Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (9): 965-978.DOI: 10.15541/jim20240050

Special Issue: 【制备方法】3D打印(202506); 【信息功能】介电、铁电、压电材料(202506); 【信息功能】柔性材料(202506)

• REVIEW • Next Articles

WEI Xiangxia1( ), ZHANG Xiaofei1, XU Kailong2, CHEN Zhangwei3(

), ZHANG Xiaofei1, XU Kailong2, CHEN Zhangwei3( )

)

Received:2024-01-29

Revised:2024-02-29

Published:2024-09-20

Online:2024-03-08

Contact:

CHEN Zhangwei, professor. E-mail: chen@szu.edu.cnAbout author:WEI Xiangxia (1989-), female, assistant professor. E-mail: xiangxia@qdu.edu.cn

Supported by:CLC Number:

WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials[J]. Journal of Inorganic Materials, 2024, 39(9): 965-978.

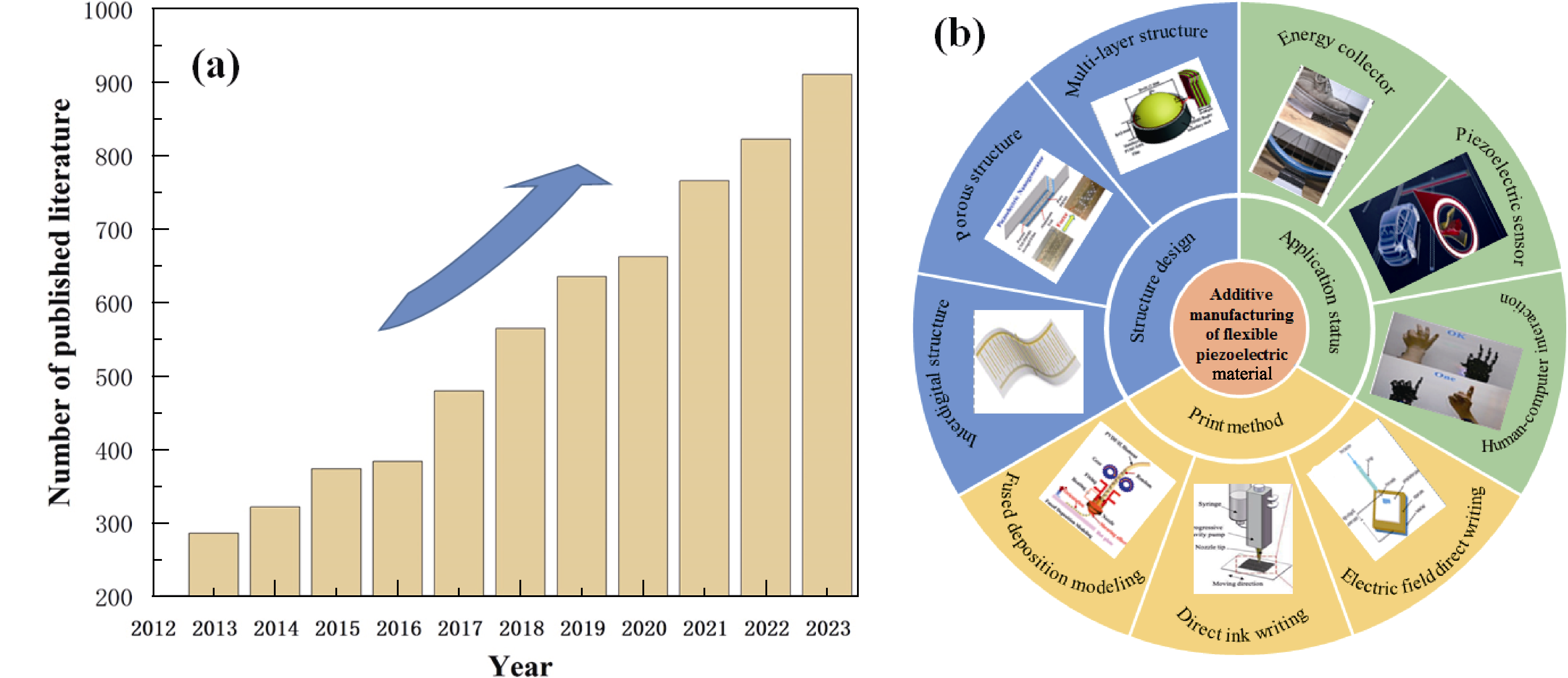

Fig. 1 Overview of additive manufacturing of flexible piezoelectric materials (a) Amount of published papers (data from Web of Science); (b) Additive manufacturing approaches, structural design and applications of flexible piezoelectric materials

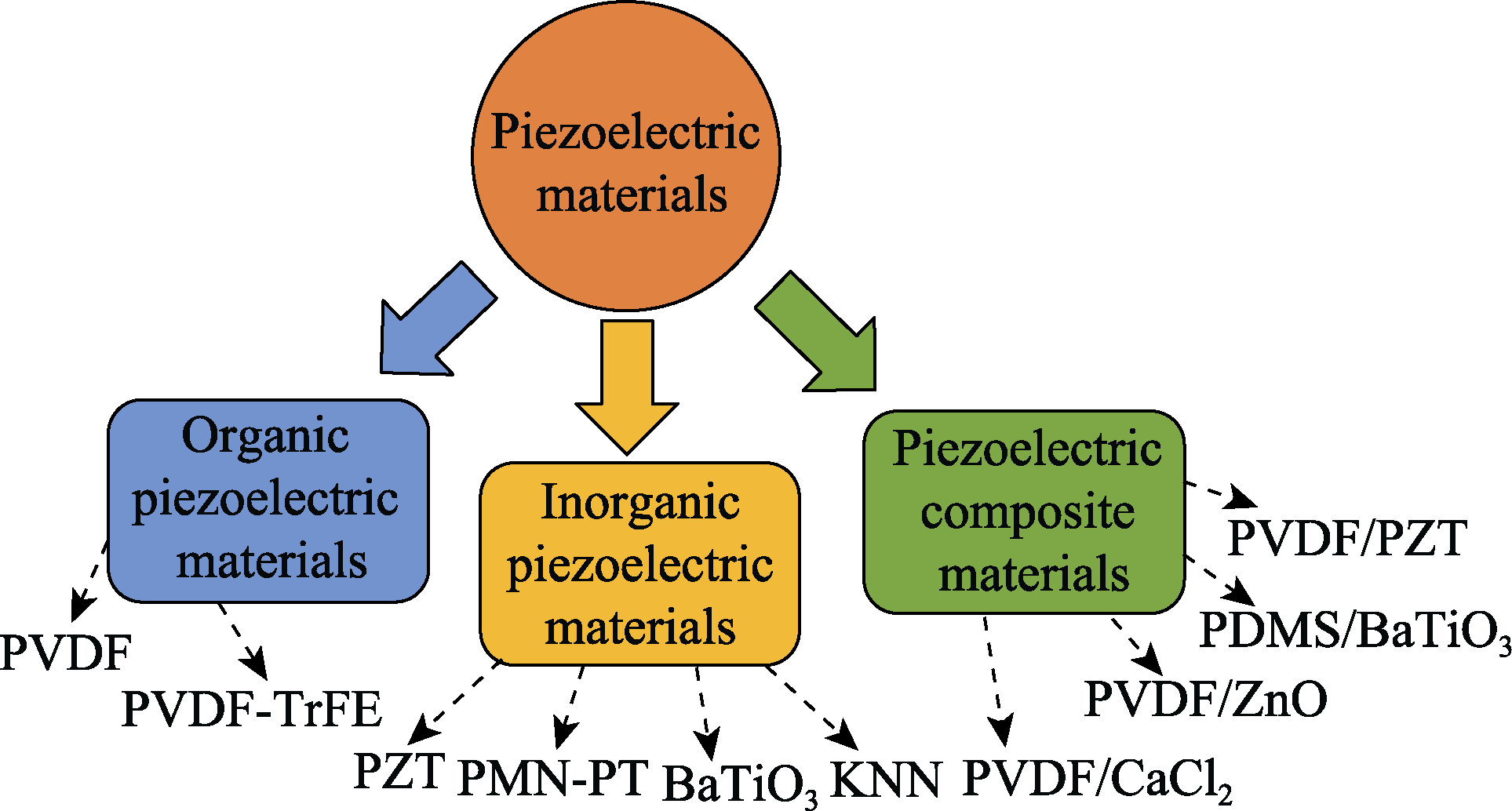

Fig. 2 Summary of classification of piezoelectric materials PVDF: Polyvinylidene fluoride; PVDF-TrFE: Polyvinylidene fluoride-trifluoroethylene; PZT: Lead zirconate titanate; PMN-PT: Lead magnesium niobate-lead titanate; KNN: Potassium sodium niobate; PDMS: Polydimethylsiloxane

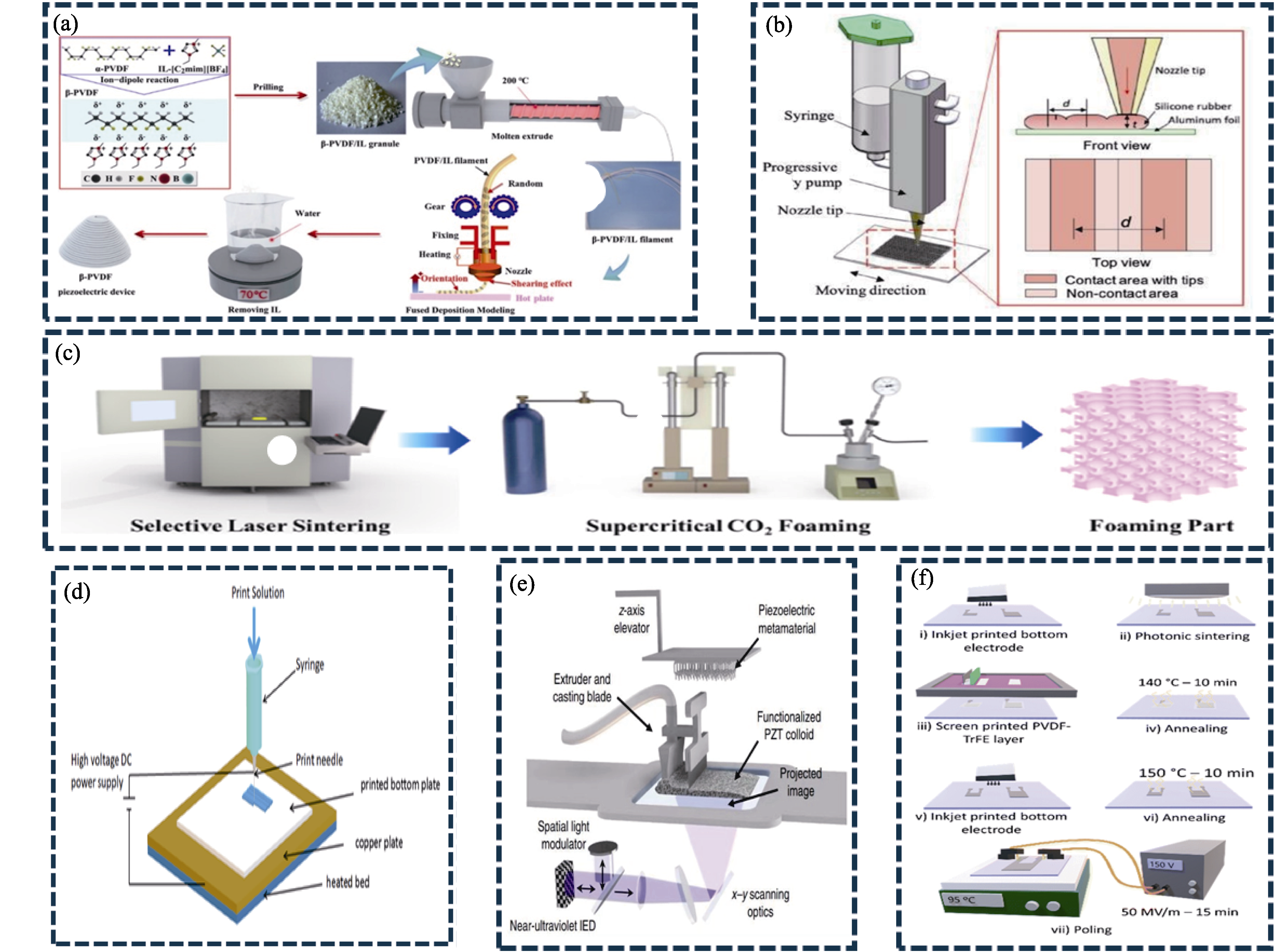

Fig. 3 Schematic diagrams of additive manufacturing processes (a) Fused deposition modeling[37]; (b) Direct ink writing[54] ; (c) Selective laser sintering[31]; (d) Electric-assisted direct writing [49]; (e) Stereolithography[50]; (f) Inkjet printing[53]

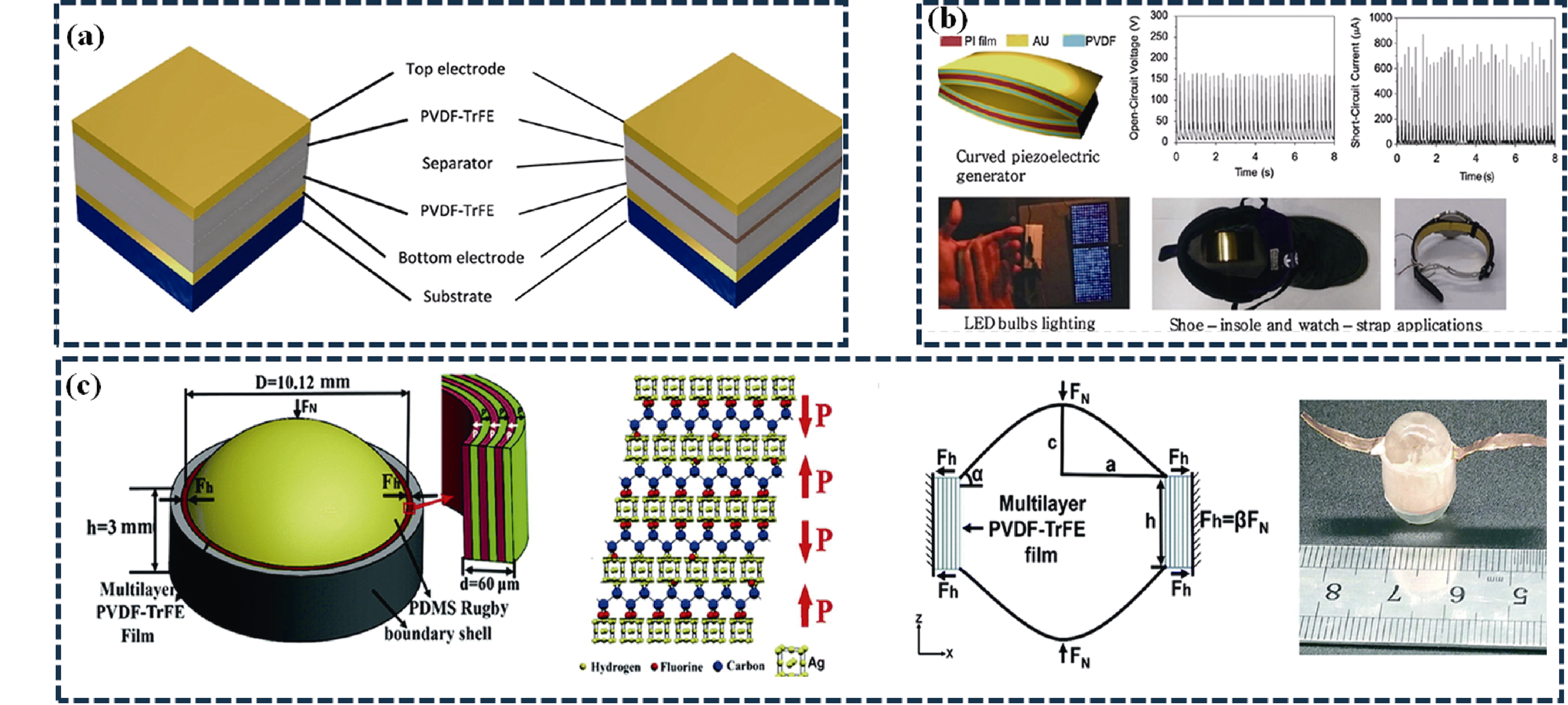

Fig. 4 Schematic diagrams of multi-layer structures of flexible piezoelectric materials (a) PVDF-TrFE composite multi-layer structures[55]; (b) Curved multi-layer piezoelectric structures[57]; (c) Rugby structures[58]

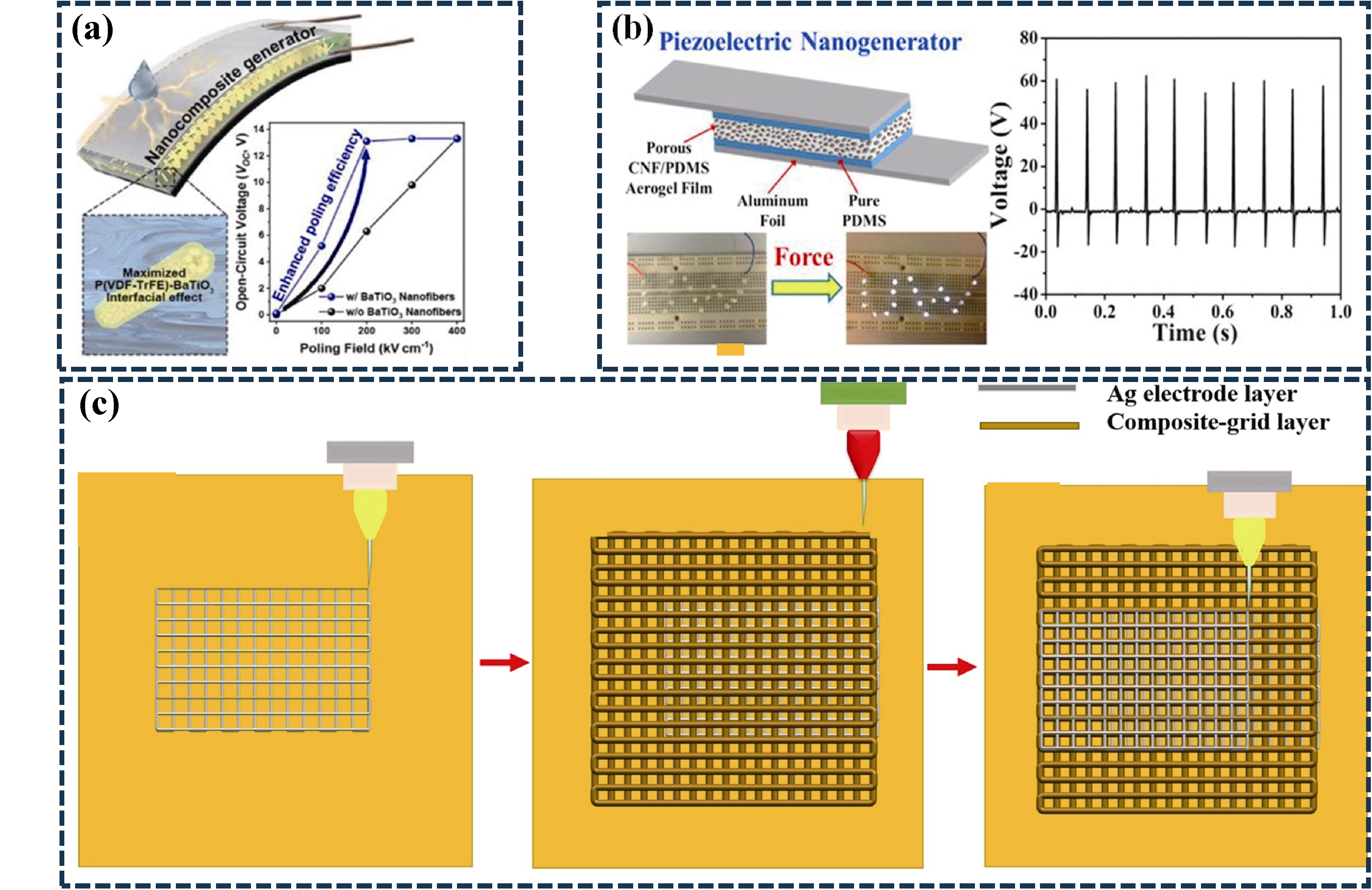

Fig. 5 Schematic diagrams of porous structures of flexible piezoelectric materials (a) PVDF-TrFE/BaTiO3 porous structures[60]; (b) CNF/PDMS porous structures[61]; (c) Grid structures[62]

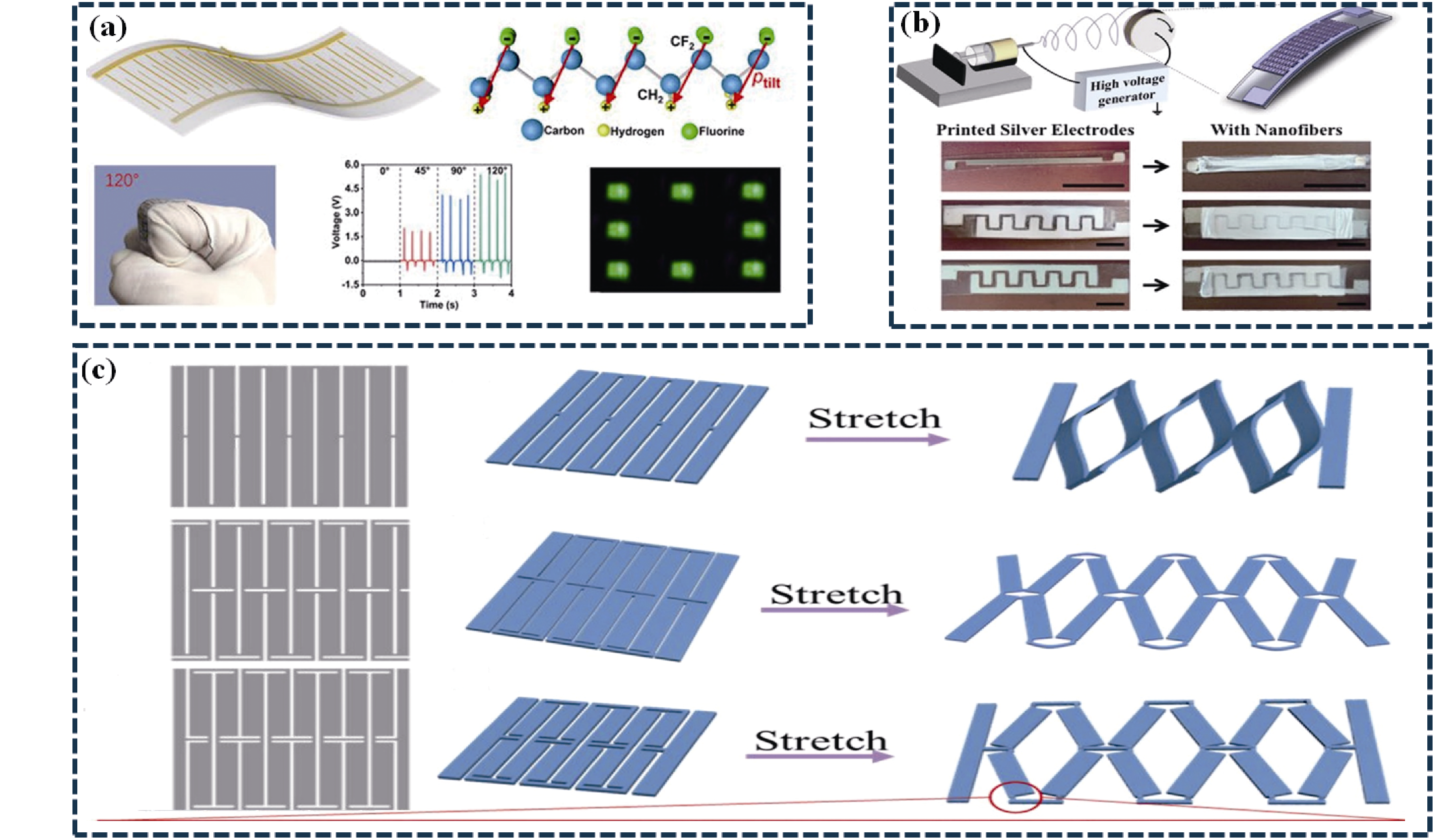

Fig. 6 Schematic diagrams of interdigital structures of flexible piezoelectric materials (a) Alternately tilted interdigital structures[63]; (b) Pt/Ti conductive interdigital structures[64]; (c) Origami structures[65]

| Material | Filler | 3D printing method | Fraction (β phase)/% | d33(d31)/(pC·N-1) | Output voltage | Output current | Ref. |

|---|---|---|---|---|---|---|---|

| PVDF | BT (10%) | DIW | 78 | - | 4 V | - | [ |

| PVDF | TrFE (30%) | DIW | 75-80 | - | 298.3 mV | - | [ |

| PVDF | GR (0.03%) | DIW | 61.52 | d33=-8.7 | 0.35 V | - | [ |

| PVDF | GR (1.5%) | SLS | - | - | 16.97 V | 274 nA | [ |

| PVDF | BT/Ag | SLS | - | - | 10 V | 142 nA | [ |

| PVDF | BT/Carbon | SLS | 92.2 | - | 5.7 V | 79.8 nA | [ |

| PVDF | BT (30%) | FDM | 84.9 | d33=4.2 | 11.5 V | 220 nA | [ |

| PVDF | IL | FDM | 93.3 | - | 8.69 V | 90.8 nA | [ |

| PVDF | TPPC (5%) | FDM | 83.8 | d33=11.85 | 6.62 V | 108.15 nA/cm2 | [ |

| PVDF | BT2 | FDM | 95.9 | - | 10.9 V | 126.9 nA | [ |

| PVDF | IL (2%) | FDM | 90 | - | 6 V | 83 nA | [ |

| PVDF | IL (15%) | FDM | 97.4 | - | 8.2 V | 300 nA | [ |

| PVDF | No fillers | FDM | 56.83 | d31=0.048 | - | 0.106 nA | [ |

| PDMS | MWCNTs | DIW | - | d33=1070 | 550 mV | - | [ |

| PDMS | BaTiO3 | DIW | - | - | 80 V | 25 mA | [ |

| PDMS | PNN-PZT | DIW | - | d33=24 | 5 V | 0.1 μA | [ |

| PDMS | BT (80%) | DIW | - | - | 45 V | 2.7 μA | [ |

| PVDF | TrFE | IJP | - | - | 3.6 V | 2.3μA | [ |

Table 1 Performance comparison of piezoelectric energy harvesters manufactured by 3D printing technology

| Material | Filler | 3D printing method | Fraction (β phase)/% | d33(d31)/(pC·N-1) | Output voltage | Output current | Ref. |

|---|---|---|---|---|---|---|---|

| PVDF | BT (10%) | DIW | 78 | - | 4 V | - | [ |

| PVDF | TrFE (30%) | DIW | 75-80 | - | 298.3 mV | - | [ |

| PVDF | GR (0.03%) | DIW | 61.52 | d33=-8.7 | 0.35 V | - | [ |

| PVDF | GR (1.5%) | SLS | - | - | 16.97 V | 274 nA | [ |

| PVDF | BT/Ag | SLS | - | - | 10 V | 142 nA | [ |

| PVDF | BT/Carbon | SLS | 92.2 | - | 5.7 V | 79.8 nA | [ |

| PVDF | BT (30%) | FDM | 84.9 | d33=4.2 | 11.5 V | 220 nA | [ |

| PVDF | IL | FDM | 93.3 | - | 8.69 V | 90.8 nA | [ |

| PVDF | TPPC (5%) | FDM | 83.8 | d33=11.85 | 6.62 V | 108.15 nA/cm2 | [ |

| PVDF | BT2 | FDM | 95.9 | - | 10.9 V | 126.9 nA | [ |

| PVDF | IL (2%) | FDM | 90 | - | 6 V | 83 nA | [ |

| PVDF | IL (15%) | FDM | 97.4 | - | 8.2 V | 300 nA | [ |

| PVDF | No fillers | FDM | 56.83 | d31=0.048 | - | 0.106 nA | [ |

| PDMS | MWCNTs | DIW | - | d33=1070 | 550 mV | - | [ |

| PDMS | BaTiO3 | DIW | - | - | 80 V | 25 mA | [ |

| PDMS | PNN-PZT | DIW | - | d33=24 | 5 V | 0.1 μA | [ |

| PDMS | BT (80%) | DIW | - | - | 45 V | 2.7 μA | [ |

| PVDF | TrFE | IJP | - | - | 3.6 V | 2.3μA | [ |

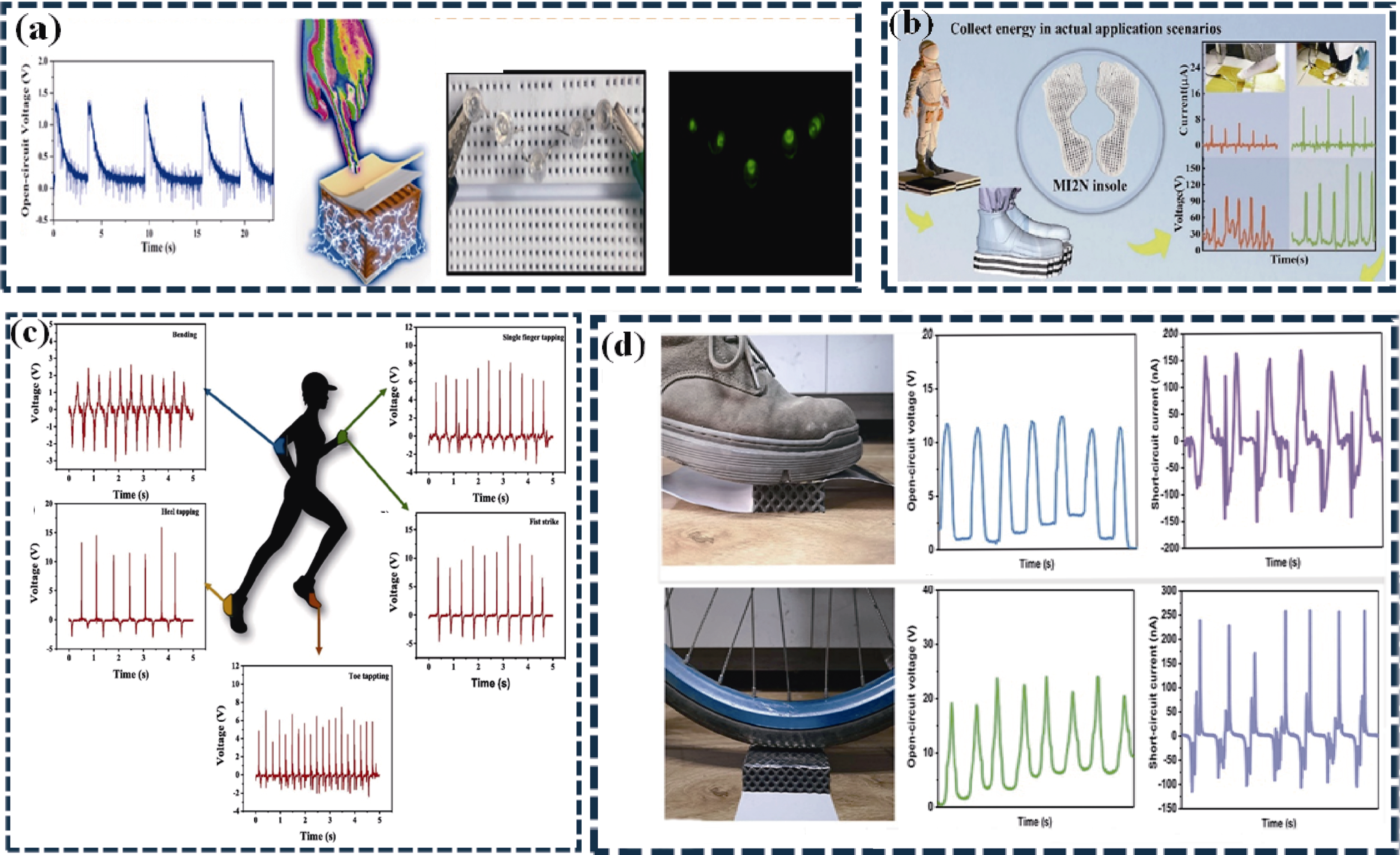

Fig. 7 Application of 3D-printed flexible piezoelectric materials in energy harvesting (a) Energy collection and illumination of LED lights by pressing with fingers[67]; (b) Application of M12N insoles[68]; (c) Piezoelectric energy harvester installed on wearable electronic devices[69]; (d) Road energy harvester[46]

Fig. 8 Application of 3D-printed flexible piezoelectric materials in piezoelectric sensing (a) Piezoelectric sensors incorporated into insoles to adapt to human movements[76]; (b) Self-powered traffic monitoring system based on PVDF[84]; (c) Schematic diagrams of wireless self-sensing boxing gloves[85]

Fig. 9 Application of 3D-printed flexible piezoelectric materials in human-computer interaction (a) Movement of the fingers translates into a change in voltage[90]; (b) Self-powered smart bracelet[91]; (c) Movements of robotic hands controlled by the movements of human hands[92]

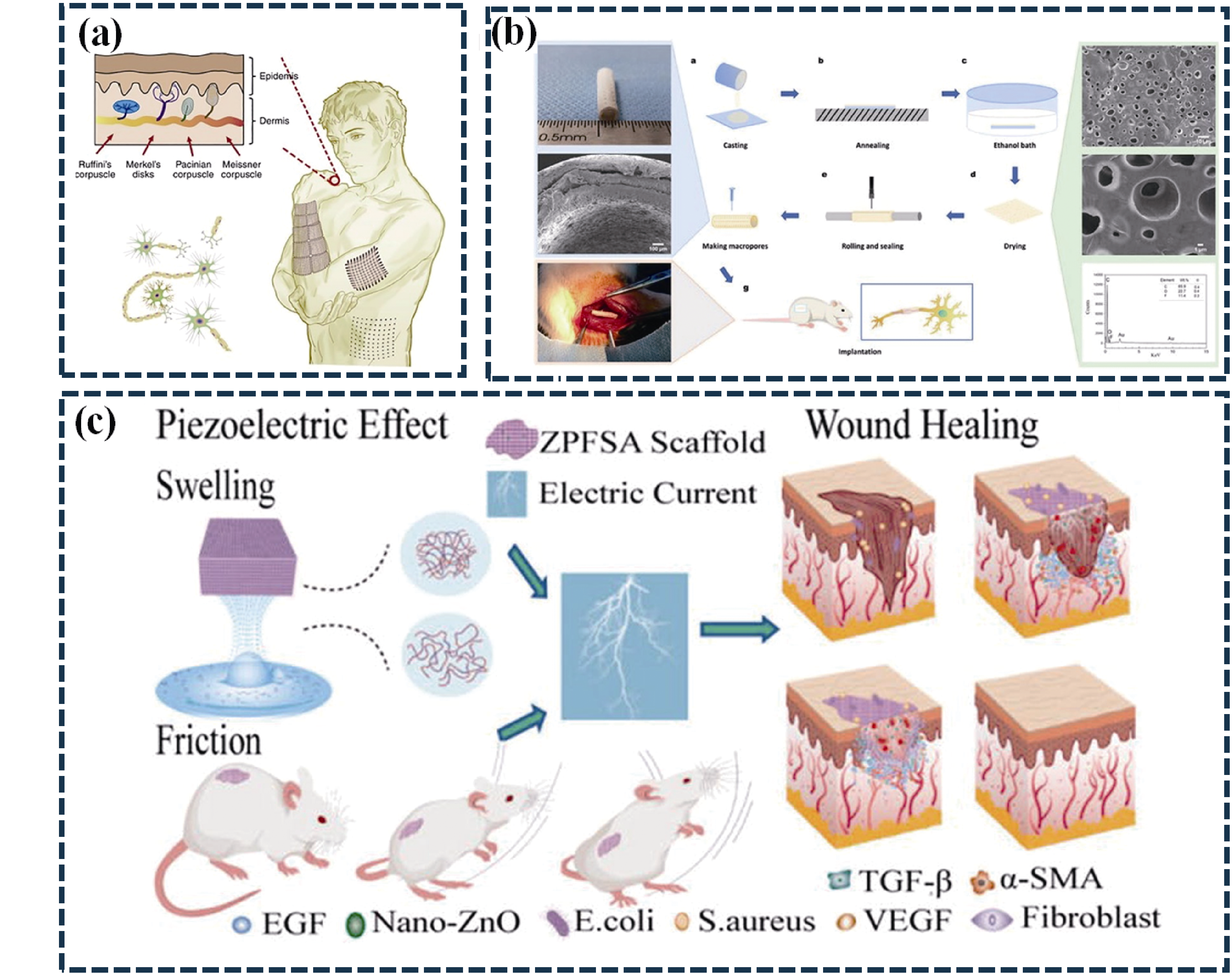

Fig. 10 Application of 3D-printed flexible piezoelectric materials in bioengineering (a) Schematic diagram of electronic skin[93]; (b) Tissue engineering scaffold composed of PVDF/PCL[94]; (c) Piezoelectric hydrogel scaffold fabricated by 3D printing technology[95]

| [1] | TUMALA M M, SALISU A, NMADU Y B. Climate change fossil fuel prices: a GARCH-MIDAS analysis. Energy Economics, 2023, 124: 106792. |

| [2] | WU Y L, MA Y L, ZHENG H Y, et al. Piezoelectric materials for flexible and wearable electronics: a review. Materials & Design, 2021, 211: 110164. |

| [3] | CHEN C, WANG X, WANG Y, et al. Additive manufacturing of piezoelectric materials. Advanced Functional Materials, 2020, 30(52): 2005141. |

| [4] | ZHENG Q, SHI B J, LI Z, et al. Recent progress on piezoelectric and triboelectric energy harvesters in biomedical systems. Advanced Science, 2017, 4(7): 1700029. |

| [5] | MEGDICH A, HABIBI M, LAPERRIERE L, et al. A review on 3D printed piezoelectric energy harvesters: materials, 3D printing techniques, and applications. Materials Today Communications, 2023, 35: 105541. |

| [6] | BICY K, GUEYE A B, ROUXEL D, et al. Lithium-ion battery separators based on electrospun PVDF: a review. Surfaces and Interfaces, 2022, 31: 101977. |

| [7] | LEE J E, SHIN Y E, LEE G H, et al. Polyvinylidene fluoride (PVDF)/cellulose nanocrystal (CNC) nanocomposite fiber and triboelectric textile sensors. Composites Part B: Engineering, 2021, 223: 109098. |

| [8] | RIBEIRO S, MEIRA R M, CORREIA D M, et al. Silica nanoparticles surface charge modulation of the electroactive phase content and physical-chemical properties of poly(vinylidene fluoride) nanocomposites. Composites Part B: Engineering, 2020, 185: 107786. |

| [9] | TU N D K, NOH M S, KO Y, et al. Enhanced electromechanical performance of P(VDF-TrFE-CTFE) thin films hybridized with highly dispersed carbon blacks. Composites Part B: Engineering, 2018, 152: 133. |

| [10] | JEONG K, KIM D H, CHUNG Y S, et al. Effect of processing parameters of the continuous wet spinning system on the crystal phase of PVDF fibers. Journal of Applied Polymer Science, 2017, 133(3): 45712. |

| [11] | SHARAFKHANI S, KOKABI M. High performance flexible actuator: PVDF nanofibers incorporated with axially aligned carbon nanotubes. Composites Part B: Engineering, 2021, 222: 109060. |

| [12] | CHEN J, AYRANCI C, TANG T. Piezoelectric performance of electrospun PVDF and PVDF composite fibers: a review and machine learning-based analysis. Materials Today Chemistry, 2023, 30: 101571. |

| [13] | WANG Y, LEI D, WU L K, et al. Effects of stretching on phase transformation of PVDF and its copolymers: a review. Open Physics, 2023, 21(1): 20220255. |

| [14] | BARRAU S, FERRI A, DACOSTA A, et al. Nanoscale investigations of α- and γ-crystal phases in PVDF-based nanocomposites. ACS Applied Materials & Interfaces, 2018, 10(15): 13092. |

| [15] | JIN L, MA S Y, DENG W L, et al. Polarization-free high- crystallization β-PVDF piezoelectric nanogenerator toward self- powered 3D acceleration sensor. Nano Energy, 2018, 50: 632. |

| [16] | WANG S, SHAO H Q, LIU Y, et al. Boosting piezoelectric response of PVDF-TrFE via MXene for self-powered linear pressure sensor. Composites Science and Technology, 2021, 202: 108600. |

| [17] | YADAV P, RAJU T D, BADHULIKA S. Self-poled hBN-PVDF nanofiber mat-based low-cost, ultrahigh-performance piezoelectric nanogenerator for biomechanical energy harvesting. ACS Applied Energy Materials, 2020, 2(7): 1970. |

| [18] | KHAN F, KOWALCHIK T, ROUNDY S, et al. Stretching-induced phase transitions in barium titanate-poly(vinylidene fluoride) flexible composite piezoelectric films. Scripta Materialia, 2021, 193: 64. |

| [19] | GEBREKRSTOS A, MADRAS G, BOSE S. Journey of electroactive β-polymorph of poly(vinylidenefluoride) from crystal growth to design to applications. Crystal Growth & Design, 2019, 19(9): 5441. |

| [20] | LU L J, DING W Q, LIU J Q, et al. Flexible PVDF based piezoelectric nanogenerators. Nano Energy, 2020, 78: 105251. |

| [21] | YANG L, WANG H, FANG S P, et al. Research progress on energy storage performance enhancement strategies for polyvinylidene fluoride based composites. Journal of Alloys and Compounds, 2023, 960: 170831. |

| [22] |

LI H, SONG H, LONG M J, et al. Mortise-tenon joint structured hydrophobic surface-functionalized barium titanate/polyvinylidene fluoride nanocomposites for printed self-powered wearable sensors. Nanoscale, 2021, 13(4): 2542.

DOI PMID |

| [23] | WANG C, DONG C, PENG W, et al. Research progress of lead-free piezoelectric ceramics. China Ceramics, 2017, 53(11): 1. |

| [24] | GAO X Y, WU J G, YU Y, et al. Giant piezoelectric coefficients in relaxor piezoelectric ceramic PNN-PZT for vibration energy harvesting. Advanced Functional Materials, 2018, 28(30): 1706895. |

| [25] |

LIU K, SUN C, SHI Y S, et al. Current status and prospect of additive manufacturing piezoceramics. Journal of Inorganic Materials, 2022, 37(3): 278.

DOI |

| [26] | PEDDIGARI M, PARK J H, HAN J H, et al. Flexible self- charging, ultrafast, high-power-density ceramic capacitor system. ACS Energy Letters, 2021, 6(4): 1383. |

| [27] | ZHANG Y, JEONG C K, YANG T N, et al. Bioinspired elastic piezoelectric composites for high-performance mechanical energy harvesting. Journal of Materials Chemistry A, 2018, 6(30): 14546. |

| [28] | GAO W X, YOU L, WANG Y J, et al. Flexible PbZr0.52Ti0.48O3 capacitors with giant piezoelectric response and dielectric tunability. Advanced Electronic Materials, 2017 3(8): 1600542. |

| [29] | ZENG Z, GAI L L, WANG X, et al. A plastic-composite-plastic structure high performance flexible energy harvester based on PIN-PMN-PT single crystal/epoxy 2-2 composite. Applied Physics Letters, 2017, 110(10): 103501. |

| [30] | KIM H, NGUYEN D C, LUU T T, et al. Recent advances in functional fiber-based wearable triboelectric nanogenerators. Nanomaterials, 2023, 13(19): 2718. |

| [31] | YANG C, SONG S P, CHEN F, et al. Fabrication of PVDF/ BaTiO3/CNT piezoelectric energy harvesters with bionic balsa wood structures through 3D printing and supercritical carbon dioxide foaming. ACS Applied Materials & Interfaces, 2021, 13(35): 41723. |

| [32] | SONG L, DAI R X, LI Y J, et al. Polyvinylidene fluoride energy harvester with boosting piezoelectric performance through 3D printed biomimetic bone structures. ACS Sustainable Chemistry & Engineering, 2021, 9(22): 7561. |

| [33] | WANG Z H, CHENG J, HU R C, et al. An approach combining additive manufacturing and dielectrophoresis for 3D-structured flexible lead-free piezoelectric composites for electromechanical energy conversion. Journal of Materials Chemistry A, 2021, 9(47): 26767. |

| [34] | HUAN Y, ZHANG X S, SONG J A, et al. High-performance piezoelectric composite nanogenerator based on Ag/(K, Na)NbO3 heterostructure. Nano Energy, 2018, 50: 62. |

| [35] | PEI H R, SHI S H, CHEN Y H, et al. Combining solid state shear milling and FFF 3D-printing strategy to fabricate high-performance biomimetic wearable fish-scale PVDF-based piezoelectric energy harvesters. ACS Applied Materials & Interfaces, 2022, 14(13): 15346. |

| [36] | SORIMPUK N P, CHOONG W H, CHUA B L. Thermoforming characteristics of PLA/TPU multi-material specimens fabricated with fused deposition modelling under different temperatures. Polymers, 2022, 14(20): 4304. |

| [37] | LIU X G, SHANG Y H, ZHANG J H, et al. Ionic liquid assisted 3D printing of self-polarized β-PVDF for flexible piezoelectric energy harvesting. ACS Applied Materials & Interfaces, 2021, 13(12): 14347. |

| [38] | IKRAM H, ALRASHID A, KOC M. Additive manufacturing of smart polymeric composites: literature review and future perspectives. Polymer Composites, 2022, 43(9): 6355. |

| [39] | WANG Z H, YUAN X T, YANG J K, et al. 3D-printed flexible, Ag-coated PNN-PZT ceramic-polymer grid-composite for electromechanical energy conversion. Nano Energy, 2020, 73: 104737. |

| [40] | CHEN F, YANG C, AN Z M, et al. Direct-ink-writing of multistage-pore structured energy collector with ultrahigh ceramic content and toughness. Materials & Design, 2022, 217: 110652. |

| [41] | HAN C, HE L R, WANG Q, et al. Solvent-exchange-assisted 3D printing of self-polarized high β-PVDF for advanced piezoelectric energy harvesting. ACS Applied Electronic Materials, 2022, 4(6): 3125. |

| [42] | SIPONKOSKI T, NELO M, JANTUNEN H, et al. A printable P(VDF-TrFE)-PZT composite with very high piezoelectric coefficient. Applied Materials Today, 2020, 20: 100696. |

| [43] | BODKHE S, TURCOT G, GOSSELIN F P, et al. One-step solvent evaporation-assisted 3D printing of piezoelectric PVDF nanocomposite structures. ACS Applied Materials & Interfaces, 2017, 9(24): 20833. |

| [44] | TU R W, SPRAGUE E, SODANO H A, et al. Precipitation-printed high-β phase poly(vinylidene fluoride) for energy harvesting. ACS Applied Materials & Interfaces, 2020, 12(52): 58072. |

| [45] | TABRIZ A G, KUOFIE H, SCOBLE J, et al. Selective laser sintering for printing pharmaceutical dosage forms. Journal of Drug Delivery Science and Technology, 2023, 86: 104699. |

| [46] | SONG S P, HAN Y, LI Y J, et al. 3D printed piezoelectric porous structure with enhanced output performance and stress-electricity response for road energy harvesting. Additive Manufacturing, 2023, 72: 103625. |

| [47] | LOW Z X, CHUA Y T, RAY B M, et al. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. Journal of Membrane Science, 2017, 523: 596. |

| [48] | LIU H C, MUKHERJEE S, LIU Y, et al. Recent studies on electrospinning preparation of patterned, core-shell, and aligned scaffolds. Journal of Applied Polymer Science, 2018, 135(31): 45670. |

| [49] | WANG A D, LIU J H, SHAO C K, et al. Electro-assisted 3D printing multi-layer PVDF/CaCl2 composite films and sensors. Coatings, 2022, 12(6): 820. |

| [50] |

CUI H C, HENSLEIGH R, YAO D S, et al. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nature Materials, 2019, 18(3): 234.

DOI PMID |

| [51] | FEI J H, RONG Y J, ZHU L S, et al. Progress in photocurable 3D printing of photosensitive polyurethane: a review. Macromolecular Rapid Communications, 2023, 44(18): 2300211. |

| [52] | SMIRNOV A, CHUGUNOV S, KHOLODKOVA A, et al. Progress and challenges of 3D-printing technologies in the manufacturing of piezoceramics. Ceramics International, 2021, 47(8): 10478. |

| [53] | ALIQUE M, MOYA A, KREUZER M, et al. Controlled poling of a fully printed piezoelectric PVDF-TrFE device as a multifunctional platform with inkjet-printed silver electrodes. Journal of Materials Chemistry C, 2022, 10(32): 11555. |

| [54] | LI H, LI R H, FANG X T, et al. 3D printed flexible triboelectric nanogenerator with viscoelastic inks for mechanical energy harvesting. Nano Energy, 2019, 58: 447. |

| [55] |

CHUNG M H, YOO S, KIM H J, et al. Enhanced output performance on LbL multilayer PVDF-TrFE piezoelectric films for charging supercapacitor. Scientific Reports, 2019, 9: 6581.

DOI PMID |

| [56] | LEE H, CHOI B. A multilayer PVDF composite cantilever in the Helmholtz resonator for energy harvesting from sound pressure. Smart Materials and Strutures, 2013, 22(11): 115025. |

| [57] | JUNG W S, LEE M J, KANG M G, et al. Powerful curved piezoelectric generator for wearable applications. Nano Energy, 2015, 13: 174. |

| [58] | YUAN X T, GAO X Y, YANG J K, et al. The large piezoelectricity and high power density of a 3D-printed multilayer copolymer in a rugby ball-structured mechanical energy harvester. Energy & Environmental Science, 2020, 13(1): 152. |

| [59] | BHATTA T, MAHARJAN P, CHO H O, et al. High-performance triboelectric nanogenerator based on Mxene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy, 2021, 81: 105670. |

| [60] | KIM Y G, KIM K T, PARK S C, et al. Enhanced poling efficiency via a maximized organic-inorganic interfacial effect for water droplet-driven energy harvesting. Nano Energy, 2022, 98: 107238. |

| [61] | ZHENG Q F, ZHANG H L, MI H Y, et al. High-performance flexible piezoelectric nanogenerators consisting of porous cellulose nanofibril (CNF)/poly(dimethylsiloxane) (PDMS) aerogel films. Nano Energy, 2016, 26: 504. |

| [62] | YAN A, YUAN X T, LI Z M, et al. 3D-printed flexible, layered ceramic-polymer composite grid with integrated structural-self- sensing function. Sensors and Actuators A: Physical, 2021, 332: 113187. |

| [63] | YUAN X T, GAO X Y, SHEN X Y, et al. A 3D-printed, alternatively tilt-polarized PVDF-TrFE polymer with enhanced piezoelectric effect for self-powered sensor application. Nano Energy, 2021, 85: 105985. |

| [64] | LIU Y, DING L B, DAI L, et al. All-ceramic flexible piezoelectric energy harvester. Advanced Functional Materials, 2022, 32(52): 2209297. |

| [65] | ZHOU X R, PARIDA K, HALEVI O, et al. All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy, 2020, 72: 104676. |

| [66] | TIAN H G, SHAN X B, WANG H, et al. Enhanced piezoelectric energy harvesting performance using trailing-edge flap. Ocean Engineering, 2023, 285: 115443. |

| [67] | PEI H R, XIE Y P, XIONG Y, et al. A novel polarization free 3D printing strategy for fabrication of poly(vinylidene fluoride) based nanocomposite piezoelectric energy harvester. Composites Part B: Engineering, 2021, 225: 109312. |

| [68] | CHEN F, AN Z M, CHEN Y H, et al. Multi-material 3D printing of piezoelectric and triboelectric integrated nanogenerators with voxel structure. Chemical Engineering Journal, 2023, 471: 144770. |

| [69] |

PAWAR O Y, LIM S. 3D-Printed piezoelectric nanogenerator with aligned graphitic carbon nitrate nanosheets for enhancing piezoelectric performance. Journal of Colloid and Interface Science, 2023, 654: 868.

DOI PMID |

| [70] | CHEN C F, CAI F X, ZHU Y, et al. 3D printing of electroactive PVDF thin films with high β-phase content. Smart Materials and Structures, 2019, 28(6): 065017. |

| [71] | SONG S P, LI Y J, WANG Q, et al. Boosting piezoelectric performance with a new selective laser sintering 3D printable PVDF/graphene nanocomposite. Composites Part A: Applied Science and Manufacturing, 2021, 147: 106452. |

| [72] | SHUAI C J, LIU G F, YANG Y W, et al. A strawberry-like Ag- decorated barium titanate enhances piezoelectric and antibacterial activities of polymer scaffold. Nano Energy, 2020, 74: 104825. |

| [73] | QI F W, ZENG Z C, YAO J, et al. Constructing core-shell structured BaTiO3 carbon boosts piezoelectric activity and cell response of polymer scaffolds. Biomaterials Advances, 2021, 126: 112129. |

| [74] | LIU J F, SHANG Y H, SHAO Z Z, et al. Three-dimensional printing to translate simulation to architecting for three-dimensional high performance piezoelectric energy harvester. Industrial & Engineering Chemistry Research, 2021, 61(1): 433. |

| [75] | LIU X G, SHANG Y H, LIU J F, et al. 3D printing-enabled in-situ orientation of BaTi2O5 nanorods in β-PVDF for high-efficiency piezoelectric energy harvesters. ACS Applied Materials & Interfaces, 2022, 14(11): 13361. |

| [76] | HE L R, LU J, HAN C, et al. Electrohydrodynamic pulling consolidated high-efficiency 3D printing to architect unusual self-polarized β-PVDF arrays for advanced piezoelectric sensing. Small, 2022, 18(15): 2200114. |

| [77] | LIU X G, LIU J F, HE L R, et al. 3D printed piezoelectric regulable cells with customized electromechanical response distribution for intelligent sensing. Advanced Functional Materials, 2022, 32(26): 2201274. |

| [78] | KIM H, TORRES F, WU Y Y, et al. Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Materials and Structures, 2017, 26(8): 085027. |

| [79] | ZASZCZYŃSKA A, GRADYS A, SAJKIEWICZ P, et al. Progress in the applications of smart piezoelectric materials for medical devices. Polymers, 2020, 12(11): 2754. |

| [80] | MAAMER B, BOUGHAMOURA A, ELBAB A M R F, et al. A review on design improvements and techniques for mechanical energy harvesting using piezoelectric and electromagnetic schemes. Energy Conversion and Management, 2019, 199: 111973. |

| [81] | TAKAHASHI K, ONO K, ARAI H, et al. Detection of pathologic heart murmurs using a piezoelectric sensor. Sensors, 2021, 21(4): 1376. |

| [82] | SAWANE M, PRASAD M. MEMS piezoelectric sensor for self- powered devices: a review. Materials Science in Semiconductor Processing, 2023, 158: 107324. |

| [83] | YANG X, MENG J S, WANG Y, et al. Novel formation of Bi@BiFe-glycolate hollow spheres and their conversion into Bi2O3/BiFeO3 composite hollow spheres with enhanced activity and durability in visible photocatalysis. New Journal of Chemistry, 2018, 42(13): 10697. |

| [84] | AZIMI S, ABOLHASANI A, MOOSAVI S M, et al. Development of a vehicle passage sensor based on a PVDF nanogenerator. ACS Applied Electronic Materials, 2021, 3(11): 4689. |

| [85] | YAO D S, CUI H C, HENSLEIGH R, et al. Achieving the upper bound of piezoelectric response in tunable, wearable 3D printed nanocomposites. Advanced Functional Materials, 2019, 29(42): 1903866. |

| [86] | CACUCCIOLO V, SHINTAKE J, KUWAJIMA Y, et al. Stretchable pumps for soft machines. Nature, 2019, 572: 516. |

| [87] | YANG T, PAN H, TIAN G, et al. Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics. Nano Energy, 2020, 72: 104706. |

| [88] | LIANG X W, ZHAO T, JIANG W, et al. Highly transparent triboelectric nanogenerator utilizing in-situ chemically welded silver nanowire network as electrode for mechanical energy harvesting and body motion monitoring. Nano Energy, 2019, 59: 508. |

| [89] | GAUR A, TIWARI S, KUMAR C, et al. Flexible, lead-free nanogenerators using poly(vinylidene fluoride) nanocomposites. Energy & Fuels, 2020, 34(5): 6239. |

| [90] | SU H X, WANG X B, LI C Y, et al. Enhanced energy harvesting ability of polydimethylsiloxane-BaTiO3-based flexible piezoelectric nanogenerator for tactile imitation application. Nano Energy, 2021, 83: 105809. |

| [91] | QI F W, CHEN N, WANG Q. Preparation of PA11/BaTiO3nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selectivelaser sintering. Materials & Design, 2017, 131: 135. |

| [92] | DENG W L, YANG T, JIN L, et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy, 2019, 55: 516. |

| [93] |

HUA Q L, SUN J L, LIU H T, et al. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing. Nature Communications, 2018, 9: 244.

DOI PMID |

| [94] | CHENG Y, XU Y, QIAN Y, et al. 3D structured self-powered PVDF/PCL scaffolds for peripheral nerve regeneration. Nano Energy, 2020, 69: 104411. |

| [95] | LIANG J C, ZENG H J, QIAO L, et al. 3D Printed piezoelectric wound dressing with dual piezoelectric response models for scar- prevention wound healing. ACS Applied Materials & Interfaces, 2022, 14(27): 30507. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [3] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [4] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [5] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [6] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [7] | TANG Ying, LI Jie, XIANG Huaicheng, FANG Weishuang, LIN Huixing, YANG Junfeng, FANG Liang. Rattling Effect: A New Mechanism Affecting the Resonant Frequency Temperature Coefficient of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 656-666. |

| [8] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [9] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [10] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [11] | ZHOU Yangyang, ZHANG Yanyan, YU Ziyi, FU Zhengqian, XU Fangfang, LIANG Ruihong, ZHOU Zhiyong. Enhancement of Piezoelectric Properties in CaBi4Ti4O15-based Ceramics through Bi3+ Self-doping Strategy [J]. Journal of Inorganic Materials, 2025, 40(6): 719-728. |

| [12] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [13] | HUANG Zipeng, JIA Wenxiao, LI Lingxia. Crystal Structure and Terahertz Dielectric Properties of (Ti0.5W0.5)5+ Doped MgNb2O6 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 647-655. |

| [14] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [15] | YIN Changzhi, CHENG Mingfei, LEI Weicheng, CAI Yiyang, SONG Xiaoqiang, FU Ming, LÜ Wenzhong, LEI Wen. Effect of Ga3+ Doping on Crystal Structure Evolution and Microwave Dielectric Properties of SrAl2Si2O8 Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 704-710. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||