Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (7): 761-768.DOI: 10.15541/jim20230518

Special Issue: 【结构材料】超高温结构陶瓷(202506); 【结构材料】高导热陶瓷(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

WU Yuhao( ), PENG Renci, CHENG Chunyu, YANG Li(

), PENG Renci, CHENG Chunyu, YANG Li( ), ZHOU Yichun(

), ZHOU Yichun( )

)

Received:2023-11-06

Revised:2024-02-28

Published:2024-07-20

Online:2024-03-08

Contact:

ZHOU Yichun, professor. E-mail: yichunzhou@xidian.edu.cn;About author:WU Yuhao (2000-), male, Master candidate. E-mail: hsarfr@163.com

Supported by:CLC Number:

WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System[J]. Journal of Inorganic Materials, 2024, 39(7): 761-768.

| Compound | Lattice constant/Å | Ecoh/(eV·atom-1) | Emix/(eV·atom-1) |

|---|---|---|---|

| HfC | a=b=c=9.293 | -10.525 | |

| Hf0.75Ta0.25C | a=9.197, b=9.197, c=9.198 | -10.696 | -0.21 |

| Hf0.5Ta0.5C | a=9.112, b=9.108, c=9.109 | -10.842 | -0.22 |

| Hf0.25Ta0.75C | a=9.034, b=9.034, c=9.023 | -10.977 | -0.15 |

| TaC | a=b=c=8.957 | -11.102 |

Table S1 Lattice constants, cohesive enthalpy ( E c o h), and mixing enthalpy ( E m i x ) of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C and TaC

| Compound | Lattice constant/Å | Ecoh/(eV·atom-1) | Emix/(eV·atom-1) |

|---|---|---|---|

| HfC | a=b=c=9.293 | -10.525 | |

| Hf0.75Ta0.25C | a=9.197, b=9.197, c=9.198 | -10.696 | -0.21 |

| Hf0.5Ta0.5C | a=9.112, b=9.108, c=9.109 | -10.842 | -0.22 |

| Hf0.25Ta0.75C | a=9.034, b=9.034, c=9.023 | -10.977 | -0.15 |

| TaC | a=b=c=8.957 | -11.102 |

| Compound | C11/GPa | C44/GPa | C12/GPa | |||

|---|---|---|---|---|---|---|

| This work | Ren et al.[ | This work | Ren et al.[ | This work | Ren et al.[ | |

| HfC | 516.2 | 540 | 175.5 | 171 | 102.9 | 112 |

| Hf0.75Ta0.25C | 554.1 | 601 | 185.9 | 187 | 114.8 | 117 |

| Hf0.5Ta0.5C | 627.2 | 654 | 182.5 | 182 | 108.9 | 120 |

| Hf0.25Ta0.75C | 687.8 | 706 | 182.6 | 183 | 120.1 | 124 |

| TaC | 679.2 | 674 | 170.9 | 167 | 137.5 | 172 |

Table 1 Elastic constants of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC

| Compound | C11/GPa | C44/GPa | C12/GPa | |||

|---|---|---|---|---|---|---|

| This work | Ren et al.[ | This work | Ren et al.[ | This work | Ren et al.[ | |

| HfC | 516.2 | 540 | 175.5 | 171 | 102.9 | 112 |

| Hf0.75Ta0.25C | 554.1 | 601 | 185.9 | 187 | 114.8 | 117 |

| Hf0.5Ta0.5C | 627.2 | 654 | 182.5 | 182 | 108.9 | 120 |

| Hf0.25Ta0.75C | 687.8 | 706 | 182.6 | 183 | 120.1 | 124 |

| TaC | 679.2 | 674 | 170.9 | 167 | 137.5 | 172 |

Fig. 2 Mechanical properties of Hf, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC (a) Bulk modulus; (b) Shear modulus; (c) Pugh' ratio; (d) Young's modulus; (e) Hardness

Fig. 3 (a) Total density of states (TDOS) for ternary HfxTa1-xC solid solution, and partial density of states (DOS) for (b) TaC, (c) HfC, (d) Hf0.75Ta0.25C, (e) Hf0.5Ta0.5C, and (f) Hf0.25Ta0.75C Colorful figures are available on website

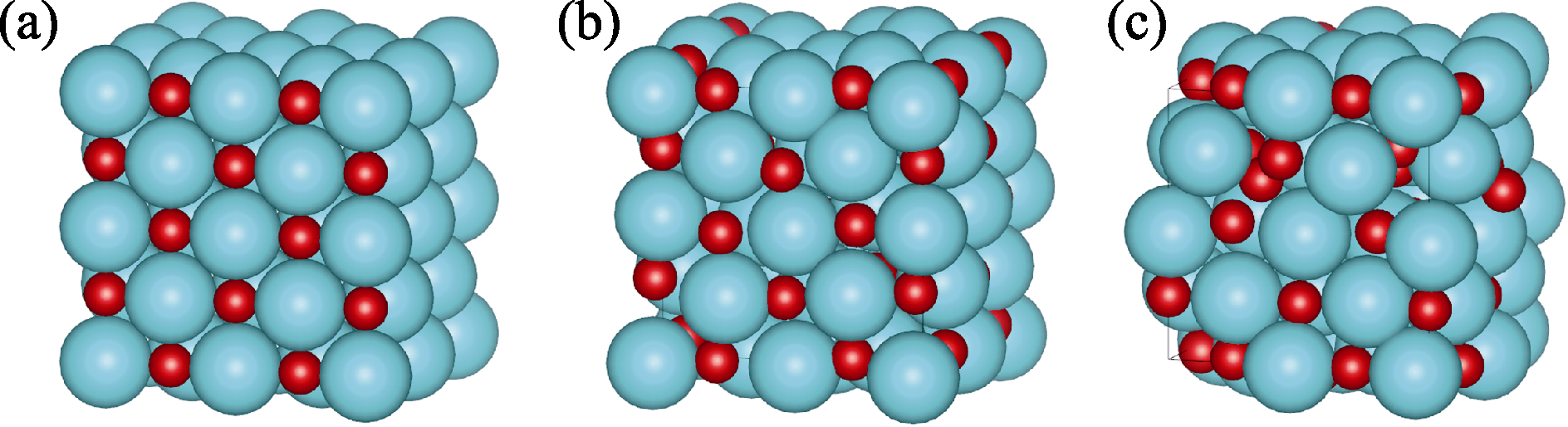

Fig. S1 Schematic diagrams of the melting process of HfC (a) Original stable crystal structure (0 ps); (b) Melting begins (0.1 ps); (c) Complete melting (2.5 ps)

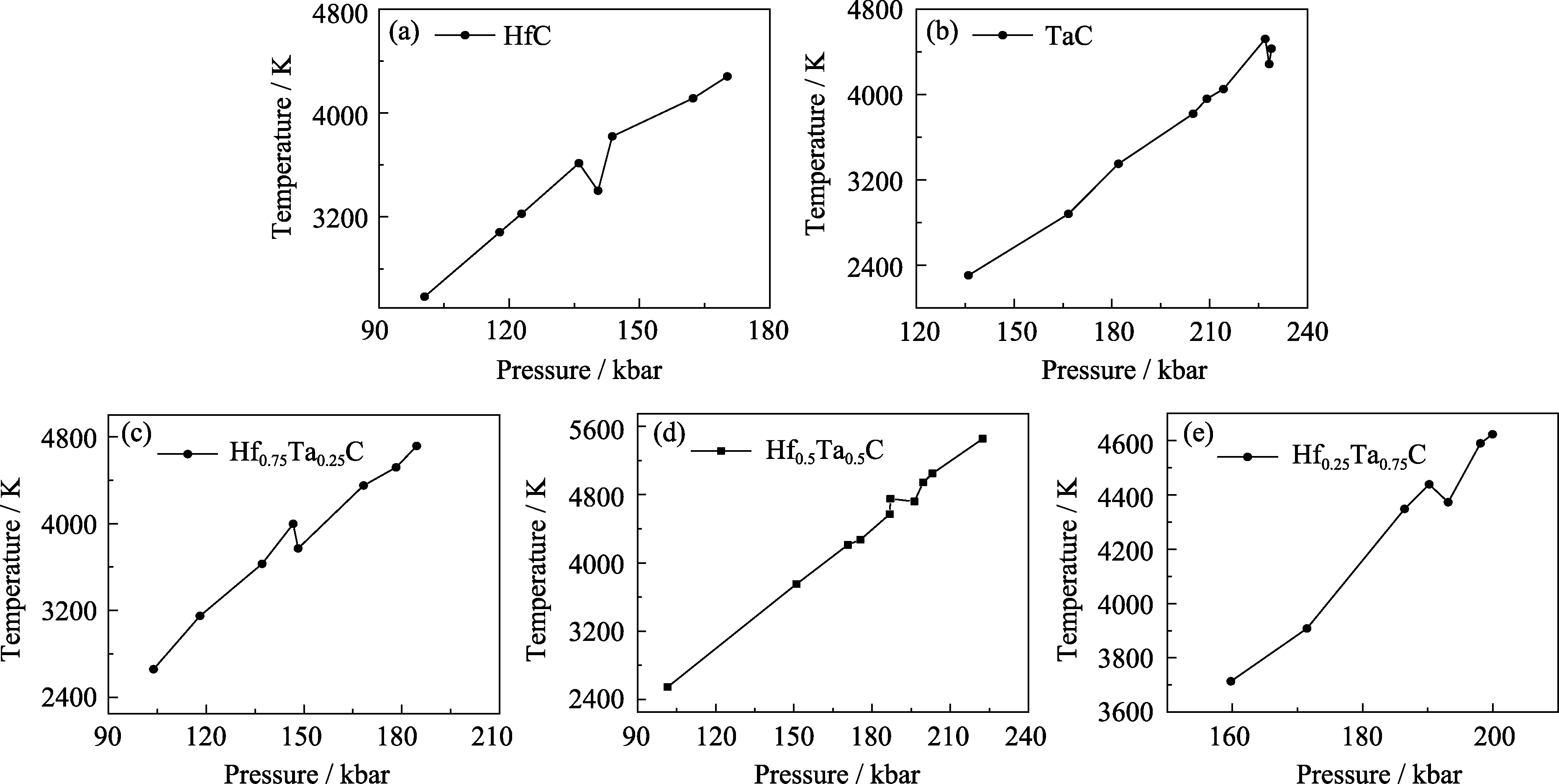

Fig. S3 Pressure-temperature isovolumetric curves during melting process The highest melting point material searched by Bayesian global optimization with deep potential molecular dynamics (a) TaC; (b) HfC; (c) Hf0.75Ta0.25C; (d) Hf0.5Ta0.5C; (e) Hf0.25Ta0.75C

| Compound | Pressure/GPa | Melting temperature/K |

|---|---|---|

| HfC | 14.05 | 3402.1 |

| Hf0.75Ta0.25C | 14.82 | 3771.8 |

| Hf0.5Ta0.5C | 19.62 | 4720.2 |

| Hf0.25Ta0.75C | 19.31 | 4373.0 |

| TaC | 22.83 | 4285.3 |

Table S2 Melting temperatures and corresponding pressures of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC

| Compound | Pressure/GPa | Melting temperature/K |

|---|---|---|

| HfC | 14.05 | 3402.1 |

| Hf0.75Ta0.25C | 14.82 | 3771.8 |

| Hf0.5Ta0.5C | 19.62 | 4720.2 |

| Hf0.25Ta0.75C | 19.31 | 4373.0 |

| TaC | 22.83 | 4285.3 |

| [1] | NI D, CHENG Y, ZHANG J, et al. Advances in ultra-high temperature ceramics, composites, and coatings. Journal of Advanced Ceramics, 2022, 11: 1. |

| [2] | FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017, 129: 94. |

| [3] | ZHANG J, ZHANG Y, FU Y, et al. Growth mechanism and ablation behavior of CVD-HfC coating on the surface of C/C composites and CVD-SiC coating. Corrosion Science, 2021, 192: 109819. |

| [4] | REN J, FENG E, ZHANG Y, et al. Influences of deposition temperature, gas flow rate and ZrC content on the microstructure and anti-ablation performance of CVD-HfC-ZrC coating. Ceramics International, 2021, 47(1): 556. |

| [5] | ZHANG M, REN X, CHU H, et al. Oxidation inhibition behaviors of the HfB2-SiC-TaSi2 coating for carbon structural materials at 1700 ℃. Corrosion Science, 2020, 177: 108982. |

| [6] | REN X, CHU H, WU K, et al. Effect of the ZrB2 content on the oxygen blocking ability of ZrB2-SiC coating at 1973 K. Journal of the European Ceramic Society, 2021, 41(2): 1059. |

| [7] | KE Y, CHEN Y I. Mechanical properties, bonding characteristics, and thermal stability of magnetron-sputtered HfNx films. Surface and Coatings Technology, 2020, 388: 125575. |

| [8] | CEDILLOS-BARRAZA O, GRASSO S, Al N N, et al. Sintering behaviour, solid solution formation and characterisation of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. Journal of the European Ceramic Society, 2016, 36(7): 1539. |

| [9] | ANDRIEVSKII R A, STREL'NIKOVA N S, POLTORATSKII N I, et al. Melting point in systems ZrC-HfC, TaC-ZrC, TaC-HfC. Soviet Powder Metallurgy and Metal Ceramics, 1967, 6: 65. |

| [10] | SMITH C J, YU X X, GUO Q, et al. Phase, hardness, and deformation slip behavior in mixed HfxTa1-xC. Acta Materialia, 2018, 145: 142. |

| [11] | ZHANG Y, LI S, LI N, et al. Experimental and theoretical study on electronic structure and mechanical property of TaxHf1-xC. Journal of Alloys and Compounds, 2021, 884: 161040. |

| [12] | KIM J, KIM M, ROH K M, et al. Bond characteristics, mechanical properties, and high-temperature thermal conductivity of (Hf1-xTax)C composites. Journal of the American Ceramic Society, 2019, 102(10): 6298. |

| [13] | ZUNGER A, WEI S H, FERREIRA L G, et al. Special quasirandom structures. Physical Review Letters, 1990, 65(3): 353. |

| [14] | PENG J, TIKHONOV E. Improving the mechanical properties of HfC-based ceramics by exploring composition space of Hf1-xTaxC and HfC1-xNx. Computational Materials Science, 2021, 195: 110464. |

| [15] | HONG Q J, VAN D W A. Prediction of the material with highest known melting point from ab initio molecular dynamics calculations. Physical Review B, 2015, 92(2): 020104. |

| [16] | AGTE C, ALTERTHUM H. Untersuchungen über systeme hochschmelzender carbide: nebst beiträgen zum problem der kohlenstoffschmelzung. Z. Tech. Physik, 1930, 11: 182. |

| [17] | RUDY E. Ternary phase equilibria in transition metal-boron- carbon-silicon systems: part V. Compendium of phase diagram data. USA: Air Force Materials Laboratory, 1969. |

| [18] | WANG Y N, WEN B, JIAO J J, et al. The highest melting point material: searched by Bayesian global optimization with deep potential molecular dynamics. Journal of Advanced Ceramics, 2023, 12(4): 803. |

| [19] | BELONOSHKO A B, SKORODUMOVA N V, ROSENGREN A, et al. Melting and critical superheating. Physical Review B, 2006, 73(1): 012201. |

| [20] | BELONOSHKO A B, DAVIS S, SKORODUMOVA N V, et al. Properties of the fcc Lennard-Jones crystal model at the limit of superheating. Physical Review B, 2007, 76(6): 064121. |

| [21] | GONZÁLEZ-CATALDO F, CORVACHO F, GUTIÉRREZ G. Melting curve of Si by means of the Z-method. Journal of Physics: Conference Series, 2018, 1043(1): 012038. |

| [22] | FOMIN Y D. Melting line and thermodynamic properties of a supeionic compound SrCl2 by molecular dynamics simulation. Physics and Chemistry of Liquids, 2022, 60(1): 59. |

| [23] | CUI C, XIAN J, LIU H, et al. Melting curve of magnesium up to 460 GPa from ab initio molecular dynamics simulations. Journal of Applied Physics, 2022, 131(19): 195901. |

| [24] | KRESSE G, FURTHMÜLLER J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane- wave basis set. Computational Materials Science, 1996, 6(1): 15. |

| [25] | KRESSE G, FURTHMÜLLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Physical review B, 1996, 54(16): 11169. |

| [26] | KRESSE G, JOUBERT D. From ultrasoft pseudopotentials to the projector augmented-wave method. Physical Review B, 1999, 59(3): 1758. |

| [27] | BLÖCHL P E. Projector augmented-wave method. Physical Review B, 1994, 50(24): 17953. |

| [28] | PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple. Physical Review Letters, 1996, 77(18): 3865. |

| [29] | PERDEW J P, RUZSINSZKY A, CSONKA G I, et al. Restoring the density-gradient expansion for exchange in solids and surfaces. Physical Review Letters, 2008, 100(13): 136406. |

| [30] | TIAN L Y, HU Q M, YANG R, et al. Elastic constants of random solid solutions by SQS and CPA approaches: the case of fcc Ti-Al. Journal of Physics: Condensed Matter, 2015, 27(31): 315702. |

| [31] | VOIGT W. Lehrbuch der kristallphysik. Leipzig: BG Teubner, 1928. |

| [32] | REUSS A. Calculation of the flow limits of mixed crystals on the basis of the plasticity of monocrystals. Zeitschrift fur Angewandte Mathematik und Mechanik, 1929, 9: 49. |

| [33] | HILL R. The elastic behaviour of a crystalline aggregate. Proceedings of the Physical Society. Section A, 1952, 65(5): 349. |

| [34] | PUGH S F. XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1954, 45(367): 823. |

| [35] | CHEN X Q, NIU H, LI D, et al. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics, 2011, 19(9): 1275. |

| [36] | DRONSKOWSKI R, BLÖCHL P E. Crystal orbital Hamilton populations (COHP): energy-resolved visualization of chemical bonding in solids based on density-functional calculations. Journal of Physical Chemistry, 1993, 97(33): 8617. |

| [37] | JHI S H, IHM J, LOUIE S G, et al. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature, 1999, 399(6732): 132. |

| [38] | FINE M E, BROWN L D, MARCUS H L. Elastic constants versus melting temperature in metals. Scripta Metallurgica, 1984, 18(9): 951. |

| [39] | WANG S L, PAN Y. Insight into the structures, melting points, and mechanical properties of NbSi2 from first-principles calculations. Journal of the American Ceramic Society, 2019, 102(8): 4822. |

| [40] | LIU S Y, ZHANG S, LIU S, et al. Phase stability, mechanical properties and melting points of high-entropy quaternary metal carbides from first-principles. Journal of the European Ceramic Society, 2021, 41(13): 6267. |

| [41] | 张硕鑫, 刘士余, 严达利, 等. Ta1-xHfxC和Ta1-xZrxC固溶体的结构稳定性和力学性质的第一性原理研究. 物理学报, 2021, 70(11): 308. |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [5] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [6] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [7] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [8] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [9] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [10] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [11] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [12] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [13] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [14] | ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao. Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance [J]. Journal of Inorganic Materials, 2024, 39(6): 715-725. |

| [15] | ZHANG Yuchen, LU Zhiyao, HE Xiaodong, SONG Guangping, ZHU Chuncheng, ZHENG Yongting, BAI Yuelei. Predictions of Phase Stability and Properties of S-group Elements Containing MAX Borides [J]. Journal of Inorganic Materials, 2024, 39(2): 225-232. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||