Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (8): 971-977.DOI: 10.15541/jim20230039

Special Issue: 【生物材料】骨骼与齿类组织修复(202506)

Previous Articles Next Articles

NI Xiaoshi( ), LIN Ziyang, QIN Muyan, YE Song(

), LIN Ziyang, QIN Muyan, YE Song( ), WANG Deping(

), WANG Deping( )

)

Received:2023-01-20

Revised:2023-02-27

Published:2023-08-20

Online:2023-03-17

Contact:

YE Song, associate professor. E-mail: yesong@tongji.edu.cn;About author:NI Xiaoshi (1997-), female, Master candidate. E-mail: 2030638@tongji.edu.cn

Supported by:CLC Number:

NI Xiaoshi, LIN Ziyang, QIN Muyan, YE Song, WANG Deping. Bioactivity and Mechanical Property of PMMA Bone Cement: Effect of Silanized Mesoporous Borosilicate Bioglass Microspheres[J]. Journal of Inorganic Materials, 2023, 38(8): 971-977.

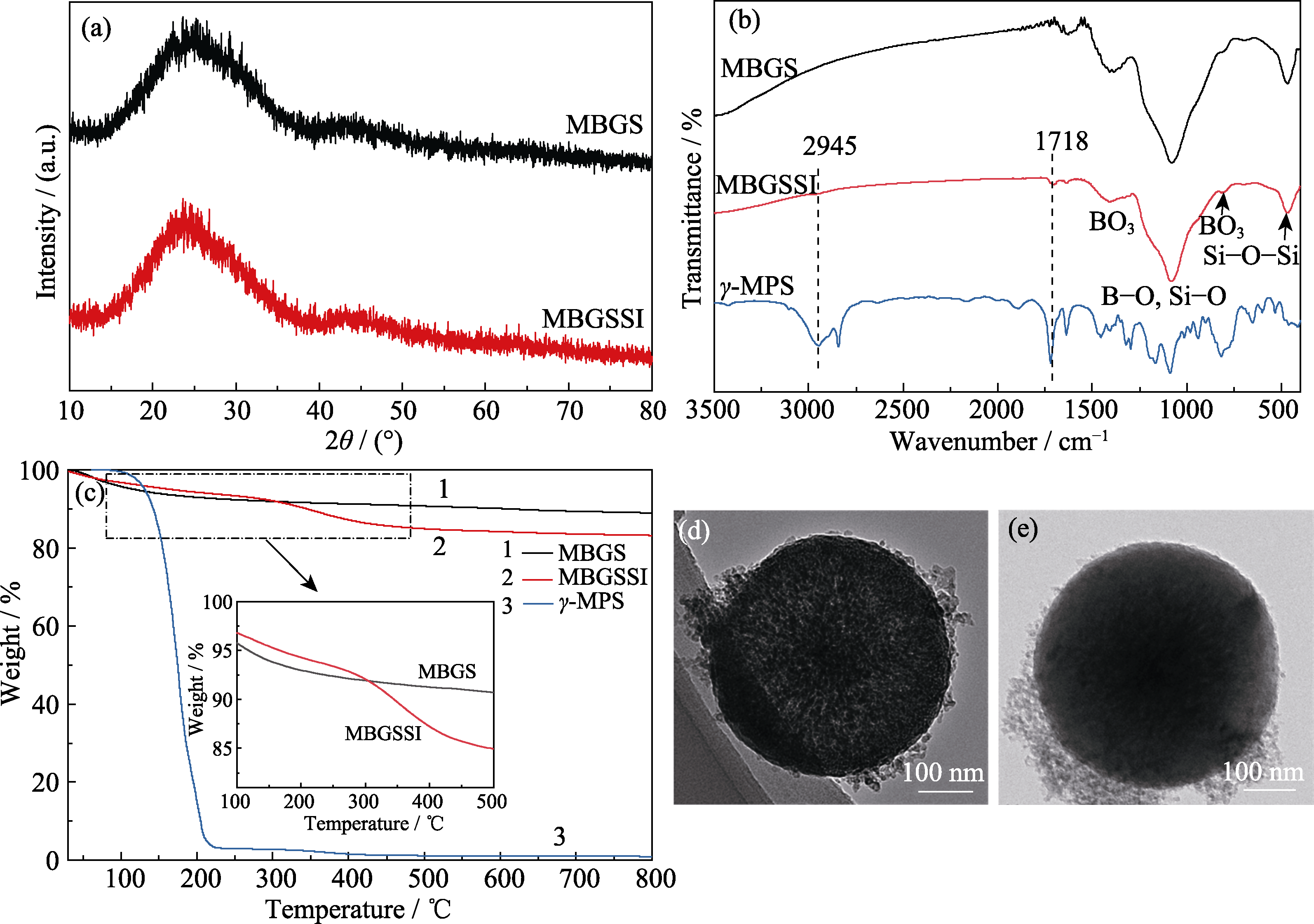

Fig. 1 Microstructures and constituents of MBGS and MBGSSI (a) XRD patterns of MBGS and MBGSSI; (b, c) FT-IR spectra (b) and TG curves (c) of MBGS, MBGSSI and γ-MPS; (d, e) TEM images of MBGS (d) and MBGSSI (e)

Fig. 2 (a) N2 adsorption-desorption isotherms and (b) corresponding pore size distributions of MBGS, and (c) schematic diagram of the surface silanization

| Sample | Specific surface area/(m2•g-1) | Average pore diameter/nm | Total pore volume/(mL•g-1) |

|---|---|---|---|

| MBGS | 84.047 | 33.9676 | 0.7137 |

| MBGSSI | 227.856 | 10.22 | 0.5822 |

Table 1 Specific surface area, average pore diameter and total pore volume of MBGS and MBGSSI

| Sample | Specific surface area/(m2•g-1) | Average pore diameter/nm | Total pore volume/(mL•g-1) |

|---|---|---|---|

| MBGS | 84.047 | 33.9676 | 0.7137 |

| MBGSSI | 227.856 | 10.22 | 0.5822 |

| Sample | C1s/% | O1s/% | Si2p/% | B1s/% | Ca2p/% |

|---|---|---|---|---|---|

| MBGS | 5.02 | 72.38 | 5.27 | 2.71 | 14.62 |

| MBGSSI 0 nm | 7.91 | 70.26 | 5.68 | 2.27 | 13.88 |

| MBGSSI 100 nm | 5.32 | 68.88 | 6.81 | 2.25 | 16.74 |

Table 2 Atomic concentrations of MBGS, MBGSSI and MBGSSI (etching depth at 100 nm)

| Sample | C1s/% | O1s/% | Si2p/% | B1s/% | Ca2p/% |

|---|---|---|---|---|---|

| MBGS | 5.02 | 72.38 | 5.27 | 2.71 | 14.62 |

| MBGSSI 0 nm | 7.91 | 70.26 | 5.68 | 2.27 | 13.88 |

| MBGSSI 100 nm | 5.32 | 68.88 | 6.81 | 2.25 | 16.74 |

| Sample | Dough time/s | Setting time/min | Peak temperature/℃ | Compressive strength/MPa | Compressive modulus/MPa | Flexural strength/MPa | Flexural modulus/MPa |

|---|---|---|---|---|---|---|---|

| PMMA | 287.5±7.8 | 11.38±0.37 | 49.15±1.45 | 70.01±1.85 | 878.67±55.84 | 67.75±1.88 | 2925.05±144.71 |

| MBGS/PMMA | 136.0±2.8 | 14.77±0.07 | 40.65±0.25 | 71.22±2.20 | 1029.66±63.54 | 44.53±2.59 | 4003.19±125.79 |

| MBGSSI/PMMA | 174.0±5.7 | 18.97±0.20 | 38.40±0.4 | 81.77±1.45 | 1091.50±75.64 | 59.42±4.34 | 3330.03±214.02 |

Table 3 Setting and mechanical properties of PMMA, MBGS/PMMA and MBGSSI/PMMA bone cements

| Sample | Dough time/s | Setting time/min | Peak temperature/℃ | Compressive strength/MPa | Compressive modulus/MPa | Flexural strength/MPa | Flexural modulus/MPa |

|---|---|---|---|---|---|---|---|

| PMMA | 287.5±7.8 | 11.38±0.37 | 49.15±1.45 | 70.01±1.85 | 878.67±55.84 | 67.75±1.88 | 2925.05±144.71 |

| MBGS/PMMA | 136.0±2.8 | 14.77±0.07 | 40.65±0.25 | 71.22±2.20 | 1029.66±63.54 | 44.53±2.59 | 4003.19±125.79 |

| MBGSSI/PMMA | 174.0±5.7 | 18.97±0.20 | 38.40±0.4 | 81.77±1.45 | 1091.50±75.64 | 59.42±4.34 | 3330.03±214.02 |

| [1] |

SHRIDHAR P, CHEN Y, KHALIL R, et al. A review of PMMA bone cement and intra-cardiac embolism. Materials, 2016, 9(10): 821.

DOI URL |

| [2] | GLADIUS L. Alternative acrylic bone cement formulations for cemented arthroplasties: present status, key issues, and future prospects. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2008, 84(2): 301. |

| [3] |

ZHU J J, JIANG G Q, QIU Z Y, et al. Modification of poly(methyl methacrylate) bone cement for vertebroplasty. Journal of Biomaterials and Tissue Engineering, 2018, 8(5): 607.

DOI URL |

| [4] |

CHEN L, ZHAI D, HUAN Z G, et al. Silicate bioceramic/PMMA composite bone cement with distinctive physicochemical and bioactive properties. RSC Advances, 2015, 5(47): 37314.

DOI URL |

| [5] | SA Y, YANG F, WIJN J R D, et al. Physicochemical properties and mineralization assessment of porous polymethylmethacrylate cement loaded with hydroxyapatite in simulated body fluid. Materials Science & Engineering C, 2016, 61: 190. |

| [6] |

FERREIRA B J M L, BARROCA N B, LOPES P P, et al. Properties of novel PMMA-co-EHA bone cements filled with hydroxyapatite. Polymer Composites, 2014, 35(4): 759.

DOI URL |

| [7] |

SERGI R, BELLUCCI D, CANNILLO V. A comprehensive review of bioactive glass coatings: state of the art, challenges and future perspectives. Coatings, 2020, 10(8): 757.

DOI URL |

| [8] |

BAINO F, FIUME E, MIOLA M, et al. Bioactive Sol-Gel glasses: processing, properties, and applications. International Journal of Applied Ceramic Technology, 2018, 15(4): 841.

DOI URL |

| [9] |

LI Y, CHEN X, NING C, et al. Facile synthesis of mesoporous bioactive glasses with controlled shapes. Materials Letters, 2015, 161: 605.

DOI URL |

| [10] |

ZHONG J P, GREENSPAN D C. Processing and properties of Sol-Gel bioactive glasses. Journal of Biomedical Materials Research, 2000, 53(6): 694.

DOI URL |

| [11] | CUI X, HUANG C C, ZHANG M, et al. Enhanced osteointegration of poly(methylmethacrylate) bone cements by incorporating strontium-containing borate bioactive glass. Journal of the Royal Society Interface, 2017, 14(131): 20161057. |

| [12] |

BOLAINA-LORENZO E D, CERVANTES-UC J M, CAUICH- RODRIGUEZ J V, et al. Effect of barium sulfate surface treatments on the mechanical properties of acrylic bone cements. Polymer Bulletin, 2020, 78(3): 1.

DOI |

| [13] | DEBNATH S, RANADE R, WUNDER S L, et al. Interface effects on mechanical properties of particle-reinforced composites. Dental Materials: Official Publication of the Academy of Dental Materials, 2004, 20(7): 677. |

| [14] |

LUNG C Y K, MATINLINNA J P. Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dental Materials, 2012, 28(5): 467.

DOI URL |

| [15] |

CHANG Y C, LIN Z Y, XIE X, et al. An injectable composite bone cement based on mesoporous borosilicate bioactive glass spheres Journal of Inorganic Materials, 2020, 35(12): 1398.

DOI URL |

| [16] |

MATINLINNA J P, LUNG C Y K, TSOI J K H. Silane adhesion mechanism in dental applications and surface treatments: a review. Dental Materials, 2018, 34(1): 13.

DOI URL |

| [17] |

ALONSO L M, GARCIA-MENOCAL J A, AYMERICH M T, et al. Calcium phosphate glasses: silanation process and effect on the bioactivity behavior of glass-PMMA composites. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2014, 102(2): 205.

DOI URL |

| [18] | SALON M C B, BAYLE P A, ABDELMOULEH M, et al. Kinetics of hydrolysis and self condensation reactions of silanes by NMR spectroscopy. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2008, 312(2): 83. |

| [19] | ISO member body. International Standard. Implants for Surgery-Acrylic Resin Cements. ISO5833: 2002. Switzerland: ISO organization-(IX-ISO), 2002. |

| [20] |

LIU X, RAHAMAN M N, DAY D E. Conversion of melt-derived microfibrous borate (13-93B3) and silicate (45S5) bioactive glass in a simulated body fluid. Journal of Materials Science. Materials in Medicine, 2013, 24(3): 583.

DOI URL |

| [21] |

ALI A A, RAMMAH Y S, EL-MALLAWANY R, et al. FTIR and UV spectra of pentaternary borate glasses. Measurement, 2017, 105: 72.

DOI URL |

| [22] |

ZAGRAJCZUK B, DZIADEK M, OLEJNICZAK Z, et al. Structural and chemical investigation of the gel-derived bioactive materials from the SiO2-CaO and SiO2-CaO-P2O5 systems. Ceramics International, 2017, 43(15): 12742.

DOI URL |

| [23] |

DOU B J, HU Q, LI J J, et al. Adsorption performance of VOCs in ordered mesoporous silicas with different pore structures and surface chemistry. Journal of Hazardous Materials, 2011, 186(2/3): 1615.

DOI URL |

| [24] |

CHEN Z D, MA Y X, GOU L A, et al. Construction of caffeic acid modified porous starch as the dual-functional microcapsule for encapsulation and antioxidant property. International Journal of Biological Macromolecules, 2022, 228: 358.

DOI URL |

| [25] |

CHRISTIAN H, V B D, BRIAN Y, et al. Polymer nanocomposites having a high filler content: synthesis, structures, properties, and applications. Nanoscale, 2019, 11(11): 4653.

DOI URL |

| [26] |

ALDABIB J M, ISHAK Z A M. Effect of hydroxyapatite filler concentration on mechanical properties of poly (methyl methacrylate) denture base. SN Applied Sciences, 2020, 2: 732.

DOI |

| [27] | KINLOCH A J. Adhesion and adhesives: science and technology: London: Chapman and Hall, 1987: 171-187. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [10] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [11] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [12] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [13] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [14] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [15] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||