|

|

Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application

ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi

2024 Vol. 39 (1): 1–16

Abstract

Abstract(

859 )

HTML

HTML(

311)

PDF

PDF(5061KB)(

920

)

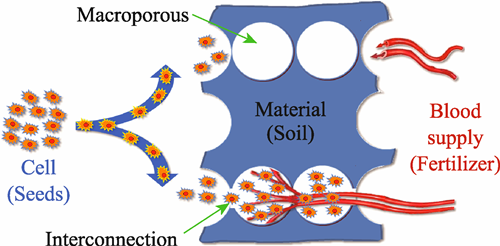

The question of what qualities excellent medical bioceramics must possess to ensure satisfactory prognosis for bone healing and reconstruction remains a topic of great interest in both clinical and biomaterial sciences. Our team has been dedicated to researching medical bioceramics since the 1990s, involving basic scientific research, applied translational research, and clinical trials. Consequently, we have amassed a wealth of research and implementation experience. In this article, we aim to explore the subject of “Functional Bioadaptability in Medical Bioceramics”, specifically focusing on calcium phosphate-based materials. We summarized how to effectively combine bioadaptability with design and manufacturing of medical bioceramics in the background of orthopedic clinical application, with the following aspects of structural adaptability, degradative adaptability, mechanical adaptability, and application adaptability. Hopefully, some suggestions put forward can ultimately provide valuable insights and recommendations for the design, production, supervision, and application of the upcoming medical bioceramics.

|

|

|

Progress of Interconnect Materials in the Third-generation Semiconductor and Their Low-temperature Sintering of Copper Nanoparticles

KE Xin, XIE Bingqing, WANG Zhong, ZHANG Jingguo, WANG Jianwei, LI Zhanrong, HE Huijun, WANG Limin

2024 Vol. 39 (1): 17–31

Abstract

Abstract(

1721 )

HTML

HTML(

361)

PDF

PDF(9911KB)(

8735

)

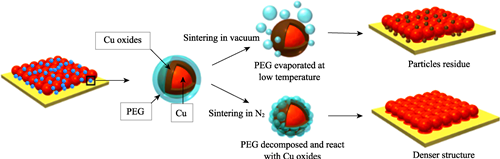

Semiconductor materials are the core of modern technology development and industrial innovation, with high frequency, high pressure, high temperature, high power, and other high properties under severe conditions or super properties needed by the “double carbon” goal, the new silicon carbide (SiC) and gallium nitride (GaN) as representative of the third generation of semiconductor materials gradually into industrial applications. For the third-generation semiconductor, there are several development directions in its packaging interconnection materials, including high-temperature solder, transient liquid phase bonding materials, conductive adhesives, and low-temperature sintered nano-Ag/Cu, of which nano-Cu, due to its excellent thermal conductivity, low-temperature sintering characteristics, and good processability, has become a new scheme for packaging interconnection, with low cost, high reliability, and scalability. Recently, the trend from material research to industrial chain end-use is pronounced. This review firstly introduces the development overview of semiconductor materials and summarizes the categories of third-generation semiconductor packaging interconnect materials. Then, combined with recent research results, it further focuses on the application of nano-Cu low-temperature sintering in electronic fields such as packaging and interconnection, mainly including the impact of particle size and morphology, surface treatment, and sintering process on the impact of nano-Cu sintered body conductivity and shear properties. Finally, it summarizes the current dilemmas and the difficulties, looking forward to the future development. This review provides a reference for the research on low-temperature sintered copper nanoparticles in the field of interconnect materials for the third-generation semiconductor.

|

|

|

Research Progress on Hard Carbon Anode for Li/Na-ion Batteries

HU Mengfei, HUANG Liping, LI He, ZHANG Guojun, WU Houzheng

2024 Vol. 39 (1): 32–44

Abstract

Abstract(

1927 )

HTML

HTML(

363)

PDF

PDF(11244KB)(

1189

)

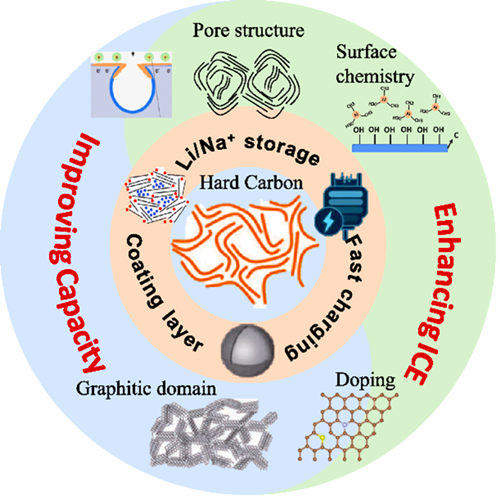

With rapid development of lithium ion batteries (LIB) and sodium ion batteries (SIB), hard carbon (HC) as new anode material has earned much attention. Besides its rich precursor sources and low cost, HC has higher Li+ storage capacity and better rate performance than graphite for LIB. Furthermore, it is also recognized as the most commercially potential anode material for SIB. However, low initial Coulombic efficiency is a common issue for HC. In addition, it is believed that the specific capacity can be further improved with the clarification of the Li/Na ion storage mechanism. In recent years, many researches on electrochemical mechanism have been conducted with some model assumptions proposed for better understanding the mechanism. This review introduced the structures and preparation approaches of HC as well as its application in LIB and SIB. The advantages, especially in fast charging, coating and other subdivision were discussed, and the different modification strategies such as pore structure design, doping, optimizing interface between electrode and electrolyte were summarized, aiming at the increase of capacity and the improvement of Coulombic efficiency of batteries.

|

|

|

2D-SiCf/SiC Interlaminar Mode I Fracture Testing and Characterization

SHI Weigang, ZHANG Chao, LI Mei, WANG Jing, ZHANG Chengyu

2024 Vol. 39 (1): 45–50

Abstract

Abstract(

619 )

HTML

HTML(

36)

PDF

PDF(4538KB)(

862

)

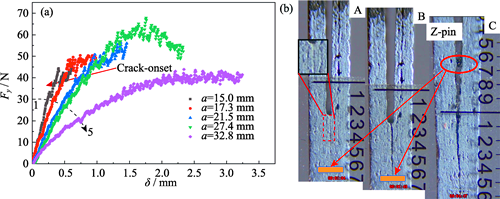

Two-dimensional braided silicon carbide fiber reinforced composite material (2D SiCf/SiC) is widely used in the aerospace field. However, owing to its weak interlaminar mechanical properties, this material is prone to initiation of interlaminar cracks and delamination failure. Therefore, a comparative study on the Wedge-loaded Double Cantilever Beam method (W-DCB) and the classical Double Cantilever Beam method (DCB) was conducted. The loading data of interlaminar crack-driving were obtained, and the relationship curve of crack opening force and opening displacement were obtained. During the loading, the visual crack propagation process was monitored through an optical microscope, which was to explore the interlaminar crack growth behaviors. Combined the theoretical analysis and the visual characteristics of the crack, the meaning of the inflection point and other characteristic points of the relationship curve is explained. What’s more, scanning electron microscope was used to analyze the characteristics of the interlaminar fracture surface to reveal growth mechanism of the delamination crack in the fracture surface. The results show that the W-DCB method is equivalent to the DCB method in measuring the initial energy release rate of interlaminar Mode I fracture in 2D-SiCf/SiC; In terms of 2D-SiCf/SiC interlaminar Mode I fracture, the multi-peak characteristic of deformation curve is not according with the post-peak loading curve predicted by classical linear elastic Fracture mechanics, which reflects complexity of interlaminar constraint relationship. The interlaminar section is structurally non-completely damaged, but still emerging local fiber-bridgings.

|

|

|

Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates

WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo

2024 Vol. 39 (1): 51–60

Abstract

Abstract(

646 )

HTML

HTML(

38)

PDF

PDF(6439KB)(

898

)

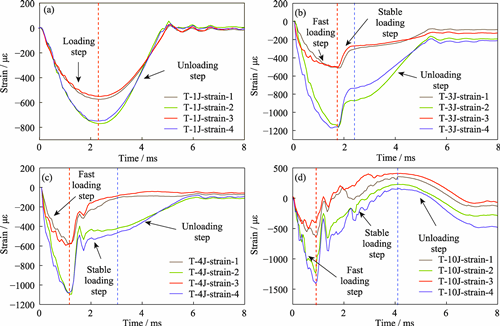

Low-velocity impact is an inevitable problem in the service of ceramic matrix composites structures in high speed aircraft. Therefore, the damage type and residual bearing capacity after low-velocity impact are critical factors for ensuring the safety of the aircraft structures. In this study, two-dimensional braided SiC/SiC composite laminates were taken as the research objects, and low-speed impact tests under different energies were carried out. The damage morphology of SiC/SiC composites was observed by computed tomography, and the damage mechanism of SiC/SiC composites during the impact process was revealed by analyzing the load history curve and strain history curve. Post-impact residual strength tests were carried out on specimens with barely visible damage and the effect of barely visible damage on the residual strength of SiC/SiC composites was investigated. The results showed that under low-velocity impact load, surface damage of specimens mainly included no surface damage, barely visible damage, semi-penetrating damage and penetrating damage. Internal damage of specimens mainly included cone cracks, yarn breakage and delamination. The residual properties of SiC/SiC composites were found to be severely affected by low velocity impact damage. The residual compressive strength of the specimen with barely visible damage was 81% of that of the undamaged specimens, and the residual tensile strength was only 68% of that of the undamaged specimens.

|

|

|

Ablation Resistance of High-entropy Oxide Coatings on C/C Composites

GUO Lingxiang, TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia

2024 Vol. 39 (1): 61–70

Abstract

Abstract(

1366 )

HTML

HTML(

86)

PDF

PDF(23433KB)(

1215

)

With improvement in service temperature of thermal structural components for the new generation hypersonic aircraft, higher requirements are put forward for the phase stability and ablation resistance of the thermal protection coatings (TPCs). Carrying out high-entropy design for traditional transition metal oxide ZrO2 and HfO2 coatings, solid-phase reaction and supersonic atmosphere plasma spraying (SAPS) were applied to prepare (Hf0.125Zr0.125Sm0.25Er0.25Y0.25)O2-δ (M1R3O), (Hf0.2Zr0.2Sm0.2Er0.2Y0.2)O2-δ (M2R3O), (Hf0.25Zr0.25Sm0.167Er0.167Y0.167)O2-δ (M3R3O) high-entropy oxide (HEO) coatings. The effects of rare earth content on phase structure evolution, phase stability and ablative resistance of HEO coatings were investigated. M2R3O coating and M3R3O coating possessed excellent phase stability and ablation resistance, which maintained stable phase structure after ablation by oxygen-acetylene flame with heat flux density of 2.38-2.40 MW/m2, without decomposition of solid solution and precipitation of rare earth components. Mass ablation rate and linear ablation rate of M2R3O coating after cyclic ablation for 180 s are 0.01 mg/s and -1.16 μm/s, respectively. Compared with M1R3O coating (0.09 mg/s, -1.34 μm/s) and M3R3O coating (0.02 mg/s, -4.51 μm/s), the reductions of ablation rate are 88.9%, 13.4%, respectively, and 50.0%, 74.3% for M2R3O coatings, respectively, presenting the best ablation resistance. M2R3O coating exhibits excellent ablation resistance due to its high melting point (>2200 ℃) and low thermal conductivity ((1.07±0.09) W/(m·K)), which effectively protects the internal SiC transition layer and C/C composites from oxidation damage, avoiding interface cracking caused by the formation of SiO2 phase.

|

|

|

Low-frequency Microwave Absorption of CIPs@Mn0.8Zn0.2Fe2O4-CNTs Composites

CHEN Haiyan, TANG Zhipeng, YIN Liangjun, ZHANG Linbo, XU Xin

2024 Vol. 39 (1): 71–80

Abstract

Abstract(

751 )

HTML

HTML(

49)

PDF

PDF(8045KB)(

745

)

Development of 5 G wireless communication and low-frequency radar detection has made low- frequency electromagnetic wave radiation a serious problem today. Although research on medium and high frequency band absorbing materials is now relatively mature, designing low frequency band absorbing materials remains a major challenge. Here, we designed a low-band composite absorbing material of 0.5-3 GHz based on the quarter-wavelength cancellation mechanism. A CIPs@Mn0.8Zn0.2Fe2O4-CNTs ternary composites were prepared by using a simple one-step hydrothermal method, which involved growing ferrite on the surface of carbonyl iron powder and carbon nanotubes. The influence of carbon nanotube content on the absorption peak frequency of the material was investigated. Experimental results show that carbon nanotubes enhances the material's attenuation coefficient by introducing additional interfacial polarization, dipole polarization and other loss mechanisms. Furthermore, coupling of high dielectric and high permeability enables the material to achieve better impedance matching in the low frequency band based on the quarter-wavelength cancellation mechanism. At a thickness of 4 mm, the reflection loss of the samples was obtained at 2.11 GHz and 1.75 GHz, with a -10 dB bandwidth of 1.70-2.70 GHz and 1.40-2.20 GHz, respectively. The composites exhibit excellent low-frequency absorption performance, endowing it highly suitable for applications helped by its simple preparation process and well low-frequency absorption. This research provides a new method for developing more effective low-frequency absorbing materials.

|

|

|

Graphene Based Mesoporous Manganese-Cerium Oxides Catalysts: Preparation and Low-temperature Catalytic Reduction of NO

WANG Yanli, QIAN Xinyi, SHEN Chunyin, ZHAN Liang

2024 Vol. 39 (1): 81–89

Abstract

Abstract(

543 )

HTML

HTML(

51)

PDF

PDF(2281KB)(

880

)

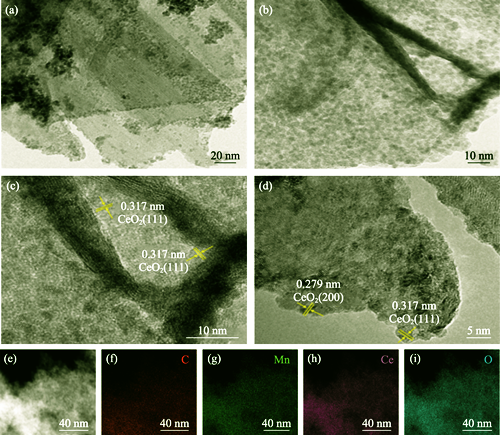

Manganese and cerium oxides are extensively used for selective catalytic reduction (SCR) in denitrification reaction due to their high redox ability and excellent low-temperature SCR activities. However, these catalysts still face problems such as easy aggregation of active components and low specific surface area, which restricts the enhancement of catalytic activity. Here, graphene based SiO2 nanocomposites (G@SiO2) with mesoporous structure was used as the template to prepare series of graphene based mesoporous manganese-cerium oxides (G@MnOx-CeO2) catalysts by hydrothermal method. The obtained catalysts were investigated for selective catalytic reduction (SCR) of NO at low temperature (100-300 ℃). The results indicate that G@MnOx-CeO2 catalyst exhibits better SCR activity than graphene based cerium oxides (G@CeO2). With the mass ratio of Mn and Ce to G@SiO2 of 0.35 and 0.90, respectively, the G@Mn(0.35)Ce(0.9) catalyst shows the best NO removal activity with the maximum conversion of 80% at 220 ℃. It is found that the addition of appropriate amount of MnOx increases specific surface area and pore volume but decreases crystallinity of the catalyst G@MnOx-CeO2. Furthermore, MnOx and CeO2 are uniformly distributed on the surface of graphene sheets in the form of nanoparticles. In addition, partial replaced Ce atoms is actually doped with Mn atoms into the structure of CeO2 to form MnOx-CeO2 solid solution, resulting in higher percentage of Mn3+and Mn4+ with higher valance states and Ce4+, and higher concentration of surface chemisorbed oxygen on the surface. These results contribute to higher SCR activity of the G@Mn(0.35)Ce(0.9) catalyst. This work provides promising basic data for the practical application of MnOx-CeO2 based catalysts in low temperature NH3-SCR.

|

|

|

pH Responsive Copper-Doped Mesoporous Silica Nanocatalyst for Enhanced Chemo-Chemodynamic Tumor Therapy

HE Qian, TANG Wanlan, HAN Bingkun, WEI Jiayuan, LÜ Wenxuan, TANG Zhaomin

2024 Vol. 39 (1): 90–98

Abstract

Abstract(

710 )

HTML

HTML(

41)

PDF

PDF(5994KB)(

3149

)

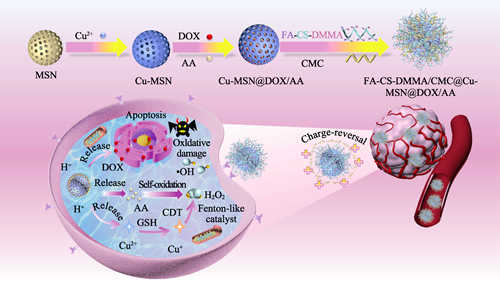

Chemodynamic therapy (CDT) uses endogenous H2O2 of tumor cells to react with Fenton catalysts to generate highly toxic hydroxyl radical (•OH), thereby killing cancer cells. However, the insufficient endogenous H2O2 and low transport efficiency of nanoparticles result in unsatisfactory anticancer efficacy. Here, we successfully synthesized a Cu2+ doped mesoporous silica nanoparticles (Cu-MSN) with excellent dispersity and small size. After loaded with doxorubicin (DOX) and ascorbate (AA), Cu-MSN was coated with folic acid (FA), dimethyl maleic anhydride (DMMA) modified chitosan (FA-CS-DMMA) and carboxymethyl chitosan (CMC) to obtain a pH responsive targeted nanocatalyst FCDC@Cu-MSN@DA. SEM images showed that particle size of FCDC@Cu-MSN@DA was about 100 nm. After 48 h in vitro, cumulative amount of Cu2+ release reached 80% and DOX release was about 57.3% in the acidic environment. After oxidation of AA, the produced exogenous H2O2 induced Cu2+ to catalytic the Fenton-like reaction, which enhanced the therapeutic effect of tumor chemodynamic therapy (CDT). Cell experiments in vitro demonstrated that FCDC@Cu-MSN@DA exhibited excellent anticancer ability in the combination of CDT and chemotherapy. This multifunctional nanocatalyst has great potential application in cancer therapy in the future.

|

|

|

Self-polarization Achieved by Compositionally Gradient Doping in BiFeO3 Thin Films

DAI Le, LIU Yang, GAO Xuan, WANG Shuhao, SONG Yating, TANG Mingmeng, DMITRY V Karpinsky, LIU Lisha, WANG Yaojin

2024 Vol. 39 (1): 99–106

Abstract

Abstract(

725 )

HTML

HTML(

48)

PDF

PDF(8205KB)(

823

)

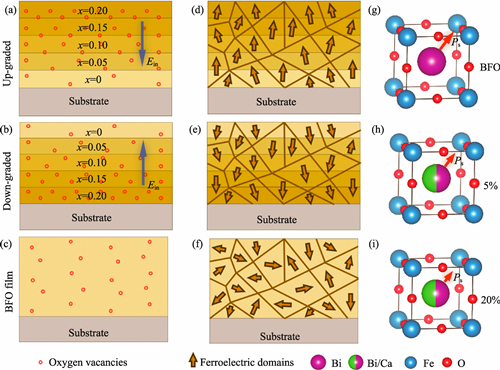

BiFeO3 is a highly promising lead-free ferroelectric material, surpassing most conventional ferroelectric materials in terms of the polarization and Curie temperature, offering a pathway for potential applications at elevated temperatures. Nevertheless, challenges arise due to strong clamping effect of substrate, large coercive fields, and high leakage currents, causing BiFeO3 films difficult to be polarized. The implementation of self-polarization presents a viable solution. Herein, we prepared BiFeO3, up-graded films (which transition from BiFeO3 to Bi0.80Ca0.20FeO2.90 from the substrate to the film surface), and down-graded films (which transition from Bi0.80Ca0.20FeO2.90 to BiFeO3 from the substrate to the film surface) using the Sol-Gel method on Pt(111)/Ti/SiO2/Si substrates. After directional distribution of defects within the film being carefully modulated, the BiFeO3 films are self-polarization when induced by build-in electric field. Piezoresponse force microscopy show that the up-graded and down-graded self-polarization behavior can be modulated by gradient direction of Ca in BiFeO3 thin films. Moreover, diode-like current-voltage signature verifies the composition gradient-induced self-polarization. The X-ray photoelectron spectroscopy results indicate that the polarization orientation mechanism may arise from the internal electric field attributed to the gradient distribution of oxygen vacancy. This work provides a new strategy to achieve self-polarization in ferroelectric thin films, as well potential novel application in improving the performance of photovoltaic or photosensitive devices as assisted by internal field via self-aligned ferroelectric polarization.

|

|

|

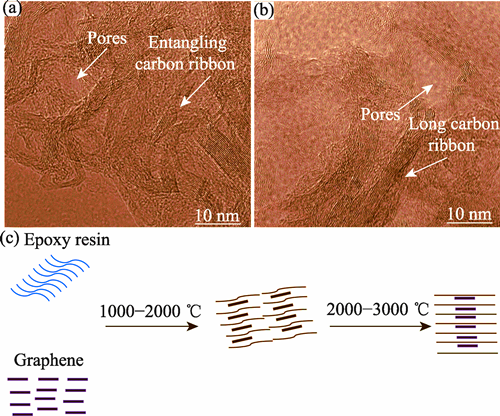

Effect of Graphene on Graphitization, Electrical and Mechanical Properties of Epoxy Resin Carbon Foam

YANG Pingjun, LI Tiehu, LI Hao, DANG Alei

2024 Vol. 39 (1): 107–112

Abstract

Abstract(

571 )

HTML

HTML(

43)

PDF

PDF(1419KB)(

1352

)

Epoxy resin (EP CF) carbon foam is a new carbon material with a three-dimensional sponge-like structure. The EP CF has high porosity, high temperature resistance, corrosion resistance, and adjustable electrical/thermal conductivity, which possesses broad application prospects. However, epoxy resin is difficult to graphitize. Therefore, graphene was used as a heterogeneous nucleation modifier to improve the graphitization degree, electrical conductivity and mechanical properties of EP CF. Graphene modified EP CF was prepared by a simple process of foaming, carbonizing, and graphitizing. Graphene as heterogeneous nucleation agent induce the carbon crystallite growth in EP CF, which increases the lattice fringe length and reduces carbon crystal tangled. The results show that the interplanar spacing (d002), grain stacking height (Lc) and graphitization degree (g) of 0 and 0.05% (in mass) graphene modified EP CF are 0.343 nm, 3.35 nm and 8.42%, 0.342 nm, 10.22 nm and 23.2%, respectively. In addition, graphene as a nucleation site affects the average cell size of EP CF. With the increase of graphene content, the average cell size of EP CF decreases firstly and then increases. Meanwhile, graphene increases the ordered structure of EP CF and improves its conductivity. When graphene is 0.05% (in mass), the conductivity of EP CF is 53.8 S·m-1. Compared with pure EP CF (compressive strain of 0.0096%), the compressive strains of 0.01%, 0.02%, 0.05%, and 0.1% (in mass) graphene modified EP CF increases to 0.208%, 0.228%, 0.187%, and 0.1146%, respectively. This study provides new research method for the preparation, carbon structure control, and properties of carbon nanomaterial/carbon foam.

|

|