Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (8): 853-864.DOI: 10.15541/jim20220019

• REVIEW • Previous Articles Next Articles

Received:2022-01-13

Revised:2022-04-12

Published:2022-08-20

Online:2022-04-26

Contact:

ZENG Yuping, professor. E-mail: yuping-zeng@mail.sic.ac.cnAbout author:ZHANG Ye (1994-), male, PhD candidate. E-mail: zhangyezn@student.sic.ac.cn

Supported by:CLC Number:

ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis[J]. Journal of Inorganic Materials, 2022, 37(8): 853-864.

| Si/g | Si3N4/g | Y2O3/g | Combustion temperature/℃ | Reaction time/s | Open porosity/% | Shrinkage/% | Ref. |

|---|---|---|---|---|---|---|---|

| 30-45 | 70-55 | 2 | 1870-2050 | 30-13 | 40.5-45.8 | / | [ |

| 30-70 | 70-30 | 5 | 1820-1982 | / | 50.0-60.0 | 2.8-3.4 | [ |

Table 1 Composition of raw materials, parameters of SHS process and properties of the fabricated samples

| Si/g | Si3N4/g | Y2O3/g | Combustion temperature/℃ | Reaction time/s | Open porosity/% | Shrinkage/% | Ref. |

|---|---|---|---|---|---|---|---|

| 30-45 | 70-55 | 2 | 1870-2050 | 30-13 | 40.5-45.8 | / | [ |

| 30-70 | 70-30 | 5 | 1820-1982 | / | 50.0-60.0 | 2.8-3.4 | [ |

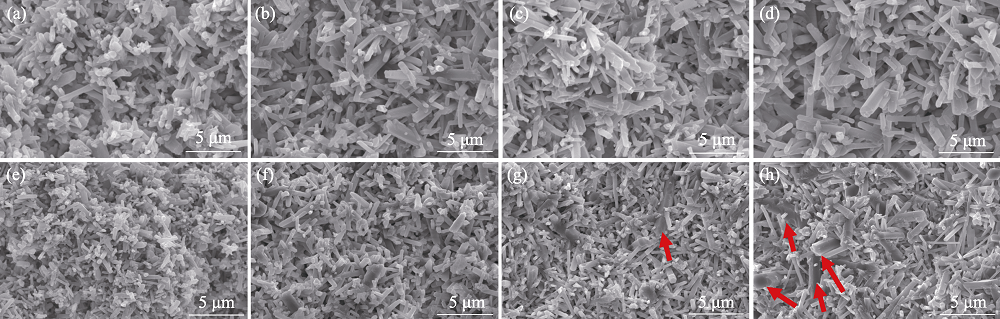

Fig 3 Microstructures of the porous Si3N4 ceramics fabricated by different (p) pressures of N2 gas (p) and average particle sizes of Si powder (d50)[46] (a) p=3 MPa, d50=2.7 μm; (b) p=5 MPa, d50=2.7 μm; (c) p=7 MPa, d50=2.7μm; (d) p=9 MPa, d50=2.7 μm; (e) p=5 MPa, d50=1.3 μm; (f) p=5 MPa, d50=2.7 μm; (g) p=5 MPa, d50=4.5 μm; (h) p=5 MPa, d50=8.7 μm

Fig. 6 Weibull plots of flexural strength for samples prepared with different types of Si3N4 diluent and shaping pressures[59] (Sample ST uses Si3N4 diluent with coarse particle size and high β phase while sample SA uses Si3N4 diluent with fine particle size and high α phase, -X represents the shaping pressure)

| SA-50 | SA-100 | SA-150 | SA-200 | ST-50 | ST-100 | ST-150 | ST-200 | Ref.[ | |

|---|---|---|---|---|---|---|---|---|---|

| R2 | 0.99 | 0.96 | 0.99 | 0.97 | 0.96 | 0.90 | 0.96 | 0.99 | - |

| m | 11.4 | 9.3 | 8.8 | 5.7 | 11.4 | 16.0 | 17.2 | 11.0 | 10.6-20.9 |

Table 2 Correlation coefficient and Weibull modulus of samples obtained with two different Si3N4 powders and varied shaping pressures[59]

| SA-50 | SA-100 | SA-150 | SA-200 | ST-50 | ST-100 | ST-150 | ST-200 | Ref.[ | |

|---|---|---|---|---|---|---|---|---|---|

| R2 | 0.99 | 0.96 | 0.99 | 0.97 | 0.96 | 0.90 | 0.96 | 0.99 | - |

| m | 11.4 | 9.3 | 8.8 | 5.7 | 11.4 | 16.0 | 17.2 | 11.0 | 10.6-20.9 |

Fig. 7 Relationship between flexural strength and porosity of ceramics prepared by different methods SSN represents sintering Si3N4 by pressureless or gas pressure sintering[10,65⇓⇓⇓⇓⇓⇓⇓⇓-74]; SRBSN represents sintering reaction-bonded Si3N4 [75⇓⇓⇓⇓⇓⇓⇓-83]; CRS represents Si3N4 fabricated by carbothermal reduction sintering[16,84⇓-86]; SHS represents Si3N4 fabricated by self-propagating high temperature synthesis[46⇓-48,56,59-60]

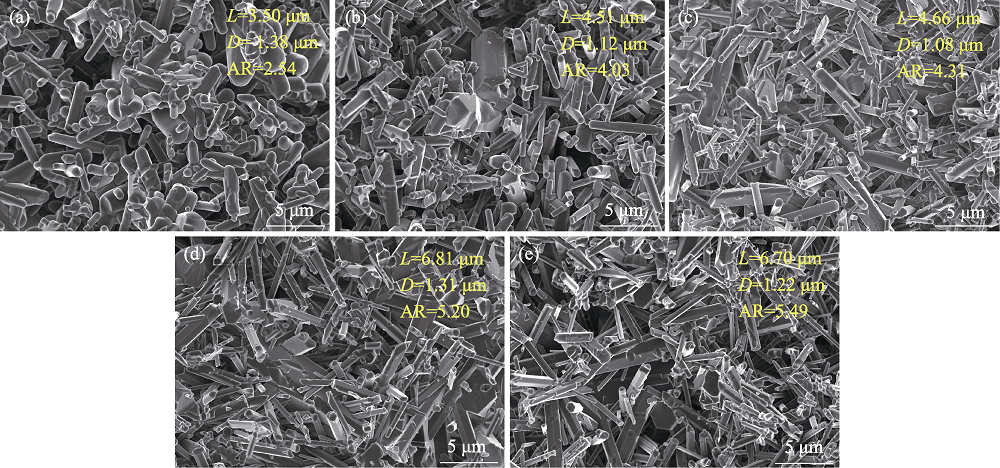

Fig. 10 Microstructures and average grain sizes of the SHS-fabricated Si3N4 ceramics prepared with different Y2O3 mass content as sintering additive[62] (a) 0; (b) 0.4%; (c) 0.8%; (d) 1.2%; (e) 1.6%. L, D, AR represents average grain length, average grain diameter, and average aspect ratio respectively

Fig. 11 Room-temperature and high-temperature flexural strength of the fabricated porous Si3N4 ceramics as function of sintering additives addition[62]

| [1] |

WANG W D, YAO D X, CHEN H B, et al. ZrSi2-MgO as novel additives for high thermal conductivity of β-Si3N4 ceramics. J. Am. Ceram. Soc., 2020, 103(3): 2090-2100.

DOI URL |

| [2] |

WANG W, YAO D, LIANG H, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. J. Eur. Ceram. Soc., 2020, 40(15): 5316-5323.

DOI URL |

| [3] |

WANG W, YAO D, LIANG H, et al. Effect of the binary nonoxide additives on the densification behavior and thermal conductivity of Si3N4 ceramics. J. Am. Ceram. Soc., 2020, 103(10): 5891-5899.

DOI URL |

| [4] |

WANG W, YAO D, LIANG H, et al. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. J. Eur. Ceram. Soc., 2021, 41(2): 1735-1738.

DOI URL |

| [5] |

BECHER P F, PAINTER G S, SHIBATA N, et al. Effects of rare- earth (RE) intergranular adsorption on the phase transformation, microstructure evolution, and mechanical properties in silicon nitride with RE2O3 + MgO additives: RE=La, Gd, and Lu. J. Am. Ceram. Soc., 2008, 91(7): 2328-2336.

DOI URL |

| [6] |

TATARKO P, KAŠIAROVA M, DUSZA J, et al. Influence of rare- earth oxide additives on the oxidation resistance of Si3N4-SiC nanocomposites. J. Eur. Ceram. Soc., 2013, 33(12): 2259-2268.

DOI URL |

| [7] |

ROUXEL T, SANGLEBOEUF J C, HUGER M, et al. Temperature dependence of Young's modulus in Si3N4-based ceramics: roles of sintering additives and of SiC-particle content. Acta Mater., 2002, 50(7): 1669-1682.

DOI URL |

| [8] |

LI X Q, YAO D X, ZUO K H, et al. Fabrication, microstructural characterization and gas permeability behavior of porous silicon nitride ceramics with controllable pore structures. J. Eur. Ceram. Soc., 2019, 39(9): 2855-2861.

DOI URL |

| [9] |

LI X Q, YAO D X, ZUO K H, et al. Microstructure and gas permeation performance of porous silicon nitride ceramics with unidirectionally aligned channels. J. Am. Ceram. Soc., 2020, 103(11): 6565-6574.

DOI URL |

| [10] |

XIA Y F, ZENG Y P, JIANG D L. Mechanical and dielectric properties of porous Si3N4 ceramics using PMMA as pore former. Ceram. Int., 2011, 37(8): 3775-3779.

DOI URL |

| [11] |

PRADEILLES N, RECORD M C, GRANIER D, et al. Synthesis of β-SiAlON: a combined method using Sol-Gel and SHS processes. Ceram. Int., 2008, 34(5): 1189-1194.

DOI URL |

| [12] |

JENNINGS H M, RICHMAN M H. Structure, formation mechanisms and kinetics of reaction-bonded silicon-nitride. J. Mater. Sci., 1976, 11(11): 2087-2098.

DOI URL |

| [13] |

ZIEGLER G, HEINRICH J, WOTTING G. Relationships between processing, microstructure and properties of dense and reaction- bonded silicon-nitride. J. Mater. Sci., 1987, 22(9): 3041-3086.

DOI URL |

| [14] | MATSUNAGA C, ZHOU Y, KUSANO D, et al. Nitridation behavior of silicon powder compacts of various thicknesses with Y2O3 and MgO as sintering additives. Int. J. Appl. Ceram, 2017, 14(6): 1157-1163. |

| [15] |

SHAN S Y, YANG J F, GAO J Q, et al. Porous silicon nitride ceramics prepared by reduction-nitridation of silica. J. Am. Ceram. Soc., 2005, 88 (9): 2594-2596.

DOI URL |

| [16] |

YANG J F, SHAN S Y, JANSSEN R, et al. Synthesis of fibrous β-Si3N4 structured porous ceramics using carbothermal nitridation of silica. Acta Mater., 2005, 53(10): 2981-2990.

DOI URL |

| [17] |

ZHI Q, WANG B, ZHAO S, et al. Synthesis and mechanical properties of highly porous ultrafine-grain Si3N4 ceramics via carbothermal reduction-nitridation combined with liquid phase sintering. Ceram. Int., 2019, 45(17): 21359-21364.

DOI URL |

| [18] |

MUNIR Z A, HOLT J B, The combustion synthesis of refractory nitrides. J. Mater. Sci., 1987, 22(2): 710-714.

DOI URL |

| [19] | ZAKI Z, MOSTAFA N, AHMED Y, et al. Processing of high- density magnesia spinel electro-conducting ceramic composite and its oxidation at 1400 ℃. Int. J. Appl. Ceram, 2016, 13(4): 662-669. |

| [20] |

ADACHI S, WADA T, MIHARA T, et al. High-pressure self- combustion sintering of alumina titanium carbide ceramic composite. J. Am. Ceram. Soc., 1990, 73(5): 1451-1452.

DOI URL |

| [21] |

BHAUMIK S K, DIVAKAR C, SINGH A K, et al. Synthesis and sintering of TiB2 and TiB2-TiC composite under high pressure. Mater. Sci. Eng., A, 2000, 279(1/2): 275-281.

DOI URL |

| [22] |

BHAUMIK S K, DIVAKAR C, DEVI S U, et al. Synthesis and sintering of SiC under high pressure and high temperature. J. Mater. Res., 1999, 14(3): 906-911.

DOI URL |

| [23] | 梁宝岩, 张艳丽, 张旺玺, 等. Ti/Al/TiN体系自蔓延高温合成钛铝氮复合材料. 粉末冶金材料科学与工程, 2014, 105(4): 417-420. |

| [24] | CINCOTTI A, LICHERI R, LOCCI A M, et al. A review on combustion synthesis of novel materials: recent experimental and modeling results. J. Chem. Technol. Biotechnol., 2003, 78(2/3): 122-127. |

| [25] |

TIAN Z B, ZHANG J, SUN S Y, et al. Combustion synthesis of α-Si3N4 with the addition of NH4Cl. Ceram. Int., 2018, 44(16): 20591-20594.

DOI URL |

| [26] |

GE Y Y, SUN S Y, WANG Q, et al. Effect of Fe-contained species on the preparation of α-Si3N4 fibers in combustion synthesis. J. Am. Ceram. Soc., 2016, 99(4): 1464-1471.

DOI URL |

| [27] |

WU X M, LIU G H, LI J Q, et al. Combustion synthesis of ZrN and AlN using Si3N4 and BN as solid nitrogen sources. Ceram. Int., 2018, 44(10): 11914-11917.

DOI URL |

| [28] |

HIRANAKA A, YI X, SAITO G, et al. Effects of Al particle size and nitrogen pressure on AlN combustion synthesis. Ceram. Int., 2017, 43(13): 9872-9876.

DOI URL |

| [29] |

SHAHIEN M, RADWAN M, KIRIHARA S, et al. Combustion synthesis of single-phase β-SiAlONs (z=2-4). J. Eur. Ceram. Soc., 2010, 30(9): 1925-1930.

DOI URL |

| [30] |

WANG Q, GE Y Y, CHEN Y, et al. SHS of Eu2+-doped β-SiAlON phosphors: impacts of N2 pressure and Si particle size. Ceram. Int., 2017, 43(5): 4456-4461.

DOI URL |

| [31] |

XU J K, HU Z L, HAN Y, et al. Combustion synthesis of MgSiN2 powders and Si3N4-MgSiN2 composite powders: effects of processing parameters. J. Am. Ceram. Soc., 2020, 103(1): 122-135.

DOI URL |

| [32] |

CUI W, ZHU Y, GE Y Y, et al. Effects of nitrogen pressure and diluent content on the morphology of gel-cast-foam-assisted combustion synthesis of elongated β-Si3N4 particles. Ceram. Int., 2014, 40(8): 12553-12560.

DOI URL |

| [33] |

CANO I G, BOROVINSKAYA I P, RODRIGUEZ M A, et al. Effect of dilution and porosity on self-propagating high-temperature synthesis of silicon nitride. J. Am. Ceram. Soc., 2002, 85(9): 2209-2211.

DOI URL |

| [34] |

YANG J H, HAN L S, CHEN Y X, et al. Effects of pelletization of reactants and diluents on the combustion synthesis of Si3N4 powder. J. Alloys Compd., 2012, 511(1): 81-84.

DOI URL |

| [35] |

WON H I, WON C W, NERSISYAN H H, et al. Salt-assisted combustion synthesis of silicon nitride with high α-phase content. J. Alloys Compd., 2010, 496(1/2): 656-659.

DOI URL |

| [36] |

CHEN Y X, LI J T, DU J S. Cost effective combustion synthesis of silicon nitride. Mater. Res. Bull., 2008, 43(6): 1598-1606.

DOI URL |

| [37] |

CANO I G, BAELO S P, RODRIGUEZ M A, et al. Self-propagating high temperature-synthesis of Si3N4: role of ammonium salt addition. J. Eur. Ceram. Soc., 2001, 21(3): 291-295.

DOI URL |

| [38] |

CHEN D Y, ZHANG B L, ZHUANG H R, et al. Synthesis of β-Si3N4 whiskers by SHS. Mater. Res. Bull., 2002, 37(8): 1481-1485.

DOI URL |

| [39] |

PENG G H, JIANG G J, ZHUANG H R, et al. Fabrication of β-Si3N4 whiskers by combustion synthesis with MgSiN2 as additives. Mater. Res. Bull., 2005, 40(12): 2139-2143.

DOI URL |

| [40] |

GERMAN R, SURI P, PARK S, Review: liquid phase sintering. J. Mater. Sci., 2009, 44(1): 1-39.

DOI URL |

| [41] |

KRSTIC Z, KRSTIC V D. Silicon nitride: the engineering material of the future. J. Mater. Sci., 2011, 47(2): 535-552.

DOI URL |

| [42] |

ZIEGLER A, IDROBO J C, CINIBULK M K, et al. Interface structure and atomic bonding characteristics in silicon nitride ceramics. Science, 2004, 306(5702): 1768-1770.

DOI URL |

| [43] |

SHIBATA N, PENNYCOOK S J, GOSNELL T R, et al. Observation of rare-earth segregation in silicon nitride ceramics at subnanometre dimensions. Nature, 2004, 428(6984): 730-733.

DOI URL |

| [44] |

CHEN D, ZHANG B, ZHUANG H, et al. Combustion synthesis of network silicon nitride porous ceramics. Ceram. Int., 2003, 29(4): 363-364.

DOI URL |

| [45] | LI W K, CHEN D Y, ZHANG B L, et al. Effect of rare-earth oxide additives on the morphology of combustion synthesized rod-like β-Si3N4crystals. Mater. Lett., 2004, 58(17/18): 2322-2325. |

| [46] |

ZHANG Y, YAO D, ZUO K, et al. Effects of N2 pressure and Si particle size on mechanical properties of porous Si3N4 ceramics prepared via SHS. J. Eur. Ceram. Soc., 2020, 40(13): 4454-4461.

DOI URL |

| [47] |

ZHANG Y, YAO D, ZUO K, et al. Fabrication and mechanical properties of porous Si3N4 ceramics prepared via SHS. Ceram. Int., 2019, 45(12): 14867-14872.

DOI URL |

| [48] |

WANG L, HE G, YANG Z, et al. Combustion synthesis of high flexural strength, low linear shrinkage and machinable porous β-Si3N4 ceramics. J. Eur. Ceram. Soc., 2020, 41(4): 2395-2399.

DOI URL |

| [49] |

CAO Y G, EG C C, ZHOU Z J, et al. Combustion synthesis of α-Si3N4 whiskers. J. Mater. Res., 1999, 14(3): 876-880.

DOI URL |

| [50] |

WAKIHARA T, YABUKI H, TATAMI J, et al. In situ measurement of shrinkage during postreaction sintering of reaction-bonded silicon nitride. J. Am. Ceram. Soc., 2008, 91(10): 3413-3415.

DOI URL |

| [51] |

WANG C, QIAO R Q, CHEN L J. Fabrication and erosion resistance of dense α-Si3N4/SiAlON coating on porous Si3N4 ceramic. RSC Adv., 2016, 6(68): 63801-63808.

DOI URL |

| [52] |

LEE J S, MUN J H, HAN B D, et al. Effect of raw-Si particle size on the properties of sintered reaction-bonded silicon nitride. Ceram. Int., 2004, 30(6): 965-976.

DOI URL |

| [53] |

KRAMER M, HOFFMANN M J, PETZOW G. Grain-growth studies of silicon-nitride dispersed in an oxynitride glass. J. Am. Ceram. Soc., 1993, 76(11): 2778-2784.

DOI URL |

| [54] |

CHEN S L, WANG L, HE G, et al. Microstructure and properties of porous Si3N4 ceramics by gelcasting-self-propagating high- temperature synthesis (SHS). J. Adv. Ceram., 2021, 11: 172-183.

DOI URL |

| [55] | ZHANG Y, YAO D, ZUO K, et al. A novel route for the fabrication of porous Si3N4 ceramics with unidirectionally aligned channels. Mater. Lett., 2020, 276: 128246. |

| [56] |

ZHANG Y, YAO D, ZUO K, et al. Effects of different types of sintering additives and post-heat treatment (PHT) on the mechanical properties of SHS-fabricated Si3N4 ceramics. Ceram. Int., 2021, 47(16): 22461-22467.

DOI URL |

| [57] | GRIFFITH A A. The phenomena of rupture and flow in solids. Philos. Trans. Royal Soc., 1920, 221: 163-198. |

| [58] |

DING H, HU Y, LI X, et al. Microstructure, mechanical properties and sintering mechanism of pressureless-sintered porous Si3N4 ceramics with YbF3-MgF2 composite sintering aids. Ceram. Int., 2020, 46(2): 2558-2564.

DOI URL |

| [59] |

ZHANG Y, YAO D, ZUO K, et al. Self-propagating high temperature synthesis (SHS) of porous Si3N4-based ceramics with considerable dimensions and study on mechanical properties and oxidation behavior. J. Eur. Ceram. Soc., 2021, 41(8): 4452-4461.

DOI URL |

| [60] |

HU Y, ZUO K, XIA Y, et al. Microstructure and permeability of porous Si3N4 supports prepared via SHS. Ceram. Int., 2021, 47(2): 1571-1577.

DOI URL |

| [61] |

KAWAI C. Effect of grain size distribution on the strength of porous Si3N4 ceramics composed of elongated β-Si3N4 grains. J. Mater. Sci., 2001, 36(23): 5713-5717.

DOI URL |

| [62] |

ZHANG Y, YU X, GU H, et al. Microstructure evolution and high-temperature mechanical properties of porous Si3N4 ceramics prepared by SHS with a small amount of Y2O3 addition. Ceram. Int., 2021, 47(4): 5656-5662.

DOI URL |

| [63] |

YU F L, WANG H R, YANG J F, et al. Effects of organic additives on microstructure and mechanical properties of porous Si3N4 ceramics. Bull. Mater. Sci., 2010, 33(3): 285-291.

DOI URL |

| [64] |

KALEMTAS A, TOPATES G, OZCOBAN H, et al. Mechanical characterization of highly porous β-Si3N4 ceramics fabricated via partial sintering & starch addition. J. Eur. Ceram. Soc., 2013, 33(9): 1507-1515.

DOI URL |

| [65] |

KAWAI C, YAMAKAWA A. Effect of porosity and microstructure on the strength of Si3N4: designed microstructure for high strength, high thermal shock resistance, and facile machining. J. Am. Ceram. Soc., 1997, 80(10): 2705-2708.

DOI URL |

| [66] |

YANG J F, DENG Z Y, OHJI T. Fabrication and characterisation of porous silicon nitride ceramics using Yb2O3 as sintering additive. J. Eur. Ceram. Soc., 2003, 23(2): 371-378.

DOI URL |

| [67] | YIN X W, LI X M, ZHANG L T, et al. Microstructure and mechanical properties of Lu2O3-doped porous silicon nitride ceramics using phenolic resin as pore-forming agent. Int. J. Appl. Ceram, 2010, 7(3): 391-399. |

| [68] | LI X M, YIN X W, ZHANG L T, et al. Microstructure and properties of porous Si3N4 ceramics with a dense surface. Int. J. Appl. Ceram, 2011, 8(3): 627-636. |

| [69] |

YUE J S, DONG B C, WANG H J. Porous Si3N4 fabricated by phase separation method using benzoic acid as pore-forming agent. J. Am. Ceram. Soc., 2011, 94(7): 1989-1991.

DOI URL |

| [70] |

DING H H, ZHAO Z H, QI T, et al. High α-β phase transition and properties of YbF3-added porous Si3N4 ceramics obtained by low temperature pressureless sintering. Int. J. Refract. Hard. Met., 2019, 78: 131-137.

DOI URL |

| [71] |

JIANG G P, YANG J F, GAO J Q, et al. Porous silicon nitride ceramics prepared by extrusion using starch as binder. J. Am. Ceram. Soc., 2008, 91(11): 3510-3516.

DOI URL |

| [72] |

LIU X H, HUANG Z Y, GE Q M, et al. Microstructure and mechanical properties of silicon nitride ceramics prepared by pressureless sintering with MgO-Al2O3-SiO2 as sintering additive. J. Eur. Ceram. Soc., 2005, 25(14): 3353-3359.

DOI URL |

| [73] |

YANG J, YANG J F, SHAN S Y, et al. Effect of sintering additives on microstructure and mechanical properties of porous silicon nitride ceramics. J. Am. Ceram. Soc., 2006, 89(12): 3843-3845.

DOI URL |

| [74] |

FAN L, ZHOU M, WANG H J, et al. Low-temperature preparation of β-Si3N4 porous ceramics with a small amount of Li2O-Y2O3. J. Am. Ceram. Soc., 2014, 97(5): 1371-1374.

DOI URL |

| [75] |

YAO D, CHEN H, ZUO K H, et al. High temperature mechanical properties of porous Si3N4 prepared via SRBSN. Ceram. Int., 2018, 44(11): 11966-11971.

DOI URL |

| [76] |

YAO D X, XIA Y F, ZENG Y P. et al. Porous Si3N4 ceramics prepared via slip casting of Si and reaction bonded silicon nitride. Ceram. Int., 2011, 37(8): 3071-3076.

DOI URL |

| [77] |

YAO D X, XIA Y F, ZUO K H, et al. The effect of fabrication parameters on the mechanical properties of sintered reaction bonded porous Si3N4 ceramics. J. Eur. Ceram. Soc., 2014, 34(15): 3461-3467.

DOI URL |

| [78] |

YAO D X, ZENG Y P. High flexural strength porous silicon nitride prepared via nitridation of silicon powder. J. Inorg. Mater., 2011, 26(4): 422-426.

DOI URL |

| [79] |

YAO D X, ZENG Y P, ZUO K H, et al. The effects of BN addition on the mechanical properties of porous Si3N4/BN ceramics prepared via nitridation of silicon powder. J. Am. Ceram. Soc., 2011, 94(3): 666-670.

DOI URL |

| [80] | YAO D X, ZENG Y P, ZUO K H, et al. Porous Si3N4 ceramics prepared via nitridation of Si powder with Si3N4 Filler and postsintering. Int. J. Appl. Ceram., 2012, 9(2): 239-245. |

| [81] | HU H L, YAO D X, XIA Y F, et al. Porous Si3N4/SiC ceramics prepared via nitridation of Si powder with SiC addition. Int. J. Appl. Ceram. 2014, 11(5): 845-850. |

| [82] |

HU H L, ZENG Y P, ZUO K H, et al. Synthesis of porous Si3N4/SiC ceramics with rapid nitridation of silicon. J. Eur. Ceram. Soc., 2015, 35(14): 3781-3787.

DOI URL |

| [83] |

HU H L, ZENG Y P, XIA Y F, et al. Rapid fabrication of porous Si3N4/SiC ceramics via nitridation of silicon powder with ZrO2 as catalyst. Ceram. Int., 2014, 40(5): 7579-7582.

DOI URL |

| [84] |

LU Y, YANG J F, LU W Z, et al. Porous silicon nitride ceramics fabricated by carbothermal reduction-reaction bonding. Mater. Manuf. Processes, 2011, 26(6): 855-861.

DOI URL |

| [85] |

SHAN S Y, JIA Q M, JIANG L H, et al. Microstructure control and mechanical properties of porous silicon nitride ceramics. Ceram. Int., 2009, 35(8): 3371-3374.

DOI URL |

| [86] |

SHAN S Y, YANG J F, GAO J Q, et al. Fabrication of porous silicon nitride with high porosity. Key Eng. Mater., 2007, 336-338: 1105-1108.

DOI URL |

| [87] |

LU H H, HUANG J L, Effect of Y2O3 and Yb2O3 on the microstructure and mechanical properties of silicon nitride. Ceram. Int., 2001, 27(6): 621-628.

DOI URL |

| [88] |

KLEMM H, PEZZOTTI G. Fracture toughness and time-dependent strength behavior of low-doped silicon nitrides for applications at 1400 ℃. J. Am. Ceram. Soc., 1994, 77(2): 553-561.

DOI URL |

| [89] |

LANGE F F. High-temperature strength behavior of hot-pressed Si3N4: evidence for subcritical crack growth. J. Am. Ceram. Soc., 1974, 57(2): 84-87.

DOI URL |

| [90] |

RILEY F L. Silicon nitride and related materials. J. Am. Ceram. Soc., 2000, 83(2): 245-265.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [8] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [9] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [10] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [11] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [12] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [13] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [14] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [15] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||