Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (12): 1332-1336.DOI: 10.15541/jim20170089

• Orginal Article • Previous Articles Next Articles

YU Yi-Ping, WANG Song, LI Wei

Received:2017-02-23

Published:2017-12-20

Online:2017-11-21

Supported by:CLC Number:

YU Yi-Ping, WANG Song, LI Wei. Laser Ablation Behavior of W/ZrC Cermet Fabricated by Displacive Compensation of Porosity (DCP) Method[J]. Journal of Inorganic Materials, 2017, 32(12): 1332-1336.

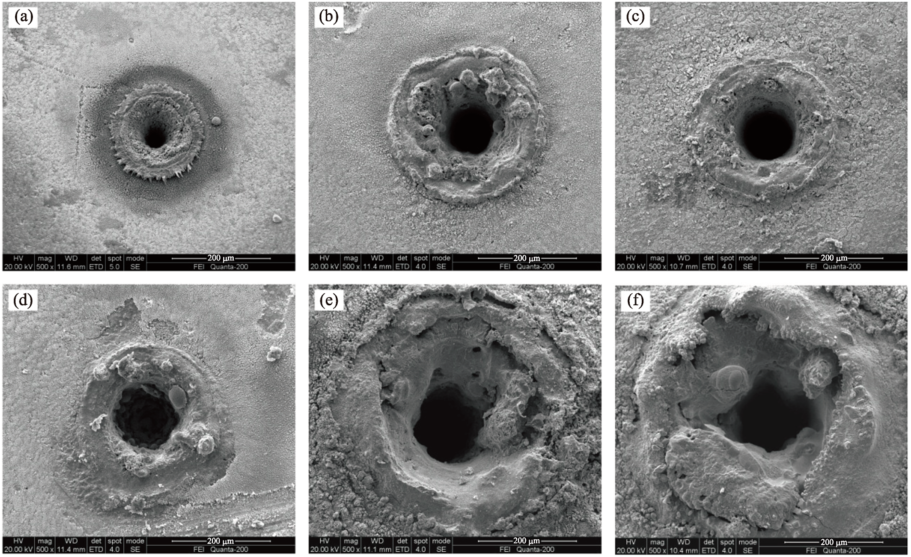

Fig. 2 Morphologies of the laser ablation surface of W/ZrC cermet Under different laser energy for 30 s: (a) 10 J/s; (b) 20 J/s; (c) 30 J/s Under different ablation time with a 30 J/s laser: (d) 5 s; (e) 60 s; (f) 120 s

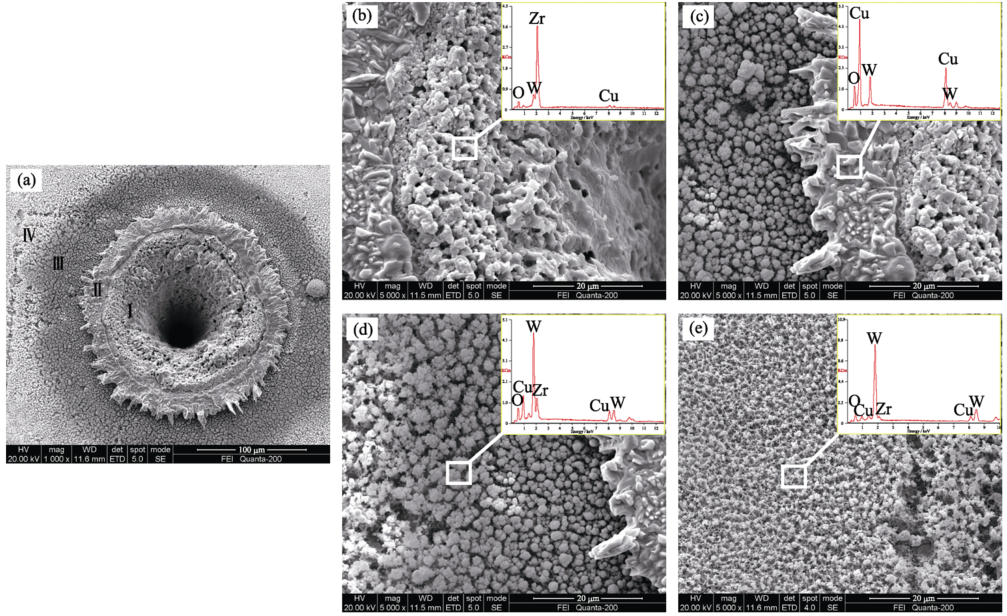

Fig. 4 Morphologies and EDS analysis of the laser ablation surface of W/ZrC cermet^(a) Macro morphology; (b-e) Micro morphologies relative to part I -IV, respectively

| [1] | YIH S W, WANG C T.Tungsten-sources, Metallurgy, Properties and Application. New York: Plenum, 1979: 35. |

| LASSNER E, SCHUBERT W D.Tungsten Properties Chemistry Technology of the Element Alloys and Chemical Compounds. New York: Plenum, 1999: 13, 16. | |

| [2] | CIFUENTES S C, MONGE M A, PEREZ P.On the oxidation mechanism of pure tungsten in the temperature range 600 - 800℃. Corrosion Science, 2012, 57: 114-121. |

| [3] | DICKERSON M B, SNYDER R L, SANDHAGE K H.Dense, near net-shaped, carbide/refractory metal composites at modest temperatures by the displacive compensation of porosity (DCP) method.Journal of the American Ceramic Society, 2002, 85(3): 730-732. |

| [4] | ZHANG S M, SONG W, LI W,et al Microstructure and properties of W-ZrC composites prepared by the displacive compensation of porosity (DCP) method.Journal of Alloys and Compounds, 2011, 509: 8327-8332. |

| [5] | DICKERSON M B, WURM P J, SCHORR J R,et al. Near net- shape, ultra-high melting, recession-resistant ZrC/W-based rocket nozzle liners via the displacive compensation of porosity (DCP) method. Journal of Materials Science, 2004, 39: 6005-6015. |

| [6] | SONG G M, ZHOU Y, WANG Y J.Effect of carbide particles on the ablation properties of tungsten composites.Materials Characterization, 2003, 50: 293-303. |

| [7] | WANG Y J, ZHOU Y, SONG G M,et al Plasma ablation behavior of ZrCp/W composites.Rare Metal Materials and Engineering, 2009, 38(5): 830-833. |

| [8] | WANG Y J, ZHOU Y, SONG G M,et al. High temperature tensile properties of 30 vol. pct ZrCp/W composite. Journal of Materials Science and Technology, 2003, 19(2): 167-170. |

| [9] | ZHANG T Q, WANG Y J, ZHOU Y,et al. Effect of ZrC particle size on microstructure and room temperature mechanical properties of ZrCp/W composites. Materials Science and Engineering A, 2010, 527: 4021-4027. |

| [10] | SONG G M, WANG Y J, ZHOU Y.The mechanical and thermophysical properties of ZrC/W composites at elevated temperature.Materials Science and Engineering A, 2002, 334: 223-232. |

| [11] | KIM J H, SEO M, KANG S.Effect of carbide particle size on the properties of W-ZrC composites.Journal of Refractory Metals and Hard Materials, 2012, 35: 49-54. |

| [12] | ZHANG S C, HILMAS G E, FAHERNHOLTZ W G.Zirconium carbide- tungsten cermets prepared by in situ reaction sintering. Journal of the American Ceramic Society, 2007, 90: 1930-1933. |

| [13] | ROOSTA M, BAHARVANDI H.The change occurred in W/ZrC composite properties by using nano reactants.Journal of Refractory Metals and Hard Materials, 2013, 37: 29-32. |

| [14] | ZHANG S M, SONG W, LI W, ,et al. Fabrication of W-ZrC cermets by reactive melt infiltration with polycarbosilane as preforms’ adhesive.Materials Science Forum, 2011, 675-677: 819-822. |

| [15] | LIU Q M, ZHANG L T, JIANG F R,et al Laser ablation behaviors of SiC-ZrC coated carbon/carbon composites.Surface & Coatings Technology, 2011, 205: 4299-4303. |

| [16] | ZHU Y L, WANG S, LI W,et al Preparation of carbon fiber- reinforced zirconium carbide matrix composites by reactive melt infiltration at relative low temperature.Scripta Materialia, 2012, 67: 822-825. |

| [1] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [2] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [3] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [4] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [5] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [6] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [7] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [8] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [9] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [10] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [11] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [12] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [13] | CAI Jia, ZHAO Fangxia, FAN Dong, HUANG Liping, NIU Yaran, ZHENG Xuebin, ZHANG Zhenzhong. Pyrolysis Behavior and Laser Ablation Resistance of PCS in Polycarbosilane Composite Coatings [J]. Journal of Inorganic Materials, 2023, 38(11): 1271-1280. |

| [14] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| [15] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||