Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (5): 457-466.DOI: 10.15541/jim20230448

Special Issue: 【能源环境】钙钛矿(202506); 【能源环境】太阳能电池(202506)

• REVIEW • Next Articles

ZHANG Hui1,2( ), XU Zhipeng1,2, ZHU Congtan1,2, GUO Xueyi1,2, YANG Ying1,2(

), XU Zhipeng1,2, ZHU Congtan1,2, GUO Xueyi1,2, YANG Ying1,2( )

)

Received:2023-09-28

Revised:2023-12-15

Published:2024-05-20

Online:2024-01-08

Contact:

YANG Ying, professor. E-mail: muyicaoyang@csu.edu.cnAbout author:ZHANG Hui (2001-), female, Master candidate. E-mail: 223512181@csu.edu.cn

Supported by:CLC Number:

ZHANG Hui, XU Zhipeng, ZHU Congtan, GUO Xueyi, YANG Ying. Progress on Large-area Organic-inorganic Hybrid Perovskite Films and Its Photovoltaic Application[J]. Journal of Inorganic Materials, 2024, 39(5): 457-466.

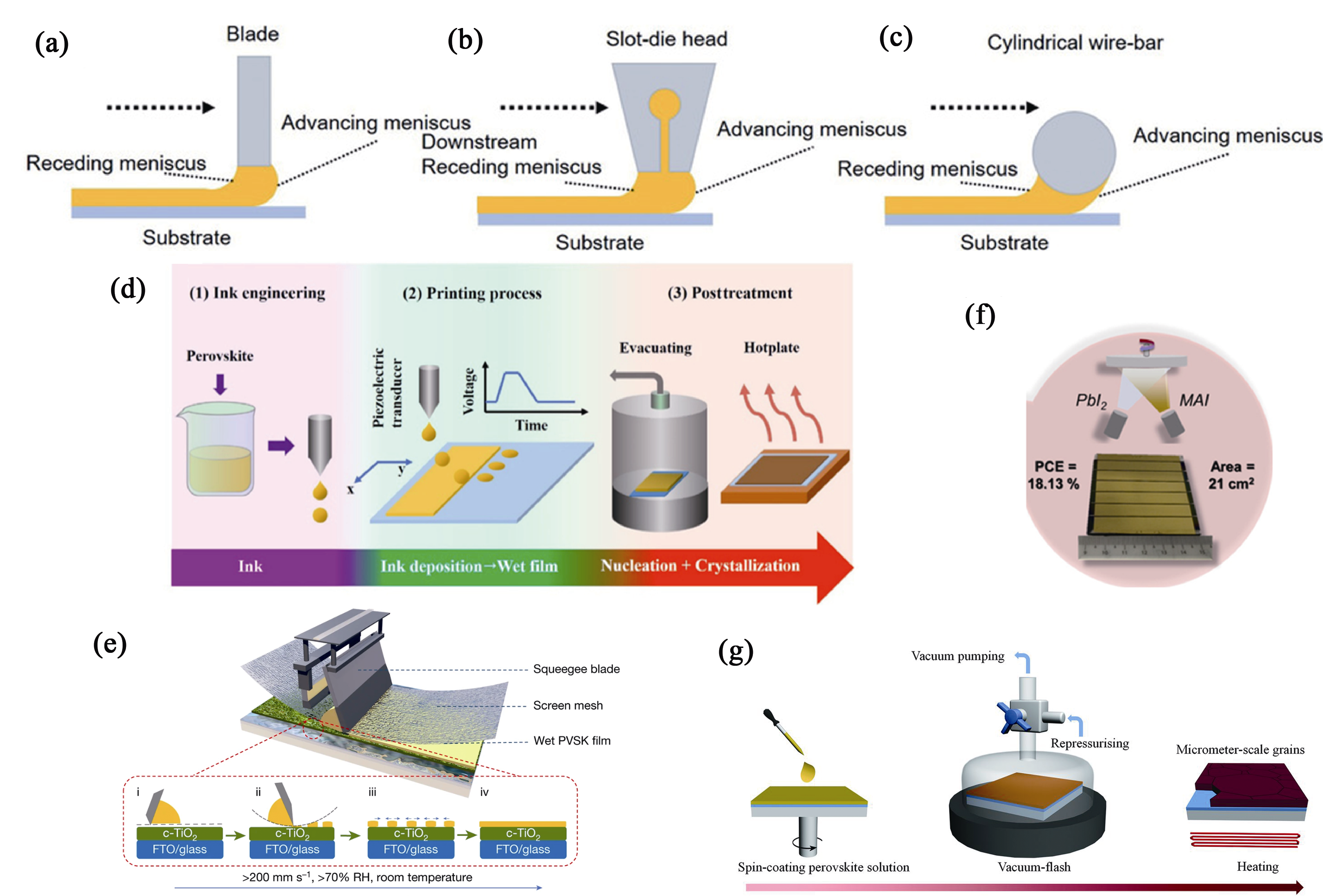

Fig. 1 Scalable-deposition techniques of large-area PSCs (a) Blade-coating; (b) Slot-die coating; (c) Bar coating[21]; (d) Inkjet printing[22]; (e) Screen printing[23]; (f) Co-evaporation[24]; (g) Vacuum flash-assisted solution process (VASP)[26]

| Perovskite layer composition | Deposition technique | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | Area/cm2 | Ref. |

|---|---|---|---|---|---|---|---|

| FA0.88Cs0.12PbI3 | One-step blade-coating | 1.00 | 21.21 | 72 | 15.30 | 205 | [ |

| MAPbI3 | One-step blade-coating | 1.08 | 23.17 | 68 | 17.06 | 1 | [ |

| FAPbI3 | Two-step blade-coating | 6.71 | 3.47 | 71 | 16.54 | 25 | [ |

| FAPbI3 | Two-step blade-coating | 6.65 | 3.72 | 75 | 18.65 | 25 | [ |

| (FACs)Pb(IBr) | Vacuum evaporation+blade-coating | 1.20 4.72 | 24.42 5.59 | 82 76 | 24.03 20.02 | 1 16 | [ |

| FA0.15MA0.85PbI3 | Screen printing | 1.10 | 23.93 | 69 | 18.12 | 1 | [ |

| MAPbI3 | Co-evaporation | 6.71 | 3.68 | 73 | 18.13 | 21 | [ |

| FA0.81MA0.15PbI2.51Br0.45 | Two-step spin-coating+VASP | 1.14 | 23.19 | 76 | 20.38 | 1 | [ |

| FA0.995MA0.005Pb(I0.995Br0.005)3 | Vacuum evaporation+spin-coating | 1.18 | 24.55 | 77 | 22.26 | 1 | [ |

Table 1 Summary of large area (≥1 cm2) perovskite layer composition, deposition techniques and corresponding PSCs performance

| Perovskite layer composition | Deposition technique | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | Area/cm2 | Ref. |

|---|---|---|---|---|---|---|---|

| FA0.88Cs0.12PbI3 | One-step blade-coating | 1.00 | 21.21 | 72 | 15.30 | 205 | [ |

| MAPbI3 | One-step blade-coating | 1.08 | 23.17 | 68 | 17.06 | 1 | [ |

| FAPbI3 | Two-step blade-coating | 6.71 | 3.47 | 71 | 16.54 | 25 | [ |

| FAPbI3 | Two-step blade-coating | 6.65 | 3.72 | 75 | 18.65 | 25 | [ |

| (FACs)Pb(IBr) | Vacuum evaporation+blade-coating | 1.20 4.72 | 24.42 5.59 | 82 76 | 24.03 20.02 | 1 16 | [ |

| FA0.15MA0.85PbI3 | Screen printing | 1.10 | 23.93 | 69 | 18.12 | 1 | [ |

| MAPbI3 | Co-evaporation | 6.71 | 3.68 | 73 | 18.13 | 21 | [ |

| FA0.81MA0.15PbI2.51Br0.45 | Two-step spin-coating+VASP | 1.14 | 23.19 | 76 | 20.38 | 1 | [ |

| FA0.995MA0.005Pb(I0.995Br0.005)3 | Vacuum evaporation+spin-coating | 1.18 | 24.55 | 77 | 22.26 | 1 | [ |

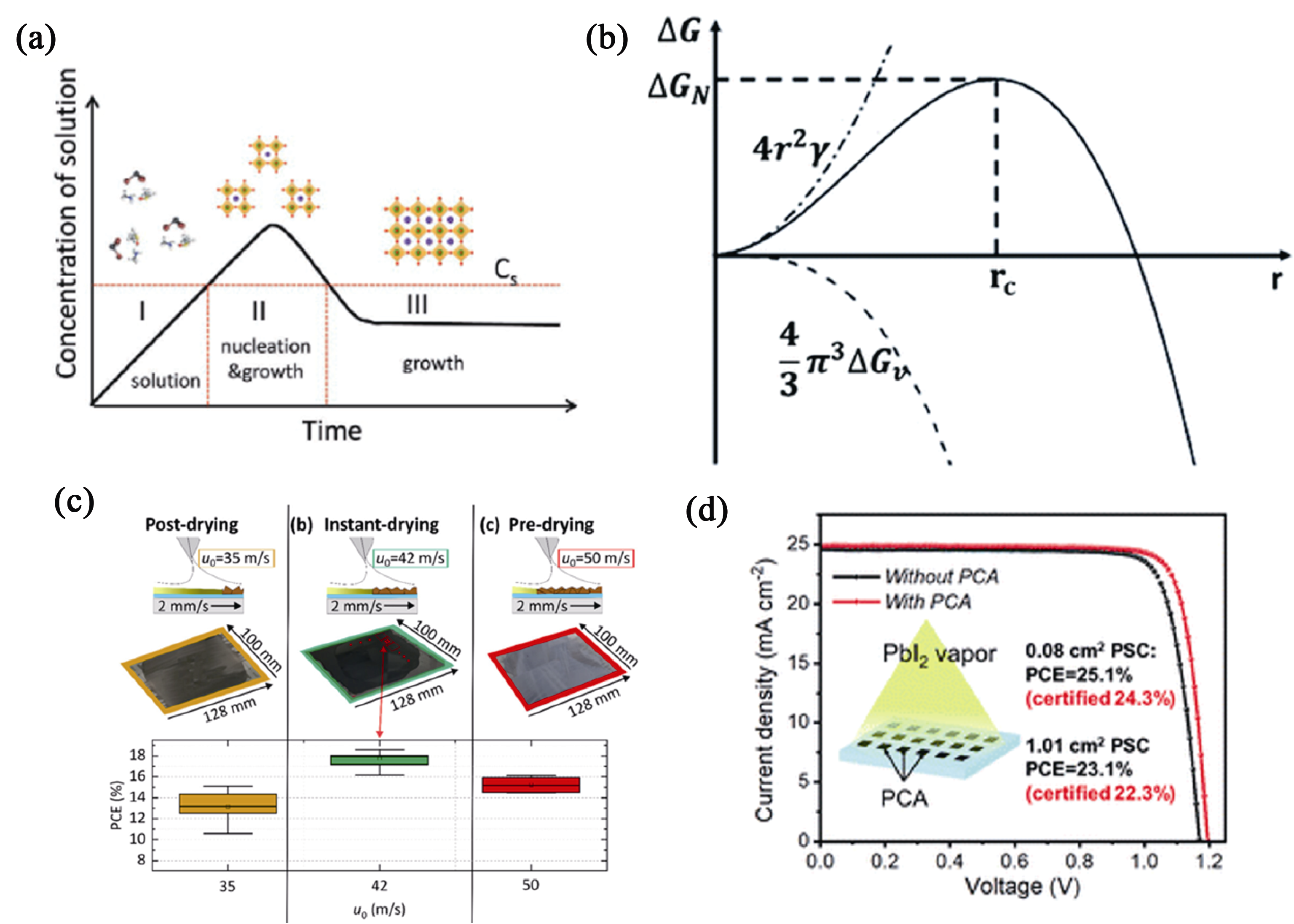

Fig. 2 Film-forming mechanism of perovskite layer (a) LaMer model for nucleation and growth of perovskite films[5]; (b) Relationship between volumetric and interfacial energy for the energy barrier to form a nucleus[28]; (c) Photographs and PCEs of PSCs from devices fabricated on test areas of the respective substrates (>100 cm2) (u0: speed of air knife)[29]; (d) J-V curves of perovskite crystal array (PCA) treated PSCs[30]

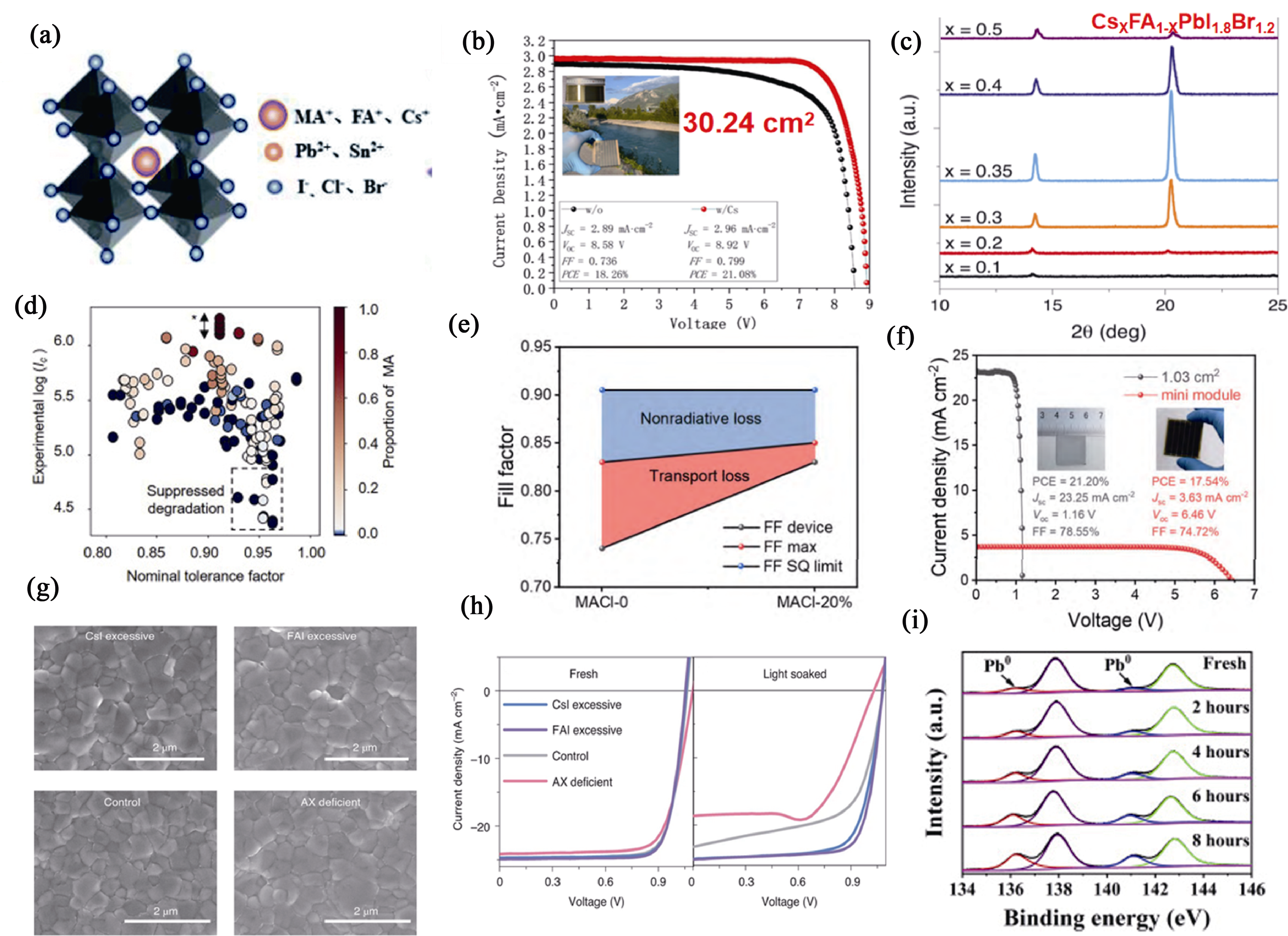

Fig. 3 Composition engineering of perovskite material ABX3 (a) Schematic diagram of crystal structure of perovskite[32]; (b) J-V curves of solar modules based on W/O and W/Cs perovskite films[34]; (c) X-ray diffraction patterns of CsxFA1-xPbI1.8Br1.2 perovskite films[35]; (d) Roles of cations in the realized degradation routes[36] (IC: instability index); (e) Fill factor limitation comprises nonradiative loss (blue area) and transport loss (pink area)[39]; (f) J-V curves of 1.03 cm2 PSCs and 10.93 cm2 mini-module level PSCs with insets showing their pictures[39]; (g) Scanning electron microscopy (SEM) images of FACs perovskite films with different compositions[40]; (h) J-V curves of FACs perovskite solar cells with different compositions before and after light soaking[40]; (i) Pb4f high-resolution X-ray photoelectron spectra of perovskite films using PbI2 precursor films with light irradiation for 0-8 h[43]

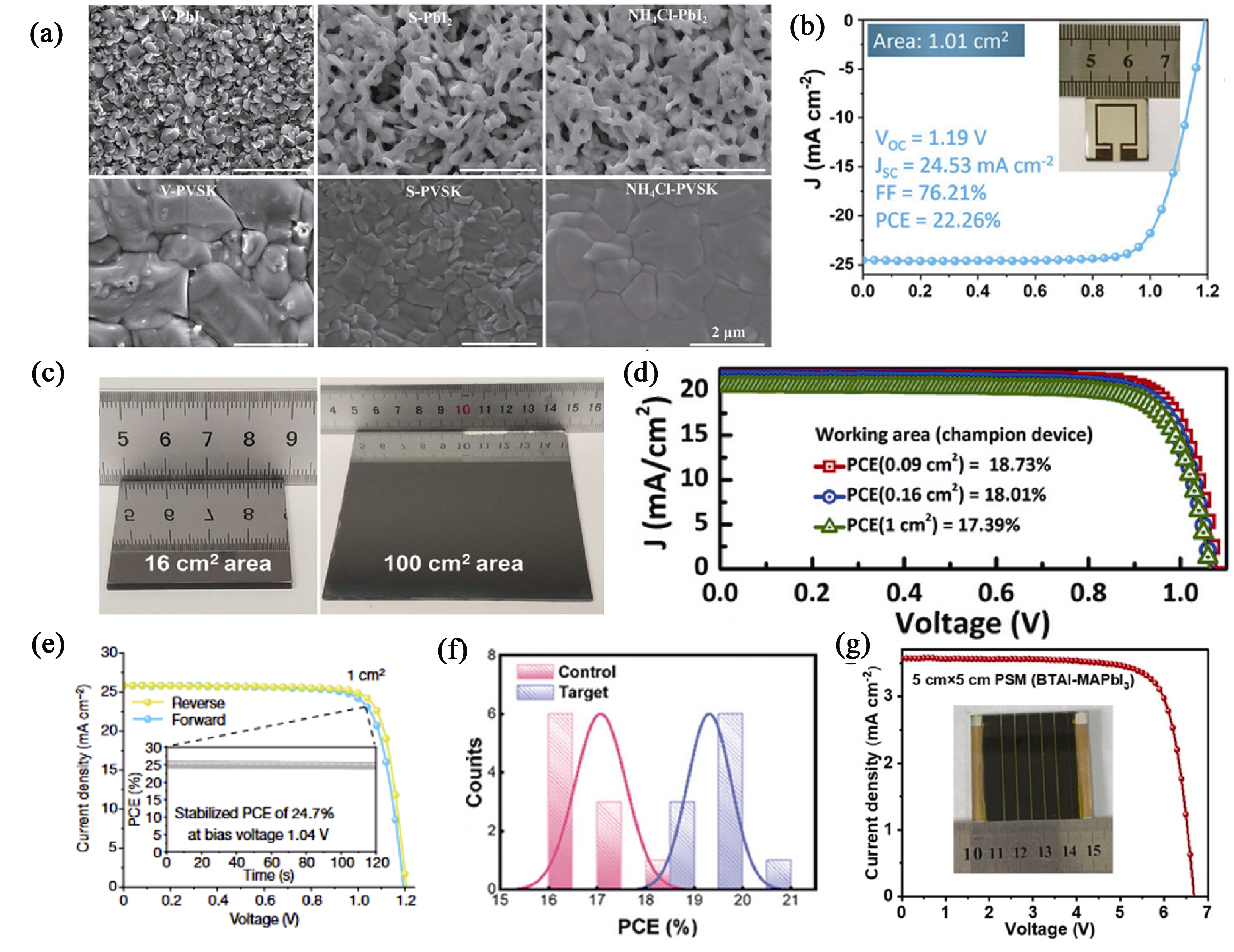

Fig. 4 Additive engineering of perovskite precursor ink (a) SEM images of vapor deposited PbI2 (V-PbI2) with solution processed PbI2 (S-PbI2) as the control films, or solution processed NH4Cl-PbI2 films, and their corresponding perovskite films[60]; (b) J-V curve and picture of a large-area PSC (1.01 cm2) based on NpMAI (NpMA: 1-naphthalenemethylammounium) treated films[61]; (c) Digital images of two pieces of representative crown-FACsPbI3 films (16 and 100 cm2 area) [63]; (d) J-V curves for the champion sulfolane treated PSCs with 0.09, 0.16, and 1 cm2 working areas[64]; (e) J-V curves of a larger device (1 cm2) with perfluorobenzene (HFB)[65]; (f) PCE distributions of 10 independent PSCs with (target) and without (control) modification[66]; (g) J-V curve and photograph of a 5 cm×5 cm BTAI-MAPbI3 based perovskite solar module (PSM)[67]

| Perovskite layer composition | Factor affecting perovskite crystallinity | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | Area/cm2 | Ref. | |

|---|---|---|---|---|---|---|---|---|

| FA0.83Cs0.17PbI3 | Solvent system | DMF/NMP | 15.35 | 1.67 | 76 | 19.54 | 65 | [ |

| MA0.6FA0.4PbI3 | 2-ME/DMSO/CBH | 5.81 16.07 | 4.25 1.53 | 78 78 | 18.126 19.15 | 18 50 | [ | |

| (FAPbI3)0.875(CsPbBr3)0.125 | DMF/DMPU | 6.69 | 3.70 | 72 | 17.71 | 10 | [ | |

| (FAPbI3)0.95(CsPbBr3)0.05 | DMF/DMPU | 10.82 | 2.15 | 77 | 17.94 | 20 | [ | |

| FA0.83Cs0.17PbI2.83Br0.17 | DMF/NMP/DPSO | 1.08 | 20.63 | 74 | 16.63 | 21 | [ | |

| (FAPbI3)0.95(MAPbBr3)0.05 | 2-ME/DMI | 15.46 | 1.71 | 76 | 20.15 | 81 | [ | |

| (FAPbI3)0.95(MAPbBr3)0.05 | 2-ME/CHP | 5.79 11.79 | 4.54 2.14 | 80 81 | 20.99 20.40 | 15 31 | [ | |

| MAPbI3 | 2-ME/DMSO | 3.19 | 7.19 | 70 | 14.57 | 2 | [ | |

| FAPbI3 | 2-ME/ACN | 8.36 | 3.06 | 67 | 17.10 | 13 | [ | |

| MAPbI3 | 2-ME/DMSO/ACN | 18.90 | 1.17 | 76 | 16.90 | 64 | [ | |

| FAPbI3 | DMF/DMSO/ACN | 9.00 | 3.14 | 76 | 21.90 | 16 | [ | |

| Cs0.03(FA0.97MA0.03)0.97Pb(I0.97Br0.03)3 | DMF/DMSO/EtOH | 1.19 3.50 | 23.98 7.57 | 74 72 | 21.04 18.95 | 1 3 | [ | |

| (FAMA)PbI3 | Type of additive | NH4Cla | 7.31 | 2.96 | 67 | 14.55 | 25 | [ |

| (FAMA)PbI3 | NpMAIa | 1.19 | 24.53 | 76 | 22.26 | 1 | [ | |

| (FACs)PbI3 | Crown | 5.63 14.29 | 4.17 1.67 | 71 58 | 16.69 13.84 | 16 100 | [ | |

| MAPbI3 | Sulfolane | 7.44 | 3.04 | 71 | 16.06 | 37 | [ | |

| FAPbI3 | Hexaflorobenzene | 1.21 | 25.2 | 80 | 25.12 | 1 | [ | |

| FAPbI3 | NAMHI | 6.61 | 3.85 | 79 | 20.10 | 10 | [ | |

| MAPbI3 | BTAI | 6.52 | 3.51 | 80 | 18.57 | 12 | [ | |

| FA0.9MA0.03Cs0.07Pb(I0.92Br0.08)3 | PMA-AA | 11.54 | 2.37 | 80 | 21.95 | 14 | [ | |

Table 2 Summary of large area (≥1 cm2) perovskite layer composition, factors influencing the crystallinity (solvent system and additive type) and performance of corresponding PSCs

| Perovskite layer composition | Factor affecting perovskite crystallinity | VOC/V | JSC/(mA·cm-2) | FF/% | PCE/% | Area/cm2 | Ref. | |

|---|---|---|---|---|---|---|---|---|

| FA0.83Cs0.17PbI3 | Solvent system | DMF/NMP | 15.35 | 1.67 | 76 | 19.54 | 65 | [ |

| MA0.6FA0.4PbI3 | 2-ME/DMSO/CBH | 5.81 16.07 | 4.25 1.53 | 78 78 | 18.126 19.15 | 18 50 | [ | |

| (FAPbI3)0.875(CsPbBr3)0.125 | DMF/DMPU | 6.69 | 3.70 | 72 | 17.71 | 10 | [ | |

| (FAPbI3)0.95(CsPbBr3)0.05 | DMF/DMPU | 10.82 | 2.15 | 77 | 17.94 | 20 | [ | |

| FA0.83Cs0.17PbI2.83Br0.17 | DMF/NMP/DPSO | 1.08 | 20.63 | 74 | 16.63 | 21 | [ | |

| (FAPbI3)0.95(MAPbBr3)0.05 | 2-ME/DMI | 15.46 | 1.71 | 76 | 20.15 | 81 | [ | |

| (FAPbI3)0.95(MAPbBr3)0.05 | 2-ME/CHP | 5.79 11.79 | 4.54 2.14 | 80 81 | 20.99 20.40 | 15 31 | [ | |

| MAPbI3 | 2-ME/DMSO | 3.19 | 7.19 | 70 | 14.57 | 2 | [ | |

| FAPbI3 | 2-ME/ACN | 8.36 | 3.06 | 67 | 17.10 | 13 | [ | |

| MAPbI3 | 2-ME/DMSO/ACN | 18.90 | 1.17 | 76 | 16.90 | 64 | [ | |

| FAPbI3 | DMF/DMSO/ACN | 9.00 | 3.14 | 76 | 21.90 | 16 | [ | |

| Cs0.03(FA0.97MA0.03)0.97Pb(I0.97Br0.03)3 | DMF/DMSO/EtOH | 1.19 3.50 | 23.98 7.57 | 74 72 | 21.04 18.95 | 1 3 | [ | |

| (FAMA)PbI3 | Type of additive | NH4Cla | 7.31 | 2.96 | 67 | 14.55 | 25 | [ |

| (FAMA)PbI3 | NpMAIa | 1.19 | 24.53 | 76 | 22.26 | 1 | [ | |

| (FACs)PbI3 | Crown | 5.63 14.29 | 4.17 1.67 | 71 58 | 16.69 13.84 | 16 100 | [ | |

| MAPbI3 | Sulfolane | 7.44 | 3.04 | 71 | 16.06 | 37 | [ | |

| FAPbI3 | Hexaflorobenzene | 1.21 | 25.2 | 80 | 25.12 | 1 | [ | |

| FAPbI3 | NAMHI | 6.61 | 3.85 | 79 | 20.10 | 10 | [ | |

| MAPbI3 | BTAI | 6.52 | 3.51 | 80 | 18.57 | 12 | [ | |

| FA0.9MA0.03Cs0.07Pb(I0.92Br0.08)3 | PMA-AA | 11.54 | 2.37 | 80 | 21.95 | 14 | [ | |

| [1] | NREL. Best research-cell efficiency chart [2023-12-13]. https://www.nrel.gov/pv/cell-efficiency.html. |

| [2] | GREEN M A, DUNLOP E D, YOSHITA M, et al. Solar cell efficiency tables (version 62). Prog. Photovoltaics, 2023, 31(7): 651. |

| [3] | BU T L, ONO L K, LI J, et al. Modulating crystal growth of formamidinium-caesium perovskites for over 200 cm2 photovoltaic sub-modules. Nat. Energy, 2022, 7(6): 528. |

| [4] | LIN H, YANG M, RU X N, et al. Silicon heterojunction solar cells with up to 26.81% efficiency achieved by electrically optimized nanocrystalline-silicon hole contact layers. Nat. Energy, 2023, 8(8): 789. |

| [5] | LEE J, LEE D, JEONG D, et al. Control of crystal growth toward scalable fabrication of perovskite solar cells. Adv. Funct. Mater., 2019, 29(47): 1807047. |

| [6] | 关英翔. 大面积钙钛矿型太阳能电池及组件制作工艺. 北京: 北京信息科技大学硕士学位论文, 2015. |

| [7] |

RONG Y G, HOU X M, HU Y, et al. Synergy of ammonium chloride and moisture on perovskite crystallization for efficient printable mesoscopic solar cells. Nat. Commun., 2017, 8: 14555.

DOI PMID |

| [8] | PARIDA B, SINGH A, SOOPY A K K, et al. Recent developments in upscalable printing techniques for perovskite solar cells. Adv. Sci., 2022, 9(14): 220308. |

| [9] | 丁建宁. 新型薄膜太阳能电池. 北京: 化学工业出版社, 2018: 81-82. |

| [10] | ZHANG H, ZHAO C X, YAO J X, et al. Dopant-free NiOx nanocrystals: a low-cost and stable hole transport material for commercializing perovskite optoelectronics. Angew. Chem. Int. Ed., 2023, 62(24): e202219307. |

| [11] |

LIU C, YANG Y, CHEN H, et al. Bimolecularly passivated interface enables efficient and stable inverted perovskite solar cells. Science, 2023, 382(6672): 810.

DOI PMID |

| [12] | WU X, GAO D P, SUN X L, et al. Backbone engineering enables highly efficient polymer holetransporting materials for inverted perovskite solar cells. Adv. Mater., 2022, 35(12): 2208431. |

| [13] | CHEN Y, LIN P, CAI B, et al. Research progress of inorganic hole transport materials in perovskite solar cells. J. Inorg. Mater., 2023, 38(9): 991. |

| [14] |

ZHU C T, GAO J, CHEN T, et al. Intrinsic thermal stability of inverted perovskite solar cells based on electrochemical deposited PEDOT. J. Energy Chem., 2023, 83: 445.

DOI |

| [15] | PARK B W, KWON H W, LEE Y H, et al. Stabilization of formamidinium lead triiodide α-phase with isopropylammonium chloride for perovskite solar cells. Nat. Energy, 2021, 6(8): 419. |

| [16] | LI J B, MUNIR R, FAN Y Y, et al. Phase transition control for high-performance blade-coated perovskite solar cells. Joule, 2(7): 1313. |

| [17] | ZHANG J W, BU T L, LI J, et al. Two-step sequential blade-coating of high quality perovskite layers for efficient solar cells and modules. J. Mater. Chem. A, 2020, 8(17): 8447. |

| [18] | WEN Y T, LI J, GAO X F, et al. Two-step sequential blade-coating large-area FA-based perovskite thin film via a controlled PbI2 microstructure. Acta Phys.-Chim. Sin., 2023, 32(2): 2203048. |

| [19] | TAN L G, ZHOU J J, ZHAO X, et al. Combined vacuum evaporation and solution process for high-efficiency large‐area perovskite solar cells with exceptional reproducibility. Adv. Mater., 2023, 35(3): 2205027. |

| [20] | 杨志春, 吴狄, 剡晓波, 等. 大面积钙钛矿薄膜制备技术的研究进展. 材料导报, 2021, 35(1): 1046. |

| [21] | LI D Y, ZHANG D Y, LIM K S, et al. A review on scaling up perovskite solar cells. Adv. Funct. Mater., 2021, 31(12): 2008621. |

| [22] | CHEN Y J, WU H J, MA J J, et al. Droplet manipulation and crystallization regulation in inkjet-printed perovskite film formation. CCS Chem., 2022, 4(5): 1465. |

| [23] | CHEN C S, CHEN J X, HAN H C, et al. Perovskite solar cells based on screen-printed thin films. Nature, 2022, 612(7939): 266. |

| [24] | LI J, WANG H, CHIN X Y, et al. Highly efficient thermally co-evaporated perovskite solar cells and mini-modules. Joule, 2020, 4(5): 1035. |

| [25] | LEYDEN M R, JIANG Y, QI Y B, et al. Chemical vapor deposition grown formamidinium perovskite solar modules with high steady state power and thermal stability. J. Mater. Chem. A, 2016, 4(34): 13125. |

| [26] |

LI X, BI D Q, YI C Y, et al. A vacuum flash-assisted solution process for high-efficiency large-area perovskite solar cells. Science, 2016, 353(6294): 58.

DOI PMID |

| [27] | SANCHEZ S, PFEIFER L, VACHOPOUOUS N, et al. Rapid hybrid perovskite film crystalization form solution. Chem. Sov. Rev., 2021, 50(12): 7108. |

| [28] | LIU C, CHENG Y B, GE Z Y. Understanding of perovskite crystal growth and film formation in scalable deposition processes. Chem. Sov. Rev., 2020, 49(6): 1653. |

| [29] | GEISTERT K, TERNES S, RITZER D B, et al. Controlling thin film morphology formation during gas quenching of slot-die coated perovskite solar modules. ACS Appl. Mater. Interfaces, 2023, 15(45): 52519. |

| [30] | SHEN Z C, HAN Q F, LUO X H, et al. Crystal-array-assisted growth of a perovskite absorption layer for efficient and stable solar cells. Energy Environ. Sci., 2022, 15(3): 1078. |

| [31] |

DUNLAP-SHOHL W A, ZHOU Y Y, PADTURE N P, et al. Synthetic approaches for halide perovskite thin films. Chem. Rev., 2019, 119(5): 3193.

DOI |

| [32] | ZHENG Z W, WANG S Y, HU Y, et al. Development of formamidinium lead iodide-based perovskite solar cells: efficiency and stability. Chem. Sci., 2022, 13(8): 2167. |

| [33] | MUSCARELLA L A, EHRLER B. The influence of strain on phase stability in mixed-halide perovskites. Joule, 2022, 6(9): 2016. |

| [34] | LIU X H, CHEN M, ZHANG Y, et al. High-efficiency perovskite photovoltaic modules achieved via cesium doping. Chem. Eng. J., 2022, 431(4): 133713. |

| [35] |

XIAO K, LIN H Y, ZHANG M, et al. Scalable processing for realizing 21.7%-efficient all-perovskite tandem solar modules. Science, 2022, 376(6594): 762.

DOI PMID |

| [36] | SUN S J, TIIHONEN A, OVIEDO F, et al. A data fusion approach to optimize compositional stability of halide perovskites. Matter, 2021, 4(4): 1305. |

| [37] |

SALIBA M, MATSUI T, DOMANSKI K, et al. Incorporation of rubidium cations into perovskite solar cells improves photovoltaic performance. Science, 2016, 354(6309): 206.

PMID |

| [38] | ZHAO Y, MA F, QU Z H, et al. Inactive (PbI2)2RbCl stabilizes perovskite films for efficient solar cells. Science, 2022, 377(6605): 531. |

| [39] | CHANG J H, FENG E M, LI H Y, et al. Crystallization and orientation modulation enable highly efficient doctor-bladed perovskite solar cells. Nano-Micro Letter, 2023, 15(issue): 164. |

| [40] | DENG Y H, XU S, CHEN S S, et al. Defect compensation in formamidinium-caesium perovskites for highly efficient solar mini- modules with improved photostability. Nat. Energy, 2021, 6(6): 633. |

| [41] | JACOBSSON T J, CORREA-BAEBA J P, NARAKI E H, et al. Unreacted PbI2 as a double-edged sword for enhancing the performance of perovskite solar cells. J. Am. Chem. Soc., 2016, 138(32): 10331. |

| [42] | MACPHERSON S, DOHERTY T A S, WINCHESTAR A J, et al. Local nanoscale phase impurities are degradation sites in halide perovskite. Nature, 2022, 607(7918): 294. |

| [43] | LIANG J W, HU X Z, WANG C, et al. Origins and influences of metallic lead in perovskite solar cells. Joule, 6(4): 816. |

| [44] | CHAO L F, NIU T T, GAO W Y, et al. Solvent engineering of the precursor solution toward large-area production of perovskite solar cells. Adv. Mater., 2021, 33(14): 2005410. |

| [45] |

BU T L, LI J, LI H Y, et al. Lead halide-templated crystallization of methylamine-free perovskite for efficient photovoltaic modules. Science, 2021, 372(6548): 1327.

DOI PMID |

| [46] |

CHEN S S, DAI X Z, XU S, et al. Stabilizing perovskite-substrate interfaces for high-performance perovskite modules. Science, 2021, 373(6557): 902.

DOI PMID |

| [47] | LI H Y, BU T, LI J, et al. Ink engineering for blade coating FA-dominated perovskites in ambient air for efficient solar cells and modules. ACS Appl. Mater. Interfaces, 2021, 13(16): 18724. |

| [48] | LEE D K, LIM K S, LEE J W, et al. Scalable perovskite coating via anti-solvent-free Lewis acid-base adduct engineering for efficient perovskite solar modules. J. Mater. Chem. A, 2021, 9(5): 3018. |

| [49] | YANG Z C, ZHANG W J, WU S H, et al. Slot-die coating large-area formamidinium-cesium perovskite film for efficient and stable parallel solar module. Adv. Sci., 2021, 7(18): eabg3749. |

| [50] | CHUNG J, KIM S, LI Y, et al. Engineering perovskite precursor inks for scalable production of high-efficiency perovskite photovoltaic modules. Adv. Energy Mater., 2023, 13(22): 2300595. |

| [51] | YOO J W, JANG J H, KIM U, et al. Efficient perovskite solar mini-modules fabricated via bar-coating using 2-methoxyethanol- based formamidinium lead tri-iodide precursor solution. Joule, 2021, 5(9): 2420. |

| [52] | LI J Z, DAGAR J, SHARGAIEVA O, et al. 20.8% slot-die coated MAPbI3 perovskite solar cells by optimal DMSO-content and age of 2-ME based precursor inks. Adv. Energy Mater., 2021, 11(10): 2003460. |

| [53] | LI J Z, DAGAR J, SHARGAIEVA O, et al. Ink design enabling slot-die coated perovskite solar cells with >22% power conversion efficiency, micro-modules, and 1 year of outdoor performance evaluation. Adv. Energy Mater., 2022, 13(33): 2203898. |

| [54] | DENG Y H, BRACKE C H V, DAI X Z, et al. Tailoring solvent coordination for high-speed, room-temperature blading of perovskite photovoltaic films. Sci. Adv., 2019, 5(12): eaax7537. |

| [55] | YUAN L H, CHEN X N, GUO X M, et al. Volatile perovskite precursor ink enables window printing of phase-pure FAPbI3 perovskite solar cells and modules in ambient atmosphere. Angew. Chem. Int. Ed., 2024, 63(7): e202316954. |

| [56] | NOEL N K, HABISREYTINGER S N, WENGER B, et al. A low viscosity, low boiling point, clean solvent system for the rapid crystallisation of highly specular perovskite films. Energy Environ. Sci., 2016, 10(1): 145. |

| [57] | LIANG Q, LIU K, SUN M, et al. Manipulating crystallization kinetics in high-performance blade-coated perovskite solar cells via cosolvent-assisted phase transition. Adv. Mater., 2022, 34(16): 2200276. |

| [58] | ZHAI P, REN L X, LI S Q, et al. Light modulation strategy for highest-efficiency water-processed perovskite solar cells. Matter, 2022, 5(12): 4450. |

| [59] |

WANG W, ZHOU J, TANG W. Passivation strategies of perovskite film defects for solar cells. J. Inorg. Mater., 2022, 37(2): 129.

DOI |

| [60] | TONG G Q, SON D, ONO L K, et al. Scalable fabrication of >90 cm2 perovskite solar modules with >1000 h operational stability based on the intermediate phase strategy. Adv. Energy Mater., 2021, 11(10): 2003712. |

| [61] | ZHOU T, XU Z Y, WANG R, et al. Crystal growth regulation of 2D/3D perovskite films for solar cells with both high efficiency and stability. Adv. Mater., 2022, 34(17): 2200705. |

| [62] |

MING Y, HU Y, MEI A, et al. Application of lead acetate additive for printable perovskite solar cell. J. Inorg. Mater., 2022, 37(2): 197.

DOI |

| [63] | CHEN R H, WU Y Z, WANG Y K, et al. Crown ether-assisted growth and scaling up of FACsPbI3 films for efficient and stable perovskite solar modules. Adv. Funct. Mater., 2021, 31(11): 2008760. |

| [64] | HUANG H H, LIU Q H, TSAI H, et al. A simple one-step method with wide processing window for high-quality perovskite mini-module fabrication. Joule, 2021, 5(4): 958. |

| [65] | HUANG Z J, BAI Y, HUANG X D, et al. Anion-π interactions supress phase impurities in FAPbI3 solar cells. Nature, 2023, 623(2023): 531. |

| [66] | MENG Y Y, WANG Y L, LIU C, et al. Epitaxial growth of α-FAPbI3 at a well-matched heterointerface for efficient perovskite solar cells and solar modules. Adv. Mater., 2024, 36(6): 2309208. |

| [67] | MIAO Y, REN M, WANG H F, et al. Surface termination on unstable methylammonium-based perovskite using a steric barrier for improved perovskite solar cells. Angew. Chem. Int. Ed., 2023, 62(51): e202312726. |

| [68] | LIU D C, CHEN C, WANG X Z, et al. Enhanced quasi-Fermi level splitting of perovskite solar cells by universal dual-functional polymer. Adv. Mater., 2023, 36(13): 2310962. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||