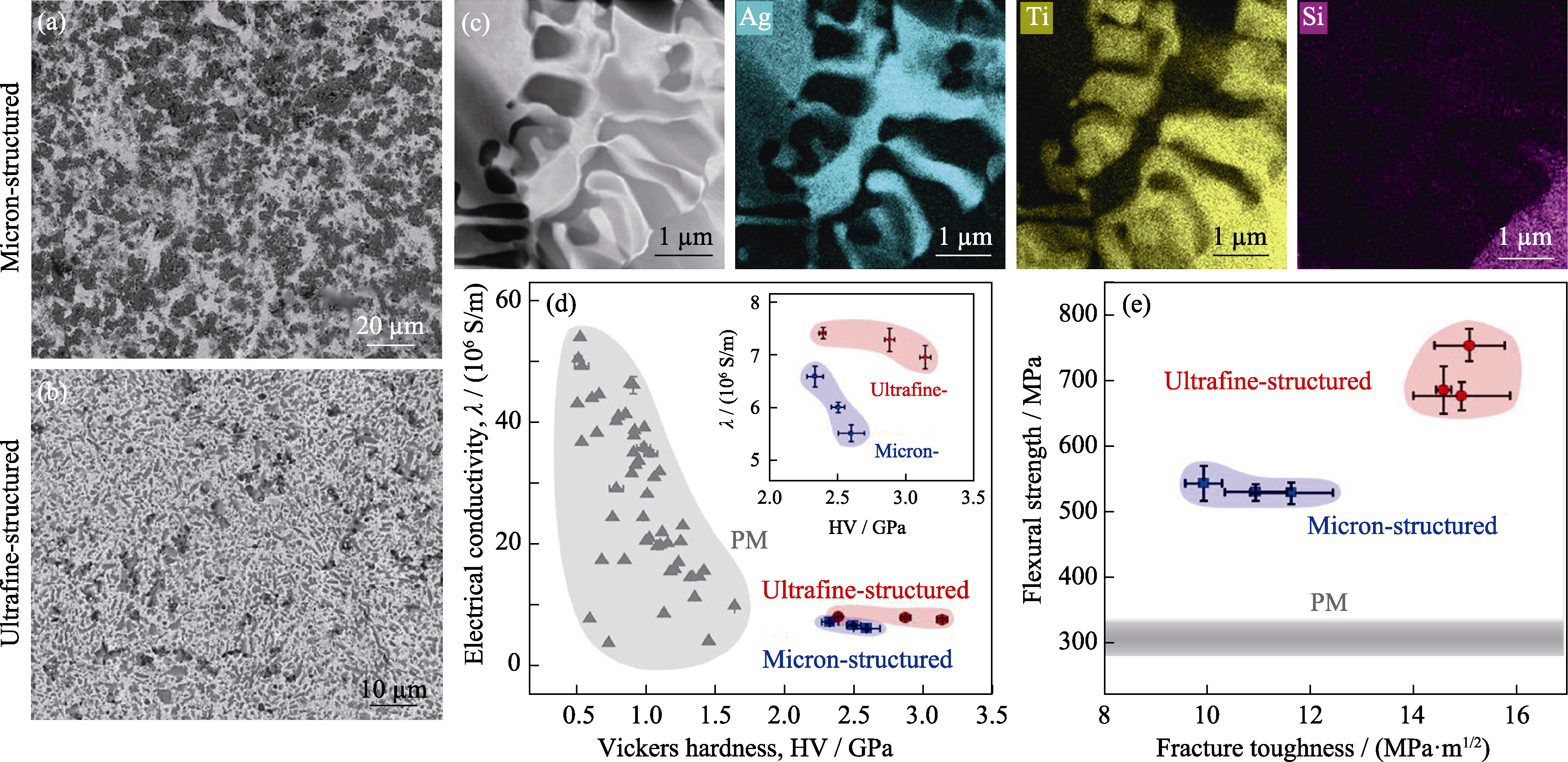

Fig. 5 Structural, mechanical and electrical characteristics of Ag-Ti3AlC2 composites made by melt infiltration technique[27] (a, b) Structures of melt infiltrated Ag-Ti3AlC2 composites with different structural dimensions of micron- (a) and ultrafine (b) length scales with dark regions showing Ti3SiC2 phase; (c) Chemical characteristics of the micron-structured Ag-Ti3AlC2 composite; (d, e) Electrical conductivity versus Vickers hardness (d) and flexural strength versus fracture toughness (e) of the melt infiltrated Ag-Ti3AlC2 composites with other Ag-MAX phase composites fabricated by powder metallurgy technique. Adapted with permission from Ref. [27] Copyright 2023, Tsinghua University Press

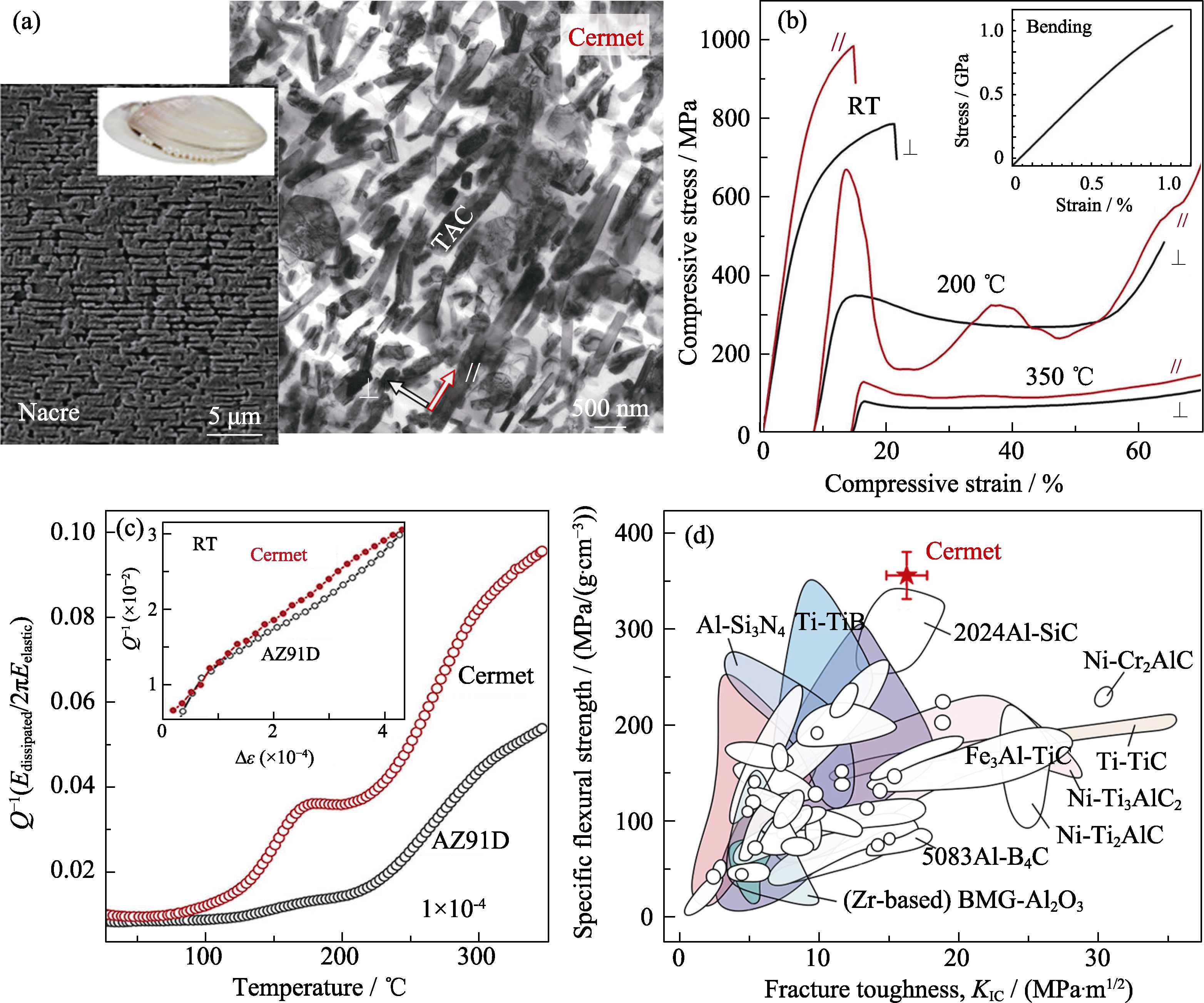

Fig. 6 Structure, mechanical properties, and damping characteristics of nacre-like Mg-Ti3AlC composites[29] (a) Structure of nacre-like composite compared to natural nacre (of Sinanodonta woodiana shell, TAC: Ti3AlC2); (b) Compressive stress-strain curves of the nacre-like composite at different temperatures when loading parallel and perpendicular to its layered structure with inset showing bending stress-strain curve of the composite at room temperature (RT); (c) Variations in the internal friction (Q-1) with temperature and strain amplitude for the composite compared to the AZ91D alloy matrix; (d) Comparison of the specific flexural strength, i.e., flexural strength normalized by density, and fracture toughness of the composite with other materials. The structure of natural nacre in (a) is adapted with permission from Ref. [30] Copyright 2016, Elsevier. (a-d) Adapted with permission from Ref. [29] Copyright 2023, Elsevier

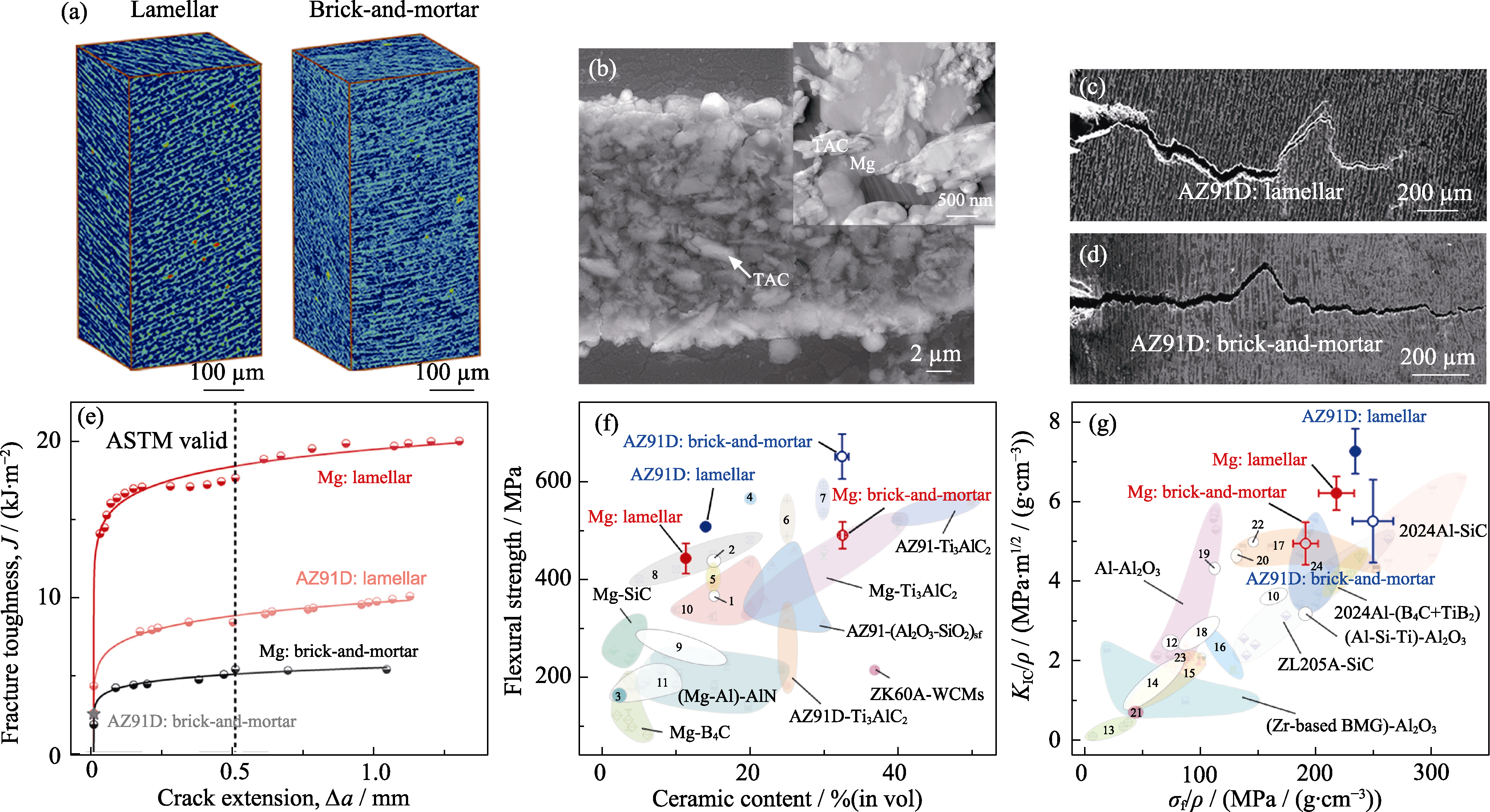

Fig. 7 Microstructure and mechanical properties of the hierarchical nacre-like Mg-Ti3AlC2 composites made by ice templating and melt infiltration techniques[31] (a) 3D structures of the composites with hierarchical nacre-like lamellar and brick-and-mortar architectures; (b) Ultrafine structure of the composite showing the preferential alignment of Ti3AlC2 platelets and full filling interspaces between platelets and metal phase in the ceramic-rich layer; (c, d) Deflected cracking paths in the composites with lamellar (c) and brick-and-mortar (d) architectures; (e) Rising R-curve behavior of the composites demonstrating stable crack propagation; (f) Variation in the flexural strength as a function of ceramic content in Mg and Mg-alloy composites reinforced with various kinds of ceramics; (g) Comparison of fracture toughness and flexural strength normalized by density for various metal-ceramic composites with nacre-like architectures. Adapted with permission from Ref. [31] Copyright 2023, Springer Nature

| [1] |

MORTENSEN A, LLORCA J. Metal matrix composites. Annual Review of Materials Research, 2010, 40: 243.

DOI URL |

| [2] |

MIRACLE D B. Metal matrix composites-from science to technological significance. Composites Science and Technology, 2005, 65(15/16): 2526.

DOI URL |

| [3] |

YU W H, SING S L, CHUA C N, et al. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: a state of the art review. Progress in Materials Science, 2019, 104: 330.

DOI URL |

| [4] | MACKE A, SCHULTZ B F, ROHATGI P. Metal matrix composites offer the automotive industry an opportunity to reduce vehicle weight, improve performance. Advanced Materials & Processes, 2012, 170: 19. |

| [5] | SUN Z M. Progress in research and development on MAX phases: a family of layered ternary compounds. Progress in Materials Science, 2011, 56: 143. |

| [6] |

BARSOUM M W, RADOVIC M. Elastic and mechanical properties of the MAX phases. Annual Review of Materials Research, 2011, 41: 195.

DOI URL |

| [7] |

EKLUND P, BECKERS M, JANSSON U, et al. The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films, 2010, 518: 1851.

DOI URL |

| [8] |

GONZALEZ-JULIAN J. Processing of MAX phases: from synthesis to applications. Journal of the American Ceramic Society, 2021, 104(2): 659.

DOI URL |

| [9] |

HU W Q, HUANG Z Y, WANG Y B, et al. Layered ternary MAX phases and their MX particulate derivative reinforced metal matrix composite: a review. Journal of Alloys and Compounds, 2021, 856: 157313.

DOI URL |

| [10] |

GUPTA S, BARSOUM M W. On the tribology of the MAX phases and their composites during dry sliding: a review. Wear, 2011, 271: 1878.

DOI URL |

| [11] |

CHEN W T, YU W B, MA C S, et al. A review of novel ternary nano-layered MAX phases reinforced AZ91D magnesium composite. Journal of Magnesium and Alloys, 2022, 10(6): 1457.

DOI URL |

| [12] |

GRIESELER R, CAMARGO M K, HOPFELD M, et al. Copper- MAX-phase composite coatings obtained by electro-co-deposition: a promising material for electrical contacts. Surface and Coatings Technology, 2017, 321: 219.

DOI URL |

| [13] |

YU W B, WANG X J, ZHAO H B, et al. Microstructure, mechanical properties and fracture mechanism of Ti2AlC reinforced AZ91D composites fabricated by stir casting. Journal of Alloys and Compounds, 2017, 702: 199.

DOI URL |

| [14] |

YU W B, ZHAO H B, WANG X J, et al. Synthesis and characterization of textured Ti2AlC reinforced magnesium composite. Journal of Alloys and Compounds, 2018, 730: 191.

DOI URL |

| [15] | YU W B, CHEN D Q, TIAN L, et al. Self-lubricate and anisotropic wear behavior of AZ91D magnesium alloy reinforced with ternary Ti2AlC MAX phases. Journal of Materials Science & Technology, 2019, 35: 275. |

| [16] |

YU W B, LI X B, VALLET M, et al. High temperature damping behavior and dynamic Young’s modulus of magnesium matrix composite reinforced by Ti2AlC MAX phase particles. Mechanics of Materials, 2019, 129: 246.

DOI URL |

| [17] |

LI X N, LI P Y, LIU Z Q, et al. Microstructure and mechanical properties of Ti3AlC2 reinforced Al-4.5Cu-1.5Mg composites fabricated by powder metallurgy. Journal of Materials Science, 2023, 58: 2570.

DOI |

| [18] | SUN H F, LI X W, ZHANG P, et al. The microstructure and tensile properties of the Ti2AlC reinforced TiAl composites fabricated by powder metallurgy. Materials Science & Engineering A, 2014, 611: 257. |

| [19] |

WANG W Z, SOKOL M, KOTA S, et al. Reaction paths and microstructures of nickel and Ti2AlC mixtures hot pressed and annealed in the 1050-1350 ℃ temperature range. Journal of Alloys and Compounds, 2020, 828: 154193.

DOI URL |

| [20] |

HUANG X C, FENG Y, QIAN G, et al. Physical, mechanical, and ablation properties of Cu-Ti3AlC2 composites with various Ti3AlC2 contents. Materials Science and Technology, 2018, 34(6): 757.

DOI URL |

| [21] |

ZHANG J, WANG J Y, ZHOU Y C. Structure stability of Ti3AlC2 in Cu and microstructure evolution of Cu-Ti3AlC2 composites. Acta Materialia, 2007, 55: 4381.

DOI URL |

| [22] |

ZHAO H, FENG Y, QIAN G, et al. Effect of Ti3AlC2 content on electrical friction and wear behaviors of Cu-Ti3AlC2 composites. Tribology Letters, 2019, 67: 96.

DOI |

| [23] | SHU S L, QIU F, LU S J, et al. Phase transitions and compression properties of Ti2AlC/TiAl composites fabricated by combustion synthesis reaction. Materials Science & Engineering A, 2012, 539: 344. |

| [24] | AI T T, LIU F, FENG X M, et al. Processing, microstructural characterization and mechanical properties of in situ Ti3AlC2/TiAl3 composite by hot pressing. Materials Science & Engineering A, 2014, 610: 297. |

| [25] |

LI L, ORTIZ C. A natural 3D interconnected laminated composite with enhanced damage resistance. Advanced Functional Materials, 2015, 25(23): 3463.

DOI URL |

| [26] |

ROY S, GIBMEIER J, KOSTOV V, et al. Internal load transfer in a metal matrix composite with a three-dimensional interpenetrating structure. Acta Materialia, 2011, 59(4): 1424.

DOI URL |

| [27] | GUO Y, XIE X, LIU Z Q, et al. Wear-resistant Ag-MAX phase 3D interpenetrating-phase composites: processing, structure and properties. Nano Research, DOI: 10.1007/s12274-023-6015-1. |

| [28] |

WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials. Nature Materials, 2015, 14: 23.

DOI PMID |

| [29] |

LIU Y Y, XIE X, LIU Z Q, et al. A strong, lightweight, and damping cermet material with a nacre-like ultrafine 3D interpenetrated architecture. Materials Today, 2023, 62: 62.

DOI URL |

| [30] |

JIAO D, LIU Z Q, ZHU Y K, et al. Mechanical behavior of mother-of-pearl and pearl with flat and spherical laminations. Materials Science and Engineering: C, 2016, 68: 9.

DOI URL |

| [31] |

LIU Y Y, XIE X, LIU Z Q, et al. Strong and tough magnesium- MAX phase composites with nacre-like lamellar and brick-and- mortar architectures. Communications Materials, 2023, 4: 30.

DOI |

| [32] |

GUPTA S, FILIMONOV D, PALANISAMY T, et al. Ta2AlC and Cr2AlC Ag-based composites - new solid lubricant materials for use over a wide temperature range against Ni-based superalloys and alumina. Wear, 2007, 262: 1479.

DOI URL |

| [33] |

AGNE M T, RADOVIC M, BENTZEL G W, et al. Stability of V2AlC with Al in 800-100 ℃ temperature range and in situ synthesis of V2AlC/Al composites. Journal of Alloys and Compounds, 2016, 666: 279.

DOI URL |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming. Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2024, 39(8): 955-964. |

| [9] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [10] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [11] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [12] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [13] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [14] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [15] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||