Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (9): 992-1004.DOI: 10.15541/jim20240036

Special Issue: 【能源环境】储能电池(202506); 【能源环境】锂离子电池(202412)

• REVIEW • Previous Articles Next Articles

LIU Pengdong1( ), WANG Zhen2,3,4, LIU Yongfeng3, WEN Guangwu1,4(

), WANG Zhen2,3,4, LIU Yongfeng3, WEN Guangwu1,4( )

)

Received:2024-02-28

Revised:2024-03-11

Published:2024-09-20

Online:2024-05-08

Contact:

WEN Guangwu, professor. E-mail: wengw@sdut.edu.cnAbout author:LIU Pengdong (1999-), male, Master candidate. E-mail: liupengdong_077@163.com

Supported by:CLC Number:

LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004.

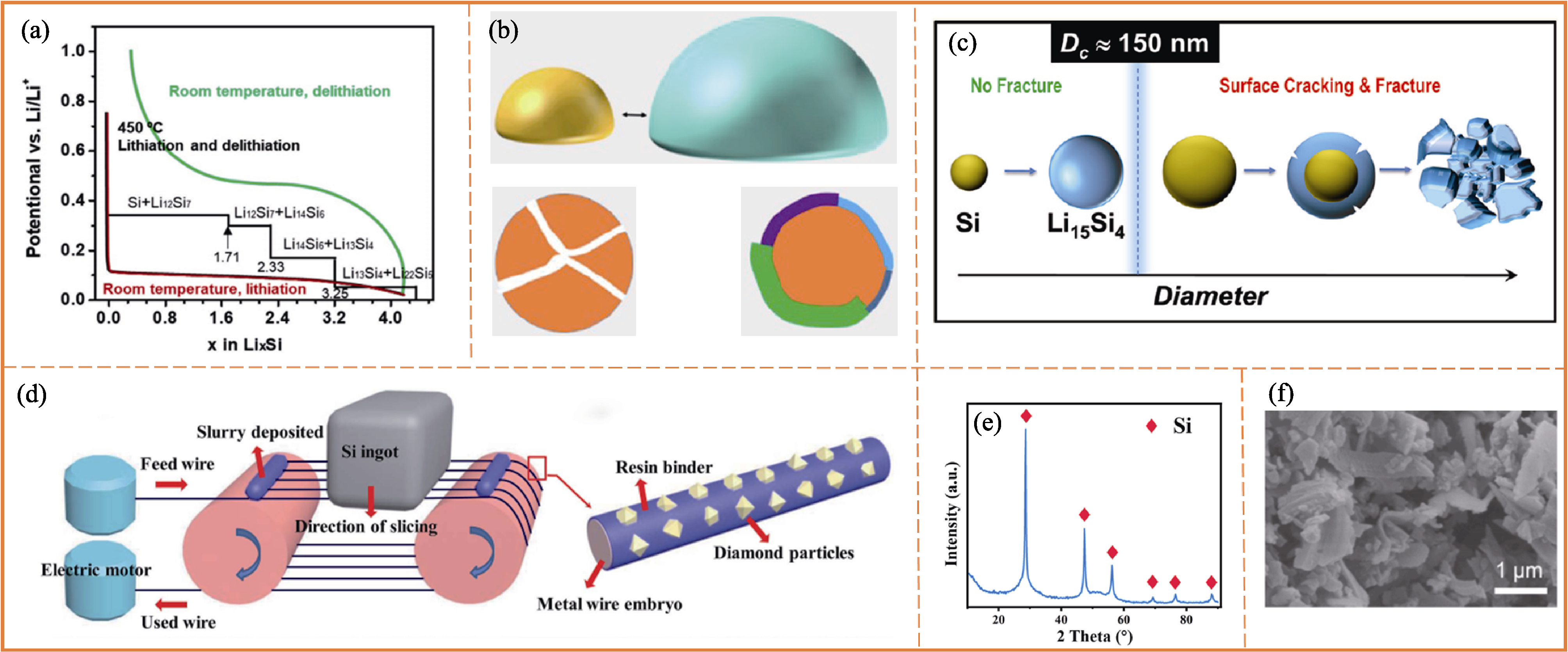

Fig. 1 Problems of Si anode and the sources and characteristics of silicon sludge (a) Lithiation/delithiation curves of Si anode at both 450 ℃ and room temperature[5]; (b) Problems in the process of Si anode lithiation/delithiation[8]; (c) Relationship between diameter size and cracking upon lithiation of individual nano silicon[9]; (d) Schematic of the multi-wire slicing of Si ingots and the typical diamond-wire saw[10]; (e) X-ray diffraction (XRD) pattern; (f) Scanning electron microscope (SEM) image of silicon sludge[13,16]

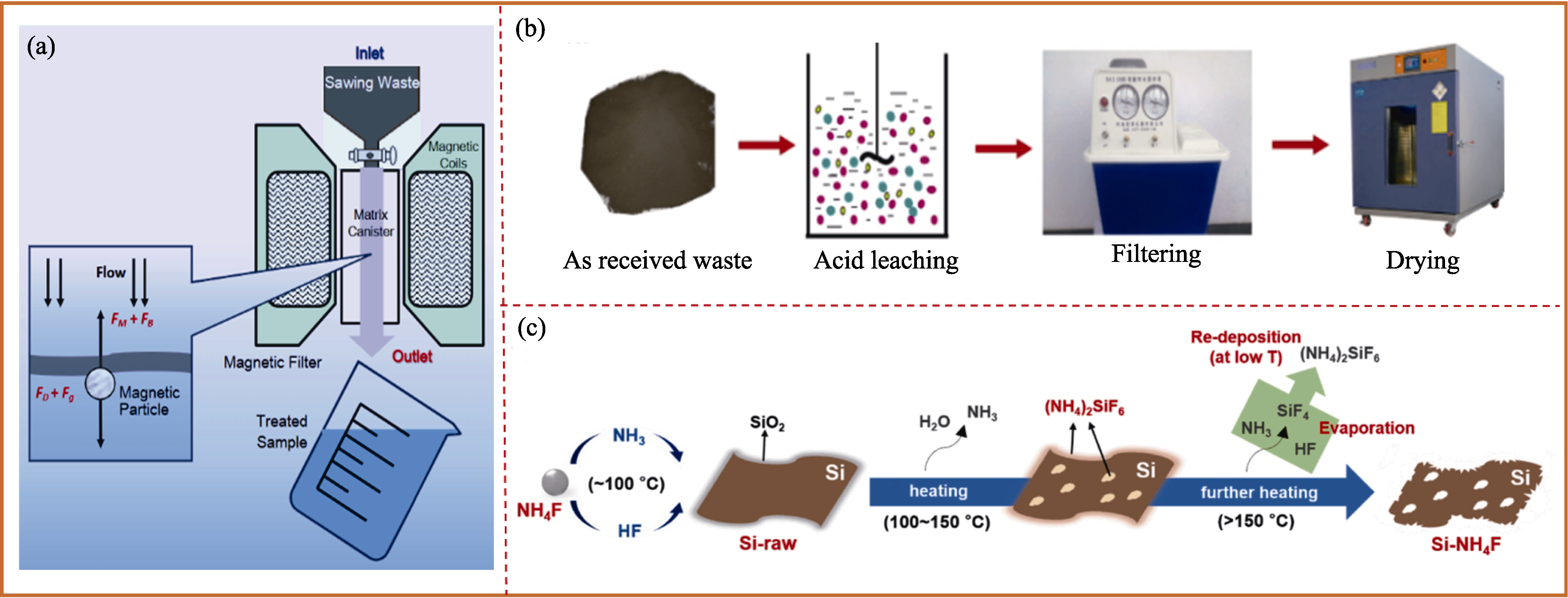

Fig. 2 Schematic diagram of removing impurities in silicon sludge (a) Magnetic separation equipment and schematic diagram of main forces exerted on a magnetic particle[24]; (b) Flow scheme of acid pickling[27]; (c) Reaction mechanism of removal of SiO2 through heat treatment of silicon sludge with NH4F[42]

| Current density/ (A·g-1) | First discharge capacity/ (mAh·g-1) | Cycle number | Capacity retention/% | Ref. |

|---|---|---|---|---|

| 0.8 | 1022.9 | 15 | 9.77 | [ |

| 0.05 | 3100 | 20 | 12.5 | [ |

| 0.2 | 3031.6 | 100 | 1.17 | [ |

| 0.1 | 1082 | 20 | 1.85 | [ |

| 0.1 | 2674.5 | 100 | 0.2 | [ |

Table 1 Electrochemical performance of purified silicon sludge

| Current density/ (A·g-1) | First discharge capacity/ (mAh·g-1) | Cycle number | Capacity retention/% | Ref. |

|---|---|---|---|---|

| 0.8 | 1022.9 | 15 | 9.77 | [ |

| 0.05 | 3100 | 20 | 12.5 | [ |

| 0.2 | 3031.6 | 100 | 1.17 | [ |

| 0.1 | 1082 | 20 | 1.85 | [ |

| 0.1 | 2674.5 | 100 | 0.2 | [ |

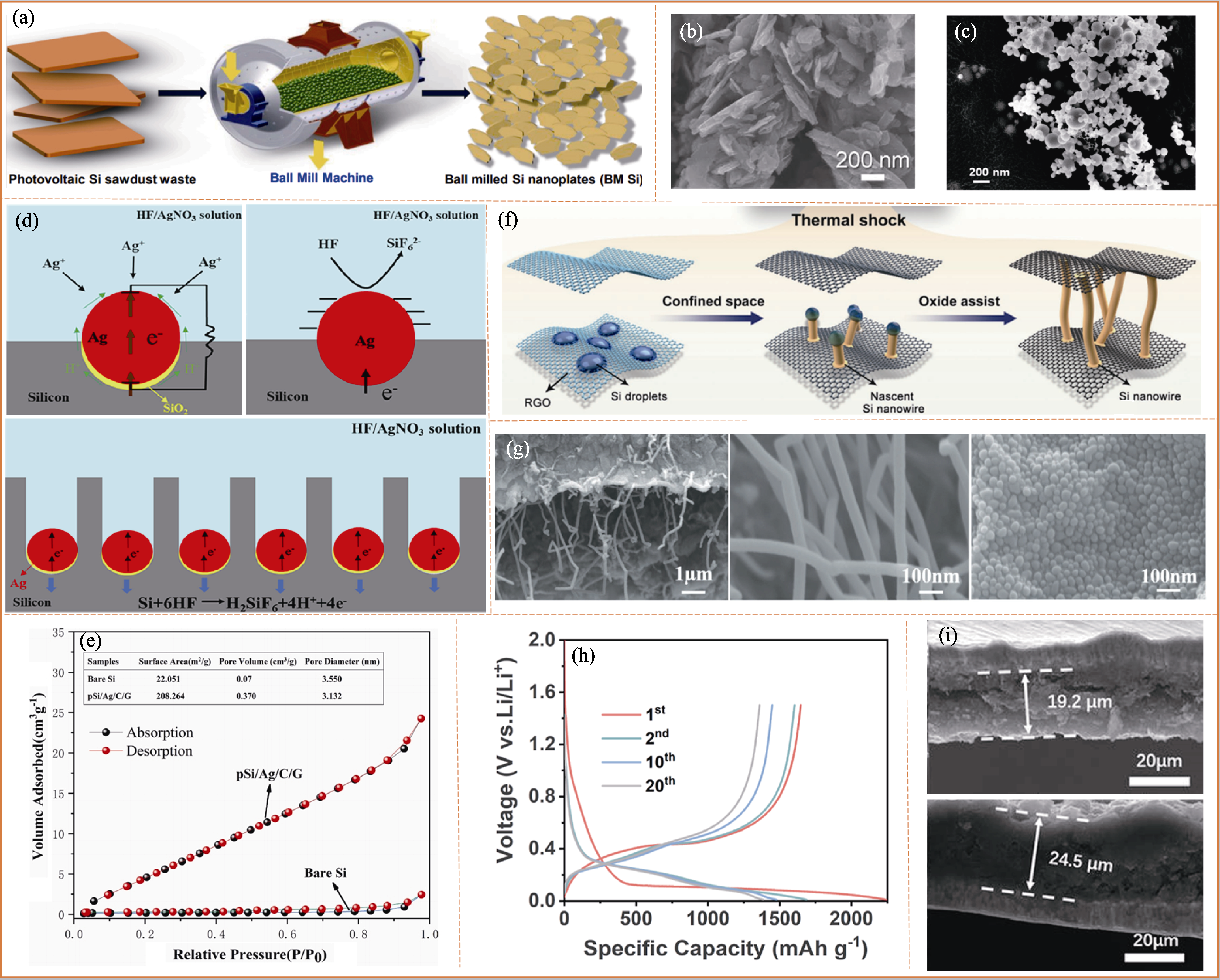

Fig. 3 Principle and characterization of nano-sized silicon sludge by different methods (a) Schematic diagram of preparing nano silicon by ball milling[59]; (b) SEM image of nano silicon prepared by stirring ball milling[61]; (c) SEM image of nano silicon prepared by transferred arc thermal plasma[62]; (d) Schematic diagram and (e) nitrogen adsorption-desorption isotherm of nano silicon by silver-assisted chemical etching[64]; (f) Schematic diagram and (g) SEM images of nano silicon by electrothermal shock method[66]; Nano silicon prepared by calcine dealloying: (h) charge-discharge curves and (i) SEM images of cross section for the working electrodes in the fresh and during initial lithiation process[67]

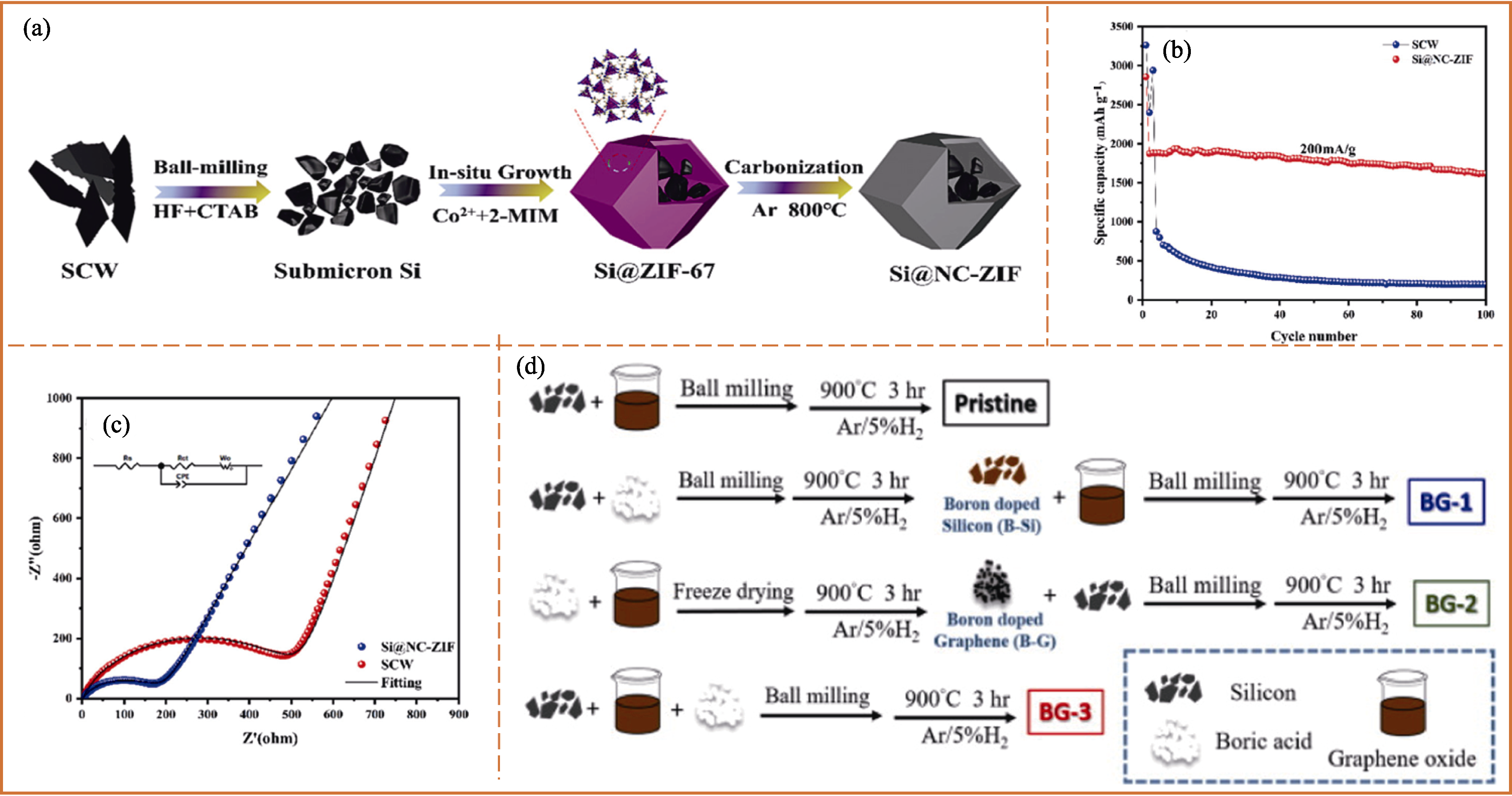

Fig. 4 Preparative schematic diagram and electrochemical performance of doping modified silicon sludge (a) Schematic diagram of the synthesis of Si@NC-ZIF composites[70]; (b) Cycling performance and (c) electrochemical impedance spectra of Si@NC-ZIF composites and silicon sludge[70]; (d) Flow scheme of silicon graphene composites prepared by boron doping[71]

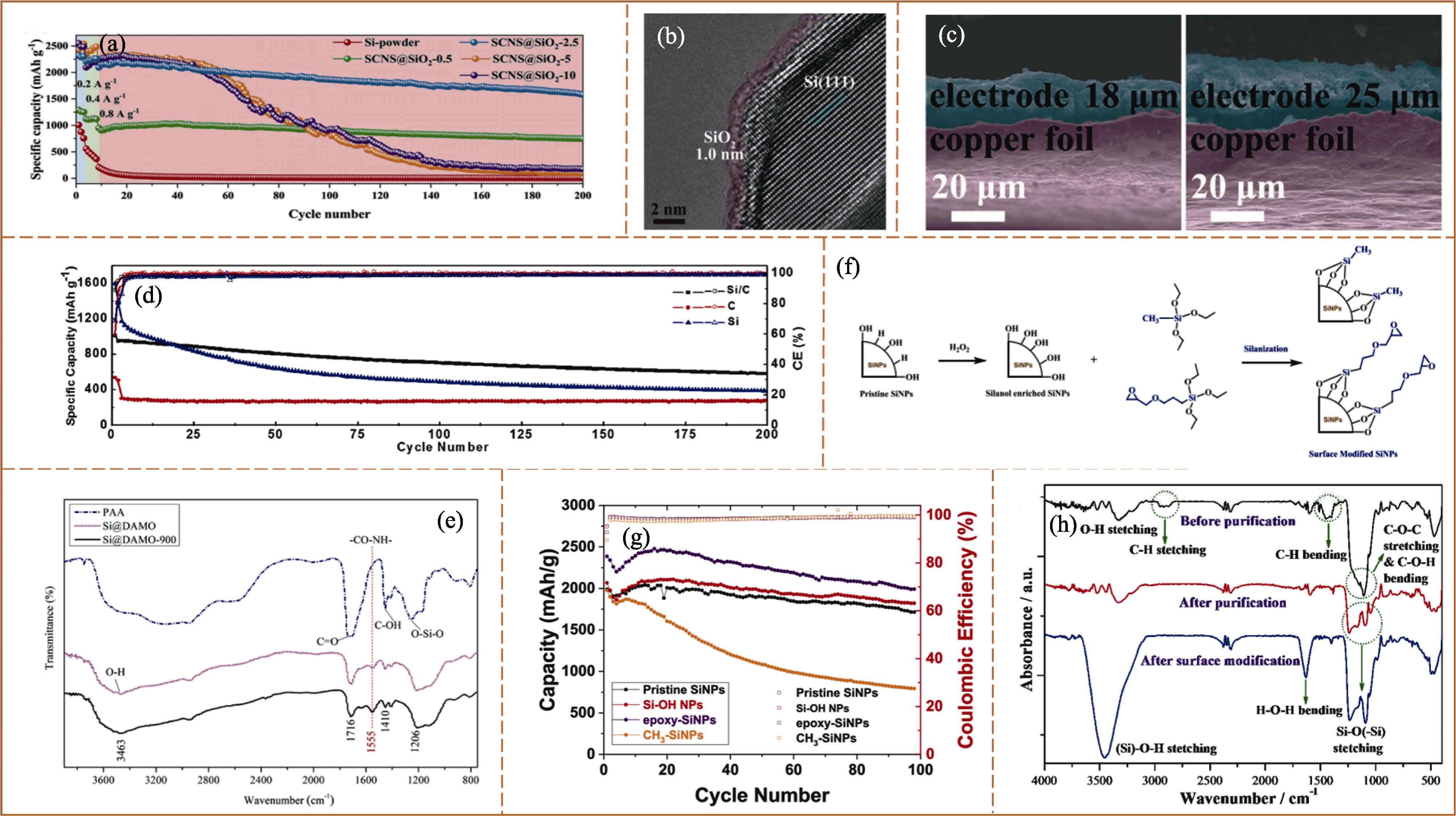

Fig. 5 Principle and characterization of surface modification of silicon sludge (a) Cycling performance of silicon sludge with different etching concentrations of hydrofluoric acid[72]; SCNS@SiO2-2.5 composites: (b) transmission electron microscope image and (c) cross sectional SEM images of the electrodes before and after 200 cycles[72]; (d) Cycling performance of silicon carbon composites prepared by lignin and silicon sludge[73]; (e) Fourier transform infrared (FT-IR) spectra of silicon sludge surface before and after DAMO modification[76]; (f) Schematic diagram of two-step introduction of epoxy functional groups[77]; (g) Cycling performance of silicon anode with different surface groups[77]; (h) FT-IR spectra of silicon sludge surface before and after SiOx films modification[10]

| Modification method | Current density/(A·g-1) | Cycle number | Discharge capacity/(mAh·g-1) | Ref. |

|---|---|---|---|---|

| Nano silicon | 0.1 | 100 | 1480 | [ |

| N-doped carbon/silicon | 1 | 200 | 1139 | [ |

| S-doped carbon/silicon | 0.5 | 700 | 686.6 | [ |

| Integrated electrode material | 1 | 250 | 1447 | [ |

| Silicon/graphite/carbon composite | 0.1 | 400 | 741 | [ |

| Porous carbon/silicon composite | 0.2 | 200 | 1527 | [ |

| Silicon/graphene composite | 0.2 | 300 | 1656 | [ |

| Si/C core-shell structure | 0.42 | 200 | 1788.9 | [ |

| Si/CNTs/C core-shell structure | 0.84 | 300 | 720 | [ |

| Si@void@C hollow structure | 1 | 300 | 1164.4 | [ |

| Si@SiOx/Ag composite material | 0.5 | 200 | 1000 | [ |

| pSi/Ag/C/G composite material | 1 | 200 | 972 | [ |

| Si/TiSi2/G@C composite material | 0.8 | 120 | 943.8 | [ |

Table 2 Electrochemical performance of silicon-based anode prepared by different modification methods

| Modification method | Current density/(A·g-1) | Cycle number | Discharge capacity/(mAh·g-1) | Ref. |

|---|---|---|---|---|

| Nano silicon | 0.1 | 100 | 1480 | [ |

| N-doped carbon/silicon | 1 | 200 | 1139 | [ |

| S-doped carbon/silicon | 0.5 | 700 | 686.6 | [ |

| Integrated electrode material | 1 | 250 | 1447 | [ |

| Silicon/graphite/carbon composite | 0.1 | 400 | 741 | [ |

| Porous carbon/silicon composite | 0.2 | 200 | 1527 | [ |

| Silicon/graphene composite | 0.2 | 300 | 1656 | [ |

| Si/C core-shell structure | 0.42 | 200 | 1788.9 | [ |

| Si/CNTs/C core-shell structure | 0.84 | 300 | 720 | [ |

| Si@void@C hollow structure | 1 | 300 | 1164.4 | [ |

| Si@SiOx/Ag composite material | 0.5 | 200 | 1000 | [ |

| pSi/Ag/C/G composite material | 1 | 200 | 972 | [ |

| Si/TiSi2/G@C composite material | 0.8 | 120 | 943.8 | [ |

| [1] | KIM T, SONG W T, SON D Y, et al. Lithium-ion batteries: outlook on present, future, and hybridized technologies. Journal of Materials Chemistry A, 2019, 7(7): 2942. |

| [2] | LI J Y, XU Q, LI G, et al. Research progress regarding Si-based anode materials towards practical application in high energy density Li-ion batteries. Materials Chemistry Frontiers, 2017, 1(9): 1691. |

| [3] |

ZHANG Y X, WU B R, MU G, et al. Recent progress and perspectives on silicon anode: synthesis and prelithiation for LIBs energy storage. Journal of Energy Chemistry, 2022, 64: 615.

DOI |

| [4] | DEVIC T, LESTRIEZ B, ROUÉ L. Silicon electrodes for Li-ion batteries. Addressing the challenges through coordination chemistry. ACS Energy Letters, 2019, 4(2): 550. |

| [5] | GUO J P, DONG D Q, WANG J, et al. Silicon-based lithium ion battery systems: state of the art from half and full cell viewpoint. Advanced Functional Materials, 2021, 31(34): 2102546. |

| [6] | MA J Y, SUNG J, LEE Y, et al. Strategic pore architecture for accommodating volume change from high Si content in lithium-ion battery anodes. Advanced Energy Materials, 2020, 10(6): 1903400. |

| [7] | XIA M T, CHEN B J, GU F, et al. Ti3C2Tx MXene nanosheets as a robust and conductive tight on Si anodes significantly enhance electrochemical lithium storage performance. ACS Nano, 2020, 14(4): 5111. |

| [8] | WU F X, MAIER J, YU Y. Guidelines and trends for next- generation rechargeable lithium and lithium-ion batteries. Chemical Society Reviews, 2020, 49(5): 1569. |

| [9] |

LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6(2): 1522.

DOI PMID |

| [10] | ZHANG L Y, ZHANG L, ZHANG J, et al. Robust polymeric coating enables the stable operation of silicon micro-plate anodes recovered from photovoltaic industry waste for high-performance Li-ion batteries. Journal of Materials Chemistry A, 2015, 3(30): 15432. |

| [11] | YANG X F, CHEN X F, QIU J Y, et al. Controllable synthesis of silicon/carbon hollow microspheres using renewable sources for high energy lithium-ion battery. Journal of Solid State Chemistry, 2021, 296: 121968. |

| [12] |

JANG H D, KIM H, CHANG H, et al. Aerosol-assisted extraction of silicon nanoparticles from wafer slicing waste for lithium ion batteries. Scientific Reports, 2015, 5: 9431.

DOI PMID |

| [13] | CHEN G, LI Y, SHENG W, et al. Al2O3 and CaO as sintering aids: a strategy to remove impurity boron and SiO2 surface-layer of diamond wire saw silicon waste. Separation and Purification Technology, 2021, 270: 118823. |

| [14] | DROUICHE N, CUELLAR P, KERKAR F, et al. Recovery of solar grade silicon from kerf loss slurry waste. Renewable and Sustainable Energy Reviews, 2014, 32: 936. |

| [15] | LIU R P, XIANG D P. Recycling photovoltaic silicon waste for fabricating porous mullite ceramics by low-temperature reaction sintering. Journal of the European Ceramic Society, 2021, 41(12): 5957. |

| [16] | MA Y C, HUANG A M, LI Y, et al. Simple preparation of Si/N- doped carbon anodes from photovoltaic industry waste for lithium- ion batteries. Journal of Alloys and Compounds, 2022, 890: 161792. |

| [17] | 楼平, 管敏渊, 彭蒙蒙, 等. 铁磁杂质对锂离子电池自放电和电化学性能的影响. 功能材料与器件学报, 2021, 27: 361. |

| [18] | 李路, 胡安生. 锂离子电池中金属及金属氧化物引发自放电的研究. 广东化工, 2021, 48: 23. |

| [19] | 郑留群, 万里鹏, 陈珠惠, 等. 杂质对锂离子电池自放电的影响. 电池, 2022, 52: 419. |

| [20] | LEI Y, QIU P, CHEN K, et al. Mechanism of ZrB2 formation in Al-Si alloy and application in Si purification. ACS Sustainable Chemistry & Engineering, 2019, 7(15): 12990. |

| [21] | WEI K, YANG S, WAN X, et al. Review of silicon recovery and purification from saw silicon powder. JOM, 2020, 72(7): 2633. |

| [22] | SHI J, SHENG L Q, LI J W, et al. Green synthesis of high- performance porous carbon coated silicon composite anode for lithium storage based on recycled silicon kerf waste. Journal of Alloys and Compounds, 2022, 919: 165854. |

| [23] | YANG F, YU W Z, WEN J L, et al. Oxygen removal and silicon recovery from polycrystalline silicon kerf loss by combining vacuum magnesium thermal reduction and hydrochloric acid leaching. Journal of Environmental Management, 2023, 338: 117829. |

| [24] | BOUTOUCHENT-GUERFI N, BOUSSOURDI M A, LAMI A, et al. Dry magnetic separation on the recovery of metal fragments from kerf slurry waste produced during the manufacture of photovoltaic solar cells. Silicon, 2020, 13(1): 149. |

| [25] | TSAI T H, WU Y F. Recovery of submicron-sized silicon-rich powder from silicon sawing waste for electrocatalyst of methanol electrooxidation. International Journal of Electrochemical Science, 2018, 13(7): 6880. |

| [26] | LIU S N, HUANG K, ZHU H M. Removal of Fe, B and P impurities by enhanced separation technique from silicon-rich powder of the multi-wire sawing slurry. Chemical Engineering Journal, 2016, 299: 276. |

| [27] | LIU Y, KONG J, ZHUANG Y X, et al. Recycling high purity silicon from solar grade silicon cutting slurry waste by carbothermic reduction in the electric arc furnace. Journal of Cleaner Production, 2019, 224: 709. |

| [28] |

YANG S C, WEI K X, MA W H, et al. Kinetic mechanism of aluminum removal from diamond wire saw powder in HCl solution. Journal of Hazardous Materials, 2019, 368: 1.

DOI PMID |

| [29] | WANG K, TAN Y, LI P T, et al. Recycling Si waste cut from diamond wire into high performance porous Si@SiO2@C anodes for Li-ion battery. Journal of Hazardous Materials, 2021, 407: 124778. |

| [30] | KONG J, JIN X, LIU Y, et al. Study on the kinetics of iron removal from silicon diamond-wire saw cutting waste: comparison between heterogeneous and homogeneous reaction methods. Separation and Purification Technology, 2019, 221: 261. |

| [31] | 王宇, 尹盛, 肖成章, 等.硅材料湿法提纯理论分析及工艺优化. 太阳能学报, 1995: 174. |

| [32] | YANG S C, WAN X H, WEI K X, et al. A new sustainable concept for silicon recovery from diamond wire saw silicon powder waste: source control and comprehensive conservation. Journal of Cleaner Production, 2022, 358: 131961. |

| [33] | YANG S C, WAN X H, WEI K X, et al. Occurrence state and dissolution mechanism of metallic impurities in diamond wire saw silicon powder. ACS Sustainable Chemistry & Engineering, 2020, 8(33): 12577. |

| [34] | WU C Y, KUO P H, DUH J G. Reviving of silicon waste with N-doped carbon core-shell structure prepared by vapor deposition polymerization of polypyrrole applied in lithium-ion battery. Surface and Coatings Technology, 2021, 421: 127418. |

| [35] | HOU S Y, TIE S N, JIANG M, et al. Microwave-assisted acid leaching for recovery of silicon from diamond-wire cutting waste Slurry. JOM, 2020, 72(7): 2656. |

| [36] | WANG K, XUE B, TAN Y, et al. Recycling of micron-sized Si powder waste from diamond wire cutting and its application in Li-ion battery anodes. Journal of Cleaner Production, 2019, 239: 117997. |

| [37] | WAGNER N P, TRON A, TOLCHARD J R, et al. Silicon anodes for lithium-ion batteries produced from recovered kerf powders. Journal of Power Sources, 2019, 414: 486. |

| [38] |

YANG H L, LIU I T, LIU C E, et al. Recycling and reuse of kerf-loss silicon from diamond wire sawing for photovoltaic industry. Waste Management, 2019, 84: 204.

DOI PMID |

| [39] | VAZQUEZ-PUFLEAU M, CHADHA T S, YABLONSKY G, et al. Elimination of carbon contamination from silicon kerf using a furnace aerosol reactor methodology. Industrial & Engineering Chemistry Research, 2015, 54(22): 5914. |

| [40] | YANG F, YU W Z, RAO Z T, et al. A new strategy for de-oxidation of diamond-wire sawing silicon waste via the synergistic effect of magnesium thermal reduction and hydrochloric acid leaching. Journal of Environmental Management, 2022, 317: 115424. |

| [41] | 孙海鸥, 赵梅玉, 李晓平, 等.一种熔盐法处理硅废料制备锂离子电池负极材料的方法: CN116387497B. 2023-07-28. |

| [42] | WANG S E, JANG I, KANG Y C, et al. Residual silica removal and nanopore generation on industrial waste silicon using ammonium fluoride and its application to lithium-ion battery anodes. Chemical Engineering Journal, 2021, 419: 129389. |

| [43] | HE Q, YU J, WANG Y H, et al. Silicon nanoparticles prepared from industrial wastes as high-performing anode materials for lithium ion batteries. Solid State Ionics, 2018, 325: 141. |

| [44] | YANG T Y, YANG G, TANG Y K, et al. Porous silicon from industrial waste engineered for superior stability lithium-ion battery anodes. Journal of Nanoparticle Research, 2021, 23: 209. |

| [45] | YU C L, TIAN X H, XIONG Z C, et al. High stability of sub-micro-sized silicon/carbon composites using recycling silicon waste for lithium-ion battery anode. Journal of Alloys and Compounds, 2021, 869: 159124. |

| [46] | SU Y X, LV Y Y, HABIBIPOUR M R, et al. Dynamic stable interface between CNT and nanosilicon for robust anode with large capacity and high rate performance. Energy Storage Materials, 2023, 61: 102892. |

| [47] | WU F, DONG Y, SU Y F, et al. Benchmarking the effect of particle size on silicon anode materials for lithium-ion batteries. Small, 2023, 19(42): 2301301. |

| [48] | YAN Z, JIANG J, ZHANG Y, et al. Scalable and low-cost synthesis of porous silicon nanoparticles as high-performance lithium-ion battery anode. Materials Today Nano, 2022, 18: 100175. |

| [49] | TANG F Q, TAN Y, JIANG T T, et al. Phosphorus-doped silicon nanoparticles as high performance LIB negative electrode. Journal of Materials Science, 2022, 57(4): 2803. |

| [50] | DI F, ZHOU W M, YANG H M, et al. Surface modification and functional structure space design to improve the cycle stability of silicon based materials as anode of lithium ion batteries. Coatings, 2021, 11(9): 1047. |

| [51] | CHAE S J, XU Y B, YI R, et al. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Advanced Materials, 2021, 33(40): 2103095. |

| [52] | SU H P, LI X R, LIU C W, et al. Scalable synthesis of micrometer-sized porous silicon/carbon composites for high- stability lithium-ion battery anodes. Chemical Engineering Journal, 2023, 451: 138394. |

| [53] | ZHANG W Y, SHI H F, WANG C D, et al. Synthesizing copper-doped silicon/carbon composite anode as cost-effective active materials for Li-ion batteries. Journal of Physics and Chemistry of Solids, 2023, 179: 111387. |

| [54] | YU Q, GE P P, LIU Z H, et al. Ultrafine SiOx/C nanospheres and their pomegranate-like assemblies for high-performance lithium storage. Journal of Materials Chemistry A, 2018, 6(30): 14903. |

| [55] | MA T Y, YU X G, CHENG X L, et al. Confined solid electrolyte interphase growth space with solid polymer electrolyte in hollow structured silicon anode for Li-ion batteries. ACS Applied Materials & Interfaces, 2017, 9(15): 13247. |

| [56] | KELLER C, DESRUES A, KARUPPIAH S, et al. Effect of size and shape on electrochemical performance of nano-silicon-based lithium battery. Nanomaterials, 2021, 11(2): 307. |

| [57] | XU Z L, LIU X M, LUO Y S, et al. Nanosilicon anodes for high performance rechargeable batteries. Progress in Materials Science, 2017, 90: 1. |

| [58] | HAN X, ZHANG Z Q, CHEN S Y, et al. Low temperature growth of graphitic carbon on porous silicon for high-capacity lithium energy storage. Journal of Power Sources, 2020, 463: 228245. |

| [59] | ZHANG Y F, MA H Y, YU C M, et al. Si nanoplates prepared by ball milling photovoltaic silicon sawdust waste as lithium-ion batteries anode material. Materials Letters, 2023, 331: 133469. |

| [60] | ZHANG S Y, XIE J, ZHANG P, et al. Low-cost and scalable preparation of nano-Si from photovoltaic waste silicon for high-performance Li-ion battery anode. Functional Materials Letters, 2021, 14(6): 2151033. |

| [61] |

KASUKABE T, NISHIHARA H, KIMURA K, et al. Beads-milling of waste Si sawdust into high-performance nanoflakes for lithium-ion batteries. Scientific Reports, 2017, 7(1): 42734.

DOI PMID |

| [62] | JIN E M, KIM M S, KIM T Y, et al. Upcycling of silicon scrap collected from photovoltaic cell manufacturing process for lithium-ion batteries via transferred arc thermal plasma. Energy, 2023, 262: 125447. |

| [63] | 李绍元, 张嘉昆, 马文会, 等.等离子活化切割硅废料制备多孔硅/碳/纳米金属复合负极材料的方法: CN111785944B. 2023-04-28. |

| [64] | WANG L, XI F S, ZHANG Z, et al. Recycling of photovoltaic silicon waste for high-performance porous silicon/silver/carbon/ graphite anode. Waste Management, 2021, 132: 56. |

| [65] | ZHANG Z, XI F S, LI S Y, et al. High-performance Si/nano- Cu/CNTs/C anode derived from photovoltaic silicon waste: a potential photovoltaic-energy storage strategy. Materials Today Energy, 2021, 20: 100671. |

| [66] | LU J J, LIU S L, LIU J H, et al. Millisecond conversion of photovoltaic silicon waste to binder-free high silicon content nanowires electrodes. Advanced Energy Materials, 2021, 11(40): 2102103. |

| [67] | CHEN M Y, DUAN P X, ZHONG Y J, et al. Constructing a sheet-stacked Si/C composite by recycling photovoltaic Si waste for Li-ion batteries. Industrial & Engineering Chemistry Research, 2022, 61(7): 2809. |

| [68] | MA Q, ZHAO Z Q, ZHAO Y, et al. A self-driven alloying/dealloying approach to nanostructuring micro-silicon for high-performance lithium-ion battery anodes. Energy Storage Materials, 2021, 34: 768. |

| [69] | 洪捐.一种利用硅废料制备镓掺杂纳米硅颗粒的方法: CN113471422B. 2023-07-07. |

| [70] | WANG M Y, XI F S, LI S Y, et al. ZIF-67-derived porous nitrogen-doped carbon shell encapsulates photovoltaic silicon cutting waste as anode in high-performance lithium-ion batteries. Journal of Electroanalytical Chemistry, 2023, 931: 117210. |

| [71] | WU Z Y, WU C Y, DUH J G. Facile synthesis of boron-doped graphene-silicon conductive network composite from recycling silicon for lithium-ion batteries anodes materials. Materials Letters, 2021, 296: 129875. |

| [72] | HU T J, ZHOU H C, ZHOU X Y, et al. Silicon cutting waste derived silicon nanosheets with adjustable native SiO2 shell for highly-stable lithiation/delithiation. Small, 2022, 19(7): 2204690. |

| [73] | LIU W W, LIU J, ZHU M H, et al. Recycling of lignin and Si waste for advanced Si/C battery anodes. ACS Applied Materials & Interfaces, 2020, 12(51): 57055. |

| [74] | PHAM T K, SHIN J, SONG H, et al. Application of Si particles recycled from industrial waste for Si/rGO electrode composition for lithium rechargeable battery production. Molecular Crystals and Liquid Crystals, 2020, 707(1): 147. |

| [75] | SHI J, JIANG X S, BAN B Y, et al. Carbon nanotubes-enhanced lithium storage capacity of recovered silicon/carbon anodes produced from solar-grade silicon kerf scrap. Electrochimica Acta, 2021, 381: 138269. |

| [76] | LIANG J H, FAN Z Q, CHEN S, et al. A novel three-dimensional cross-linked net structure of submicron Si as high-performance anode for LIBs. Journal of Alloys and Compounds, 2021, 860: 158433. |

| [77] | JIANG S S, HU B, SAHORE R T, et al. Surface-functionalized silicon nanoparticles as anode material for lithium-ion battery. ACS Applied Materials & Interfaces, 2018, 10(51): 44924. |

| [78] | JUNG C H, CHOI J, KIM W S, et al. A nanopore-embedded graphitic carbon shell on silicon anode for high performance lithium ion batteries. Journal of Materials Chemistry A, 2018, 6(17): 8013. |

| [79] | JEONG S, LI X L, ZHENG J M, et al. Hard carbon coated nano-Si/graphite composite as a high performance anode for Li-ion batteries. Journal of Power Sources, 2016, 329: 323. |

| [80] | LU B, MA B J, YU R Z, et al. Photovoltaic monocrystalline silicon waste-derived hierarchical silicon/flake graphite/carbon composite as low-cost and high-capacity anode for lithium-ion batteries. ChemistrySelect, 2017, 2(12): 3479. |

| [81] | DUAN H, XU H, WU Q, et al. Silicon/graphite/amorphous carbon as anode materials for lithium secondary batteries. Molecules, 2023, 28(2): 464. |

| [82] | LIU X, LIU H T, DAI X Q, et al. Scalable silicon@sulfur-doped carbon composites via a low-cost facile method for high- performance lithium-ion battery anodes. Journal of Alloys and Compounds, 2023, 946: 169330. |

| [83] | SHAO R, NIU J, ZHU F, et al. A facile and versatile strategy towards high-performance Si anodes for Li-ion capacitors: concomitant conductive network construction and dual-interfacial engineering. Nano Energy, 2019, 63: 103824. |

| [84] | SHI J, JIANG X S, SUN J F, et al. Recycled silicon-based anodes with three-dimensional hierarchical porous carbon framework synthesized by a self-assembly CaCO3 template method for lithium ion battery. Journal of Alloys and Compounds, 2021, 858: 157703. |

| [85] | PHAM T K, SHIN J H, KARIMA N C, et al. Application of recycled Si from industrial waste towards Si/rGO composite material for long lifetime lithium-ion battery. Journal of Power Sources, 2021, 506: 230244. |

| [86] | FAN Z Q, ZHENG S S, HE S, et al. Preparation of micron Si@C anodes for lithium ion battery by recycling the lamellar submicron silicon in the kerf slurry waste from photovoltaic industry. Diamond and Related Materials, 2020, 107: 107898. |

| [87] | WANG C D, NIU X X, WANG D H, et al. Simple preparation of Si/CNTs/C composite derived from photovoltaic waste silicon powder as high-performance anode material for Li-ion batteries. Powder Technology, 2022, 408: 117744. |

| [88] | MA Q, QU J K, CHEN X, et al. Converting micro-sized kerf-loss silicon waste to high-performance hollow-structured silicon/carbon composite anodes for lithium-ion batteries. Sustainable Energy & Fuels, 2020, 4(9): 4780. |

| [89] | ZHANG J K, LI S Y, XI F S, et al. Si@SiOx/Ag composite anodes with high initial Coulombic efficiency derive from recyclable silicon cutting waste. Chemical Engineering Journal, 2022, 447: 137563. |

| [90] | ZHANG Y C, CHEN M Y, CHEN Z Y, et al. A novel Si/TiSi2/ G@C composite as anode material with excellent lithium storage performances. Materials Letters, 2021, 299: 130078. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | TAN Bowen, GENG Shuanglong, ZHANG Kai, ZHENG Bailin. Composition-gradient Design of Silicon Electrodes to Mitigate Mechanochemical Coupling Degradation [J]. Journal of Inorganic Materials, 2025, 40(7): 772-780. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [5] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [6] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [9] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [10] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [11] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [12] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [13] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [14] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [15] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||