Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (6): 571-583.DOI: 10.3724/SP.J.1077.2014.13506

• Orginal Article • Previous Articles Next Articles

LIU Gang1,2, YAN Yan1

Received:2013-10-01

Revised:2013-11-29

Published:2014-06-20

Online:2014-05-27

About author:LIU Gang. E-mail: liugangswu@126.com

Supported by:CLC Number:

LIU Gang, YAN Yan. Research Progress of Porous Ceramics Produced by Freeze Casting Technique[J]. Journal of Inorganic Materials, 2014, 29(6): 571-583.

Add to citation manager EndNote|Ris|BibTeX

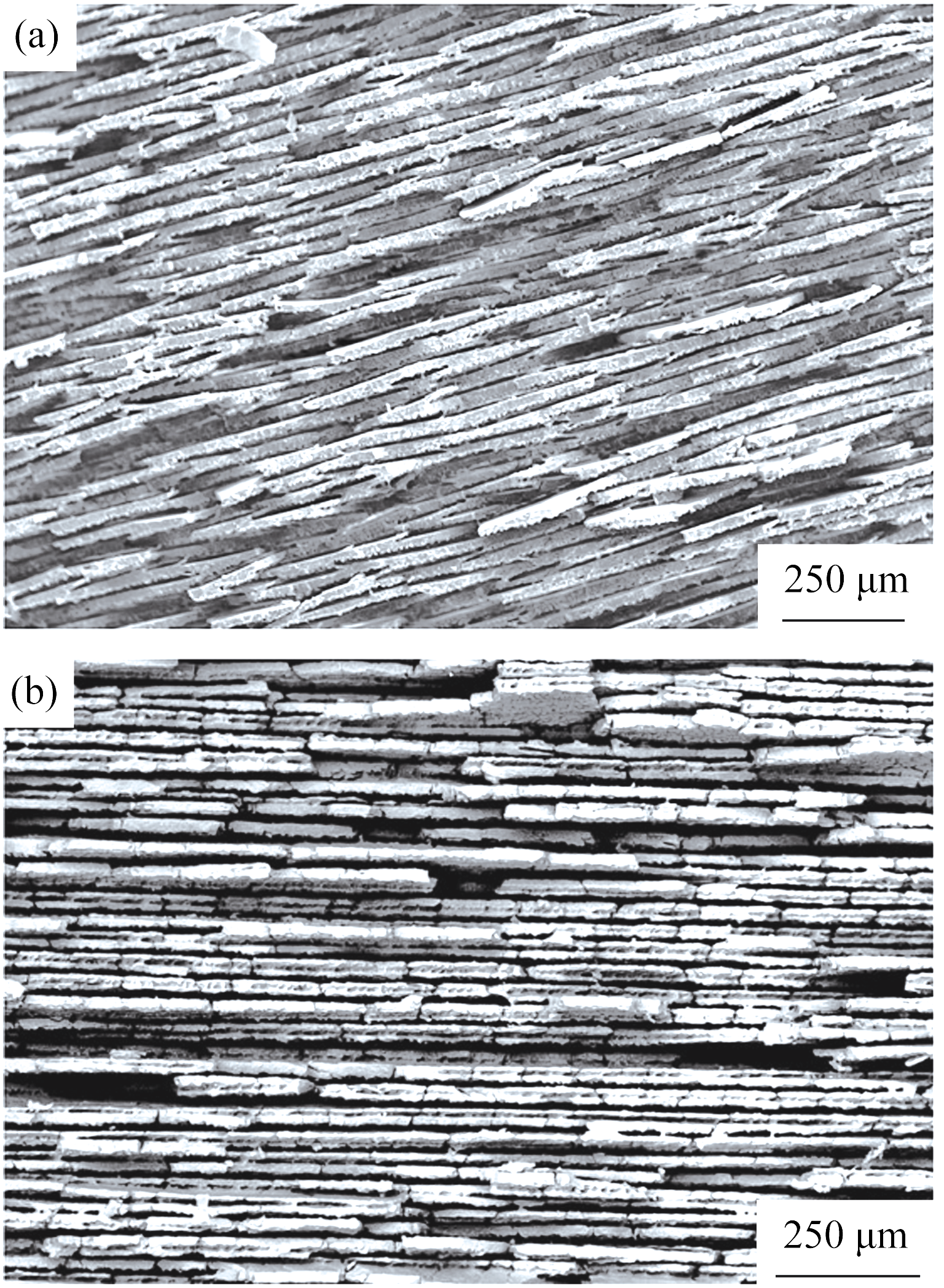

Fig. 8 Typical cross-section SEM images of porous alumina obtained by water-based freeze casting[21] (a) Ice growth direction perpendicular to the page; (b) Ice growth direction from bottom to top

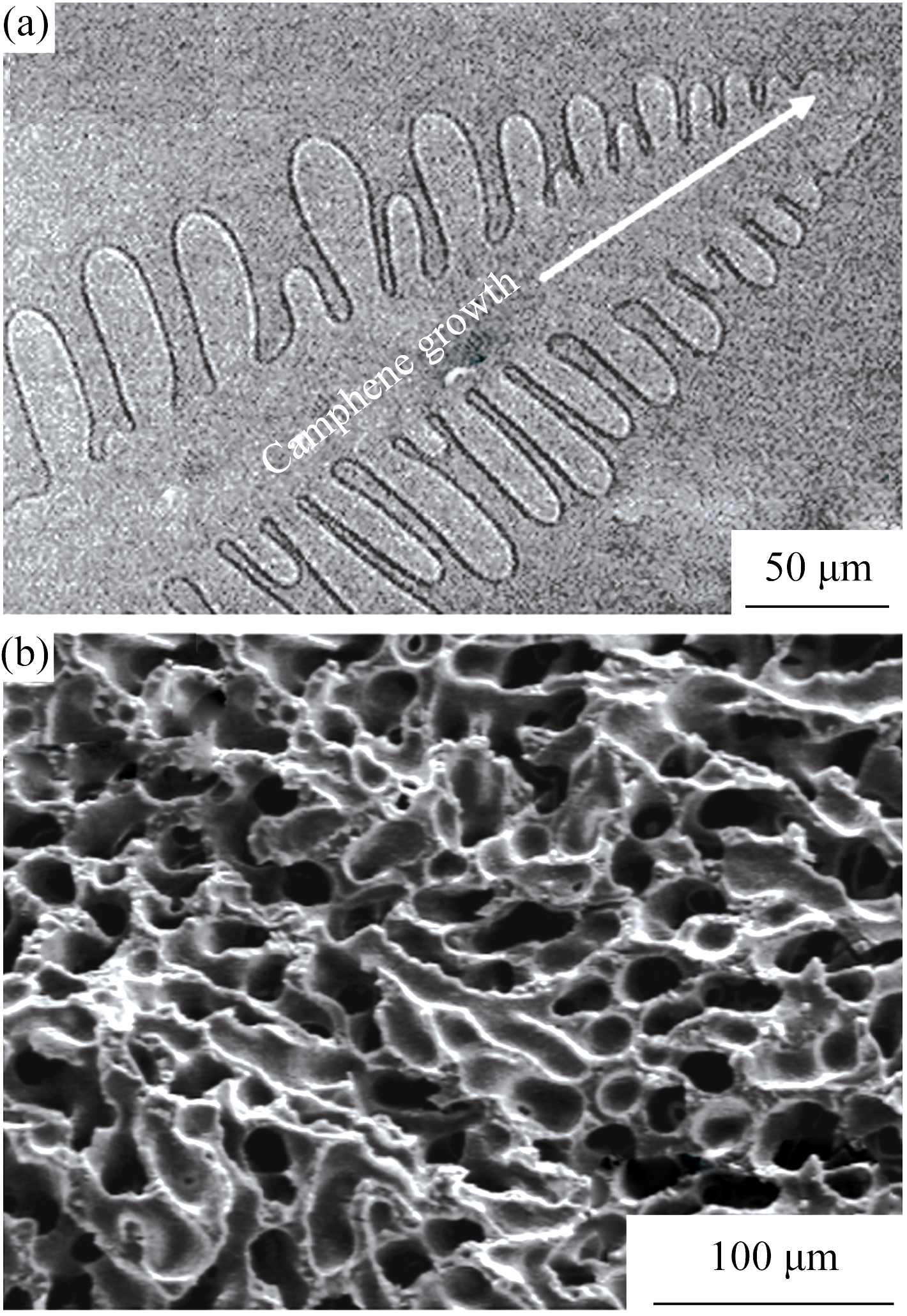

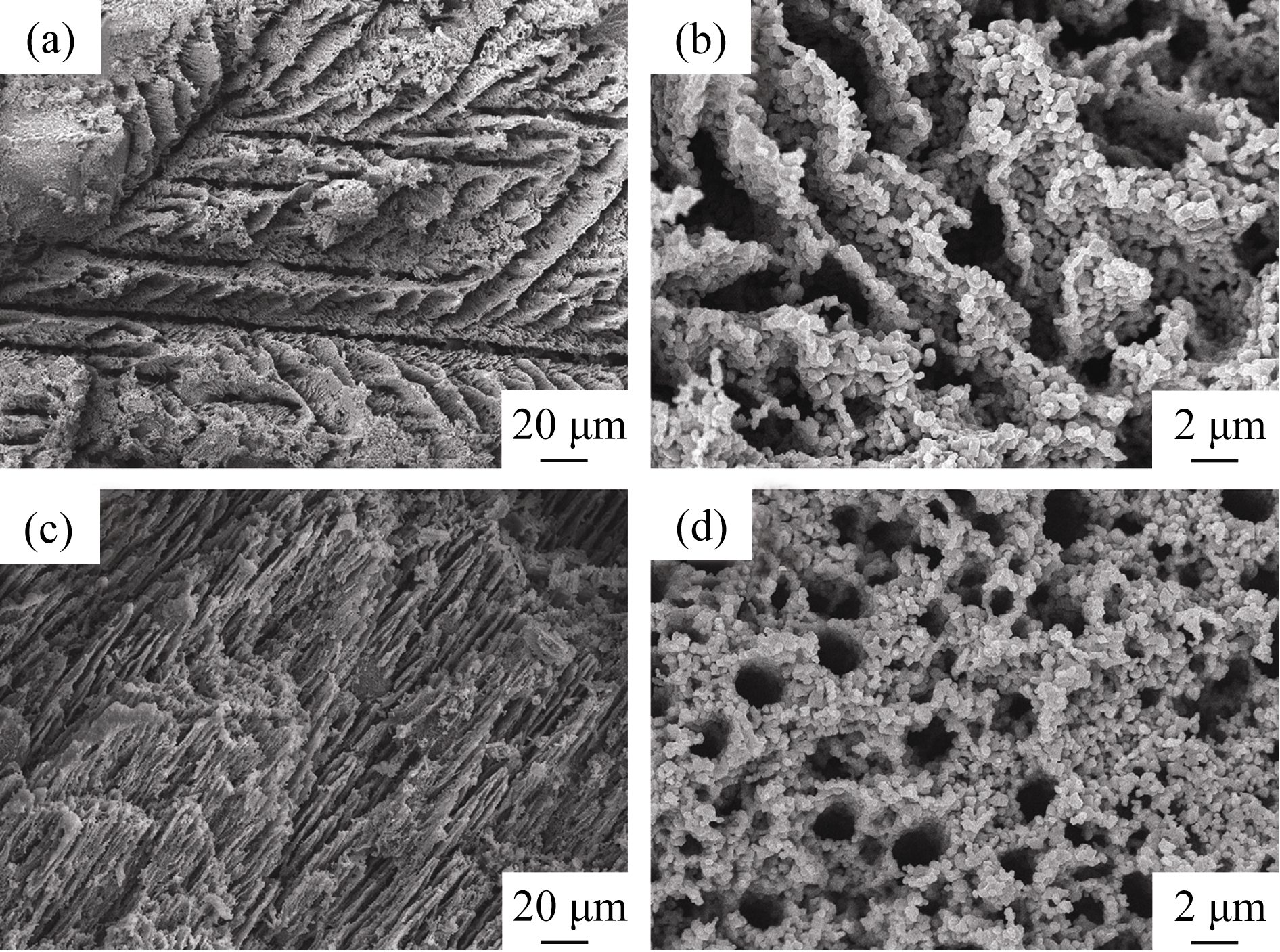

Fig. 9 Dentritic structure during solidification of camphene]43] (a) and typical SEM images of porous alumina obtained by camphene-based freeze casting (b)[20]

Fig. 10 Cross-sectional SEM images of the Al2O3-ZrO2 composite ceramics obtained from slurries with different initial solids loading[23] (a) 40wt%; (b) 50wt%; (c) 60wt%; (d) 70wt%; (e) 80wt%. Solidification direction is perpendicular to the page

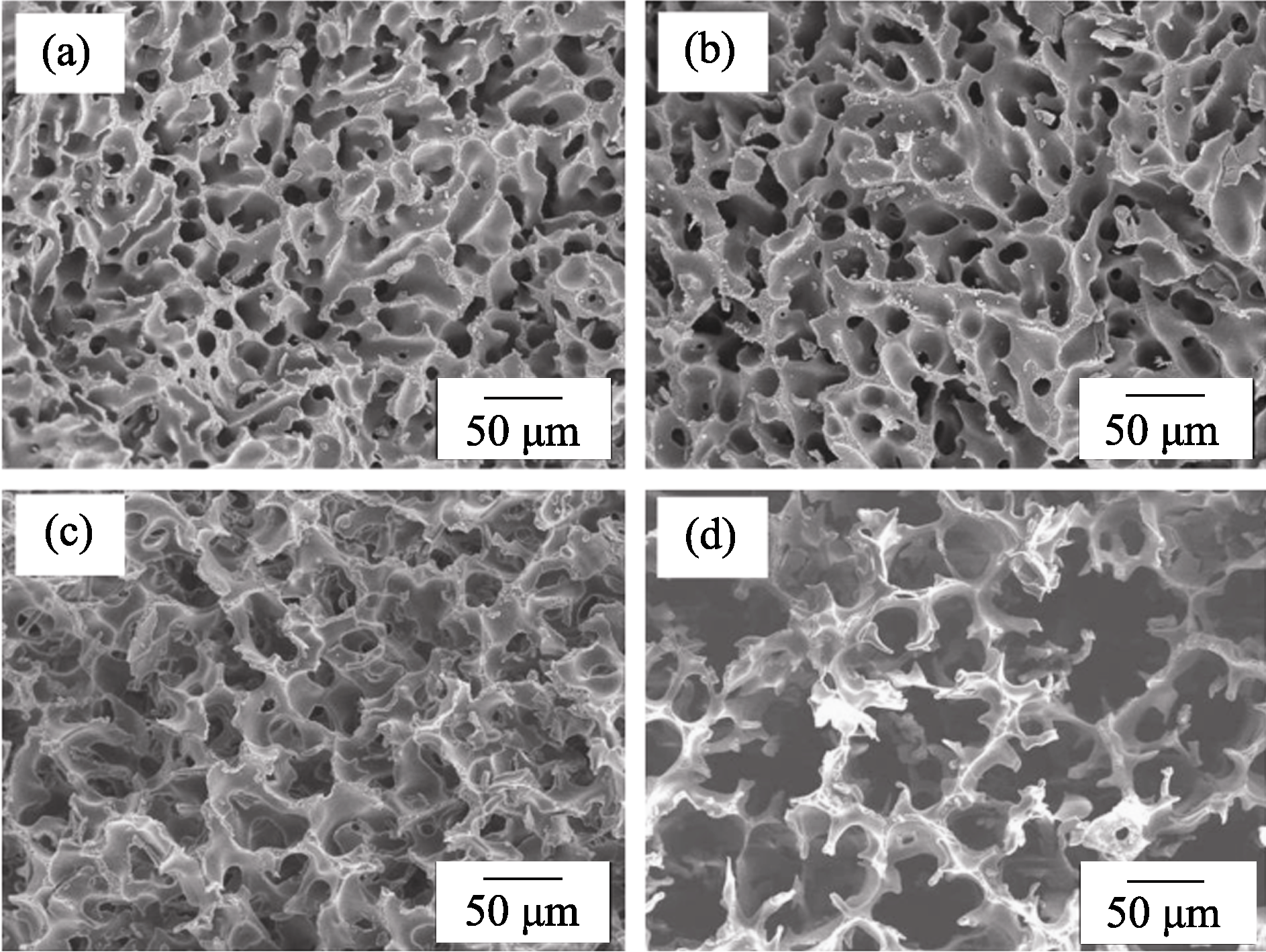

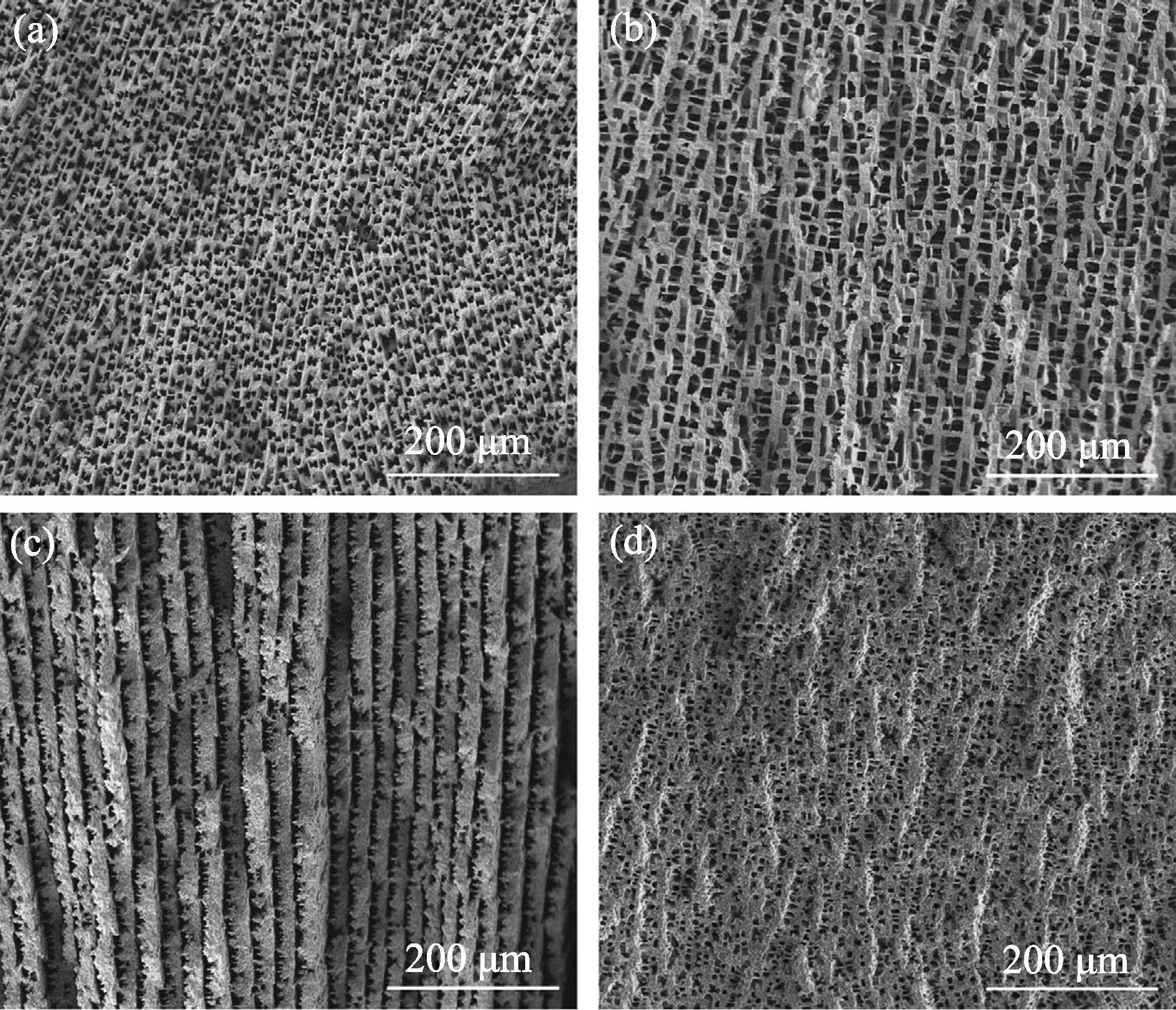

Fig. 11 SEM images of the porous alumina ceramics sintered at 1400℃ for 5 h with initial solid loadings of 20vol%(a), 15vol%(b), 10vol%(c), and 5vol% (d), showing porous structures at low magnification[44]

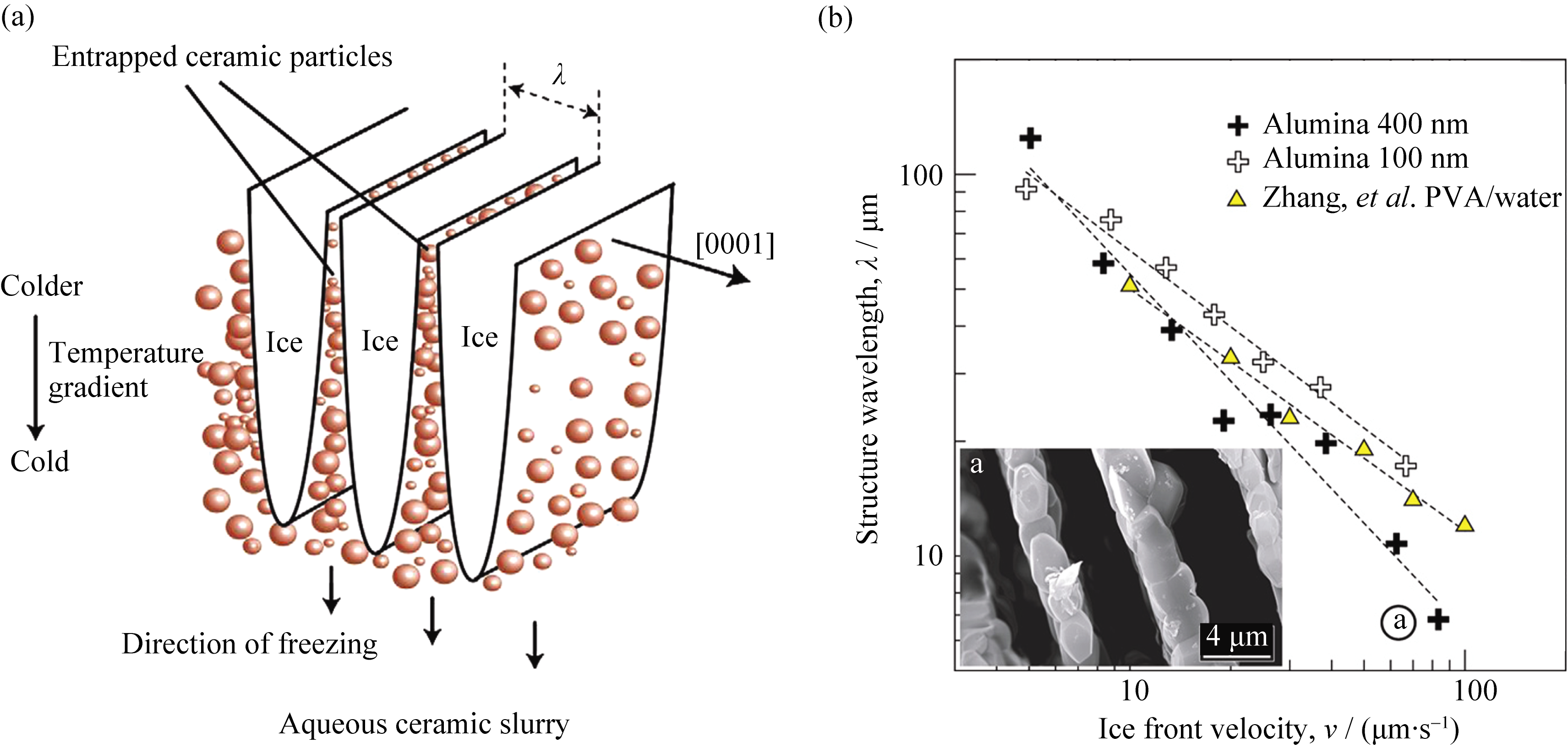

Fig. 13 Pattern formation and particle segregation during freeze casting of ceramic slurries (a) and the wavelength of the <br/>structure is defined. (b) Variation of structure wavelength vs ice front velocity[21]

Fig. 14 SEM images of porous TiO2 with cross-section parallel and perpendicular to the ice growth direction[52] (a) 3wt% PVA, parallel; (b) 3wt% PVA, perpendicular; (c) 6wt% PVA, parallel; (d) 6wt% PVA, perpendicular

Fig. 15 SEM images of porous alumina ceramics, which are prepared by using (a) 20vol% slurry without glycerol, (b) 20vol% slurry with glycerol, (c) 30vol% slurry without glycerol and (d) 30vol% slurry with glycerol[55] The direction of fracture parallels to the ice front

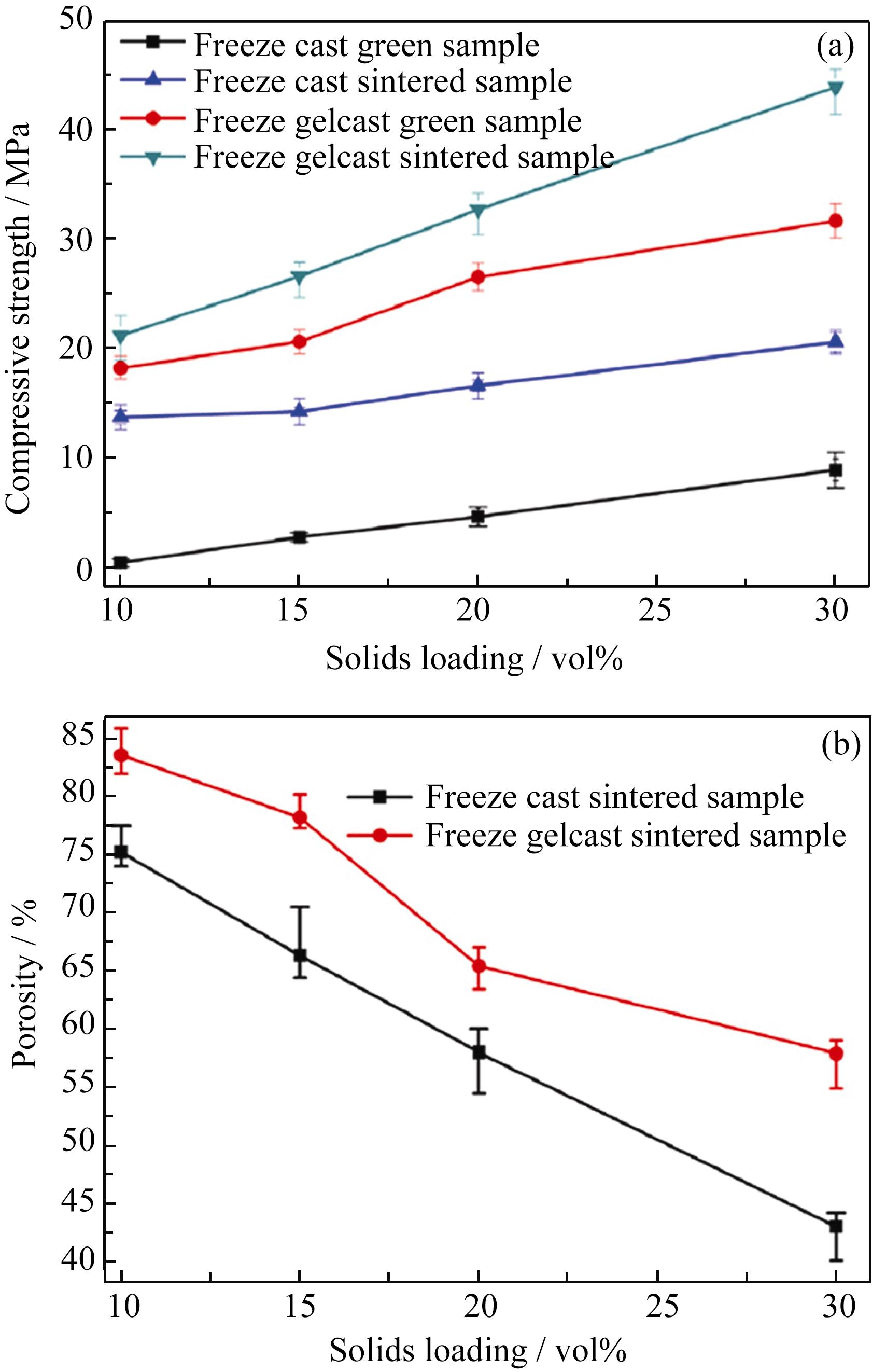

Fig. 23 Compressive strengths of freeze cast and freeze gelcast samples versus solids loading (a) and porosities of the sintered samples versus solids loading (b)[24]

| [1] | STUDART A R, GONZENBACH U T, TERVOORT E, et al. Processing routes to macroporous ceramics: a review. J. Am. Ceram. Soc., 2006, 89(6): 1771-1789. |

| [2] | COLOMBO P. Conventional and novel processing methods for cellular ceramics. Philos. T. R. Soc. A, 2006, 364(1838): 109-124. |

| [3] | SEPULVEDA P, BINNER J G P. Processing of cellular ceramics by foaming and in situ polymerisation of organic monomers. J. Eur. Ceram. Soc, 1999, 19(12): 2059-2066. |

| [4] | NANGREJO M R, BAO X J, EDIRISINGHE M J. Preparation of silicon carbide-silicon nitride composite foams from pre-ceramic polymers. J. Eur. Ceram. Soc., 2000, 20(11): 1777-1785. |

| [5] | MATOVIC B, BABIC B, EGELJA A, et al. Preparation of porous silica ceramics using the wood template. Mater. Manuf. Process, 2009, 24(10/11): 1109-1113. |

| [6] | TULLIANI J M, MONTANARO L, BELL T J, et al. Semiclosed-cell mullite foams: preparation and macro- and micromechanical character-rization. .J. Am. Ceram. Soc, 1999, 82(4): 961-968. |

| [7] | LI S H, WIJN DE, LAYROLLE P, et al. Synthesis of macroporous hydroxyapatite scaffolds for bone tissue engineering.J. Biomed. Mater. Res, 2002, 61(1): 109-120. |

| [8] | LIU D M. Influence of porosity and pore size on the compressive strength of porous hydroxyapatite ceramic.Ceram. Int, 1997, 23(2):135-139. |

| [9] | PABST W, GREGOVOVÁ E, MALANGRÉ D, et al. Elastic properties and damping behavior of alumina-zirconia composites at room temperature. Ceram. Int., 2012, 38(7) : 5931-5939. |

| [10] | BINKS B P. Macroporous silica from solid-stabilized emulsion templates. Adv. Mater., 2002, 14(24): 1824-1827. |

| [11] | AHMAD R, HA J H, SONG I H. Particle-stabilized ultra-low density zirconia toughened alumina foams. J. Eur. Ceram. Soc, 2013, 33(13/14): 2559-2564. |

| [12] | GONZENBACH U T, STUDART A R, TERVOORT E, et al. Macroporous ceramics from particle-stabilized wet foams. J. Am. Ceram. Soc, 2007, 90(1):16-22. |

| [13] | MORITZ T, RICHTER H J. Ceramic bodies with complex geometries and ceramic shells by freeze casting using ice as mold material.J. Am. Ceram. Soc, 2006, 89(8): 2394-2398. |

| [14] | SOFIE S W, DOGAN F. Freeze casting of aqueous alumina slurries with glycerol. J. Am. Ceram. Soc, 2001, 84(7): 1459-1464. |

| [15] | STATHAM M J, HAMMETT E, HARRIS B, et al. Net-shape manufacture of low-cost ceramic shapes by freeze-gelation. J. Sol-Gel Sci. Technol., 1998, 13(1/2/3): 171-175. |

| [16] | FUKASAWA T, ANDO M, OHJI T, et al. Synthesis of porous ceramics with complex pore structure by freeze-dry processing. J. Am. Ceram. Soc, 2001, 84(1): 230-232. |

| [17] | ZHANG H F, HUSSAIN I, BRUST M, et al. Aligned two- and three-dimensional structures by directional freezing of polymers and nanoparticles.Nat. Mater, 2005, 4(10): 787-793. |

| [18] | DEVILLE S, SAIZ E, NALLA R K. Freezing as a path to build complex composites. Science, 2006, 311(5760): 515-518. |

| [19] | DEVILLE S. Freeze-casting of porous ceramics: A review of current achievements and issues. Adv. Eng. Mater., 2008, 10(3): 155-169. |

| [20] | ARAKI K, HALLORAN J W. Porous ceramic bodies with interconnected pore channels by a novel freeze casting technique. J. Am. Ceram. Soc, 2005, 88(5): 1108-1114. |

| [21] | DEVILLE S, SAIZ E, TOMSIA A P. Ice-templated porous alumina structures.Acta Mater, 2007, 55(6): 1965-1974. |

| [22] | ZHANG Y, ZUO K, ZENG Y P. Effects of gelatin addition on the microstructure of freeze-cast porous hydroxyapatite cerarmics.Ceram. Int, 2009, 35(6): 2151-2154. |

| [23] | LIU G, ZHANG D, MEGGS C, et al. Porous Al2O3-ZrO2 composites fabricated by an ice template method.Scr. Mater, 2010, 62(7): 466-468. |

| [24] | ZHANG D, ZHANG Y, XIE R, et al. Freeze gelcasting of aqueous alumina suspensions for porous ceramics. Ceram. Int, 2012, 38(7): 6063-6066. |

| [25] | ZHANG Y, ZHOU K C, BAO Y X, et al. Effects of rheological properties on ice-templated porous hydroxyapatite ceramics. Mater.Sci. Eng. C. Mater. Biol. Appl, 2013, 33(1): 340-346. |

| [26] | KORBER C, RAU G, COSMAN M D, et al. Interaction of particles and a moving ice-liquid interface .J. Cryst. Growth, 1985, 72(3): 649-662. |

| [27] | WEGST U G K, SCHECTER M, DONIUS A E, et al. Biomaterials by freeze casting . Philos. T. R. Soc. A, 2010, 368(1917): 2099-2121. |

| [28] | BOLLING G F, CISSE J. Theory for interaction of particles with a solidifying front.J. Cryst. Growth, 1971, 10(1): 56-66. |

| [29] | MACCHETTA A, TURNER I G, BOWEN C R. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method.Acta Biomater, 2009 5(4): 1319-1327. |

| [30] | HAN J, HU L, ZHANG Y, et al. Fabrication of ceramics with complex porous structures by the impregnate-freeze-casting process .J. Am. Ceram. Soc, 2009, 92(9): 2165-2167. |

| [31] | JING L, ZUO K, ZHANG F, et al. The controllable microstructure of porous Al2O3 ceramics prepared via a novel freeze casting route .Ceram. Int, 2010, 36(8): 2499-2503. |

| [32] | RODRIGUEZ-PARRA J M, MORENO R, ISABEL NIETO M. Effect of cooling rate on the microstructure and porosity of alumina produced by freeze casting .J. Serb. Chem.l Soc, 2012,77(12): 1775-1785. |

| [33] | YOON H J, KIM U C, KIM J H, et al. Macroporous alumina ceramics with aligned microporous walls by unidirectionally freezing foamed aqueous ceramic suspensions .J. Am. Ceram. Soc, 2010, 93(6): 1580-1582. |

| [34] | DEVILLE S, SAIZ E, TOMSIA A P. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering .Biomater, 2006, 27(32): 5480-5489. |

| [35] | FU Q, RAHAMAN M N, DOGAN F, et al. Freeze casting of porous hydroxyapatite scaffolds. I. processing and general microstructure . J. Biomed. Mater. Res. B, 2008, 86B(1): 125-135. |

| [36] | FU Q, RAHAMAN M N, DOGAN F, et al. Freeze casting of porous hydroxyapatite scaffolds. II. sintering, microstructure, and mechanical behavior . J. Biomed. Mater. Res. B, 2008, 86B(2): 514-522. |

| [37] | FU Q, RAHAMAN M N, DOGAN F, et al. Freeze-cast hydroxyapatite scaffolds for bone tissue engineering applications .Biomed. Mater, 2008, 3(2): 025005. |

| [38] | LANDI E, VALENTINI F, TAMPIERI A. Porous hydroxyapatite/ gelatine scaffolds with ice-designed channel-like porosity for biomedical applications .Acta Biomater, 2008, 4(6): 1620-1626. |

| [39] | CHINO Y, DUNAND D C. Directionally freeze-cast titanium foam with aligned, elongated pores .Acta Mater, 2008, 56(1): 105-113. |

| [40] | LI J C, DUNAND D C. Mechanical properties of directionally freeze-cast titanium foams .Acta Mater, 2011, 59(1): 146-158. |

| [41] | WETTLAUFER J S, WORSTER M G, HUPPERT H E. Natural convection during solidification of an alloy from above with application to the evolution of sea ice. J Fluid Mech, 1997, 344(291-316): 291-316. |

| [42] | WETTLAUFER J S, WORSTER M G, HUPPERT H E. The phase evolution of young sea ice . Geophys. Res. Lett., 1997, 24(10): 1251-1254. |

| [43] | YOON B H, LEE E J, KIM H E. Highly aligned prous silicon carbide ceramics by freezing polycarbosilane/camphene solution .J. Am. Ceram. Soc, 2007, 90(6): 1753-1759. |

| [44] | KOH Y H, SONG J H, LEE E J, et al. Freezing dilute ceramic/ camphene slurry for ultra-high porosity ceramics with completely interconnected pore networks .J. Am. Ceram. Soc, 2006, 89(10): 3089-3093. |

| [45] | DU J, ZHANG X, HONG C, et al. Microstructure and mechanical properties of ZrB2-SiC porous ceramic by camphene-based freeze casting .Ceram. Int, 2013, 39(2): 953-957. |

| [46] | FARHANGDOUST S, ZAMANIAN A, YASAEI M, et al. The effect of processing parameters and solid concentration on the mechanical and microstructural properties of freeze-casted macroporous hydroxyapatite scaffolds .Mater. Sci. Eng. C Mater. Biol. Appl, 2013, 33(1): 453-460. |

| [47] | HONG C, ZHANG X, HAN J, et al. Ultra-high-porosity zirconia ceramics fabricated by novel room-temperature freeze-casting .Scr. Mater , 2009, 60(7): 563-566. |

| [48] | HONG C, ZHANG X, HAN J, et al. Camphene-based freeze-cast ZrO2 foam with high compressive strength .Mater. Chem. and Phys, 2010, 119(3): 359-362. |

| [49] | HOU Z, YE F, LIU L, et al. Effects of solid content on the phase assemblages, mechanical and dielectric properties of porous α-SiAlON ceramics fabricated by freeze casting. Ceram. Int, 2013, 39(2): 1075-1079. |

| [50] | LEE S H, JUN S H, KIM H E, et al. Piezoelectric properites of PZT-based ceramic with highly aligned pores . J. Am. Ceram. Soc. 2008, 91(6): 1912-1915. |

| [51] | LI D, LI M. Preparation of porous alumina ceramic with ultra-high porosity and long straight pores by freeze casting. J. Porous Mater., 2012,19(3): 345-349. |

| [52] | REN L, ZENG Y P, JIANG D. Preparation of porous TiO2 by a novel freeze casting .Ceram. Int, 2009, 35(3): 1267-1270. |

| [53] | YE F, ZHANG J, LIU L, et al. Effect of solid content on pore structure and mechanical properties of porous silicon nitride ceramics produced by freeze casting .Mater. Sci. Eng. A, Struct Mater, Prop. Microstruct.Process, 2011, 528(3): 1421-1424. |

| [54] | YOON B H, KOH Y H, PARK C S, et al. Generation of large pore channels for bone tissue engineering using camphene-based freeze casting .J. Am. Ceram. Soc, 2007, 90(6): 1744-1752. |

| [55] | ZHANG Y, HU L, HAN J, et al. Freeze casting of aqueous alumina slurries with glycerol for porous ceramics .Ceram. Int, 2010, 36(2): 617-621. |

| [56] | ZHANG R, FANG D, PEI Y, et al. Microstructure, mechanical and dielectric properties of highly porous silicon nitride ceramics produced by a new water-based freeze casting .Ceram. Int, 2012, 38(5): 4373-4377. |

| [57] | ZHANG Y, ZUO K, ZENG Y P. Effects of gelatin addition on the microstructure of freeze-cast porous hydroxyapatite cerarmics .Ceram. Inter, 2009, 35(6): 2151-2154. |

| [58] | HAN J, HONG C, ZHANG X, et al. Highly porous ZrO2 ceramics fabricated by a camphene-based freeze-casting route: microstructure and properties .J. Eur. Ceram. Soc, 2010, 30(1): 53-60. |

| [59] | CHU T M G, ORTON D G, HOLLISTER S J, et al. Mechanical and in vivo performance of hydroxyapatite implants with controlled archite-ctures .Biomater. , 2002, 23(5): 1283-1293. |

| [60] | DEL REAL R P, WOLKE J G C, VALLET-REGI M, et al. A new method to produce macropores in calcium phosphate cements. Biomater., 2002, 23(17): 3673-3680. |

| [61] | RAHAMAN M N, FU Q. Manipulation of porous bioceramic microstructures by freezing of suspensions containing binary mixtures of solvents .J. Am. Ceram. Soc, 2008, 91(12): 4137-4140. |

| [62] | LIU X, RAHAMAN M N, FU Q. Oriented bioactive glass (13-93) scaffolds with controllable pore size by unidirectional freezing of camphene-based suspensions: Microstructure and mechanical response. Acta Biomater, 2011,7(1): 406-416. |

| [63] | SOON Y M, SHIN K H, KOH Y H, et al. Compressive strength and processing of camphene-based freeze cast calcium phosphate scaffolds with aligned pores .Mater. Lett, 2009, 63(17): 1548-1550. |

| [64] | XIA Y, ZENG Y P, JIANG D. Microstructure and mechanical properties of porous Si3N4 ceramics prepared by freeze-casting .Mater. Des, 2012, 33: 98-103. |

| [65] | YE F, ZHANG J, ZHANG H, et al. Effect of sintering temperature on microstructure and mechanical properties of highly porous silicon nitride ceramics produced by freeze casting . Mater. Sci. Eng. A, Struct Mater, Prop. Microstruct. Process., 2010, 527(2425): 6501-6504. |

| [66] | LI J, ZUO K, LIU W, et al. Porous Al2O3 prepared via freeze casting and its biocompatibility.Ceramic Materials and Components for Energy and Environmental Applications 2010, 210(537-543): 537-543. |

| [67] | DEVILLE S. Freeze-casting of porous biomaterials: structure, properties and opportunities .Mater, 2010, 3(3): 1913-1927. |

| [68] | SOFIE S W. Fabrication of functionally graded and aligned porosity in thin ceramic substrates with the novel freeze- tape-casting process .J. Am. Ceram. Soc, 2007, 90(7): 2024-2031. |

| [69] | CHEN Y, BUNCH J, LI T, et al. Novel functionally graded acicular electrode for solid oxide cells fabricated by the freeze- tape-casting process. J. Power Sources, 2012, 213(93-99): 93-99. |

| [70] | REN L, ZENG Y P, JIANG D. Fabrication of gradient pore TiO2 sheets by a novel freeze-tape-casting process .J. Am. Ceram. Soc, 2007, 90(9): 3001-3004. |

| [71] | WEI P, SOFIE S, ZHANG Q, et al. Metal supported solid oxide fuel cell by freeze tape casting. Solid Oxide Fuel Cells, 2011, 35(1): 379-383. |

| [72] | WASCHKIES T, OBERACKER R, HOFFMANN M J. Control of lamellae spacing during freeze casting of ceramics using doubleside cooling as a novel processing route .J. Am. Ceram. Soc, 2009, 92(1): S79-S84. |

| [73] | PREISS A, SU B, COLLINS S, et al. Tailored graded pore structure in zirconia toughened alumina ceramics using double-side cooling freeze casting . J. Eur. Ceram. Soc., 2012, 32(8): 1575-1583. |

| [74] | LEE J H, CHOI H J, YOON S Y, et al. Porous mullite ceramics derived from coal fly ash using a freeze-gel casting/polymer sponge technique J. Porous Mater., 2013, 20(1): 219-226. |

| [75] | MONMATURAPOJ N, SOODSAWANG W, THEPSUWAN W. Porous hydroxyapatite scaffolds produced by the combination of the gel-casting and freeze drying techniques. J. Porous Mater., 2012, 19(4): 441-447. |

| [76] | CHEN P Y, MCKITTRICK J. XXX_record.do?product=UA&search_mode=GeneralSearch&qid=4&SID=P2Zcqa7oFMcmXTlScDM&page=1&doc=1&cacheurlFromRightClick=no"Compressive mechanical properties of demineralized and deproteinized cancellous bone . J. Mech. Behav. Biomed. Mater., 2011, 4(7): 961-973. |

| [77] | BARG S, INNOCENTINI M D M, MELONI R V, et al. Physical and high-temperature permeation features of double-layered cellular filtering membranes prepared via freeze casting of emulsified powder suspensions. Journal of Membrane Science, 2011, 383(1/2): 35-43. |

| [78] | XIE X, ZHOU Y L, BI H C, et al. Large-range control of the microstructures and properties of three-dimensional porous graphene. Sciencefic reports, 2013, 3(2117): 1-6. |

| [1] | WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials [J]. Journal of Inorganic Materials, 2024, 39(9): 965-978. |

| [2] | YANG Xin, HAN Chunqiu, CAO Yuehan, HE Zhen, ZHOU Ying. Recent Advances in Electrocatalytic Nitrate Reduction to Ammonia Using Metal Oxides [J]. Journal of Inorganic Materials, 2024, 39(9): 979-991. |

| [3] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [4] | HUANG Jie, WANG Liuying, WANG Bin, LIU Gu, WANG Weichao, GE Chaoqun. Research Progress on Modulation of Electromagnetic Performance through Micro-nanostructure Design [J]. Journal of Inorganic Materials, 2024, 39(8): 853-870. |

| [5] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [6] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [7] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [8] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [9] | ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix [J]. Journal of Inorganic Materials, 2024, 39(6): 623-633. |

| [10] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [11] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [12] | ZHANG Hui, XU Zhipeng, ZHU Congtan, GUO Xueyi, YANG Ying. Progress on Large-area Organic-inorganic Hybrid Perovskite Films and Its Photovoltaic Application [J]. Journal of Inorganic Materials, 2024, 39(5): 457-466. |

| [13] | LI Zongxiao, HU Lingxiang, WANG Jingrui, ZHUGE Fei. Oxide Neuron Devices and Their Applications in Artificial Neural Networks [J]. Journal of Inorganic Materials, 2024, 39(4): 345-358. |

| [14] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [15] | HU Mengfei, HUANG Liping, LI He, ZHANG Guojun, WU Houzheng. Research Progress on Hard Carbon Anode for Li/Na-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(1): 32-44. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||