Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (1): 107-112.DOI: 10.15541/jim20230385

• RESEARCH LETTER • Previous Articles

YANG Pingjun1,2( ), LI Tiehu1,2(

), LI Tiehu1,2( ), LI Hao1,2(

), LI Hao1,2( ), DANG Alei1,2

), DANG Alei1,2

Received:2023-08-28

Revised:2023-10-20

Published:2024-01-20

Online:2023-11-22

Contact:

LI Tiehu, professor. E-mail: litiehu@nwpu.edu.cn;About author:YANG Pingjun (1991-), PhD candidate. E-mail: pjyang@mail.nwpu.edu.cn

Supported by:CLC Number:

YANG Pingjun, LI Tiehu, LI Hao, DANG Alei. Effect of Graphene on Graphitization, Electrical and Mechanical Properties of Epoxy Resin Carbon Foam[J]. Journal of Inorganic Materials, 2024, 39(1): 107-112.

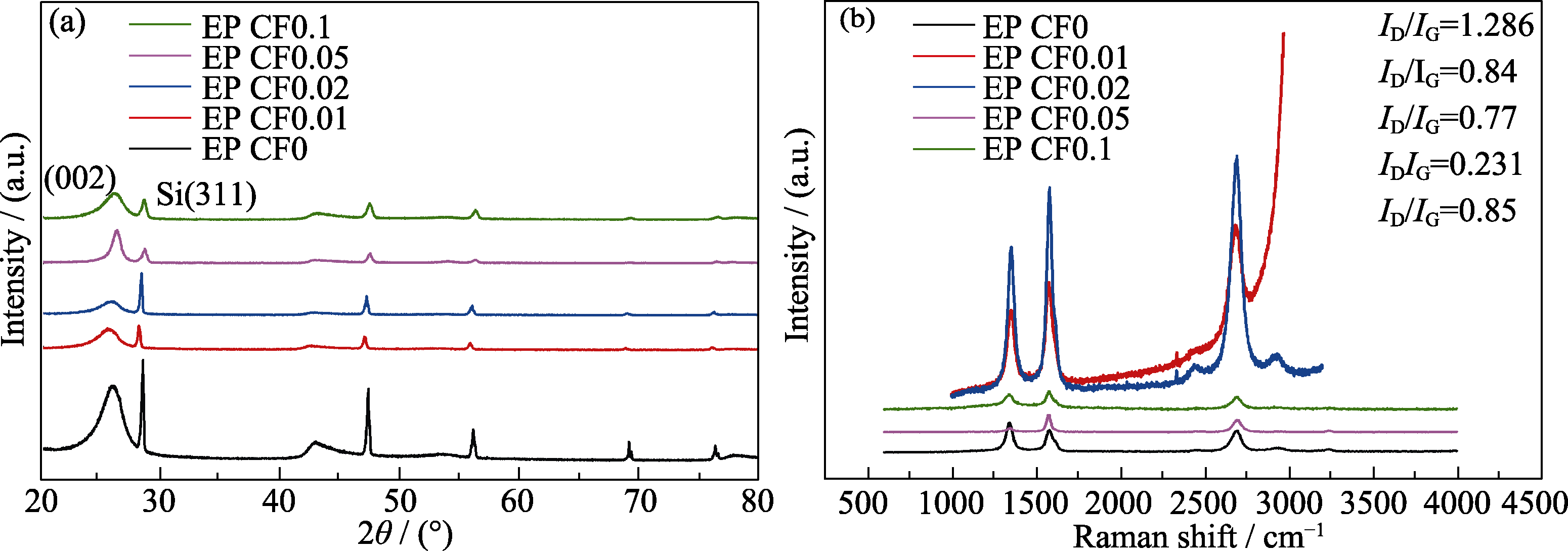

Fig. 1 Structure parameters of EP CF modified by different contents of graphene after graphitization treatment at 3000 ℃ for 0.5 h (a) XRD patterns; (b) Raman spectra. Colorful figures are available on website

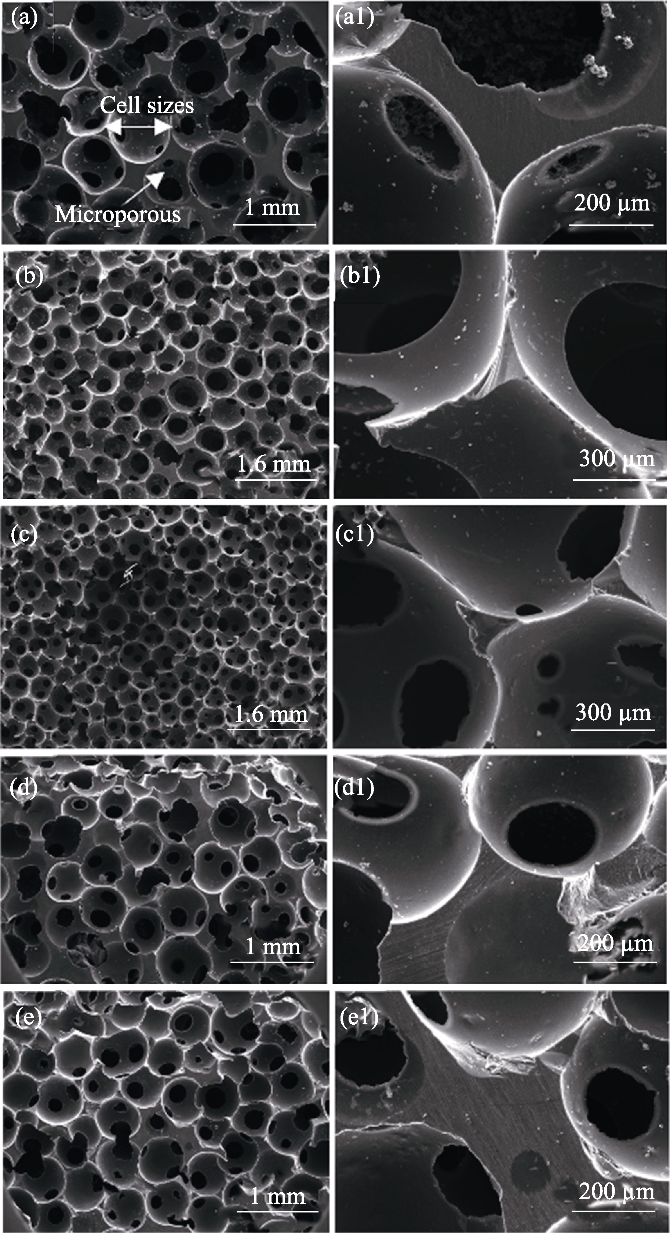

Fig. 2 SEM images of modified EP CF by different graphene contents after graphitization treatment at 3000 ℃ for 0.5 h (a, a1) EP CF0; (b, b1) EP CF0.01; (c, c1) EP CF0.02; (d, d1) EP CF0.05; (e, e1) EP CF0.1

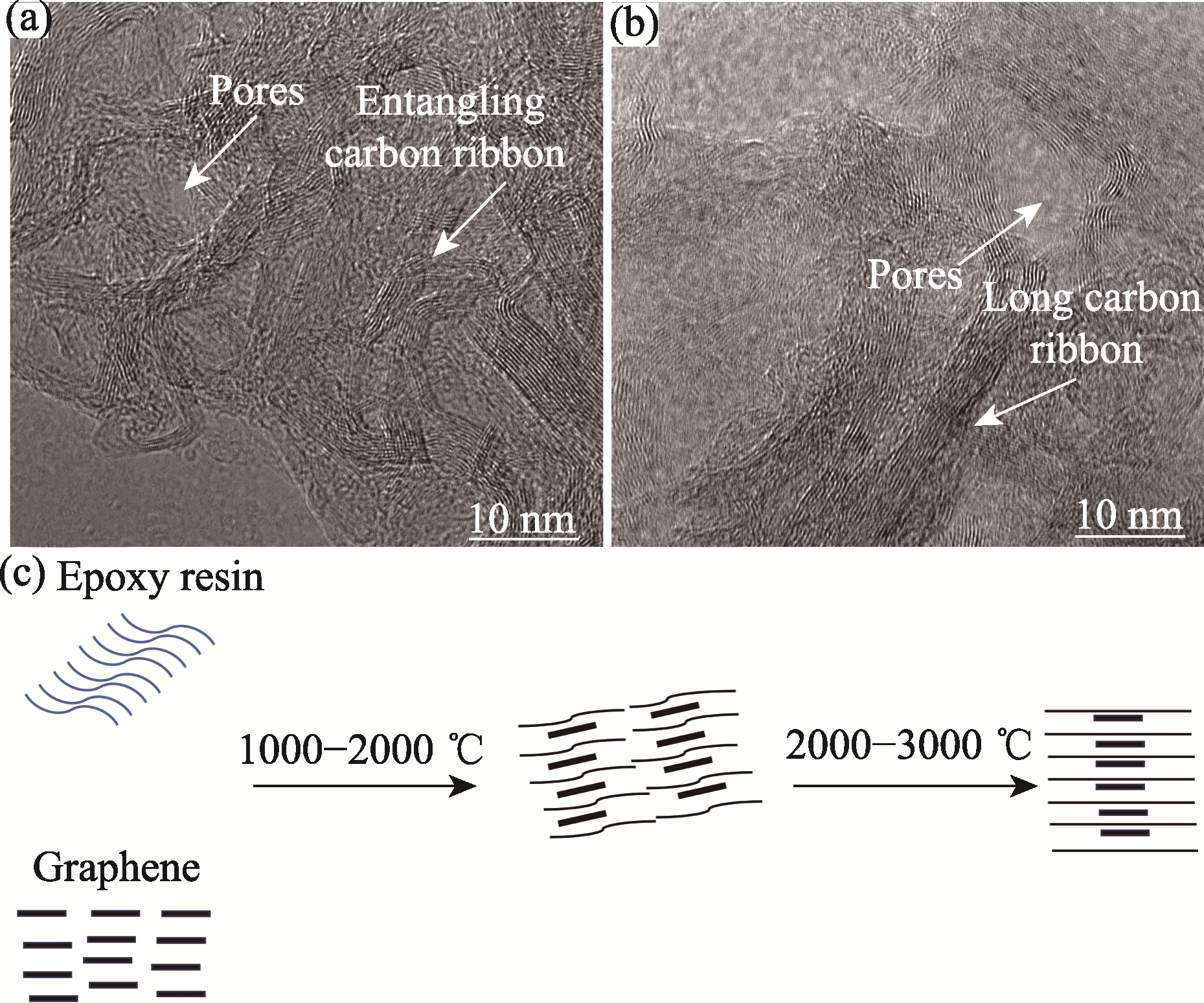

Fig. 3 HRTEM images of EP CF and its graphitization mechanism (a) EP CF0; (b) EP CF0.05; (c) Schematic diagram of graphitization mechanism of EP CF treated at 3000 ℃for 0.5 h

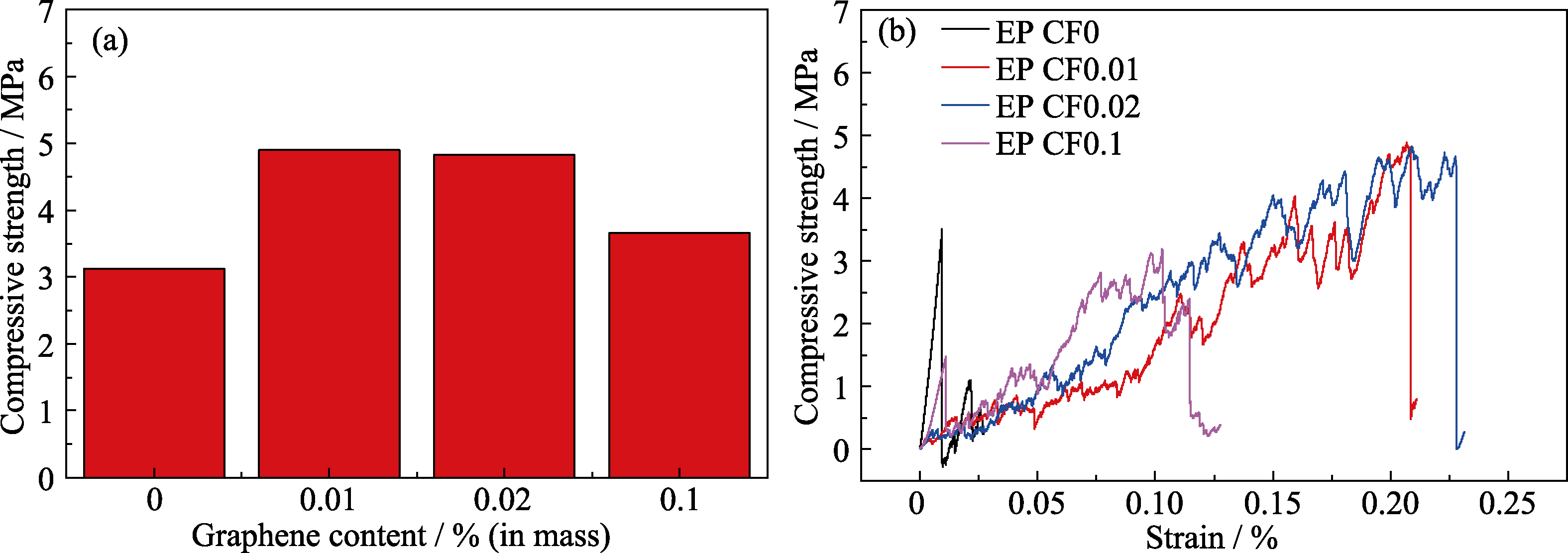

Fig. 5 Mechanical properties of EP CF modified by different graphene contents after graphitization at 3000 ℃ for 0.5 h (a) Compressive strength; (b) Variation of stress with strain; Colorful figures are available on website

| Sample | 2θ002/(°) | d002/nm | Lc/nm | g/% |

|---|---|---|---|---|

| EP CF0 | 25.9 | 0.3431 | 3.35 | 8.42 |

| EP CF0.01 | 25.6 | 0.343 | 3.62 | 11.22 |

| EP CF0.02 | 25.77 | 0.343 | 4.22 | 11.22 |

| EP CF0.05 | 26.27 | 0.342 | 10.22 | 23.2 |

| EP CF0.1 | 26.1 | 0.3425 | 4.46 | 16.5 |

Table S1 Crystalline parameters of EP CF modified by different graphene contents after treatment at 3000 ℃ for 0.5 h

| Sample | 2θ002/(°) | d002/nm | Lc/nm | g/% |

|---|---|---|---|---|

| EP CF0 | 25.9 | 0.3431 | 3.35 | 8.42 |

| EP CF0.01 | 25.6 | 0.343 | 3.62 | 11.22 |

| EP CF0.02 | 25.77 | 0.343 | 4.22 | 11.22 |

| EP CF0.05 | 26.27 | 0.342 | 10.22 | 23.2 |

| EP CF0.1 | 26.1 | 0.3425 | 4.46 | 16.5 |

| Sample | Density/(g·cm-3) | Electrical conductivity/(S·m-1) | Compressive strength/MPa |

|---|---|---|---|

| EP CF0 | 0.470 | 25.79 | 3.13 |

| EP CF0.01 | 0.460 | 27.70 | 4.90 |

| EP CF0.02 | 0.469 | 27.79 | 4.82 |

| EP CF0.05 | 0.460 | 53.80 | 2.00 |

| EP CF0.1 | 0.463 | 45.90 | 3.66 |

Table S2 Physical, electrical and mechanical properties of EP CF modified by different graphene content after graphitization treatment at 3000 ℃ for 0.5 h

| Sample | Density/(g·cm-3) | Electrical conductivity/(S·m-1) | Compressive strength/MPa |

|---|---|---|---|

| EP CF0 | 0.470 | 25.79 | 3.13 |

| EP CF0.01 | 0.460 | 27.70 | 4.90 |

| EP CF0.02 | 0.469 | 27.79 | 4.82 |

| EP CF0.05 | 0.460 | 53.80 | 2.00 |

| EP CF0.1 | 0.463 | 45.90 | 3.66 |

| [1] |

JEONG H, KANG Y G, RYU S S, et al. Fabrication of high- strength macroporous carbons with tunable pore size by a simple powder process using phenolic resin microspheres. Ceramics International, 2021, 47(7):8820.

DOI URL |

| [2] |

YU K J, ZENG Y, WANG G L, et al. rGO/Fe3O4hybrid induced ultra-efficient EMI shielding performance of phenolic-based carbon foam. RSC Advances, 2019, 9(36):20643.

DOI URL |

| [3] |

LIU H G, WU S Q, YOU C Y, et al. Fe3O4 nanoparticles decorated flexible carbon foam for efficient electromagnetic interference shielding. Ceramics International, 2022, 48(13):19452.

DOI URL |

| [4] | SONG S A, LEE Y M, KIM Y S, et al. Mechanical and thermal properties of carbon foam derived from phenolic foam reinforced with composite particles. Composite Structures, 2017, 173: 1. |

| [5] | INAGAKI M, QIU J S, GUO Q G. Carbon foam: preparation and application. Carbon, 2015, 87: 128. |

| [6] |

MOHAN P. A critical review: the modification, properties, and applications of epoxy resins. Polymer-Plastics Technology and Engineering, 2013, 52(2):107.

DOI URL |

| [7] | SZELUGA U, PUSZ S, KUMANEK B, et al. Carbon foam based on epoxy/novolac precursor as porous micro-filler of epoxy composites. Composites: Part A, 2018, 105: 28. |

| [8] |

LI N, YANG Q Y, WEI Y X, et al. Phosphorus-doped hard carbon with controlled active groups and microstructure for high performance sodium-ion batteries. Journal of Materials Chemistry A, 2020, 8(39):20486.

DOI URL |

| [9] |

LEI S W, GUO Q G, SHI J L, et al. Preparation of phenolic-based carbon foam with controllable pore structure and high compressive strength. Carbon, 2010, 48 (9): 2644.

DOI URL |

| [10] | TALABI S I, LUZ A P, PANDOLFELLI V C, et al. Structural evolution during the catalytic graphitization of a thermosetting refractory binder and oxidation resistance of the derived carbons. Materials Chemistry and Physics, 2018, 212: 113. |

| [11] |

LIU H G, WU S Q, TIAN N, et al. Carbon foams: 3D porous carbon materials holding immense potential. Journal of Materials Chemistry A, 2020, 8(45):23699.

DOI URL |

| [12] | NAGEL B, PUSZ S, TRZEBICKA B. Review: tailoring the properties of macroporous carbon foams. Journal of Materials Science, 2014, 49: 1. |

| [13] | LI H, LI T H, DENG W B, et al. Preparation and adsorption properties of graphene-modified pitch-based carbon foam composites. Polymers, 2022, 14: 4455. |

| [14] |

YANG P J, LI T H, LI H, et al. Progress in the graphitization and applications of modified resin carbons. New Carbon Materials, 2023, 38(1):96.

DOI URL |

| [15] | YANG P J, LI T H, LI H, et al. Effect of coal tar pitch modification on the structure and char yield of pyrolysis epoxy resin carbons. Diamond & Related Materials, 2023, 137: 110099. |

| [16] |

CHEN J, XIONG X, XIAO P. The effect of MWNTs on the microstructure of resin carbon and thermal conductivity of C/C composites. Solid State Sciences, 2009, 11(11): 1890.

DOI URL |

| [17] |

YI S J, CHEN J H, LI H Y, et al. Effect of graphite oxide on graphitization of furan resin carbon. Carbon, 2010, 48(3):912.

DOI URL |

| [18] | SCHUEPFER D B, BADACZEWSKI F, GUERRA-CASTRO J M, et al. Assessing the structural properties of graphitic and non- graphitic carbons by Raman spectroscopy. Carbon, 2020, 161: 359. |

| [19] | THAPLIYAL V, ALABDULKARIM M E, WHELAN D R, et al. A concise review of the Raman spectra of carbon allotropes. Diamond & Related Materials, 2022, 127: 109180. |

| [20] | ZHANG K, LI Y F, CHEN T T, et al. Preparation and properties of graphene nanosheets/carbon foam composites. Journal of Analytical and Applied Pyrolysis, 2016, 117: 290. |

| [21] |

JING H, MIAO Z N, ZENG Z, et al. Carbonization of graphene-doped isocyanate-based polyimide foams to achieve carbon foams with excellent electromagnetic interference shielding performance. Materials, 2021, 14(24):7551.

DOI URL |

| [22] | MILANI M A, GONZÁLEZ D, QUIJADA R, et al. Polypropylene/ graphene nanosheet nanocomposites by in situ polymerization: synthesis, characterization and fundamental properties. Composites Science and Technology, 2013, 84: 1. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | YANG Mingkai, HUANG Zeai, ZHOU Yunxiao, LIU Tong, ZHANG Kuikui, TAN Hao, LIU Mengying, ZHAN Junjie, CHEN Guoxing, ZHOU Ying. Co-production of Few-layer Graphene and Hydrogen from Methane Pyrolysis Based on Cu and Metal Oxide-KCl Molten Medium [J]. Journal of Inorganic Materials, 2025, 40(5): 473-480. |

| [5] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [6] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [9] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [10] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [11] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [12] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [13] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [14] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [15] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||