Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (7): 754-760.DOI: 10.15541/jim20230582

• RESEARCH ARTICLE • Previous Articles Next Articles

WANG Kanglong1,2( ), YIN Jie1(

), YIN Jie1( ), CHEN Xiao1, WANG Li1, LIU Xuejian1(

), CHEN Xiao1, WANG Li1, LIU Xuejian1( ), HUANG Zhengren1,3

), HUANG Zhengren1,3

Received:2023-12-18

Revised:2024-02-17

Published:2024-07-20

Online:2024-02-22

Contact:

YIN Jie, professor. E-mail: jieyin@mail.sic.ac.cn;About author:WANG Kanglong (1999-), male, Master candidate. E-mail: wangkanglong@hnu.edu.cn

Supported by:CLC Number:

WANG Kanglong, YIN Jie, CHEN Xiao, WANG Li, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics Prepared by Selective Laser Sintering Printing Combined with Solid-phase Sintering at Atmospheric Pressure[J]. Journal of Inorganic Materials, 2024, 39(7): 754-760.

| Laser power/ W | Hatch distance/ μm | Scanning speed/ (mm·s-1) | Preheating temperature/ ℃ | Layer thickness/ mm | Energy density / (J·mm-3) |

|---|---|---|---|---|---|

| 35 | 80 | 7620 | 60 | 0.1 | 0.057 |

Table 1 Parameters for SLS printing

| Laser power/ W | Hatch distance/ μm | Scanning speed/ (mm·s-1) | Preheating temperature/ ℃ | Layer thickness/ mm | Energy density / (J·mm-3) |

|---|---|---|---|---|---|

| 35 | 80 | 7620 | 60 | 0.1 | 0.057 |

| Abbreviation | Experimental procedure |

|---|---|

| SLS-SSiC | Solid-phase sintering at atmospheric pressure after SLS |

| CIP-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP |

| CIP-PIP-1-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP followed by PIP once |

| CIP-PIP-2-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP followed by PIP twice |

| PIP-4-SSiC | Solid-phase sintering at atmospheric pressure after SLS and PIP four times |

Table 2 Abbreviations for experimental procedures

| Abbreviation | Experimental procedure |

|---|---|

| SLS-SSiC | Solid-phase sintering at atmospheric pressure after SLS |

| CIP-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP |

| CIP-PIP-1-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP followed by PIP once |

| CIP-PIP-2-SSiC | Solid-phase sintering at atmospheric pressure after SLS and CIP followed by PIP twice |

| PIP-4-SSiC | Solid-phase sintering at atmospheric pressure after SLS and PIP four times |

| Sample | Bulk density/ (g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa | Fracture toughness/(MPa·m1/2) | |

|---|---|---|---|---|---|---|

| SLS-SSiC | Gradation | 1.41 | 52.16 | 3.49 | — | — |

| D50=82 μm | 1.30 | 54.23 | 3.12 | — | — | |

| CIP-SSiC | Gradation | 2.54 | 6.37 | 136.8 | 127 | 1.98 |

| D50=82 μm | 2.29 | 10.01 | 99.4 | 111 | 1.72 | |

| CIP-PIP-1-SSiC | Gradation | 2.67 | 7.43 | 142.1 | 118 | 2.16 |

| D50=82 μm | 2.53 | 7.05 | 120.5 | 107 | 2.09 | |

| CIP-PIP-2-SSiC | Gradation | 2.69 | 7.27 | 150.3 | 106 | 2.04 |

| D50=82 μm | 2.51 | 7.59 | 123.9 | 113 | 2.11 | |

| PIP-4-SSiC | Gradation | 2.29 | 20.2 | 59.6 | 89 | 1.37 |

| D50=82 μm | 2.15 | 19.8 | 55.7 | 75 | 1.19 | |

Table 3 Effect of different processes on properties of SiC ceramics with gradation and D50=82 μm systems

| Sample | Bulk density/ (g·cm-3) | Open porosity/% | Flexural strength/MPa | Elastic modulus/GPa | Fracture toughness/(MPa·m1/2) | |

|---|---|---|---|---|---|---|

| SLS-SSiC | Gradation | 1.41 | 52.16 | 3.49 | — | — |

| D50=82 μm | 1.30 | 54.23 | 3.12 | — | — | |

| CIP-SSiC | Gradation | 2.54 | 6.37 | 136.8 | 127 | 1.98 |

| D50=82 μm | 2.29 | 10.01 | 99.4 | 111 | 1.72 | |

| CIP-PIP-1-SSiC | Gradation | 2.67 | 7.43 | 142.1 | 118 | 2.16 |

| D50=82 μm | 2.53 | 7.05 | 120.5 | 107 | 2.09 | |

| CIP-PIP-2-SSiC | Gradation | 2.69 | 7.27 | 150.3 | 106 | 2.04 |

| D50=82 μm | 2.51 | 7.59 | 123.9 | 113 | 2.11 | |

| PIP-4-SSiC | Gradation | 2.29 | 20.2 | 59.6 | 89 | 1.37 |

| D50=82 μm | 2.15 | 19.8 | 55.7 | 75 | 1.19 | |

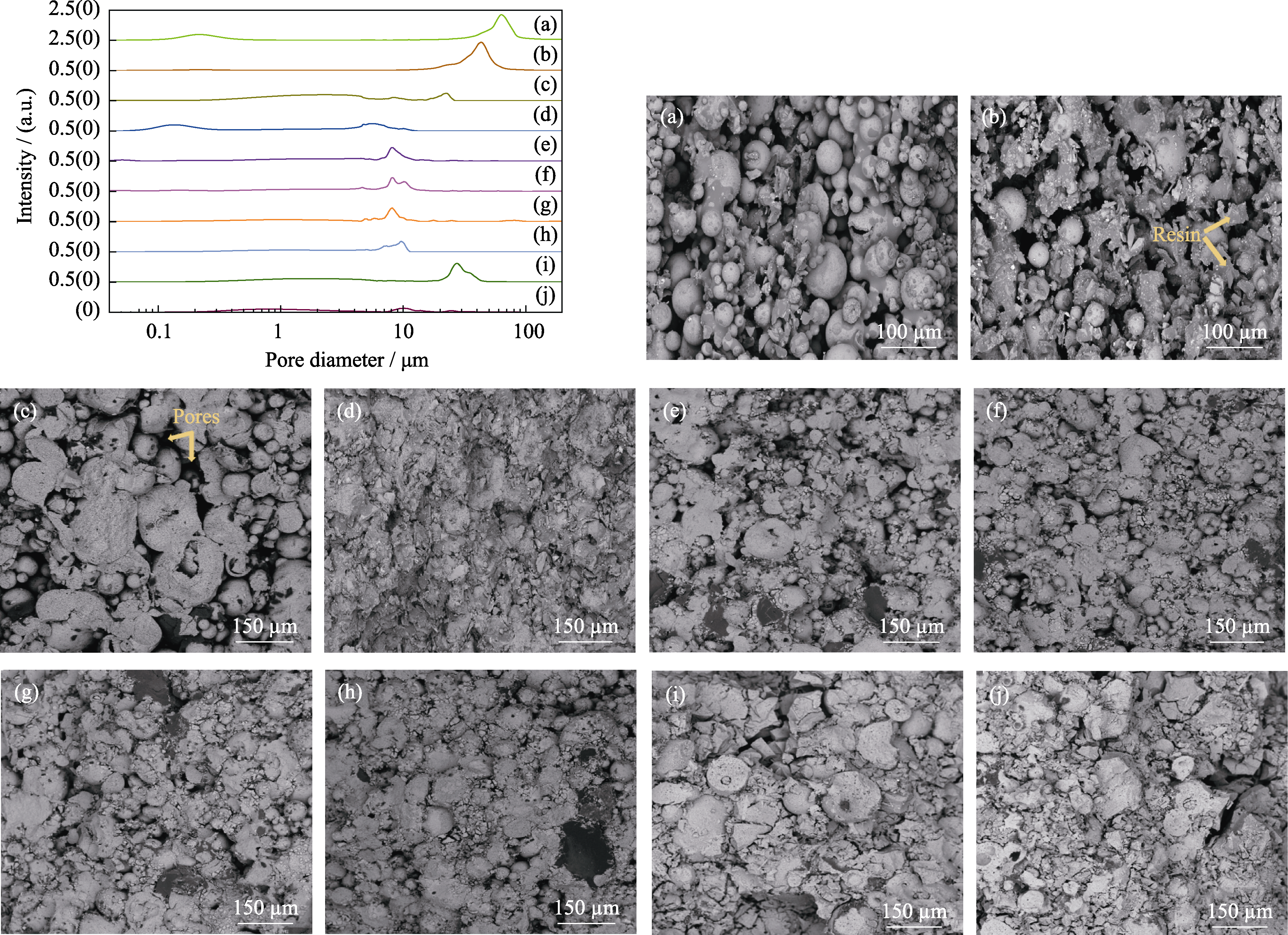

Fig. 3 Pore size distribution and corresponding SEM images of the samples D50=82 μm system: (a) SLS, (c) CIP, (e) CIP-PIP-1, (g) CIP-PIP-2, (i) PIP-4 Graded system: (b) SLS, (d) CIP, (f) CIP-PIP-1, (h) CIP-PIP-2, (j) PIP-4

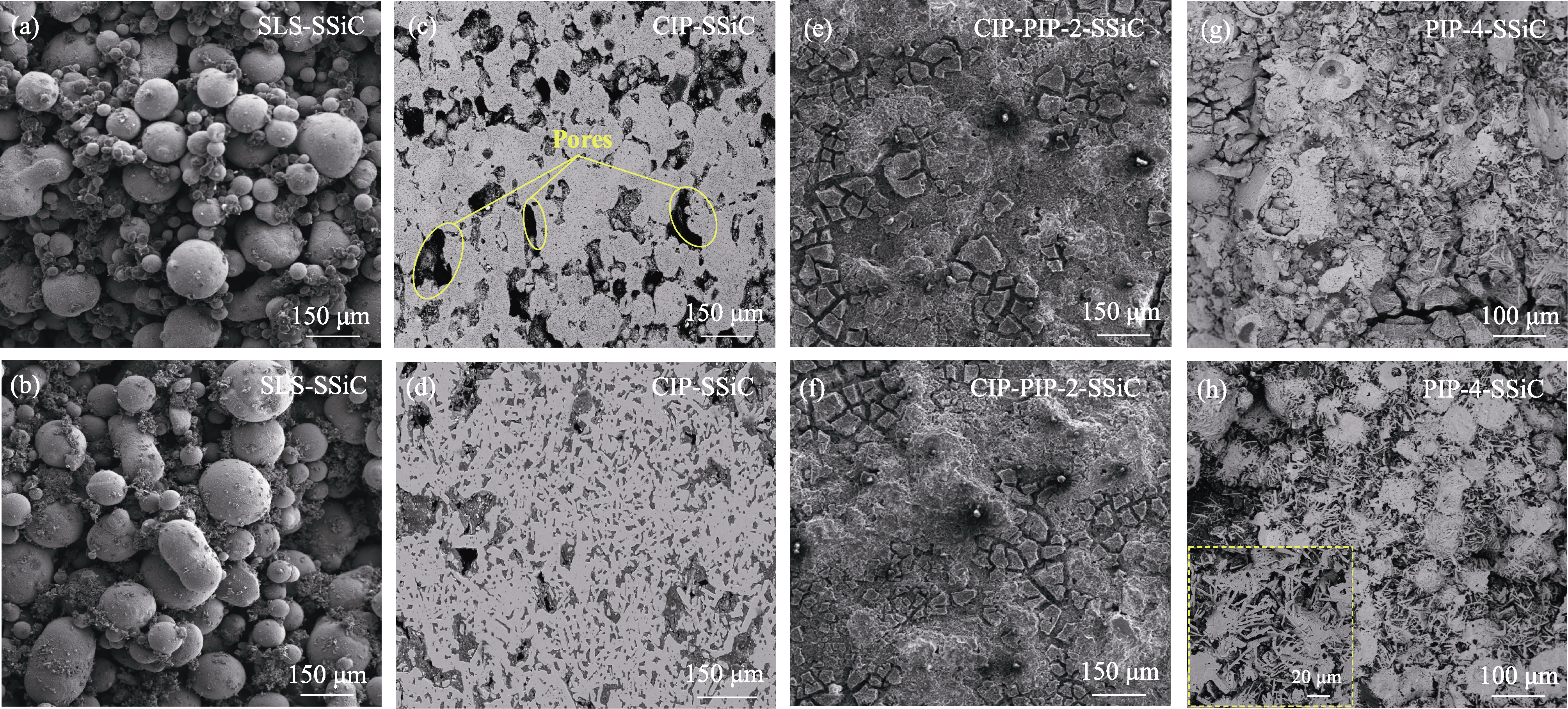

Fig. 5 SEM images of sintered bodies in each stage D50=82 μm system: (a) SLS-SSiC, (c) CIP-SSiC, (e) CIP-PIP-2-SSiC, (g) PIP-4-SSiC Graded system: (b) SLS-SSiC, (d) CIP-SSiC, (f) CIP-PIP-2-SSiC, (h) PIP-4-SSiC

| Sample | Bulk density / (g·cm-3) | Open porosity/% | Flexural strength/MPa | Ref. |

|---|---|---|---|---|

| CIP-SSiC PIP-4-SSiC | 2.67 | 6.37 | 136.8 | This work |

| 2.29 | 20.2 | 59.6 | ||

| CIP-SSiC | — | 7.02 | 56.2 | [ |

| CIP | 2.12 | 33.88 | 59.47 | [ |

| PIP-7 | — | 10 | 20 | [ |

| PIP-8 | 2.45 | 5.05 | 152.6 | [ |

Table 4 Comparison of densities and flexural strengths of SiC ceramics prepared in this work with literature reports

| Sample | Bulk density / (g·cm-3) | Open porosity/% | Flexural strength/MPa | Ref. |

|---|---|---|---|---|

| CIP-SSiC PIP-4-SSiC | 2.67 | 6.37 | 136.8 | This work |

| 2.29 | 20.2 | 59.6 | ||

| CIP-SSiC | — | 7.02 | 56.2 | [ |

| CIP | 2.12 | 33.88 | 59.47 | [ |

| PIP-7 | — | 10 | 20 | [ |

| PIP-8 | 2.45 | 5.05 | 152.6 | [ |

| [1] | KOYANAGI T, TERRANI K, HARRISON S, et al. Additive manufacturing of silicon carbide for nuclear applications. Journal of Nuclear Materials, 2021, 543: 152577. |

| [2] | WANG X, GAO X, ZHANG Z, et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. Journal of the European Ceramic Society, 2021, 41(9): 4671. |

| [3] | SINGH S, RATHI K, PAL K. Synthesis, characterization of graphene oxide wrapped silicon carbide for excellent mechanical and damping performance for aerospace application. Journal of Alloys and Compounds, 2018, 740: 436. |

| [4] | 魏华阳, 赵小玻, 徐鸿照, 等. 固含量对凝胶注模成型碳化硅陶瓷性能的影响. 现代技术陶瓷, 2016, 37(4): 296. |

| [5] | 王阳阳, 贾晨, 徐敏, 等. 注浆成型碳化硅陶瓷材料成型工艺研究. 佛山陶瓷, 2023, 33(10): 23. |

| [6] | WANG Y, CHENG Y, CHEN Y, et al. Lattice-structured SiC ceramics obtained via 3D printing, gel casting, and gaseous silicon infiltration sintering. Ceramics International, 2022, 48(5): 6488. |

| [7] | HE R, ZHOU N, ZHANG K, et al. Progress and challenges towards additive manufacturing of SiC ceramic. Journal of Advanced Ceramics, 2021, 10(4): 637. |

| [8] | BAI X, DING G, ZHANG K, et al. Stereolithography additive manufacturing and sintering approaches of SiC ceramics. Open Ceramics, 2021, 5: 100046. |

| [9] | HASSANIN H, ESSA K, ELSHAER A, et al. Micro-fabrication of ceramics: additive manufacturing and conventional technologies. Journal of Advanced Ceramics, 2021, 10(1): 1. |

| [10] | WANG K, YIN J, CHEN X, et al. Microstructure and properties of liquid phase sintered SiC ceramics fabricated via selective laser printing and precursor impregnation and pyrolysis. Ceramics International, 2024, 50(3): 4315. |

| [11] | WANG K, YIN J, CHEN X, et al. Advances on direct selective laser printing of ceramics: an overview. Journal of Alloys and Compounds, 2024, 975: 172821. |

| [12] | CHEN X, YIN J, LIU X, et al. Effect of laser power on mechanical properties of SiC composites rapidly fabricated by selective laser sintering and direct liquid silicon infiltration. Ceramics International, 2022, 48(13): 19123. |

| [13] | CHEN X, YIN J, HUANG L, et al. Microstructural tailoring, mechanical and thermal properties of SiC composites fabricated by selective laser sintering and reactive melt infiltration. Journal of Advanced Ceramics, 2023, 12(4): 830. |

| [14] | LI H, LIU Y, LIU Y, et al. Influence of sintering temperature and CVI time on mechanical properties of 3D-printed alumina ceramics. Materials Letters, 2021, 285: 129096. |

| [15] | JIN L, ZHANG K, XU T, et al. The fabrication and mechanical properties of SiC/SiC composites prepared by SLS combined with PIP. Ceramics International, 2018, 44(17): 20992. |

| [16] | ZHONG H, WANG Z, ZHOU H, et al. Properties and microstructure evolution of Cf/SiC composites fabricated by polymer impregnation and pyrolysis (PIP) with liquid polycarbosilane. Ceramics International, 2017, 43(10): 7387. |

| [17] | 张喜飞, 陈定, 顾华志, 等. 碳源对反应烧结碳化硅性能的影响. 硅酸盐通报, 2024, 43(1): 312. |

| [18] | GU X S, YIN J, WANG K L, et al. Effect of particle grading on properties of silicon carbide ceramics by binder jetting printing. Journal of Inorganic Materials, 2023, 38(12): 1373. |

| [19] | XING Y Y, WU H B, LIU X J, et al. Grain composition on solid- state-sintered SiC ceramics. Journal of Inorganic Materials, 2018, 33(11): 1167. |

| [20] | 夏思婕. 碳化硅粉末激光选区烧结/冷等静压复合工艺及其后处理研究. 武汉: 华中科技大学硕士学位论文, 2016. |

| [21] | 陈鹏, 朱小刚, 吴甲民, 等. 基于SLS/CIP工艺SiC陶瓷的制备及其性能. 材料工程, 2019, 47(3): 87. |

| [22] | PELANCONI M, COLOMBO P, ORTONA A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. Journal of the European Ceramic Society, 2021, 41(10): 5056. |

| [23] | 张坤. 基于SLS和PIP的SiCp/SiC陶瓷基复合材料成型机理及其性能研究. 哈尔滨: 哈尔滨理工大学博士学位论文, 2021. |

| [1] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [2] | GU Xuesu, YIN Jie, WANG Kanglong, CUI Chong, MEI Hui, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics by Binder Jetting Printing [J]. Journal of Inorganic Materials, 2023, 38(12): 1373-1378. |

| [3] | HUANG Yihua, HUANG Zhengren, SHA Wenhao, ZHOU Yabin, TAN Zhouxi, ZHANG Mingkang. Thick SiC Green Bodies: Degreasing Analysis and Pressureless High Density Sintering [J]. Journal of Inorganic Materials, 2023, 38(10): 1163-1168. |

| [4] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [5] | HUANG Yi-Hua, JIANG Dong-Liang, CHEN Zhong-Ming, LIU Xue-Jian, ZHANG Xian-Feng, LIAO Zhen-Kui, HUANG Zheng-Ren. Fabrication and Property of rGO/SiC Composite [J]. Journal of Inorganic Materials, 2018, 33(11): 1147-1153. |

| [6] | HU Hai-Long, ZENG Yu-Ping, ZUO Kai-Hui, XIA Yong-Feng, YAO Dong-Xu. Effect of Sintering Additive Composition on the Mechanical and Tribological Properties of Si3N4/SiC Ceramics [J]. Journal of Inorganic Materials, 2014, 29(8): 885-890. |

| [7] | LU You-Jun, WANG Yan-Min, PAN Zhi-Dong, HUANG Zhen-Kun, WU Lan-Er. Effect of Carbon Nanoparticle Content on Machinability and Wettability of Carbon/Silicon Carbide Ceramics [J]. Journal of Inorganic Materials, 2014, 29(4): 429-432. |

| [8] | LI Jia-Ke, LIU Lei, LIU Xin. Joining of SiC Ceramic by 22Ti-78Si High-temperature Eutectic Brazing Alloy [J]. Journal of Inorganic Materials, 2011, 26(12): 1314-1318. |

| [9] | TANG Hui-Yi,ZHU De-Gui,LIU Bo,SUN Hong-Liang. High Temperature Oxidation Mechanism of Ti3SiC2-64vol%SiC Ceramics [J]. Journal of Inorganic Materials, 2009, 24(4): 821-826. |

| [10] | LI Jia-Ke,LIU Lei,LIU Yi-Chun,ZHANG Wen-Long,HU Wen-Bin. Preparation of Ti-Si Eutectic Brazes and its Weldability to SiC [J]. Journal of Inorganic Materials, 2009, 24(1): 204-208. |

| [11] | DING Shu-Qiang,ZENG Yu-Ping,JIANG Dong-Liang. Preparation and Properties of In~Situ Reaction Bonded Porous SiC Ceramics [J]. Journal of Inorganic Materials, 2006, 21(6): 1397-1403. |

| [12] | YUE Zhen-Xing WANG Xian-Li ZHANG Liang-Ying YAO Xi. Preparation of Ph(Zn1/3Nb2/3)O3-based Diphasic Ceramics with X7R Character by Particle-coating Method [J]. Journal of Inorganic Materials, 1999, 14(1): 66-70. |

| [13] | WANG Chang-Xiang,ZHENG Chang-Qiong,ZHOU Xin,YIN Guang-Fu,DENG Jie,MENG Yong-Gang,WEN Shi-Zhu. Biological metion Properties and Mechanism of UHMWPE-SiC Ceramics Friction Pair [J]. Journal of Inorganic Materials, 1998, 13(6): 877-881. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||