Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (12): 1396-1404.DOI: 10.15541/jim20230288

Special Issue: 【能源环境】热电材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Jianbo1( ), TIAN Zhen1, JIANG Quanwei1, YU Lifeng1, KANG Huijun1,2(

), TIAN Zhen1, JIANG Quanwei1, YU Lifeng1, KANG Huijun1,2( ), CAO Zhiqiang1,2, WANG Tongmin1,2

), CAO Zhiqiang1,2, WANG Tongmin1,2

Received:2023-06-19

Revised:2023-07-25

Published:2023-08-21

Online:2023-08-21

Contact:

KANG Huijun, professor. E-mail: kanghuijun@dlut.edu.cnAbout author:LI Jianbo (1991-), male, PhD candidate. E-mail: lijianbo0408@mail.dlut.eud.cn

Supported by:CLC Number:

LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3[J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404.

Fig. 3 XRD patterns of CaTiO3 (a, b) powders and (c, d) bulks doped with different elements; (e) SEM image of powder and (f) BES image of bulk for the pristine CaTiO3 sample

| Atom | Atomic radius/pm | Ionic radius/pm |

|---|---|---|

| Ca | 174 | 99 (M2+) |

| Ti | 132 | 68 (M4+) |

| Cr | 118 | 84 (M3+) |

| Nb | 134 | 70 (M5+) |

| Dy | 177.3 | 90.8 (M3+) |

| Ce | 182.4 | 103.4 (M3+) |

| La | 187.7 | 106 (M3+) |

Table 1 Atomic radii and ionic radii of different atoms

| Atom | Atomic radius/pm | Ionic radius/pm |

|---|---|---|

| Ca | 174 | 99 (M2+) |

| Ti | 132 | 68 (M4+) |

| Cr | 118 | 84 (M3+) |

| Nb | 134 | 70 (M5+) |

| Dy | 177.3 | 90.8 (M3+) |

| Ce | 182.4 | 103.4 (M3+) |

| La | 187.7 | 106 (M3+) |

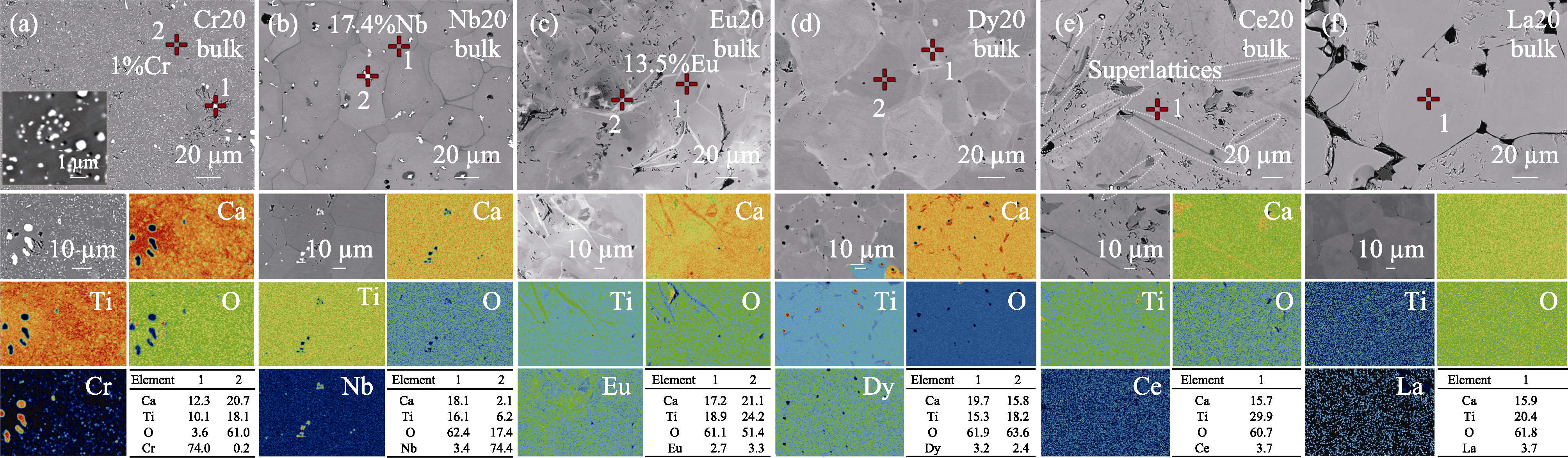

Fig. 5 EPMA images, element mappings, and corresponding chemical compositions of (a) Cr20, (b) Nb20, (c) Eu20, (d) Dy20, (e) Ce20, and (f) La20 bulks Unit in tables: % (in atom)

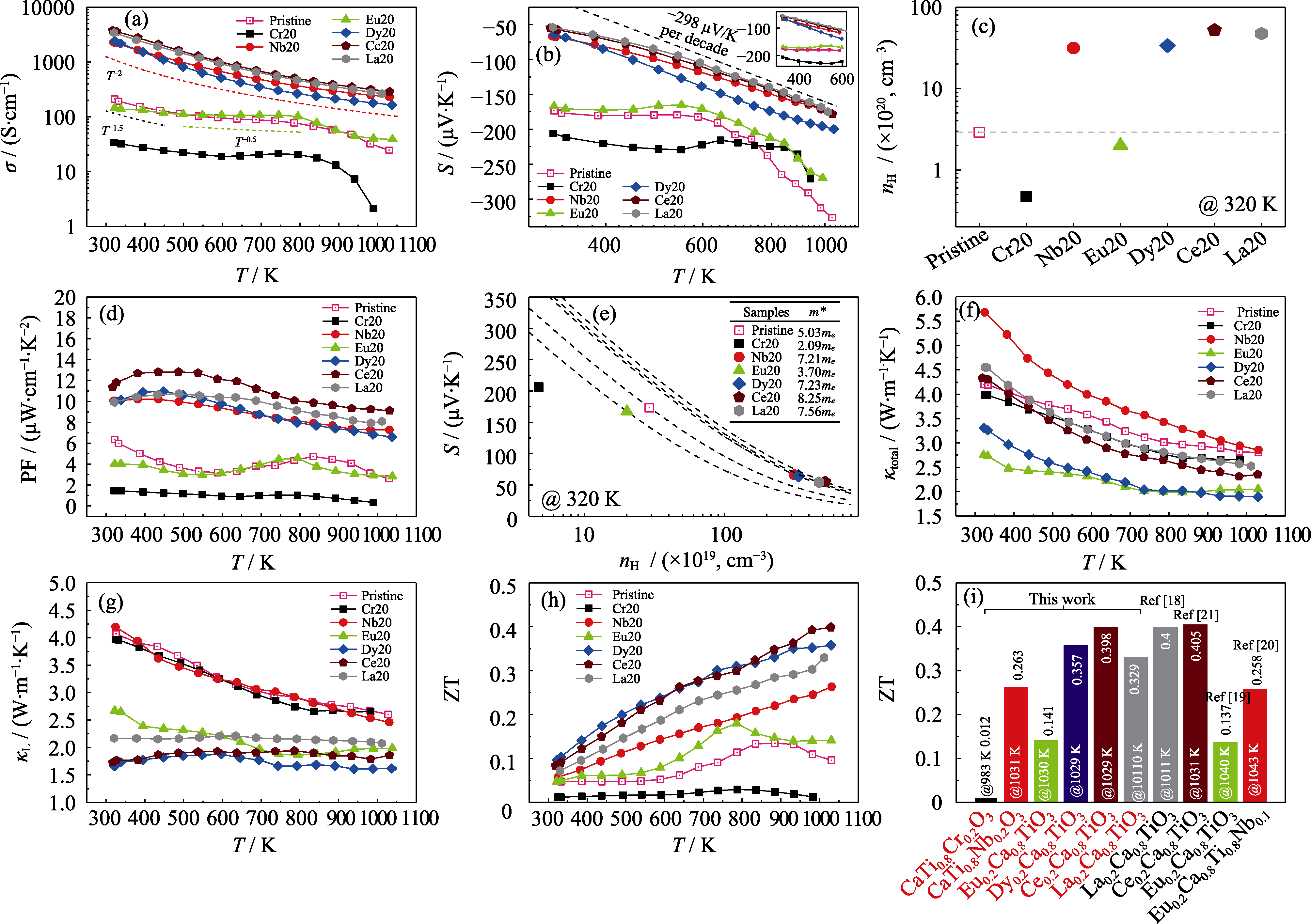

Fig. 6 Temperature-dependence of (a) electrical conductivity, (b) Seebeck coefficient with inset showing enlarged plots in temperature range of 300-600 K, (d) power factor, (f) total thermal conductivity, (g) lattice thermal conductivity, and (h) ZT of Cr20, Nb20, Eu20, Dy20, Ce20, and La20 bulks, and their (c) carrier concentration at 320 K, (e) Pisarenko curves and (i) ZT compared to literature[18⇓⇓-21]

| Chemical composition | Purity | Production factories |

|---|---|---|

| CaCl2 | ≥ 99.99% | Aladdin |

| DyCl3·6H2O | ≥ 99.99% | Aladdin |

| EuCl3·6H2O | ≥ 99.99% | Aladdin |

| La(NO3)3·6H2O | ≥ 99.99% | Aladdin |

| CeCl3·7H2O | ≥ 99.99% | Aladdin |

| CrCl3 | ≥ 99.99% | Aladdin |

| NbCl5 | ≥ 99.9% | Aladdin |

| C16H36O4Ti | ≥ 99% | Aladdin |

| NbCl5 | ≥ 99.9% | Aladdin |

| NaOH | ≥ 99% | Aladdin |

| C2H6O2 | ≥ 95% | Aladdin |

Table S1 Summary of the raw materials used for experiments

| Chemical composition | Purity | Production factories |

|---|---|---|

| CaCl2 | ≥ 99.99% | Aladdin |

| DyCl3·6H2O | ≥ 99.99% | Aladdin |

| EuCl3·6H2O | ≥ 99.99% | Aladdin |

| La(NO3)3·6H2O | ≥ 99.99% | Aladdin |

| CeCl3·7H2O | ≥ 99.99% | Aladdin |

| CrCl3 | ≥ 99.99% | Aladdin |

| NbCl5 | ≥ 99.9% | Aladdin |

| C16H36O4Ti | ≥ 99% | Aladdin |

| NbCl5 | ≥ 99.9% | Aladdin |

| NaOH | ≥ 99% | Aladdin |

| C2H6O2 | ≥ 95% | Aladdin |

Fig. S2 Temperature-dependent (a) thermal diffusion, (b) specific heat, (c) electrical thermal conductivity, and (d) Lorenz constant for pristine for Pristine CaTiO3, Cr20, Nb20, Eu20, Dy20, Ce20, and La20 samples

Fig. S4 Temperature-dependence of the (a) electrical conductivity, (b) Seebeck coefficient, and (c) power factor of CaTi0.8Nb0.2O3 (Nb20) sintered at (a) 1400, (b) 1450, and (c) 1500 ℃, respectively

| Nominal chemical composition | Composition sample code | Measured density/ (g·cm-3) | Theoretical density/(g·cm-3) | Relative density/% |

|---|---|---|---|---|

| CaTiO3 | Pristine | 3.85 | 4.04 | 95.2 |

| CaTi0.8Cr0.2O3 | Cr20 | 3.89 | 4.06 | 95.8 |

| CaTi0.8Nb0.2O3 | Nb20 | 4.07 | 4.30 | 94.6 |

| Eu0.2Ca0.8TiO3 | Eu20 | 4.39 | 4.70 | 93.4 |

| Dy0.2Ca0.8TiO3 | Dy20 | 4.48 | 4.76 | 94.1 |

| Ce0.2Ca0.8TiO3 | Ce20 | 4.40 | 4.63 | 95.0 |

| La0.2Ca0.8TiO3 | La20 | 4.19 | 4.62 | 90.7 |

Table S2 Nominal chemical compositions, sample codes, measured densities, theoretical densities, and relative densities of the prepared bulk samples

| Nominal chemical composition | Composition sample code | Measured density/ (g·cm-3) | Theoretical density/(g·cm-3) | Relative density/% |

|---|---|---|---|---|

| CaTiO3 | Pristine | 3.85 | 4.04 | 95.2 |

| CaTi0.8Cr0.2O3 | Cr20 | 3.89 | 4.06 | 95.8 |

| CaTi0.8Nb0.2O3 | Nb20 | 4.07 | 4.30 | 94.6 |

| Eu0.2Ca0.8TiO3 | Eu20 | 4.39 | 4.70 | 93.4 |

| Dy0.2Ca0.8TiO3 | Dy20 | 4.48 | 4.76 | 94.1 |

| Ce0.2Ca0.8TiO3 | Ce20 | 4.40 | 4.63 | 95.0 |

| La0.2Ca0.8TiO3 | La20 | 4.19 | 4.62 | 90.7 |

| [1] |

BRENDAN J K, CHRISTOPHER J H, BRYAN C C. Phase transitions in perovskite at elevated temperatures: a powder neutron diffraction study. Journal of Physics: Condensed Matter, 1999, 11(6): 1479.

DOI URL |

| [2] |

SHI J, GUO L. ABO3-based photocatalysts for water splitting. Progress in Natural Science: Materials International, 2012, 22(6): 592.

DOI URL |

| [3] |

MANAN A, NAWAZ A, AHMAD A S, et al. Preparation and microwave dielectric properties of CaTiO3added Mg0.95Ni0.05-Ti0.98Zr0.02O3 composite ceramics for high frequency applications. Materials Science-Poland, 37(4): 639.

DOI URL |

| [4] | OLIVEIRA R, SILVA R, DE MORAIS J, et al. Effects of CaTiO3 addition on the microwave dielectric properties and antenna properties of BiVO4 ceramics. Composites Part B: Engineering, 2019, 175: 107122. |

| [5] | SAHOO S, DASH U, PARASHAR S, et al. Frequency and temperature dependent electrical characteristics of CaTiO3nano-ceramic prepared by high-energy ball milling. Journal of Advanced Ceramics, 2013, 2: 291. |

| [6] |

CAI J, CAO A, HUANG J, et al. Understanding oxygen vacancies in disorder-engineered surface and subsurface of CaTiO3 nanosheets on photocatalytic hydrogen evolution. Applied Catalysis B: Environmental, 2020, 267: 118378.

DOI URL |

| [7] |

MANJUNATH K, G THIMMANNA C. Studies on synthesis, characterization and applications of nano CaTiO3powder. Current Nanomaterials, 2016, 1(2): 145.

DOI URL |

| [8] | PASSI M, PAL B. A review on CaTiO3 photocatalyst: activity enhancement methods and photocatalytic applications. Powder Technology, 2021, 388: 274. |

| [9] | SINGH B K, HAFEEZ M A, KIM H, et al. Inorganic waste forms for efficient immobilization of radionuclides. ACS ES&T Engineering, 2021, 1(8): 1149. |

| [10] |

CHEN Y, LIN Z, ZHANG Z, et al. Dielectric and MLCC property of modified (Sr,Ca)TiO3based energy storage ceramic. Journal of Inorganic Materials, 2022, 37(9): 976.

DOI URL |

| [11] |

ZHOU W M, CHEN Q H, KE M Z, et al. Preparation and properties of CaTiO3:Pr3+/TiO2-mica fluorescent pearlescent pigments. Journal of Inorganic Materials, 2014, 29(12): 1275.

DOI URL |

| [12] |

TIAN B Z, JIANG X P, CHEN J, et al. Low lattice thermal conductivity and enhanced thermoelectric performance of SnTe via chemical electroless plating of Ag. Rare Metals, 2022, 41(1): 86.

DOI |

| [13] |

LIU K J, ZHANG Z W, CHEN C, et al. Entropy engineering in CaZn2Sb2-YbMg2Sb2 Zintl alloys for enhanced thermoelectric performance. Rare Metals, 2022, 41(9): 2998.

DOI |

| [14] |

ZHANG R Z, HU X Y, GUO P, et al. Thermoelectric transport coefficients of n-doped CaTiO3, SrTiO3 and BaTiO3: a theoretical study. Physica B: Condensed Matter, 2012, 407(7): 1114.

DOI URL |

| [15] |

NOOR N A, ALAY-E-ABBAS S M, HASSAN M, et al. The under-pressure behaviour of mechanical, electronic and optical properties of calcium titanate and its ground state thermoelectric response. Philosophical Magazine, 2017, 97(22): 1884.

DOI URL |

| [16] |

ZHOU H Y, LIU X Q, ZHU X L, et al. CaTiO3 linear dielectric ceramics with greatly enhanced dielectric strength and energy storage density. Journal of the American Ceramic Society, 2018, 101(5): 1999.

DOI URL |

| [17] |

CAVALCANTE L S, MARQUES V S, SCZANCOSKI J C, et al. Synthesis, structural refinement and optical behavior of CaTiO3 powders: a comparative study of processing in different furnaces. Chemical Engineering Journal, 2008, 143(1): 299.

DOI URL |

| [18] | LI J, WANG Y, YANG X, et al. Processing bulk insulating CaTiO3 into a high-performance thermoelectric material. Chemical Engineering Journal, 2022, 428: 131121. |

| [19] | XIAO X, WIDENMEYER M, MUELLER K, et al. A squeeze on the perovskite structure improves the thermoelectric performance of europium calcium titanates. Materials Today Physics, 2018, 7: 96. |

| [20] | XIAO X, XIE W, WIDENMEYER M, et al. Synergistic effects of Eu and Nb dual substitution on improving the thermoelectric performance of the natural perovskite CaTiO3. Materials Today Physics, 2022, 26: 100741. |

| [21] |

LI J, WANG Y, JIANG X, et al. Emerging homogeneous superlattices in CaTiO3bulk thermoelectric materials. Materials Horizons, 2023, 10(2): 454.

DOI URL |

| [22] |

CHI F, QIN Y, ZHOU S, et al. Eu3+-site occupation in CaTiO3 perovskite material at low temperature. Current Applied Physics, 2017, 17(1): 24.

DOI URL |

| [23] |

ITO M, MATSUDA T. Thermoelectric properties of non-doped and Y-doped SrTiO3 polycrystals synthesized by polymerized complex process and hot pressing. Journal of Alloys and Compounds, 2009, 477(1): 473.

DOI URL |

| [24] |

WANG Y, FAN H J. Sr1-xLaxTiO3 nanoparticles: synthesis, characterization and enhanced thermoelectric response. Scripta Materialia, 2011, 65(3): 190.

DOI URL |

| [25] |

SHANG P P, ZHANG B P, LI J F, et al. Effect of sintering temperature on thermoelectric properties of La-doped SrTiO3ceramics prepared by Sol-Gel process and spark plasma sintering. Solid State Sciences, 2010, 12(8): 1341.

DOI URL |

| [26] |

KIKUCHI A, OKINAKA N, AKIYAMA T. A large thermoelectric figure of merit of La-doped SrTiO3 prepared by combustion synthesis with post-spark plasma sintering. Scripta Materialia, 2010, 63(4): 407.

DOI URL |

| [27] |

LI J B, WANG J, LI J F, et al. Broadening the temperature range for high thermoelectric performance of bulk polycrystalline strontium titanate by controlling the electronic transport properties. Journal of Materials Chemistry C, 2018, 6(28): 7594.

DOI URL |

| [28] | WANG J, ZHANG B Y, KANG H J, et al. Record high thermoelectric performance in bulk SrTiO3 via nano-scale modulation doping. Nano Energy, 2017, 35: 387. |

| [29] |

LU Z, ZHANG H, LEI W, et al. High-figure-of-merit thermoelectric La-doped A-site-deficient SrTiO3 ceramics. Chemistry of Materials, 2016, 28(3): 925.

DOI URL |

| [30] |

KIMIJIMA T, KANIE K, NAKAYA M, et al. Hydrothermal synthesis of size- and shape-controlled CaTiO3 fine particles and their photocatalytic activity. CrystEngComm, 2014, 16(25): 5591.

DOI URL |

| [31] |

FU B G, YANG J C, GAO Z K, et al. Hot pressing sintering process and sintering mechanism of W-La2O3-Y2O3-ZrO2. Rare Metals, 2021, 40(7): 1949.

DOI |

| [32] | KIM Y J, ZHAO L D, KANATZIDIS M G, et al. Analysis of nanoprecipitates in a Na-doped PbTe-SrTe thermoelectric material with a high figure of merit. ACS Applied Materials & Interfaces, 2017, 9(26): 21791. |

| [33] |

MOOS R, GNUDI A, HÄRDTL K H. Thermopower of Sr1-xLaxTiO3 ceramics. Journal of Applied Physics, 1995, 78(8): 5042.

DOI URL |

| [34] |

KIM H S, GIBBS Z M, TANG Y, et al. Characterization of Lorenz number with Seebeck coefficient measurement. APL Materials, 2015, 3(4): 041506.

DOI URL |

| [35] | SINGARAVELU S, KLOPF J, KRAFFT G, et al. Laser nitriding of niobium for application to superconducting radio-frequency accelerator cavities. Journal of Vacuum Science & Technology B, 2011, 29(6): 061803. |

| [36] |

COOK B A, KRAMER M J, HARRINGA J L, et al. Analysis of nanostructuring in high figure-of-merit Ag1-xPbmSbTe2+m thermoelectric materials. Advanced Functional Materials, 2009, 19(8): 1254.

DOI URL |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [3] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [4] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [5] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [6] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [7] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [8] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [9] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [10] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [11] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [12] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| [13] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [14] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [15] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||