Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (3): 271-280.DOI: 10.15541/jim20240385

Special Issue: 【结构材料】高导热陶瓷(202506); 【结构材料】高熵陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Ziwei1,2( ), GONG Weilu1,2, CUI Haifeng1, YE Li1(

), GONG Weilu1,2, CUI Haifeng1, YE Li1( ), HAN Weijian1, ZHAO Tong1,2

), HAN Weijian1, ZHAO Tong1,2

Received:2024-08-21

Revised:2024-10-16

Published:2025-03-20

Online:2025-03-12

Contact:

YE Li, associate professor. E-mail: yeli@iccas.ac.cnAbout author:LI Ziwei (1998-), female, Master candidate. E-mail: liziwi21@iccas.ac.cn

CLC Number:

LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties[J]. Journal of Inorganic Materials, 2025, 40(3): 271-280.

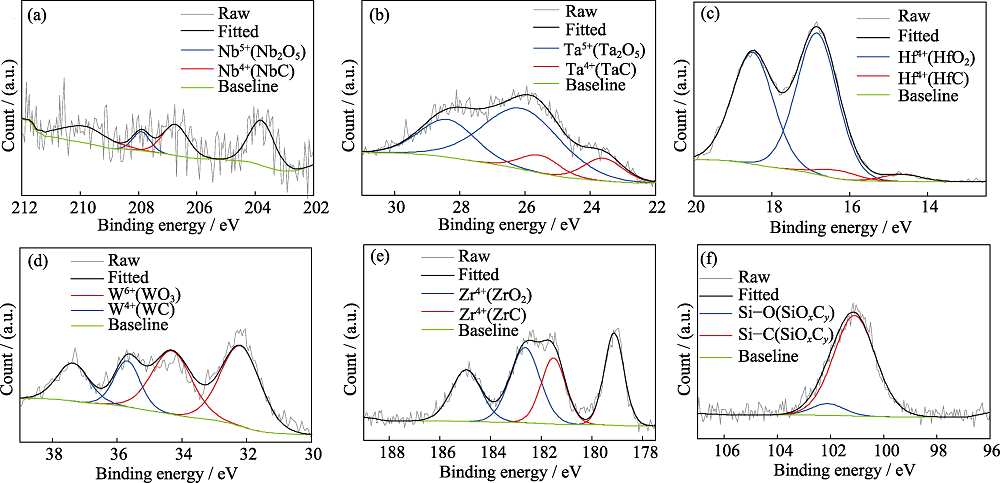

Fig. 2 XPS spectra of HEC-W5-SiCi obtained at different pyrolysis temperatures (a, b) Nb3d and Ta4f of HEC-W5-SiCi-1000; (c, d) Hf4f and W4f of HEC-W5-SiCi-1200; (e, f) Zr3d and Si2p of HEC-W5-SiCi-1400. Colorful figures are available on website

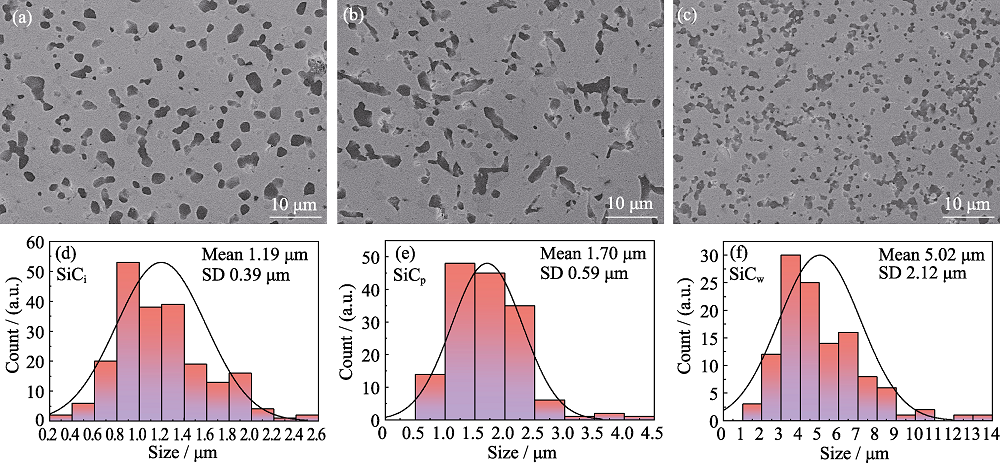

Fig. 6 (a-c) Surface SEM images and (d-f) grain size statistics of SiC in (a, d) HEC-W5-SiCi, (b, e) HEC-W5-SiCp, and (c, f) HEC-W5-SiCw bulk ceramics

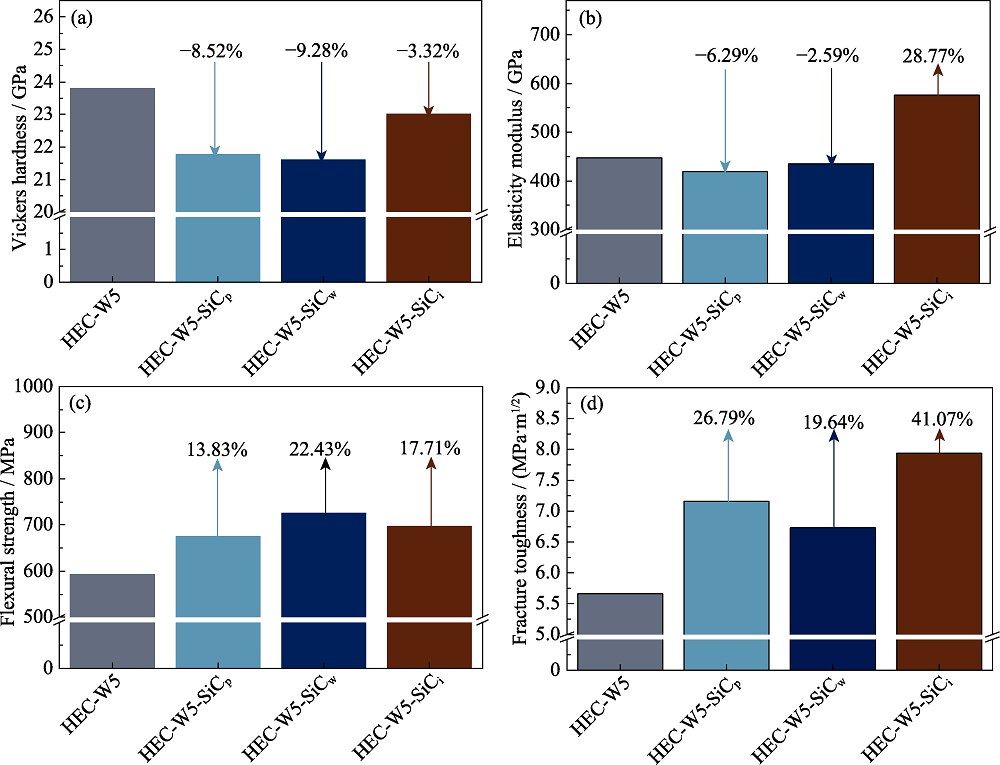

Fig. 7 Mechanical properties of HEC-W5, HEC-W5-SiCp, HEC-W5-SiCw, and HEC-W5-SiCi ceramics (a) Vickers hardness; (b) Elasticity modulus; (c) Flexural strength; (d) Fracture toughness

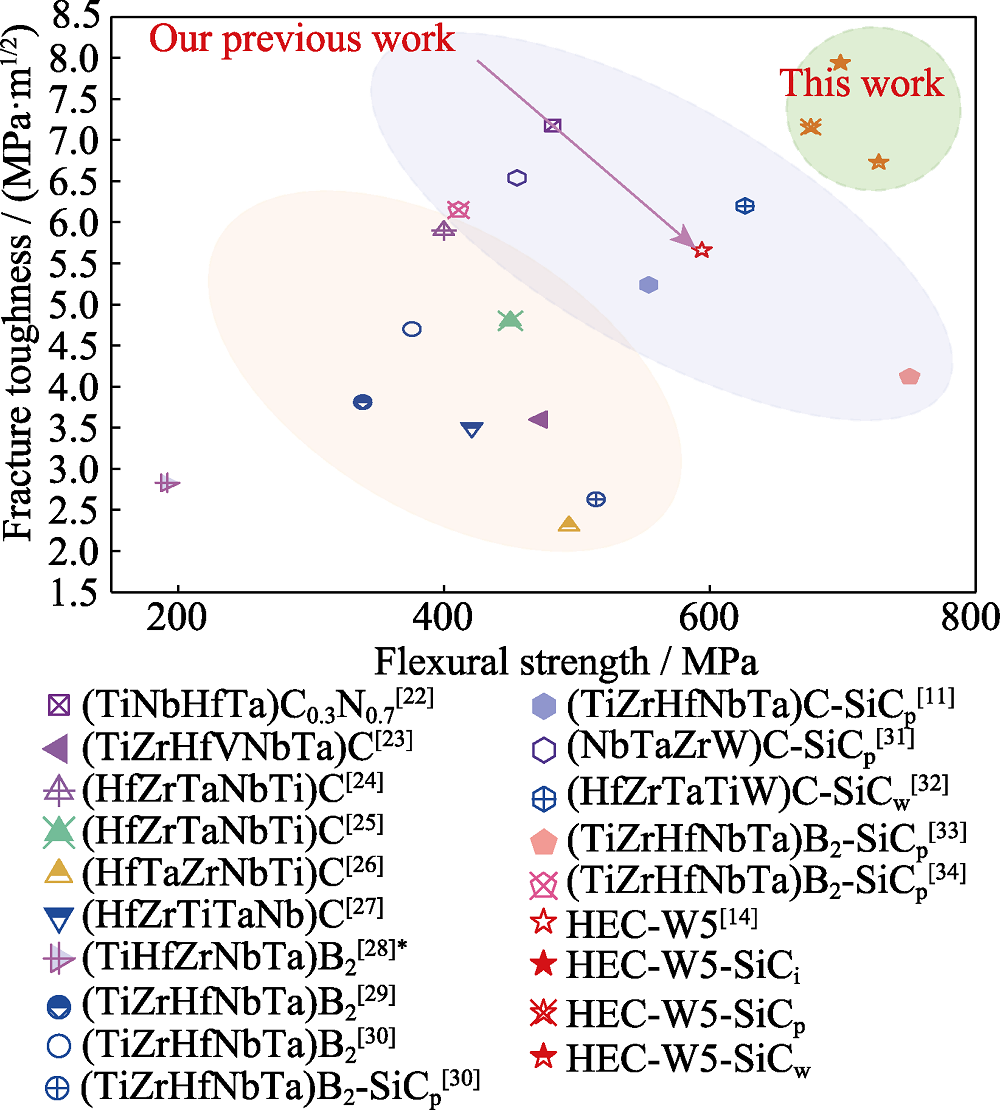

Fig. 9 Flexural strength and fracture toughness of HEC-W5- SiCi ceramics of this work and data in literature[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34] *This literature only has fracture toughness data.

| Empirical formula | Content/(%, in mass) | |||||||

|---|---|---|---|---|---|---|---|---|

| Zr | Hf | Nb | Ta | W | Si | C | O | |

| (Zr0.238Hf0.237Nb0.237Ta0.237W0.05)-Si0.347C1.405O0.031 | 13.1 | 25.6 | 13.3 | 25.9 | 5.5 | 5.9 | 10.2 | 0.3 |

Table S1 Elemental content analysis of HEC-SiCi-1600

| Empirical formula | Content/(%, in mass) | |||||||

|---|---|---|---|---|---|---|---|---|

| Zr | Hf | Nb | Ta | W | Si | C | O | |

| (Zr0.238Hf0.237Nb0.237Ta0.237W0.05)-Si0.347C1.405O0.031 | 13.1 | 25.6 | 13.3 | 25.9 | 5.5 | 5.9 | 10.2 | 0.3 |

| Sample | Vickers hardness/GPa | Elasticity modulus/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Shape factor, Y |

|---|---|---|---|---|---|

| HEC-W5 | 23.82±0.49 | 447.07±3.71 | 593±15 | 5.6±0.2 | 2.537 |

| HEC-W5-SiCp | 21.79±0.78 | 418.96±5.24 | 675±12 | 7.1±0.5 | 2.535 |

| HEC-W5-SiCw | 21.61±0.35 | 435.50±4.38 | 726±18 | 6.7±0.3 | 2.533 |

| HEC-W5-SiCi | 23.03±0.63 | 575.70±8.25 | 698±9 | 7.9±0.6 | 2.534 |

Table S2 Mechanical properties of HEC-W5, HEC-W5-SiCp, HEC-W5-SiCw, and HEC-W5-SiCi ceramics

| Sample | Vickers hardness/GPa | Elasticity modulus/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Shape factor, Y |

|---|---|---|---|---|---|

| HEC-W5 | 23.82±0.49 | 447.07±3.71 | 593±15 | 5.6±0.2 | 2.537 |

| HEC-W5-SiCp | 21.79±0.78 | 418.96±5.24 | 675±12 | 7.1±0.5 | 2.535 |

| HEC-W5-SiCw | 21.61±0.35 | 435.50±4.38 | 726±18 | 6.7±0.3 | 2.533 |

| HEC-W5-SiCi | 23.03±0.63 | 575.70±8.25 | 698±9 | 7.9±0.6 | 2.534 |

| Sample | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Ref. |

|---|---|---|---|

| (Ti0.25Nb0.25Hf0.25Ta0.25)C0.3N0.7 | 481±56b | 7.17±0.62c | [22] |

| (TiZrHfVNbTa)C | 473±21b | 3.6±0.2c | [23] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 400b | 5.9c | [24] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 450±64b | 4.8±0.2c | [25] |

| (Hf0.2Ta0.2Zr0.2Nb0.2Ti0.2)C | 494b | 2.306d | [26] |

| (Hf0.2Zr0.2Ti0.2Ta0.2Nb0.2)C | 421±27a | 3.5±0.3d | [27] |

| (Ti0.2Hf0.2Zr0.2Nb0.2Ta0.2)B2 | - | 2.83±0.15e | [28] |

| (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 | 376±25b | 4.70±0.27c | [29] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2 | 339±17a | 3.81±0.40c | [30] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 447±45a | 4.85±0.33c | [30] |

| (NbTaZrW)C-50SiCP | 455b | 6.54c | [31] |

| (HfZrTaTiW)C-1.5wt%SiCnw | 626.5b | 6.2e | [32] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 750±43b | 4.12±0.20e | [33] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 476±42b | 4.63±0.23c | [34] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-20SiCp | 554±73a | 5.24±0.41c | [11] |

| HEC-W5 | 593±15b | 5.6±0.2c | [14] |

| HEC-W5-SiCp | 675±12b | 7.1±0.5c | This work |

| HEC-W5-SiCw | 726±18b | 6.7±0.3c | This work |

| HEC-W5-SiCi | 698±9b | 7.9±0.6c | This work |

Table S3 Flexural strength and fracture toughness of HEC-W5-SiCi ceramics and previous studies[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34]

| Sample | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Ref. |

|---|---|---|---|

| (Ti0.25Nb0.25Hf0.25Ta0.25)C0.3N0.7 | 481±56b | 7.17±0.62c | [22] |

| (TiZrHfVNbTa)C | 473±21b | 3.6±0.2c | [23] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 400b | 5.9c | [24] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 450±64b | 4.8±0.2c | [25] |

| (Hf0.2Ta0.2Zr0.2Nb0.2Ti0.2)C | 494b | 2.306d | [26] |

| (Hf0.2Zr0.2Ti0.2Ta0.2Nb0.2)C | 421±27a | 3.5±0.3d | [27] |

| (Ti0.2Hf0.2Zr0.2Nb0.2Ta0.2)B2 | - | 2.83±0.15e | [28] |

| (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 | 376±25b | 4.70±0.27c | [29] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2 | 339±17a | 3.81±0.40c | [30] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 447±45a | 4.85±0.33c | [30] |

| (NbTaZrW)C-50SiCP | 455b | 6.54c | [31] |

| (HfZrTaTiW)C-1.5wt%SiCnw | 626.5b | 6.2e | [32] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 750±43b | 4.12±0.20e | [33] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 476±42b | 4.63±0.23c | [34] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-20SiCp | 554±73a | 5.24±0.41c | [11] |

| HEC-W5 | 593±15b | 5.6±0.2c | [14] |

| HEC-W5-SiCp | 675±12b | 7.1±0.5c | This work |

| HEC-W5-SiCw | 726±18b | 6.7±0.3c | This work |

| HEC-W5-SiCi | 698±9b | 7.9±0.6c | This work |

| [1] | DUBE T C, ZHANG J. Underpinning the relationship between synthesis and properties of high entropy ceramics: a comprehensive review on borides, carbides and oxides. Journal of the European Ceramic Society, 2024, 44(3): 1335. |

| [2] | YE B L, WEN T Q, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high- entropy ceramics. Acta Materialia, 2019, 170: 15. |

| [3] | YE B L, WEN T Q, HUANG K H, et al. First-principles study, fabrication, and characterization of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramic. Journal of the American Ceramic Society, 2019, 102(7): 4344. |

| [4] | MA M D, SUN Y N, WU Y J, et al. Nanocrystalline high-entropy carbide ceramics with improved mechanical properties. Journal of the American Ceramic Society, 2022, 105(1): 606. |

| [5] | YE B L, WEN T Q, CHU Y H. High-temperature oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics in air. Journal of the American Ceramic Society, 2020, 103(1): 500. |

| [6] | YE B L, WEN T Q, LIU D, et al.Oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics at 1073-1473 K in air. Corrosion Science, 2019, 153: 327. |

| [7] | WANG Y C, ZHANG B H, ZHANG C Y, et al. Ablation behaviour of (Hf-Ta-Zr-Nb)C high entropy carbide ceramic at temperatures above 2100 ℃. Journal of Materials Science & Technology, 2022, 113: 40. |

| [8] | WANG F, YAN X L, WANG T Y, et al. Irradiation damage in (Zr0.25Ta0.25Nb0.25Ti0.25)C high-entropy carbide ceramics. Acta Materialia, 2020, 195: 739. |

| [9] | CAO Z N, SUN J L, MENG L T, et al. Progress in densification and toughening of high entropy carbide ceramics. Journal of Materials Science & Technology, 2023, 161: 10. |

| [10] | RITCHIE R O. Toughening materials: enhancing resistance to fracture. Philosophical Transactions of the Royal Society A: Mathematical Physical and Engineering Sciences, 2021, 379(2203): 20200437. |

| [11] | LU K, LIU J X, WEI X F, et al. Microstructures and mechanical properties of high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C ceramics with the addition of SiC secondary phase. Journal of the European Ceramic Society, 2020, 40(5): 1839. |

| [12] | LUO S C, GUO W M, ZHOU Y Z, et al. Textured and toughened high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiCw ceramics. Journal of Materials Science & Technology, 2021, 94: 99. |

| [13] | SUN J L, ZHAO J Z, CHEN Y C, et al. Macro-micro-nano multistage toughening in nano-laminated graphene ceramic composites. Materials Today Physics, 2022, 22: 100595. |

| [14] | GONG W L, YE L, SONG R H, et al. Polymer-derived W-doping (Zr, Hf, Nb, Ta)C high entropy ceramics: preparation, properties and DFT calculation. Ceramics International, 2024, 50(5): 8284. |

| [15] | YU Y X, GUO Y D, CHENG X, et al. Pyrolysis behavior of titanium-containing polycarbosilane in air. Journal of Inorganic and Organometallic Polymers and Materials, 2010, 20(4): 714. |

| [16] | LYU Y, TANG H T, ZHAO G D. Effect of Hf and B incorporation on the SiOC precursor architecture and high-temperature oxidation behavior of SiHfBOC ceramics. Journal of the European Ceramic Society, 2020, 40(2): 324. |

| [17] | WANG X Z, ZHANG L Y, WANG Y F. Preparation of HfC-SiC ultra-high-temperature ceramics by the copolycondensation of HfC and SiC precursors. Journal of Materials Science, 2022, 57(7): 4467. |

| [18] | WU Y H, CHEN F H, HAN W J, et al. Synthesis and pyrolysis of non-oxide precursors for ZrC/SiC and HfC/SiC composite ceramics. Ceramics International, 2020, 46(14): 22102. |

| [19] | WU S B, SONG K R, SHI F Y, et al. Polymer precursor synthesis of novel ZrC-SiC ultrahigh-temperature ceramics and modulation of their molecular structure. Ceramics International, 2023, 49(1): 707. |

| [20] | RAO X H, ZHANG F H, LUO X H, et al. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Materials Science and Engineering: A, 2019, 744: 426. |

| [21] | 朱和国, 王天驰, 贾阳, 等. 复合材料原理(第2版). 北京: 电子工业出版社, 2016:55-73. |

| [22] | WANG H Y, BI J Q, YANG Y, et al. Preparation, characterization and performance of high-entropy carbonitride ceramics. Ceramics International, 2024, 50(2): 3034. |

| [23] | CHEN L, ZHANG W, TAN Y Q, et al. Influence of vanadium content on the microstructural evolution and mechanical properties of (TiZrHfVNbTa)C high-entropy carbides processed by pressureless sintering. Journal of the European Ceramic Society, 2021, 41(16): 60. |

| [24] | WANG F, ZHANG X, YAN X L, et al. The effect of submicron grain size on thermal stability and mechanical properties of high-entropy carbide ceramics. Journal of the American Ceramic Society, 2020, 103(8): 4463. |

| [25] | YU D, YIN J, ZHANG B H, et al. Pressureless sintering and properties of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics: the effect of pyrolytic carbon. Journal of the European Ceramic Society, 2021, 41(6): 3823. |

| [26] | SUN K B, YANG Z W, MU R J, et al. Densification and joining of a (HfTaZrNbTi)C high-entropy ceramic by hot pressing. Journal of the European Ceramic Society, 2021, 41(6): 3196. |

| [27] | FENG L, CHEN W T, FAHRENHOLTZ W G, et al. Strength of single-phase high-entropy carbide ceramics up to 2300 ℃. Journal of the American Ceramic Society, 2020, 104(1): 419. |

| [28] | GU J F, ZOU J, SUN S K, et al. Dense and pure high-entropy metal diboride ceramics sintered from self-synthesized powders via boro/carbothermal reduction approach. Science China Materials, 2019, 62(12): 1898. |

| [29] | QIAO L G, LIU Y, GAO Y, et al. First-principles prediction, fabrication and characterization of (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 high-entropy borides. Ceramics International, 2022, 48(12): 17234. |

| [30] | LIU J X, SHEN X Q, WU Y, et al. Mechanical properties of hot-pressed high-entropy diboride-based ceramics. Journal of Advanced Ceramics, 2020, 9(4): 503. |

| [31] | PENG F, WEI Z, SONG Q Q, et al. Simultaneous hardening and toughening of a high-entropy (NbTaZrW)C ceramic carbide using SiC particle. Journal of the American Ceramic Society, 2023, 106(7): 4443. |

| [32] | SUN J L, ZHAO J, CHEN Y, et al. Toughening in low-dimensional nanomaterials high-entropy ceramic nanocomposite. Composites Part B: Engineering, 2022, 231: 109586. |

| [33] | KOMBAMUTHU V, ÜNSAL H, CHLUP Z, et al. Effect of SiC on densification, microstructure and mechanical properties of high entropy diboride (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2. Journal of the European Ceramic Society, 2024, 106(7): 5358. |

| [34] | HUANG F L, WANG H L, FANG C, et al. Improved damage tolerance and oxidation resistance of (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) B2-SiC by introducing chopped carbon fibers. Journal of Advanced Ceramics, 2024, 13(1): 101. |

| [1] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [2] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | BAO Weichao, GUO Xiaojie, XIN Xiaoting, PENG Pai, WANG Xingang, LIU Jixuan, ZHANG Guojun, XU Fangfang. Establishment of Symbiotic Structure with Metal Atomic-layer Phase-separation in Carbide Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 17-22. |

| [8] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [9] | WANG Hao, LIU Xuechao, ZHENG Zhong, PAN Xiuhong, XU Jintao, ZHU Xinfeng, CHEN Kun, DENG Weijie, TANG Meibo, GUO Hui, GAO Pan. Performance of Lateral 4H-SiC Photoconductive Semiconductor Switches by Extrinsic Backside Trigger [J]. Journal of Inorganic Materials, 2024, 39(9): 1070-1076. |

| [10] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [11] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [12] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [13] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [14] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [15] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||