Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 964-970.DOI: 10.15541/jim20250051

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHONG Weimin1( ), ZHAO Ke2, WANG Kewei3, LIU Dianguang4, LIU Jinling1(

), ZHAO Ke2, WANG Kewei3, LIU Dianguang4, LIU Jinling1( ), AN Linan3

), AN Linan3

Received:2025-02-11

Revised:2025-04-01

Published:2025-09-20

Online:2025-04-09

Contact:

LIU Jinling, professor. E-mail: liujinling@swjtu.edu.cnAbout author:ZHONG Weimin (2000-), male, Master candidate. E-mail: 2772759347@qq.com

Supported by:CLC Number:

ZHONG Weimin, ZHAO Ke, WANG Kewei, LIU Dianguang, LIU Jinling, AN Linan. Effect of Oscillatory Pressure Amplitude on Microstructures and Wear Resistance of Tungsten Carbide[J]. Journal of Inorganic Materials, 2025, 40(9): 964-970.

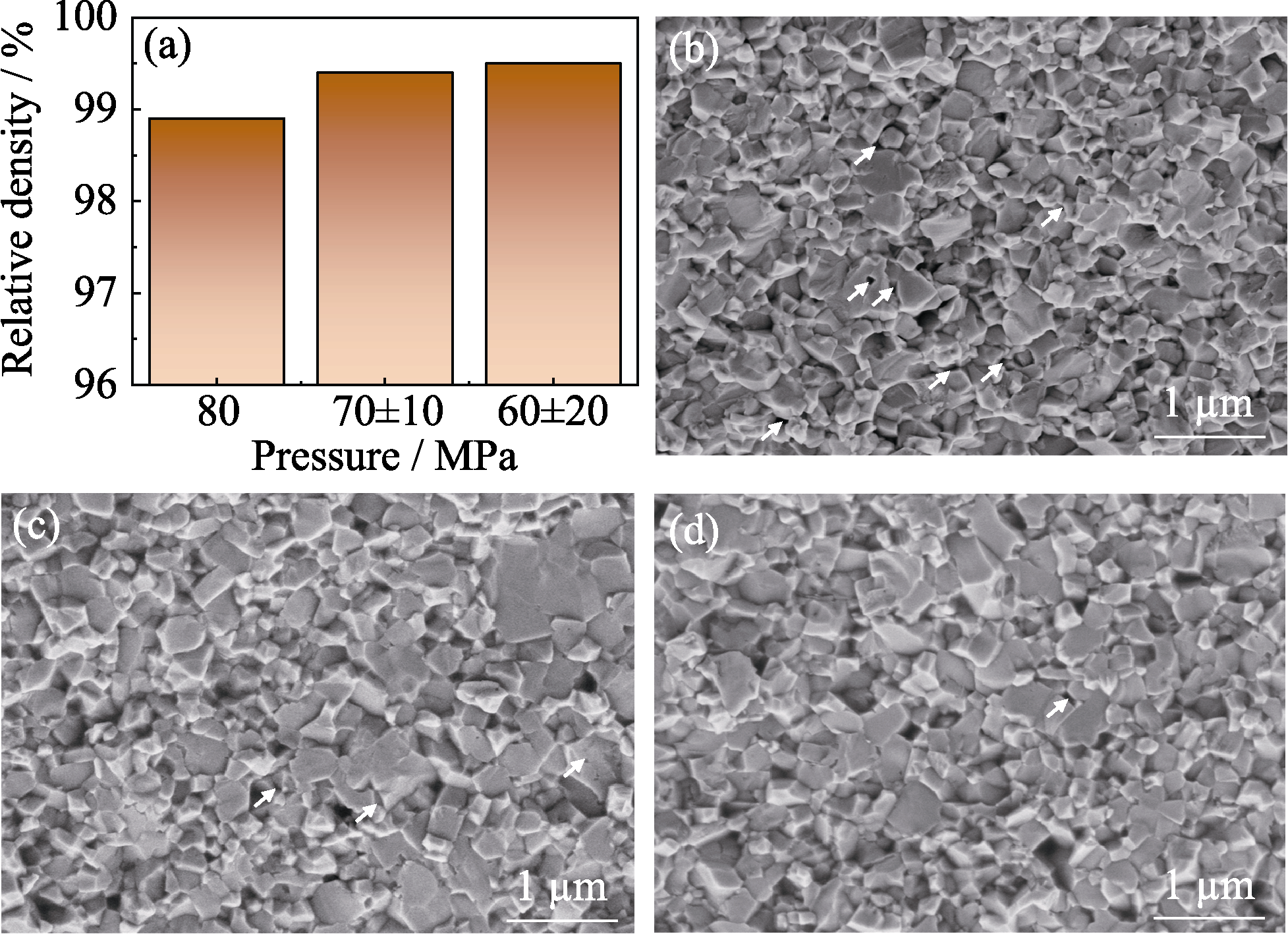

Fig. 4 Relative densities and fracture morphologies of WC samples prepared under different pressure amplitudes (a) Histogram of relative density against pressure for WC samples; (b-d) Fracture morphologies of WC samples prepared under (b) 80, (c) (70±10), and (d) (60±20) MPa

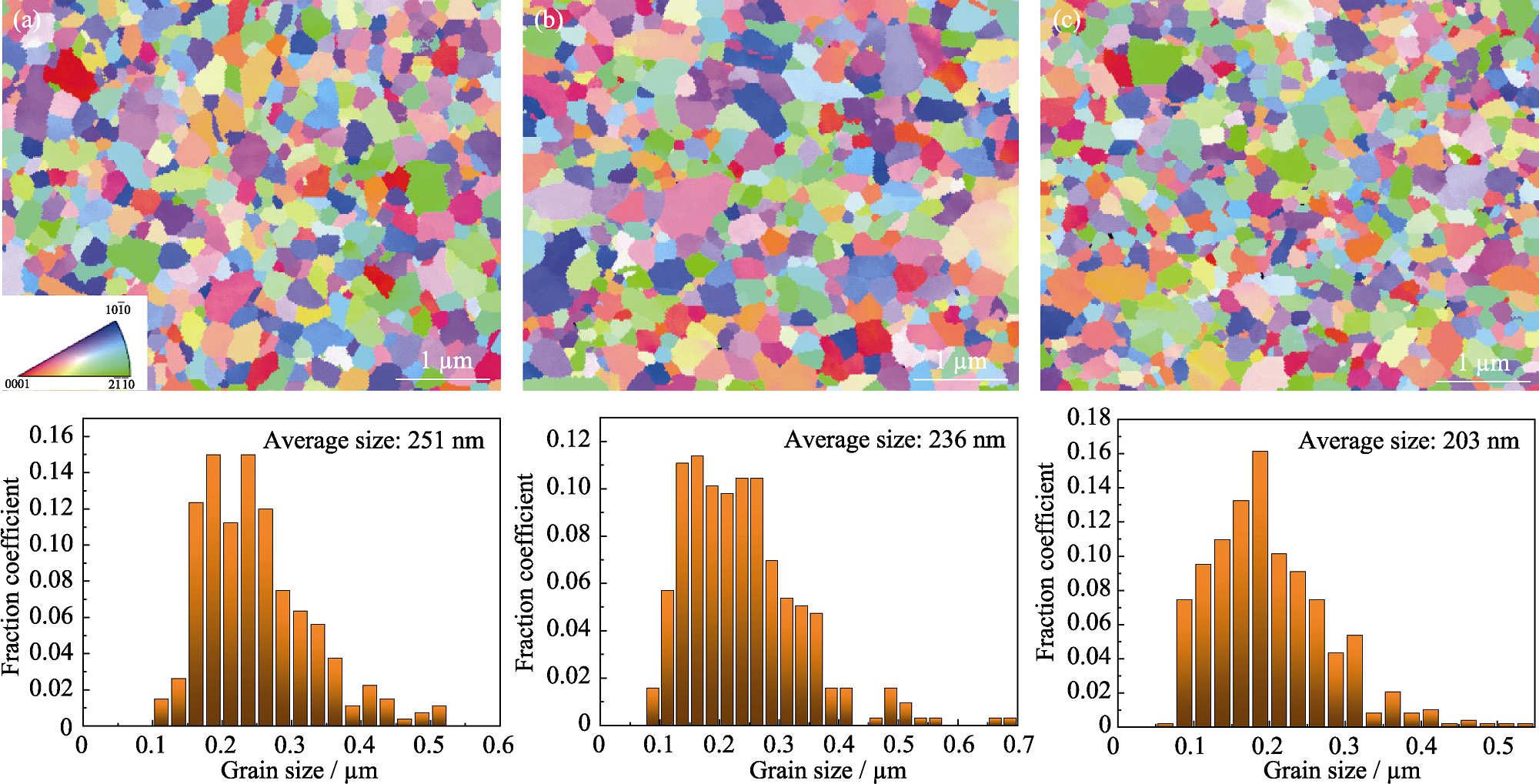

Fig. 5 Diagrams of grain orientations (up) and grain size distributions (down) for WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa. Colorful figures are available on website

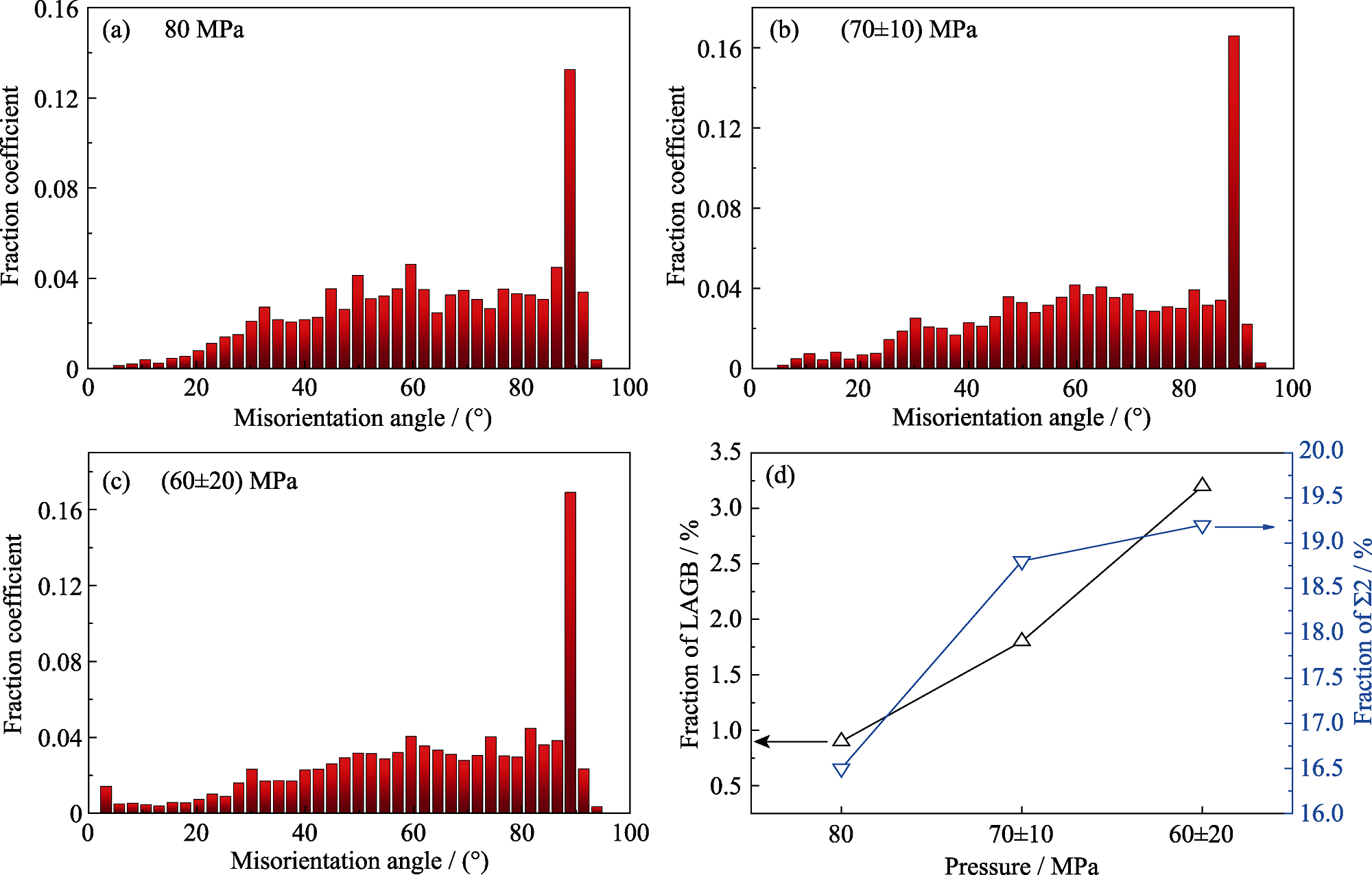

Fig. 6 (a-c) Statistical diagrams of grain misorientation angle and (d) variation in fraction of low angle grain boundary (LAGB) and Σ2 grain boundary for WC samples prepared under different pressure amplitudes

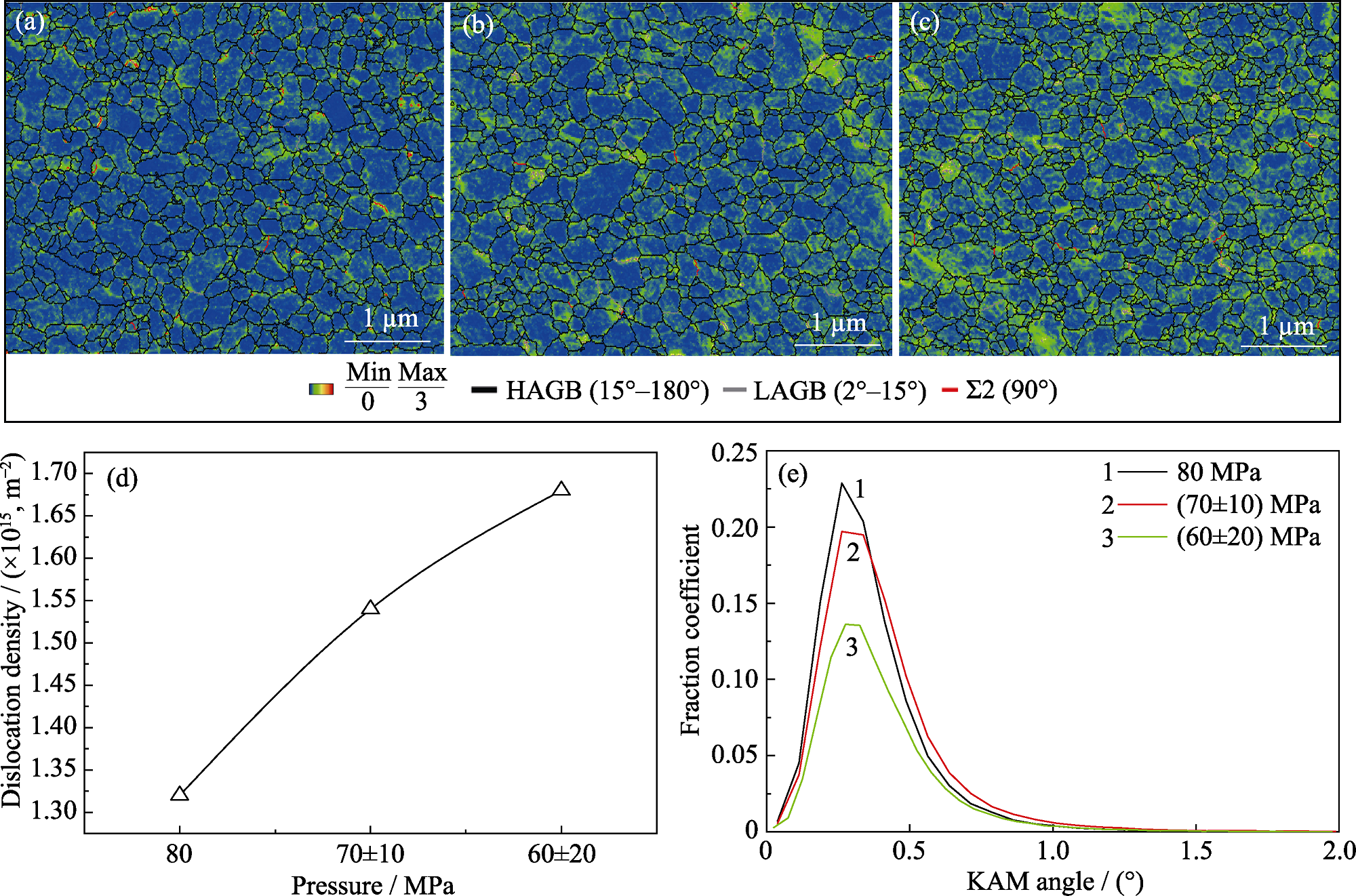

Fig. 7 (a-c) KAM maps, (d) dislocation densities, and (e) statistical diagrams of KAM angle for WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa. HAGB: high angle grain boundary. Colorful figures are available on website

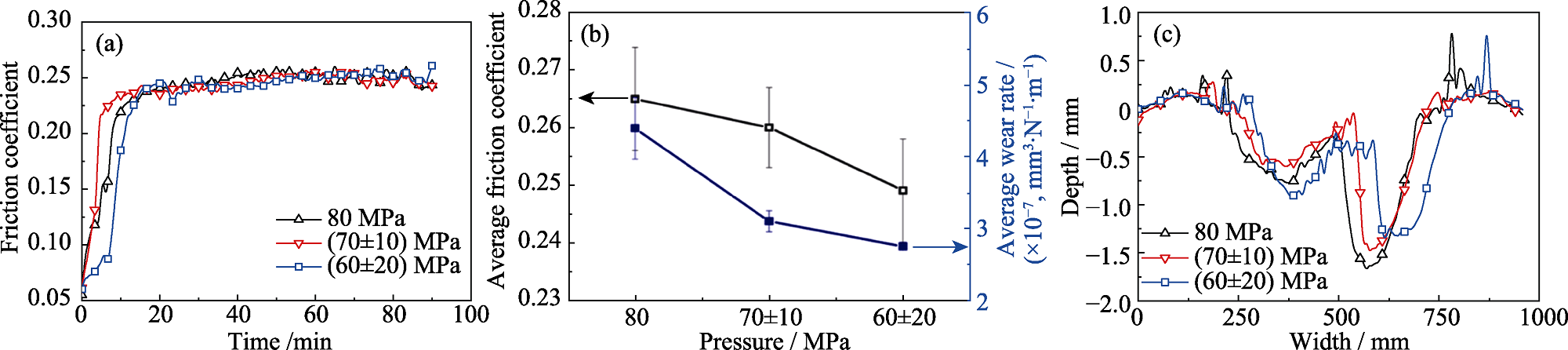

Fig. 8 Tribological properties of WC samples prepared under different pressure amplitudes (a) Friction coefficient as a function of time; (b) Average friction coefficient and wear rate vs. pressure; (c) Wear scar depth vs. width

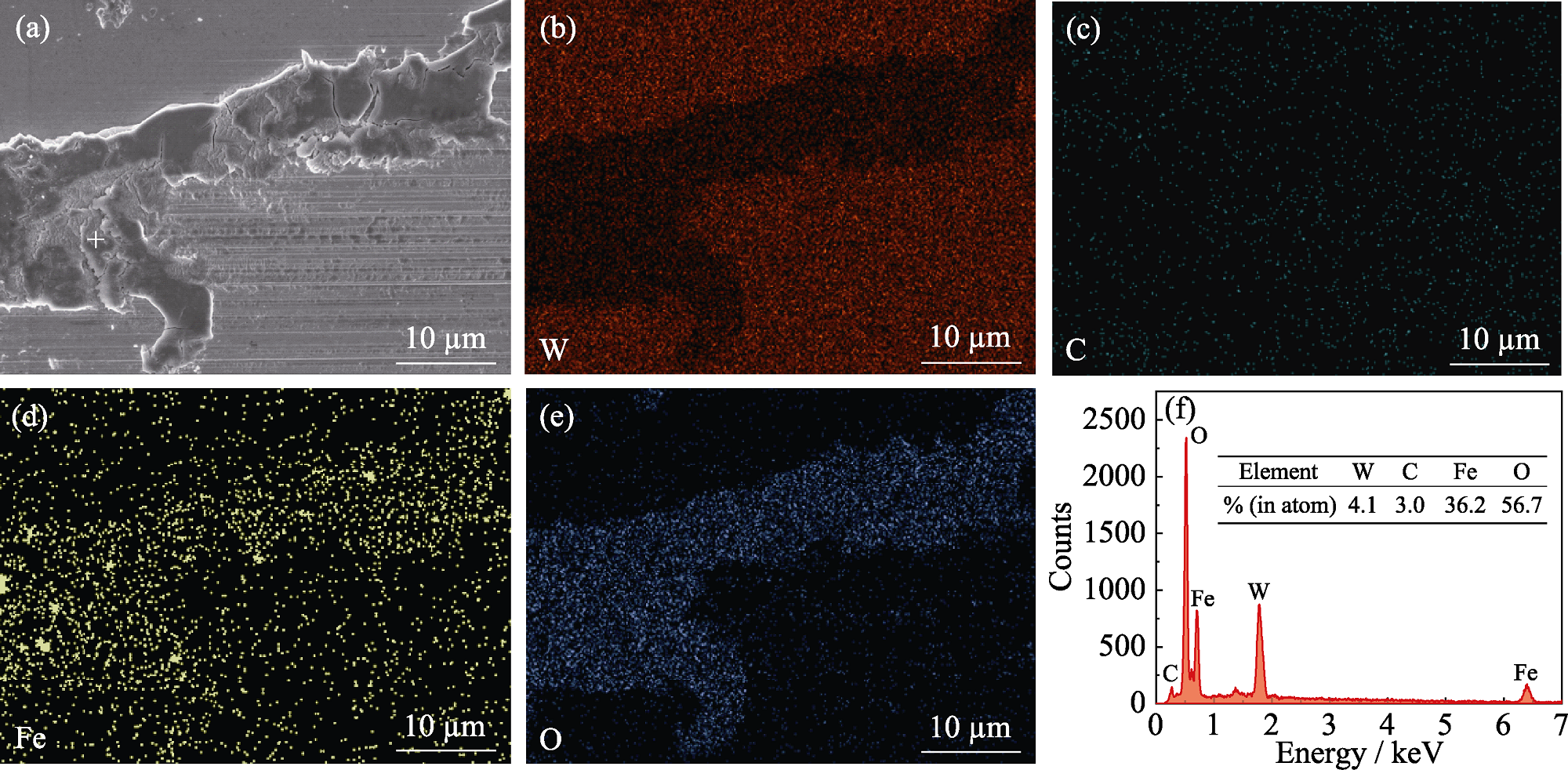

Fig. 10 Morphology and element characterization of adhesive phase of WC sample prepared under pressure amplitude of 10 MPa (a) SEM image; (b-e) EDS mappings corresponding to (a); (f) EDS spectrum corresponding to point in (a) marked with + symbol

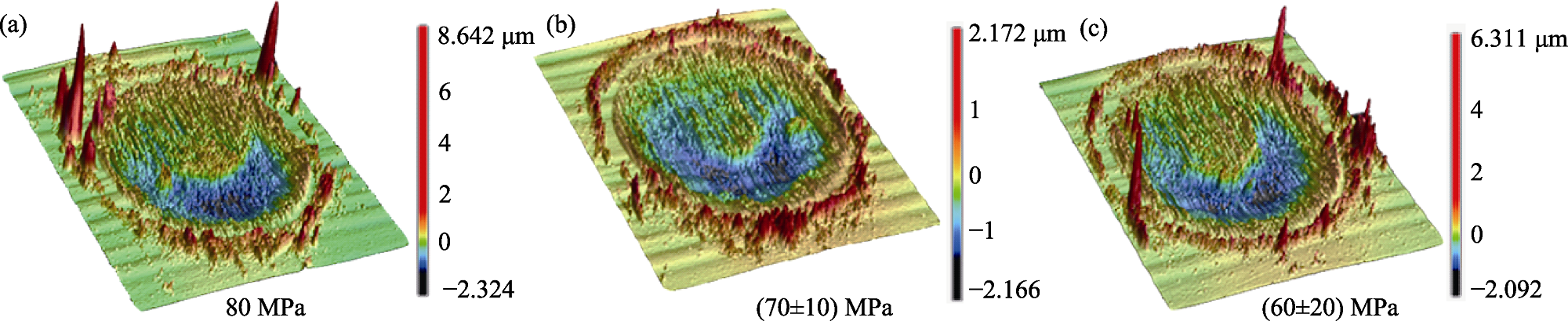

Fig. S2 Three-dimensional surface topographies of WC samples prepared under different pressure amplitudes (a) 80 MPa; (b) (70±10) MPa; (c) (60±20) MPa

| [1] | SUN J L, ZHAO J, HUANG Z F, et al. A review on binderless tungsten carbide: development and application. Nano-Micro Letters, 2020, 12: 162. |

| [2] | REN X Y, MIAO H Z, PENG Z J. A review of cemented carbides for rock drilling: an old but still tough challenge in geo-engineering. International Journal of Refractory Metals and Hard Materials, 2013, 39: 61. |

| [3] | KORNAUS K, RACZKA M, GUBERNAT A, et al. Pressureless sintering of binderless tungsten carbide. Journal of the European Ceramic Society, 2017, 37(15): 4567. |

| [4] | GUBERNAT A, RUTKOWSKI P, GRABOWSKI G, et al. Hot pressing of tungsten carbide with and without sintering additives. International Journal of Refractory Metals and Hard Materials, 2014, 43: 193. |

| [5] | ANDERSON K P, WOLLMERSHAUSER J A, RYOU H, et al. Nanostructural effects beyond Hall-Petch: towards superhard tungsten carbide. Acta Materialia, 2024, 275: 120004. |

| [6] | SHON I J, KIM B R, DOH J M, et al. Properties and rapid consolidation of ultra-hard tungsten carbide. Journal of Alloys and Compounds, 2010, 489(1): L4. |

| [7] | KUMAR A K N, WATABE M, KUROKAWA K. The sintering kinetics of ultrafine tungsten carbide powders. Ceramics International, 2011, 37(7): 2643. |

| [8] | 邹芹, 李爽, 李艳国. 无粘结相WC硬质合金的研究进展. 硬质合金, 2021, 38(4): 297. |

| [9] | MAZO I, MOLINARI A, SGLAVO V M. Electrical resistance flash sintering of tungsten carbide. Materials & Design, 2022, 213: 110330. |

| [10] |

LIU J L, LIU D G, REN K, et al. Research progress on the flash sintering mechanism of oxide ceramics and its application. Journal of Inorganic Materials, 2022, 37(5): 473.

DOI |

| [11] | HUANG B, CHEN L D, BAI S Q. Bulk ultrafine binderless WC prepared by spark plasma sintering. Scripta Materialia, 2006, 54(3): 441. |

| [12] | ZHAO J F, HOLLAND T, UNUVAR C, et al. Sparking plasma sintering of nanometric tungsten carbide. International Journal of Refractory Metals & Hard Materials, 2009, 27(1): 130. |

| [13] | CHA S I, HONG S H. Microstructures of binderless tungsten carbides sintered by spark plasma sintering process. Materials Science and Engineering A, 2003, 356(1/2): 381. |

| [14] | LANTSEV E, MALEKHONOVA N, NOKHRIN A, et al. Influence of oxygen on densification kinetics of WC nanopowders during SPS. Ceramics International, 2021, 47(3): 4294. |

| [15] | MA D J, KOU Z L, LIU Y J, et al. Sub-micro binderless tungsten carbide sintering behavior under high pressure and high temperature. International Journal of Refractory Metals & Hard Materials, 2016, 54: 427. |

| [16] | GRASSO S, POETSCHKE J, RICHTER V, et al. Low-temperature spark plasma sintering of pure nano WC powder. Journal of the American Ceramic Society, 2013, 96(6): 1702. |

| [17] | XIE Z P, LI S, AN L N. A novel oscillatory pressure-assisted hot pressing for preparation of high-performance ceramics. Journal of the American Ceramic Society, 2014, 97(4): 1012. |

| [18] | ZHAO K, ZHONG W M, SUN M Y, et al. Sintering mechanism of pure B4C ceramic prepared by hot oscillating pressing and with excellent mechanical properties. Advanced Engineering Materials, 2024, 26(16): 2400695. |

| [19] | WANG K W, ZHAO K, LIU J L, et al. Interplay of microstructure and mechanical properties of WC-6Co cemented carbides by hot oscillating pressing method. Ceramics International, 2021, 47(14): 20731. |

| [20] | LIU D G, FAN J Y, ZHAO K, et al. Preparation of super-strong ZrO2 ceramics using dynamic hot forging. Journal of the European Ceramic Society, 2023, 43(2): 733. |

| [21] | ZHAO K, FENG P Z, TAN J, et al. A new route to fabricate high- performance binderless tungsten carbide: dynamic sinter forging. Journal of the American Ceramic Society, 2023, 106(6): 3343. |

| [22] | HE Z B, CHEN F, LIU D G, et al. Sintering behavior of simulating core FCM fuel via hot oscillatory pressing. Journal of Inorganic Materials, 2024, 39(5): 501. |

| [23] | 张渤涛, 姚曙, 范建业, 等. 电场辅助动态热锻制备超高韧3YSZ陶瓷. 粉末冶金材料科学与工程, 2024, 29(4): 290. |

| [24] | FOX R T, NILSSON R. Binderless tungsten carbide carbon control with pressureless sintering. International Journal of Refractory Metals & Hard Materials, 2018, 76: 82. |

| [25] | POETSCHKE J, RICHTER V, MICHAELIS A. Fundamentals of sintering nanoscaled binderless hardmetals. International Journal of Refractory Metals and Hard Materials, 2015, 49: 124. |

| [26] | PORZ L. 60 years of dislocations in ceramics: a conceptual framework for dislocation mechanics in ceramics. International Journal of Ceramic Engineering & Science, 2022, 4(4): 214. |

| [27] | ZHAO M J, ZHU Q Q, ZOU J, et al. Binderless nanocrystalline tungsten carbide with enhanced hardness induced by high-pressure sintering. Journal of the European Ceramic Society, 2024, 44(8): 4875. |

| [28] | DONG H F, LI B Z, LIU B B, et al. Extraordinary high- temperature mechanical properties in binder-free nanopolycrystalline WC ceramic. Journal of Materials Science & Technology, 2022, 97: 169. |

| [29] | WANG H B, LOU H Z, XING M, et al. Exploring the origin of wear in cemented carbides via molecular dynamics simulations. International Journal of Refractory Metals and Hard Materials, 2024, 118: 106476. |

| [30] | SALEM M N, DING K, RӦDEL J, et al. Thermally enhanced dislocation density improves both hardness and fracture toughness in single-crystal SrTiO3. Journal of the American Ceramic Society, 2023, 106: 1344. |

| [31] | XU H Y, JI W, GUO W M, et al. Enhanced mechanical properties and oxidation resistance of zirconium diboride ceramics via grain-refining and dislocation regulation. Advanced Science, 2022, 9(6): 2104532. |

| [32] | MISHRA M, TANGPATJAROEN C, SZLUFARSKA I. Plasticity- controlled friction and wear in nanocrystalline SiC. Journal of the American Ceramic Society, 2014, 97(4): 1194. |

| [33] | FU L C, ZHOU L P. Effect of applied magnetic field on wear behavior of martensitic steel. Journal of Materials Research and Technology, 2019, 8(3): 2880. |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | ZHENG Yuanshun, YU Jian, YE Xianfeng, LIANG Dong, ZHU Wanting, NIE Xiaolei, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Boosting the Thermoelectric Performance of Full-Heusler Fe2VAl Alloy via Substituting Al Site with V [J]. Journal of Inorganic Materials, 2025, 40(12): 1425-1432. |

| [3] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [4] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [5] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [6] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [7] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [8] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [9] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [10] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [11] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [12] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [13] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [14] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| [15] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||