Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (10): 1077-1083.DOI: 10.15541/jim20230565

Special Issue: 【结构材料】热障与环境障涂层(202506)

• PERSPECTIVE • Next Articles

TAO Shunyan1( ), YANG Jiasheng1, SHAO Fang1, WU Yingchen1,2, ZHAO Huayu1, DONG Shaoming3, ZHANG Xiangyu3, XIONG Ying4

), YANG Jiasheng1, SHAO Fang1, WU Yingchen1,2, ZHAO Huayu1, DONG Shaoming3, ZHANG Xiangyu3, XIONG Ying4

Received:2024-03-25

Revised:2024-05-27

Published:2024-10-20

Online:2024-10-09

About author:TAO Shunyan (1969-), male, professor. E-mail: sytao@mail.sic.ac.cn

Supported by:CLC Number:

TAO Shunyan, YANG Jiasheng, SHAO Fang, WU Yingchen, ZHAO Huayu, DONG Shaoming, ZHANG Xiangyu, XIONG Ying. Thermal Spray Coatings for Aircraft CMC Hot-end Components: Opportunities and Challenges[J]. Journal of Inorganic Materials, 2024, 39(10): 1077-1083.

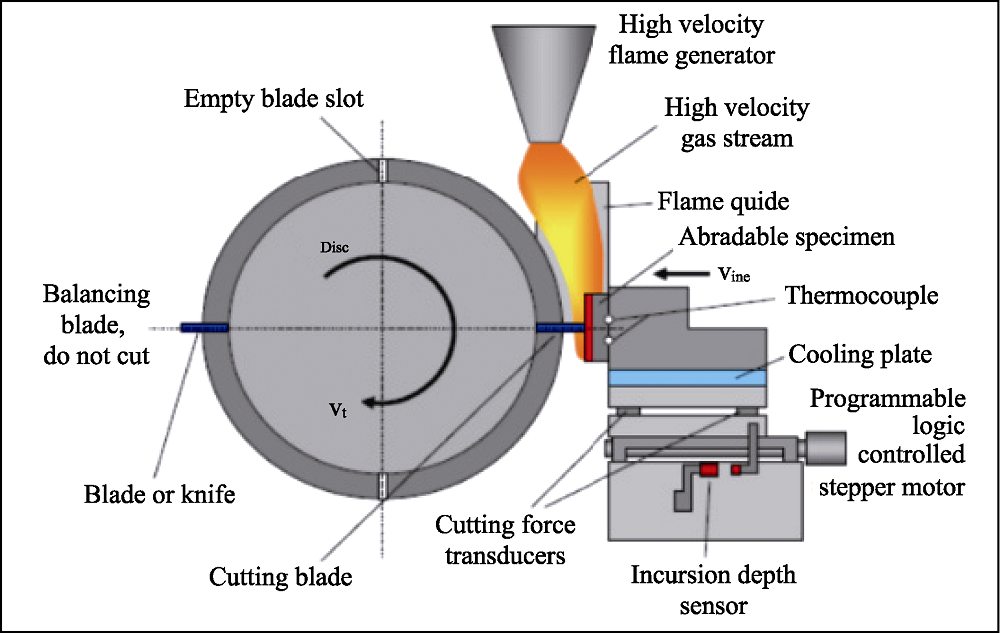

Fig. 10 Schematic drawing of the Sulzer Innotec abradability test rig [44] The oxygen / propane high temperature gas is used to heat the test piece, which can be heated to 1200 ℃; Scratch speed: 50-450 m/s; Feed rate: 1.5-3000 μm/s

| [1] | CORMAN G S, LUTHRA K L. Development history of GE's prepreg melt infiltrated ceramic matrix composite material and applications. Comprehensive Composite Materials II, 2018, 5: 325. |

| [2] | LEONARD G, STEGMAIER J. Development of an aeroderivative gas turbine dry low emissions combustion system. Journal of Engineering for Gas Turbines and Power, 1994, 116(3): 542. |

| [3] | ZHU D M, HARDER B. The development of HfO2-rare earth based oxide materials and barrier coatings for thermal protection systems. Materials Science & Technology 2014 Conference & Exhibition, Pittsburgh, 2014. |

| [4] | 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料在航空发动机上的应用需求及挑战. 材料工程, 2019, 47(2): 1. |

| [5] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15: 804.

DOI PMID |

| [6] | CLARKE D R, OECHSNER M, PADTURE N P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891. |

| [7] | LEE K N, ZHU D M, LIMA R S. Perspectives on environmental barrier coatings (EBCs) manufactured via air plasma spray (APS) on ceramic matrix composites (CMCs): a tutorial paper. Journal of Thermal Spray Technology, 2021, 30: 40. |

| [8] | TEJERO-MARTIN D, BENNETT C, HUSSAIN T. A review on environmental barrier coatings: history, current state of the art and future developments. Journal of the European Ceramic Society, 2021, 41: 1747. |

| [9] | 江舟, 倪建洋, 张小锋, 等. 陶瓷基复合材料及其环境障涂层发展现状研究. 航空制造技术, 2020, 63(14): 48. |

| [10] | 郑伟, 张佳平, 杨翠波. 陶瓷基复合材料环境障涂层研究进展. 纤维复合材料, 2021, 2: 65. |

| [11] | 刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料环境障涂层研究进展. 材料工程, 2018, 46(10): 1. |

| [12] | 赵春玲, 杨博, 李阔, 等. 陶瓷基复合材料表面环境障涂层材料研究进展. 中国材料进展, 2021, 40(4): 257. |

| [13] | 白博添, 章德铭, 冀晓鹃, 等. 环境障涂层选材研究进展. 热喷涂技术, 2022, 14(3): 1. |

| [14] | HERMAN H, SAMPATH S, MCCUNE R. Thermal spray: current status and future trends. MRS Bulletin, 2000, 25(7): 17. |

| [15] | LEE K N. Yb2Si2O7 environmental barrier coatings with reduced bond coat oxidation rates via chemical modifications for long life. Journal of the American Ceramic Society, 2019, 102(3): 1507. |

| [16] | RICHARDS B T, YOUNG K A, DE FRANQUEVILLE F, et al. Response of ytterbium disilicate-silicon environmental barrier coatings to thermal cycling in water vapor. Acta Materials, 2016, 106: 1. |

| [17] | ZHU D M. Advanced environmental barrier coatings for SiC/SiC ceramic matrix composite turbine components//Engineered ceramics: current status and future prospects. Hoboken: John Wiley & Sons, 2015. |

| [18] | BAKAN E, SOHN Y J, VASSEN R. Microstructure and phase composition evolution of silicon-hafnia feedstock during plasma spraying and following cyclic oxidation. Acta Materialia, 2021, 214: 117007. |

| [19] | LI C, HE J, MA Y, et al. Evolution mechanism of the microstructure and mechanical properties of plasma-sprayed yttria-stabilized hafnia thermal barrier coating at 1400 ℃. Ceramics International, 2020, 46: 23417. |

| [20] | LI G, LU X R, HUANG J Q, et al. Thermal cycling behavior and failure mechanism of the Si-HfO2 environmental barrier coating bond coats prepared by atmospheric plasma spraying. Journal of Alloys and Compounds, 2022, 913: 165319. |

| [21] | ZHANG Z Y, PARK Y J, KIM D H, et al. High-temperature oxidation performance of novel environmental barrier coating 50HfO2-50SiO2/YxYb(2-x)Si2O7 at 1475 ℃. Journal of the European Ceramic Society, 2023, 43: 1127. |

| [22] | JACOBSON N S. Corrosion of silicon-based ceramics in combustion environments. Journal of the American Ceramic Society, 1993, 76(1): 3. |

| [23] | OPILA E J. Variation of the oxidation rate of silicon carbide with water-vapor pressure. Journal of the American Ceramic Society, 1999, 82(3): 625. |

| [24] | KLEMM H. Silicon nitride for high-temperature applications. Journal of the American Ceramic Society, 2010, 93(6): 1501. |

| [25] | BAKAN E, MARCANO D, ZHOU D P, et al. Yb2Si2O7environmental barrier coatings deposited by various thermal spray techniques: a preliminary comparative study. Jouranl of Thermal Spray Technology, 2017, 26: 1011. |

| [26] | CHEN D Y, PEGLER A, DWIVEDI G, et al. Thermal cycling behavior of air plasma-sprayed and low-pressure plasma-sprayed environmental barrier coatings. Coatings, 2021, 11: 868. |

| [27] | DONG Y, REN K, LU Y, et al. High-entropy environmental barrier coating for the ceramic matrix composites. Journal of the European Ceramic Society, 2019, 39(7): 2574. |

| [28] | SUN L, LUO Y, TIAN Z, et al. High temperature corrosion of (Er0.25Tm0.25Yb0.25Lu0.25)2Si2O7 environmental barrier coating material subjected to water vapor and molten calcium- magnesium-aluminosilicate (CMAS). Corrosion Science, 2020, 175: 108881. |

| [29] | RIDLEY M, OPILA E. Thermochemical stability and microstructural evolution of Yb2Si2O7in high-velocity high-temperature water vapor. Journal of the European Ceramic Society, 2020, 41(5): 3141. |

| [30] | TURCER L R, PADTURE N P. Towards multifunctional thermal environmental barrier coatings (TEBCs) based on rare-earth pyrosilicate solid-solution ceramics. Scripta Materialia, 2018, 154: 111. |

| [31] | TIAN Z, ZHENG L, LI Z, et al. Exploration of the low thermal conductivities of γ-Y2Si2O7, β-Y2Si2O7, β-Yb2Si2O7, and β-Lu2Si2O7 as novel environmental barrier coating candidates. Journal of the European Ceramic Society, 2016, 36(11): 2813. |

| [32] | TIAN Z, ZHENG L, WANG J, et al. Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5 (RE=Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. Journal of the European Ceramic Society, 2016, 36(1): 189. |

| [33] | VISWANATHAN V, DWIVEDI G, SAMPATH S. Multilayer, multimaterial thermal barrier coating systems: design, synthesis, and performance assessment. Journal of the American Ceramic Society, 2015, 98(6): 1769. |

| [34] | GLEDHILL A D, REDDY K M, DREXLER J M, et al. Mitigation of damage from molten fly ash to air-plasma-sprayed thermal barrier coatings. Materials Science and Engineering: A, 2011, 528(24): 7214. |

| [35] | KRAMER S, YANG J, LEVI C G. Infiltration-inhibiting reaction of gadolinium zirconate thermal barrier coatings with CMAS melts. Journal of the American Ceramic Society, 2008, 91(2): 576. |

| [36] | VARDELLE A, MOREAU C, AKEDO J, et al. The 2016 thermal spray roadmap. Journal of Thermal Spray Technology, 2016, 25(8): 1376. |

| [37] | LI W, ZHAO H Y, ZHONG X H, et al. Air plasma-sprayed yttria and yttria-stabilized zirconia thermal barrier coatings subjected to calcium-magnesium-alumino-silicate (CMAS). Journal of Thermal Spray Technology, 2014, 23(6): 975. |

| [38] | MECHNICH P, BRAUE W. Air plasma-sprayed Y2O3 coatings for Al2O3/Al2O3 ceramic matrix composites. Journal of the European Ceramic Society, 2013, 33: 2645. |

| [39] | AUSSAVY D, BOLOT R, MONTAVON G, et al. YSZ-polyester abradable coatings manufactured by APS. Journal of Thermal Spray Technology, 2016, 25(1/2): 252. |

| [40] | SPORER D, REFKE A, DRATWINSKI M, et al. New high-temperature seal system for increased efficiency of gas turbines. Sealing Technology, 2008, 10: 9. |

| [41] | HUANG J Q, LIU R Y, HU Q, et al. High temperature abradable sealing coating for SiCf/SiC ceramic matrix composites. Ceramics International, 2023, 49: 1779. |

| [42] | GUO M Q, CUI Y J, WANG C L, et al. Design and characterization of BSAS-polyester abradable environmental barrier coatings (A/EBCs) on SiC/SiC composites. Surface & Coatings Technology, 2023, 465: 129617. |

| [43] | QIN D D, NIU Y R, LI H, et al. Fabrication and characterization of Yb2Si2O7-based composites as novel abradable sealing coatings. Ceramics International, 2021, 47: 23153. |

| [44] | STEINKE T, MAUER G, VAΒEN R, et al. Process design and monitoring for plasma sprayed abradable coatings. Journal of Thermal Spray Technology, 2010, 19: 756. |

| [45] | LIANG J J, MATSUMOTO K, KAWAGISHI K, et al. Morphological evolution of thermal barrier coatings with equilibrium (EQ) and NiCoCrAlY bond coats during thermal cycling. Surface & Coatings Technology, 2012, 207: 413. |

| [1] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [2] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [3] | ZHAO Rida, TANG Sufang. Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix [J]. Journal of Inorganic Materials, 2024, 39(6): 623-633. |

| [4] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [5] | LI Guangyu, YUE Yifan, WANG Bo, ZHANG Chengyu, SUO Tao, LI Yulong. Damage of 2D-SiC/SiC Composites under Projectile Impact and Tensile Properties after Impact [J]. Journal of Inorganic Materials, 2024, 39(5): 494-500. |

| [6] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [7] | LI Lei, CHENG Qunfeng. Recent Advances in the High Performance MXenes Nanocomposites [J]. Journal of Inorganic Materials, 2024, 39(2): 153-161. |

| [8] | XU Xiangming, Husam N ALSHAREEF. Perspective of MXetronics [J]. Journal of Inorganic Materials, 2024, 39(2): 171-178. |

| [9] | LI La, SHEN Guozhen. 2D MXenes Based Flexible Photodetectors: Progress and Prospects [J]. Journal of Inorganic Materials, 2024, 39(2): 186-194. |

| [10] | BA Kun, WANG Jianlu, HAN Meikang. Perspectives for Infrared Properties and Applications of MXene [J]. Journal of Inorganic Materials, 2024, 39(2): 162-170. |

| [11] | YIN Jianyu, LIU Nishuang, GAO Yihua. Recent Progress of MXene in Pressure Sensing [J]. Journal of Inorganic Materials, 2024, 39(2): 179-185. |

| [12] | LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs [J]. Journal of Inorganic Materials, 2024, 39(2): 145-152. |

| [13] | DENG Shungui, ZHANG Chuanfang. MXene Multifunctional Inks: a New Perspective toward Printable Energy-related Electronic Devices [J]. Journal of Inorganic Materials, 2024, 39(2): 195-203. |

| [14] | CHEN Ze, ZHI Chunyi. MXene Based Zinc Ion Batteries: Recent Development and Prospects [J]. Journal of Inorganic Materials, 2024, 39(2): 204-214. |

| [15] | DING Haoming, CHEN Ke, LI Mian, LI Youbing, CHAI Zhifang, HUANG Qing. Chemical Scissor-mediated Structural Editing of Inorganic Materials [J]. Journal of Inorganic Materials, 2024, 39(2): 115-128. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||