无机材料学报 ›› 2025, Vol. 40 ›› Issue (2): 168-176.DOI: 10.15541/jim20240287 CSTR: 32189.14.10.15541/jim20240287

所属专题: 【结构材料】热障与环境障涂层(202506)

侯佳琪1( ), 陈睿聪1, 曾耀莹1, 周磊2, 张佳平1(

), 陈睿聪1, 曾耀莹1, 周磊2, 张佳平1( ), 付前刚1

), 付前刚1

收稿日期:2024-06-12

修回日期:2024-07-25

出版日期:2025-02-20

网络出版日期:2024-09-02

通讯作者:

张佳平, 研究员. E-mail: zhangjiaping@nwpu.edu.cn作者简介:侯佳琪(1999-), 女, 博士研究生. E-mail: houjiaqi@mail.nwpu.edu.cn

基金资助:

HOU Jiaqi1( ), CHEN Ruicong1, ZENG Yaoying1, ZHOU Lei2, ZHANG Jiaping1(

), CHEN Ruicong1, ZENG Yaoying1, ZHOU Lei2, ZHANG Jiaping1( ), FU Qiangang1

), FU Qiangang1

Received:2024-06-12

Revised:2024-07-25

Published:2025-02-20

Online:2024-09-02

Contact:

ZHANG Jiaping, professor. E-mail: zhangjiaping@nwpu.edu.cnAbout author:HOU Jiaqi (1999-), female, PhD candidate. E-mail: houjiaqi@mail.nwpu.edu.cn

Supported by:摘要:

涂层的完整和致密性直接影响其性能。对于存在缺陷或者受到损伤的涂层, 报废并重新制备不仅浪费原材料, 还会延长制备周期。因此, 经济有效的解决方法是修复涂层, 以恢复其防护能力。本研究采用经济实用的气相渗硅法修复一次包埋法制备的多孔SiC涂层缺陷, 并对比研究了修复前后涂层的抗热震及烧蚀性能。结果表明, 修复后的包埋SiC涂层在室温~1773 K热震15次后, 其与基体之间结合良好, 失重率降低了97.05%。在氧乙炔火焰下烧蚀30 s后, 修复后的涂层中心烧蚀区域的碳纤维被SiO2所包覆, 未出现裸露或损伤。与修复前相比, 其质量损失率和厚度损失率分别降低了97.02%和67.99%。抗热震和烧蚀性能改善归因于修复后涂层致密度提高, 缺陷减少, 并且渗硅过程引入的单质Si在高温下更容易氧化生成SiO2, 有效愈合缺陷和阻挡氧气渗透, 从而防止了基体氧化损伤。本研究提出的新型涂层修复策略具有经济可行性, 为涂层缺陷及损伤修复和稳定服役提供了新途径。

中图分类号:

侯佳琪, 陈睿聪, 曾耀莹, 周磊, 张佳平, 付前刚. 气相渗硅法修复SiC涂层及其抗热震和烧蚀性能[J]. 无机材料学报, 2025, 40(2): 168-176.

HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration[J]. Journal of Inorganic Materials, 2025, 40(2): 168-176.

图3 涂层的相组成及形貌

Fig. 3 Phase composition and morphologies of the coatings (a) XRD pattern, (b, c) surface and (d) cross-section morphologies for P-S coating;(e) XRD pattern, (f) surface morphology, (g) EDS analysis of Spot 1 and (h) cross-section morphology for G-S coating

| Sample | Density/(g·cm-3) | Porosity/% |

|---|---|---|

| P-S | 1.80 | 7.31 |

| G-S | 1.87 | 3.92 |

表1 涂层试样的密度及孔隙率

Table 1 Densities and porosities of coating samples

| Sample | Density/(g·cm-3) | Porosity/% |

|---|---|---|

| P-S | 1.80 | 7.31 |

| G-S | 1.87 | 3.92 |

图5 热震测试后涂层试样的形貌

Fig. 5 Morphologies of coating samples after thermal shock test (a) Macroscopic, (b, c) surface and (d) cross-section morphologies for P-S coating sample; (e) Macroscopic, (f, g) surface and (h) cross-section morphologies for G-S coating sample

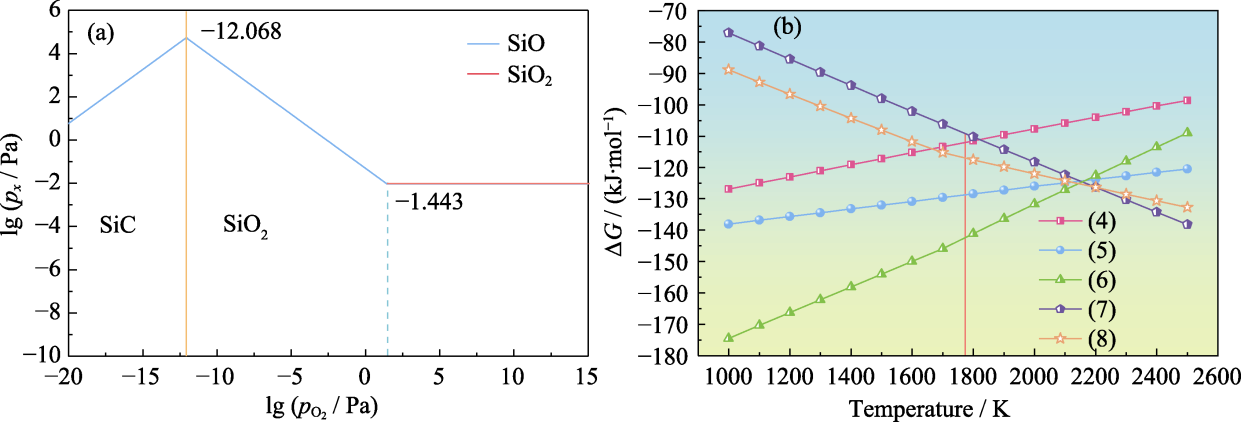

图6 涂层主要氧化产物的蒸气压随氧分压的变化(a)和氧化反应的吉布斯自由能随温度的变化(b)

Fig. 6 Variations of vapor pressure of main oxidation products for coatings with partial pressure of oxygen (a) and Gibbs free energy of oxidation reaction with temperature (b) Colorful figures are available on website

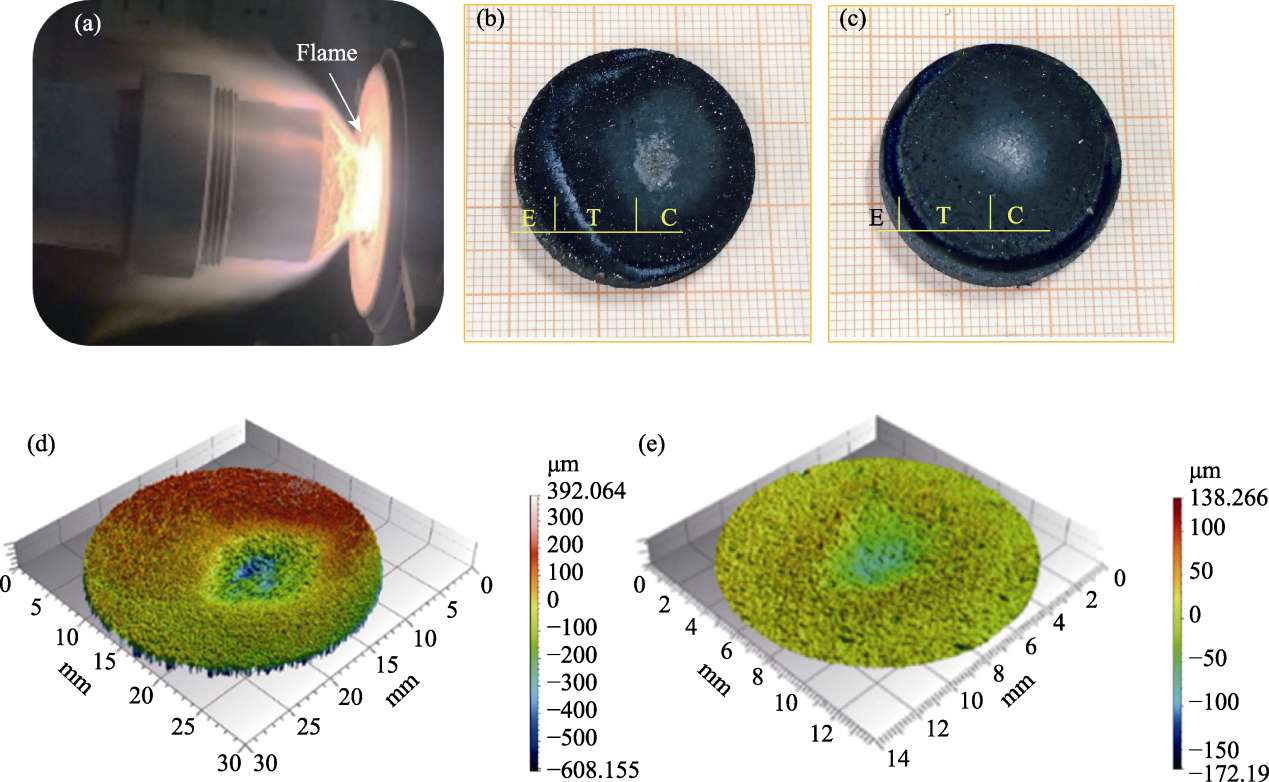

图8 涂层试样的宏观形貌及三维轮廓

Fig. 8 Macroscopic morphology and 3D profile of the coating samples (a) Image of the process of ablation; (b, c) Macroscopic morphologies of (b) P-S and (c) G-S coating samples; (d, e) 3D profiles of (d) P-S and (e) G-S coating samples. Colorful figures are available on website

图9 (a)涂层表面温度随时间的变化曲线, (b)涂层的质量和厚度损失率, (c)P-S和(d)G-S涂层试样的XRD图谱

Fig. 9 (a) Variation curves of coating surface temperature with time, (b) mass and thickness loss rates, and (c, d) XRD patterns of P-S (c) and G-S (d) coating samples

图10 烧蚀后涂层C区域的表面形貌和EDS分析

Fig. 10 Surface morphologies and EDS analyses of C region in coatings after ablation (a, b) Surface morphology of P-S coating; (c) EDS analysis of Spot 2 in Fig. (a); (d, e) Surface morphology of G-S coating; (f) EDS analysis of Spot 3 in Fig. (e)

图11 烧蚀后涂层T、E区域的表面形貌和EDS分析

Fig. 11 Surface morphologies and EDS analyses of T and E regions in coatings after ablation (a) Surface morphology of T region, (b) EDS analysis of Spot 4, (c) surface morphology of E region and (d) EDS analysis of Spot 5 for P-S coating; (e) Surface morphology of T region, (f) EDS analysis of Spot 6, (g) surface morphology of E region and (h) EDS analysis of Spot 7 for G-S coating

| [1] | OPEKA M, TALMY I, ZAYKOSKI J. Oxidation-based materials selection for 2000 ℃+hypersonic aerosurfaces: theoretical considerations and historical experience. Journal of Materials Science, 2004, 39: 5887. |

| [2] | ZHANG X, WANG Y, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [3] | DU H. Research progress on integrated thermal management and key technology of hypersonic vehicles. Equipment Environmental Engineering, 2023, 20(1): 43. |

| [4] | LI C, CROSKY A. The effect of carbon fabric treatment on delamination of 2D-C/C composites. Composites Science and Technology, 2006, 66(15): 2633. |

| [5] | FRIEDRICH C, GADOW R, SPEICHER M. Protective multilayer coatings for carbon-carbon composites. Surface and Coatings Technology, 2002, 151: 405. |

| [6] | LI J, LUO R. Study of the mechanical properties of carbon nanofiber reinforced carbon/carbon composites. Composites Part A: Applied Science & Manufacturing, 2008, 39(11): 1700. |

| [7] | 王海军, 王齐华, 顾秀娟. 碳/碳复合材料抗氧化行为的研究进展. 材料科学与工程学报, 2003, 21(1): 117. |

| [8] | FU Q, ZHANG P, ZHUANG L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science & Technology, 2022, 96: 31. |

| [9] | 褚衍辉, 付前刚, 李贺军, 等. 炭/炭复合材料高温防氧化陶瓷涂层的研究新进展. 材料工程, 2010, 86: 86. |

| [10] | JIN X, FAN X, LU C, et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. Journal of the European Ceramic Society, 2018, 38(1): 1. |

| [11] | ZHOU L, FU Q, HU D, et al. Oxidation protective SiC-Si coating for carbon/carbon composites by gaseous silicon infiltration and pack cementation: a comparative investigation. Journal of the European Ceramic Society, 2021, 41(1): 194. |

| [12] | XIN Y, HUANG Q, SU Z, et al. A double layer nanostructure SiC coating for anti-oxidation protection of carbon/carbon composites prepared by chemical vapor reaction and chemical vapor deposition. Ceramics International, 2013, 39(5): 5053. |

| [13] | ZHAO Z, LI K, LI W, et al. Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites. Ceramics International, 2018, 44(7): 7481. |

| [14] | FU Q, LI H, SHI X, et al. Silicon carbide coating to protect carbon/carbon composites against oxidation. Scripta Materialia, 2005, 52(9): 923. |

| [15] | ZHU X, ZHANG Y, SU Y, et al. SiC-Si coating with micro-pores to protect carbon/carbon composites against oxidation. Journal of the European Ceramic Society, 2021, 41(1): 114. |

| [16] | SONG S, YIN J, ZHU Y, et al. Optical coating on Cf/SiC composites via aqueous slurry painting and reaction bonding. Journal of Inorganic Materials, 2017, 32(2): 210. |

| [17] | YANG Z, YIN Z, ZHAO Z, et al. Microstructure and properties of SiO2-based ceramic cores with ball-shaped powders by the preceramic polymer technique in N2 atmosphere. Materials Chemistry and Physics, 2020, 243: 122609. |

| [18] | PAVESE M, FINO P, BADINI C, et al. HfB2/SiC as a protective coating for 2D Cf/SiC composites: effect of high temperature oxidation on mechanical properties. Surface and Coatings Technology, 2008, 202(10): 2059. |

| [19] | HUANG J, ZENG X, LI H, et al. Influence of the preparation temperature on the phase, microstructure and anti-oxidation property of a SiC coating for C/C composites. Carbon, 2004, 42(8/9): 1517. |

| [20] | ZHANG P, ZHANG Y, CHEN G, et al. High-temperature oxidation behavior of CVD-SiC ceramic coating in wet oxygen and structural evolution of oxidation product: experiment and first-principle calculations. Applied Surface Science, 2021, 556: 149808. |

| [21] | GOLESTANI F, ZAKERI M, RAZAVI M, et al. Microstructure and ablative properties of Si-SiC coating prepared by spark plasma sintering. Ceramics International, 2018, 44(7): 8403. |

| [22] | 张武装, 熊翔, 曾毅. 包埋法制备SiC涂层C/C复合材料及真空热处理对涂层的影响. 粉末冶金材料科学与工程, 2011, 16(2): 6. |

| [23] | ZHANG P, FU Q, CHENG C, et al. Microstructure evolution of in-situ SiC-HfB2-Si ternary coating and its corrosion behaviors at ultra-high-temperatures. Journal of the European Ceramic Society, 2021, 41(13): 6223. |

| [24] | ZHOU L, ZHANG J, HU D, et al. High temperature oxidation and ablation behaviors of HfB2-SiC/SiC coatings for carbon/carbon composites fabricated by dipping-carbonization assisted pack cementation. Journal of Materials Science & Technology, 2022, 111: 88. |

| [25] | ZHANG J, HOU J, ZHOU L, et al. TaSi2 modified HfB2-SiC coating: preparation and ablation behavior. Journal of the American Ceramic Society, 2024, 107(1): 461. |

| [26] | WANG P, LI H, SUN J, et al. The effect of HfB2 content on the oxidation and thermal shock resistance of SiC coating. Surface and Coatings Technology, 2018, 339: 124. |

| [27] | TANAY R, MANAS K, MANAB M. Thermal shock behavior of ZrB2-MoSi2-SiC Composites. Journal of Alloys and Compounds, 2022, 9924: 166443. |

| [28] | ARTHUR H, VICTOR L. Volatility diagrams for silica, silicon nitride, and silicon carbide and their application to high-temperature decomposition and oxidation. Journal of the American Ceramic Society, 1990, 73(10): 2785. |

| [29] | WANG W, FU Q. Recovery in oxidation behavior of damaged SiC-ZrB2/SiC coating of carbon/carbon composites. Journal of Materiomics, 2023, 9(3): 541. |

| [30] | DU J, YU G, JIA Y, et al. Ultra-high temperature ablation behaviour of 2.5D SiC/SiC under an oxy-acetylene torch. Corrosion Science, 2022, 201: 110263. |

| [31] | ZHANG J, QU J, FU Q. Ablation behavior of nose-shaped HfB2- SiC modified carbon/carbon composites exposed to oxyacetylene torch. Corrosion Science, 2019, 151: 87. |

| [32] | 王首豪. ZrC改性C/C-SiC复合材料高温性能及影响机理研究. 大连: 大连理工大学博士学位论文, 2020: 97. |

| [33] | YU Y, HAN Z, CHENG Y, et al. Ablation behavior of 3D PyC-Cf/ SiHfBOC composites under an oxyacetylene torch environment above 2000 ℃. Ceramics International, 2024, 50(9): 14011. |

| [34] | ZHOU H, ZHANG X, GAO L, et al. Ablation properties of ZrB2- SiC ultra-high temperature ceramic coatings. Journal of Inorganic Materials, 2013, 28(3): 256. |

| [35] | ZHEN Q, LI Z, HU P, et al. A glass-ceramic coating with self- healing capability and high infrared emissivity for carbon/carbon composites. Corrosion Science, 2018, 141: 81. |

| [36] | LI J, ZHAN Y, WANG H, et al. Long-life ablation resistance ZrB2-SiC-TiSi2 ceramic coating for SiC coated C/C composites under oxidizing environments up to 2200 K. Journal of Alloys and Compounds, 2020, 824: 153934. |

| [1] | 肖晓琳, 王玉祥, 谷佩洋, 朱圳荣, 孙勇. 二维无机材料调控病损皮肤组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 860-870. |

| [2] | 王宇彤, 常江, 徐合, 吴成铁. 硅酸盐生物陶瓷/玻璃促创面修复的研究进展:作用、机制和应用方式[J]. 无机材料学报, 2025, 40(8): 911-920. |

| [3] | 余艺平, 肖鹏, 赵长浩, 徐梦迪, 姚立冬, 李伟, 王松. 耐高温层状Ta/Ta0.5Hf0.5C金属陶瓷的高频等离子体风洞烧蚀行为研究[J]. 无机材料学报, 2025, 40(7): 790-798. |

| [4] | 陈曦, 袁媛, 谭业强, 刘昌胜. 无机非金属生物材料发展战略研究[J]. 无机材料学报, 2025, 40(5): 449-456. |

| [5] | 林元伟, 景昭, 陈鹤拓, 李佳恒, 覃显鹏, 周国红, 王士维. SiCp掺杂Cf/Li2O-Al2O3-SiO2复合材料耐烧蚀性能研究[J]. 无机材料学报, 2025, 40(10): 1153-1162. |

| [6] | 李筱暄, 付前刚, 文子豪, 杨金山, 倪德伟, 张洁, 程源, 刘昱轩, 褚衍辉, 蔡飞燕, 王京阳, 张幸红. 极端环境用超高温陶瓷结构材料研究进展[J]. 无机材料学报, 2025, 40(10): 1045-1078. |

| [7] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| [8] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [9] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| [10] | 郑斌, 康凯, 张青, 叶昉, 解静, 贾研, 孙国栋, 成来飞. 前驱体转化陶瓷法制备Ti3SiC2陶瓷及其热稳定性研究[J]. 无机材料学报, 2024, 39(6): 733-740. |

| [11] | 张幸红, 王义铭, 程源, 董顺, 胡平. 超高温陶瓷复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 571-590. |

| [12] | 郭晓阳, 张小琳, 姜岩, 田原, 耿志. Ti掺杂Hf(Zr)B2-SiC抗烧蚀涂层的制备及其抗烧蚀机理[J]. 无机材料学报, 2024, 39(12): 1357-1366. |

| [13] | 王博, 蔡德龙, 朱启帅, 李达鑫, 杨治华, 段小明, 李雅楠, 王轩, 贾德昌, 周玉. SrAl2Si2O8增强BN陶瓷的力学性能及抗热震性能[J]. 无机材料学报, 2024, 39(10): 1182-1188. |

| [14] | 郭凌翔, 唐颖, 黄世伟, 肖博澜, 夏东浩, 孙佳. C/C复合材料高熵氧化物涂层抗烧蚀性能[J]. 无机材料学报, 2024, 39(1): 61-70. |

| [15] | 蔡佳, 赵芳霞, 范栋, 黄利平, 牛亚然, 郑学斌, 张振忠. 聚碳硅烷基复合涂层PCS裂解行为及其抗激光烧蚀性能[J]. 无机材料学报, 2023, 38(11): 1271-1280. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||