Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (12): 1275-1280.DOI: 10.15541/jim20220294

• RESEARCH ARTICLE • Previous Articles Next Articles

WU Xishi1,2( ), ZHU Yunzhou2(

), ZHU Yunzhou2( ), HUANG Qing1, HUANG Zhengren1,2(

), HUANG Qing1, HUANG Zhengren1,2( )

)

Received:2022-05-25

Revised:2022-06-30

Published:2022-12-20

Online:2022-08-04

Contact:

ZHU Yunzhou, associate professor. E-mail: yunzhouzhu@mail.sic.ac.cn;About author:WU Xishi (1991-), male, PhD. E-mail: wuxishi@nimte.ac.cn

Supported by:CLC Number:

WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites[J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280.

| Sample | PF/% | EG/% | Pore former* | Residual carbon**/% | Average pore size/nm | Bulk density/(g·cm-3) |

|---|---|---|---|---|---|---|

| 1 | 50 | 50 | FeCl2 (1%) | 23+1.1 | 190±15 | 0.73±0.01 |

| 2 | 50 | 50 | H3BO3 (1.5%) | 24.3±0.9 | 642±15 | 0.74±0.01 |

| 3 | 50 | 50 | FeCl2 (1%) + H3BO3 (1.5%) | 24.1±1.7 | 1226±48 | 0.74±0.03 |

| 4 | 50 | 50 | H3BO3 (2.5%) | 25.8±2.1 | 1552±38 | 0.79±0.03 |

| 5 | 50 | 50 | H3BO3 (3.5%) | 26.7±1.5 | 2363±54 | 0.79±0.03 |

Table 1 Composition of resin solution and properties of porous carbons after pyrolysis

| Sample | PF/% | EG/% | Pore former* | Residual carbon**/% | Average pore size/nm | Bulk density/(g·cm-3) |

|---|---|---|---|---|---|---|

| 1 | 50 | 50 | FeCl2 (1%) | 23+1.1 | 190±15 | 0.73±0.01 |

| 2 | 50 | 50 | H3BO3 (1.5%) | 24.3±0.9 | 642±15 | 0.74±0.01 |

| 3 | 50 | 50 | FeCl2 (1%) + H3BO3 (1.5%) | 24.1±1.7 | 1226±48 | 0.74±0.03 |

| 4 | 50 | 50 | H3BO3 (2.5%) | 25.8±2.1 | 1552±38 | 0.79±0.03 |

| 5 | 50 | 50 | H3BO3 (3.5%) | 26.7±1.5 | 2363±54 | 0.79±0.03 |

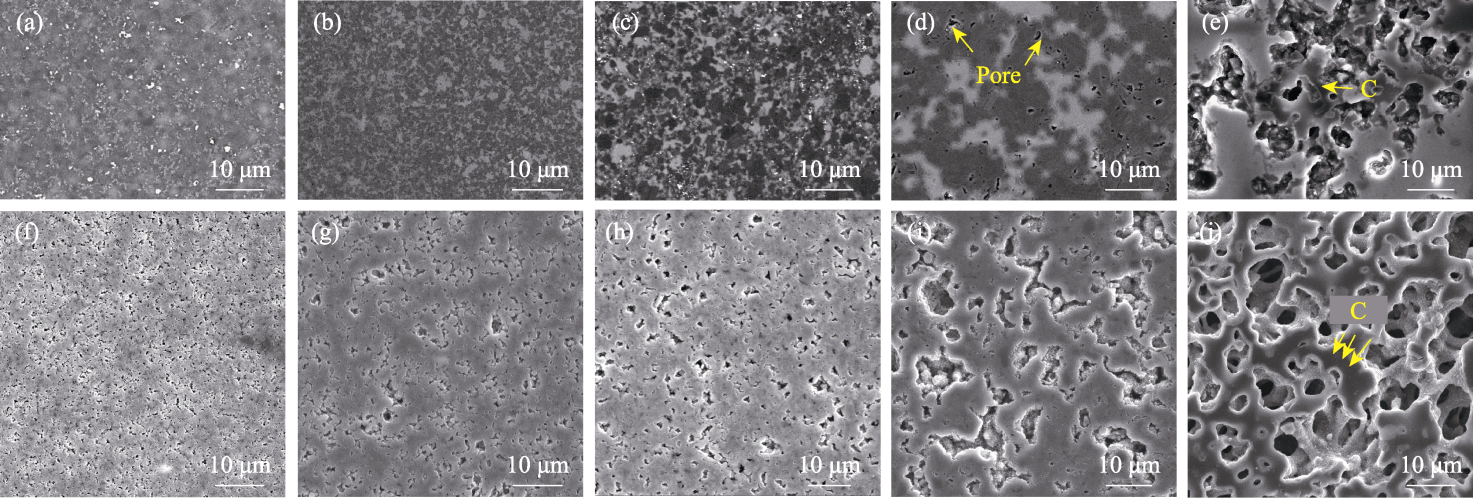

Fig. 2 Morphologies of the polished surfaces before and after HF-HNO3 corrosion of RBSC fabricated from preforms with different pore sizes (a, f) 190 nm; (b, g) 642 nm; (c, h) 1226 nm; (d, i) 1552 nm; (e, j) 2363 nm

| Pore size/nm | Open porosity/% | Density/ (g·cm-3) | Flexural strength/MPa | Residual Si/(%, in volume) |

|---|---|---|---|---|

| 190 | 0.97 | 2.93 | 296±28 | 16 |

| 642 | 1.26 | 2.91 | 268±46 | 14 |

| 1226 | 1.87 | 2.88 | 248±22 | 16 |

| 1552 | 3.51 | 2.81 | 238±44 | 12 |

| 2363 | 18.76 | 2.10 | 115±32 | 13 |

Table 2 Properties of the RBSC fabricated from preforms with different pore sizes

| Pore size/nm | Open porosity/% | Density/ (g·cm-3) | Flexural strength/MPa | Residual Si/(%, in volume) |

|---|---|---|---|---|

| 190 | 0.97 | 2.93 | 296±28 | 16 |

| 642 | 1.26 | 2.91 | 268±46 | 14 |

| 1226 | 1.87 | 2.88 | 248±22 | 16 |

| 1552 | 3.51 | 2.81 | 238±44 | 12 |

| 2363 | 18.76 | 2.10 | 115±32 | 13 |

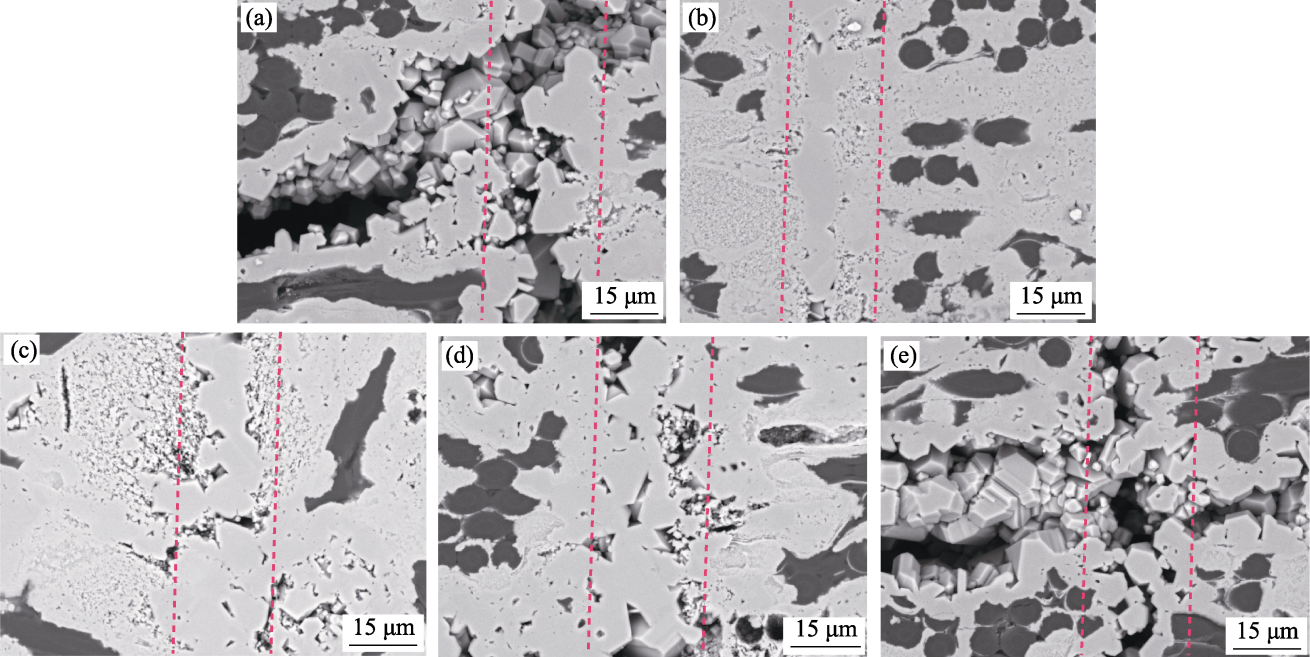

Fig. 4 Surface microstructures after HF-HNO3 corrosion of joining samples with different pore sizes (a) 14 nm; (b) 190 nm; (c) 316 nm; (d) 642 nm; (e) 1226 nm

| Pore size/nm | Flexural strength/MPa | Strength retention/% |

|---|---|---|

| 14 | 90±28 | 61 |

| 190 | 125±12 | 85 |

| 316 | 77±10 | 52 |

| 642 | 107±15 | 73 |

| 1226 | 65±22 | 44 |

Table 3 Properties of joining samples with different pore sizes

| Pore size/nm | Flexural strength/MPa | Strength retention/% |

|---|---|---|

| 14 | 90±28 | 61 |

| 190 | 125±12 | 85 |

| 316 | 77±10 | 52 |

| 642 | 107±15 | 73 |

| 1226 | 65±22 | 44 |

| Sample | PF/ % | EG/ % | Dispersant*/% | Pore former** (FeCl2)/% | α-SiC powder/% |

|---|---|---|---|---|---|

| 1 | 40 | 40 | 4 | 1 | 20 |

| 2 | 35 | 35 | 4 | 1 | 30 |

| 3 | 30 | 30 | 4 | 1 | 40 |

| 4 | 25 | 25 | 4 | 1 | 50 |

| 5 | 22.5 | 22.5 | 4 | 1 | 55 |

Table 4 Composition of resin-based slurry

| Sample | PF/ % | EG/ % | Dispersant*/% | Pore former** (FeCl2)/% | α-SiC powder/% |

|---|---|---|---|---|---|

| 1 | 40 | 40 | 4 | 1 | 20 |

| 2 | 35 | 35 | 4 | 1 | 30 |

| 3 | 30 | 30 | 4 | 1 | 40 |

| 4 | 25 | 25 | 4 | 1 | 50 |

| 5 | 22.5 | 22.5 | 4 | 1 | 55 |

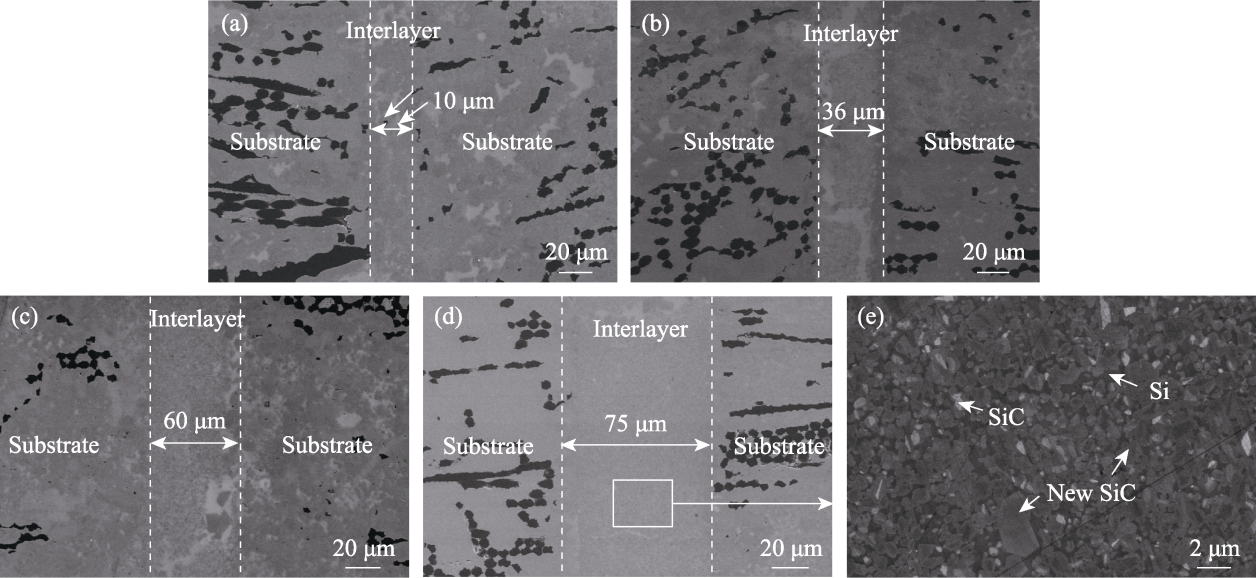

Fig. 6 Microstructures of the joint with different contents of inert filler ((a) 30%; (b) 40%; (c) 50%; (d) 55%, in mass) and (e) partial enlargement of (d)

| [1] |

CHENG T B, WANG X R, ZHANG R B, et al. Tensile properties of two-dimensional carbon fiber reinforced silicon carbide composites at temperatures up to 2300 ℃. Journal of the European Ceramic Society, 2020, 40(3): 630-635.

DOI URL |

| [2] |

CHEN S, CHEN P, DUAN J, et al. Thermal cycling behavior of bi-layer Yb2Si2O7/SiC EBC coated Cf/SiC composites in burner rig tests. Advanced Composites and Hybrid Materials, 2022, 5: 2184-2192.

DOI URL |

| [3] |

BERBON M Z, DIETRICH D R, MARSHALL D B, et al. Transverse thermal conductivity of thin C/SiC composites fabricated by slurry infiltration and pyrolysis. Journal of the American Ceramic Society, 2001, 84(10): 2229-2234.

DOI URL |

| [4] |

CAO X Y, YIN X W, FAN X M, et al. High temperature flexural properties of SiBC modified C/SiC composites. Ceramics International, 2014, 40(4): 6185-6190.

DOI URL |

| [5] |

LIU Y, ZHU Y Z, YANG Y, et al. Microstructure of reaction layer and its effect on the joining strength of SiC/SiC joints brazed using Ag-Cu-In-Ti alloy. Journal of Advanced Ceramics, 2014, 3(1): 71-75.

DOI URL |

| [6] |

SAIED M A, LLOYD I K, HALLER W K, et al. Joining dental ceramic layers with glass. Dental Materials, 2011, 27(10): 1011-1016.

DOI PMID |

| [7] |

YANG H, ZHOU X B, SHI W, et al. Thickness-dependent phase evolution and bonding strength of SiC ceramics joints with active Ti interlayer. Journal of the European Ceramic Society, 2017, 37(4): 1233-1241.

DOI URL |

| [8] |

JEONG D H, SEPTIADI A, FITRIANI P, et al. Joining of SiCf/SiC using polycarbosilane and polysilazane preceramic mixtures. Ceramics International, 2018, 44(9): 10443-10450.

DOI URL |

| [9] |

SINGH M, LARA-CURZIO E. Design, fabrication, and testing of ceramic joints for high temperature SiC/SiC composites. Journal of Engineering for Gas Turbines and Power-Transactions of the ASME, 2001, 123(2): 288-292.

DOI URL |

| [10] |

SINGH M. Microstructure and mechanical properties of reaction- formed joints in reaction-bonded silicon carbide ceramics. Journal of Materials Science, 1998, 33(24): 5781-5787.

DOI URL |

| [11] |

LI S B, MA M L, GAO J Q, et al. Reaction forming of joints in silicon carbide ceramic materials. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2008, 483-484: 747-750.

DOI URL |

| [12] |

LUO Z H, JIANG D L, ZHANG J X, et al. Development of SiC-SiC joint by reaction bonding method using SiC/C tapes as the interlayer. Journal of the European Ceramic Society, 2012, 32(14): 3819-3824.

DOI URL |

| [13] |

ZHANG Y M, YUAN Z Y, ZHOU Y F. Gelcasting of silicon carbide ceramics using phenolic resin and furfuryl alcohol as the gel former. Ceramics International, 2014, 40(23): 7873-7878.

DOI URL |

| [14] |

WU X S, ZHU Y Z, PEI B B, et al. Effect of FeCl2 on the pore structure of porous carbon obtained from phenol formaldehyde resin and ethylene glycol. Materials Letters, 2018, 215: 50-52.

DOI URL |

| [15] |

WU X S, SU R H, ZHU Y Z, et al. Pore structure control of porous carbon obtained from phenol formaldehyde resin and ethylene glycol: the effect of H3BO3 on the pore structure. RSC Advances, 2019, 9(8): 4203-4209.

DOI URL |

| [16] |

WU X S, SU R H, PEI B B, et al. Pore structure control of porous carbon via the synergistic effect of boric acid and divalent metal iron salt. Materials Letters, 2019, 255: 126539.

DOI URL |

| [17] | BEHRENDT D, SINGH M. Effect of carbon preform pore volume and infiltrants on the composition of reaction-formed silicon carbide materials. J. Mater. Synth. Process., 1994, 2(2): 117-123. |

| [18] |

WANG Y, TAN S, JIANG D. The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon, 2004, 42(8/9): 1833-1839.

DOI URL |

| [19] | HILLIG W B. Melt infiltration approach to ceramic matrix composites. Journal of the American Ceramic Society, 1988, 71(2): 96-99. |

| [20] |

XU S J, QIAO G J, WANG H J, et al. Microstructure evolution and reaction mechanism of microporous carbon derived SiC ceramic. Journal of Inorganic Materials, 2009, 24(2): 291-296.

DOI URL |

| [21] |

SUYAMA S, KAMEDA T, ITOH Y. Development of high-strength reaction-sintered silicon carbide. Diamond and Related Materials, 2003, 12(3-7): 1201-1204.

DOI URL |

| [1] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [2] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [3] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [4] | GUO Ziyu, ZHU Yunzhou, WANG Li, CHEN Jian, LI Hong, HUANG Zhengren. Effect of Zn2+ Catalyst on Microporous Structure of Porous Carbon Prepared from Phenolic Resin/Ethylene Glycol [J]. Journal of Inorganic Materials, 2025, 40(5): 466-472. |

| [5] | LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 271-280. |

| [6] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [7] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [8] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [9] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [10] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [11] | WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System [J]. Journal of Inorganic Materials, 2024, 39(7): 761-768. |

| [12] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [13] | SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi. Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units [J]. Journal of Inorganic Materials, 2024, 39(6): 662-670. |

| [14] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [15] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||