Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (7): 830-838.DOI: 10.15541/jim20220662

Special Issue: 【生物材料】骨骼与齿类组织修复(202506)

• RESEARCH LETTER • Previous Articles Next Articles

WU Wei1,2( ), BAKHET Shahd2, ASANTE Naomi Addai2, KAREEM Shefiu2, KOMBO Omar Ramadhan3, LI Binbin2, DAI Honglian1,2(

), BAKHET Shahd2, ASANTE Naomi Addai2, KAREEM Shefiu2, KOMBO Omar Ramadhan3, LI Binbin2, DAI Honglian1,2( )

)

Received:2022-11-05

Revised:2022-12-18

Published:2023-03-20

Online:2023-03-20

Contact:

DAI Honglian, professor. E-mail: daihonglian@whut.edu.cnAbout author:WU Wei (1998-), male, Master. E-mail: 2625276216@qq.com

Supported by:CLC Number:

WU Wei, BAKHET Shahd, ASANTE Naomi Addai, KAREEM Shefiu, KOMBO Omar Ramadhan, LI Binbin, DAI Honglian. In vitro Study of Biphasic Calcium Magnesium Phosphate Microspheres for Angiogenesis and Bone Formation[J]. Journal of Inorganic Materials, 2023, 38(7): 830-838.

| Gene | Primer sequence |

|---|---|

| VEGF | AGGAGTACCCCGACGAGATAGA CACATCTGCTGTGCTGTAGGAA |

| FGF | ACAGGAGCGACCAGCACATT TTGGTGTCTGCGAGCCGTAT |

| COL I | CACTGCAAGAACAGCGTAGC AAGTTCCGGTGTGACTCGTG |

| OPN | ACACTTTCACTCCAATCGTCCCTAC GGACTCCTTAGACTCACCGCTCTT |

Table 1 Primer sequences used in RT-qPCR

| Gene | Primer sequence |

|---|---|

| VEGF | AGGAGTACCCCGACGAGATAGA CACATCTGCTGTGCTGTAGGAA |

| FGF | ACAGGAGCGACCAGCACATT TTGGTGTCTGCGAGCCGTAT |

| COL I | CACTGCAAGAACAGCGTAGC AAGTTCCGGTGTGACTCGTG |

| OPN | ACACTTTCACTCCAATCGTCCCTAC GGACTCCTTAGACTCACCGCTCTT |

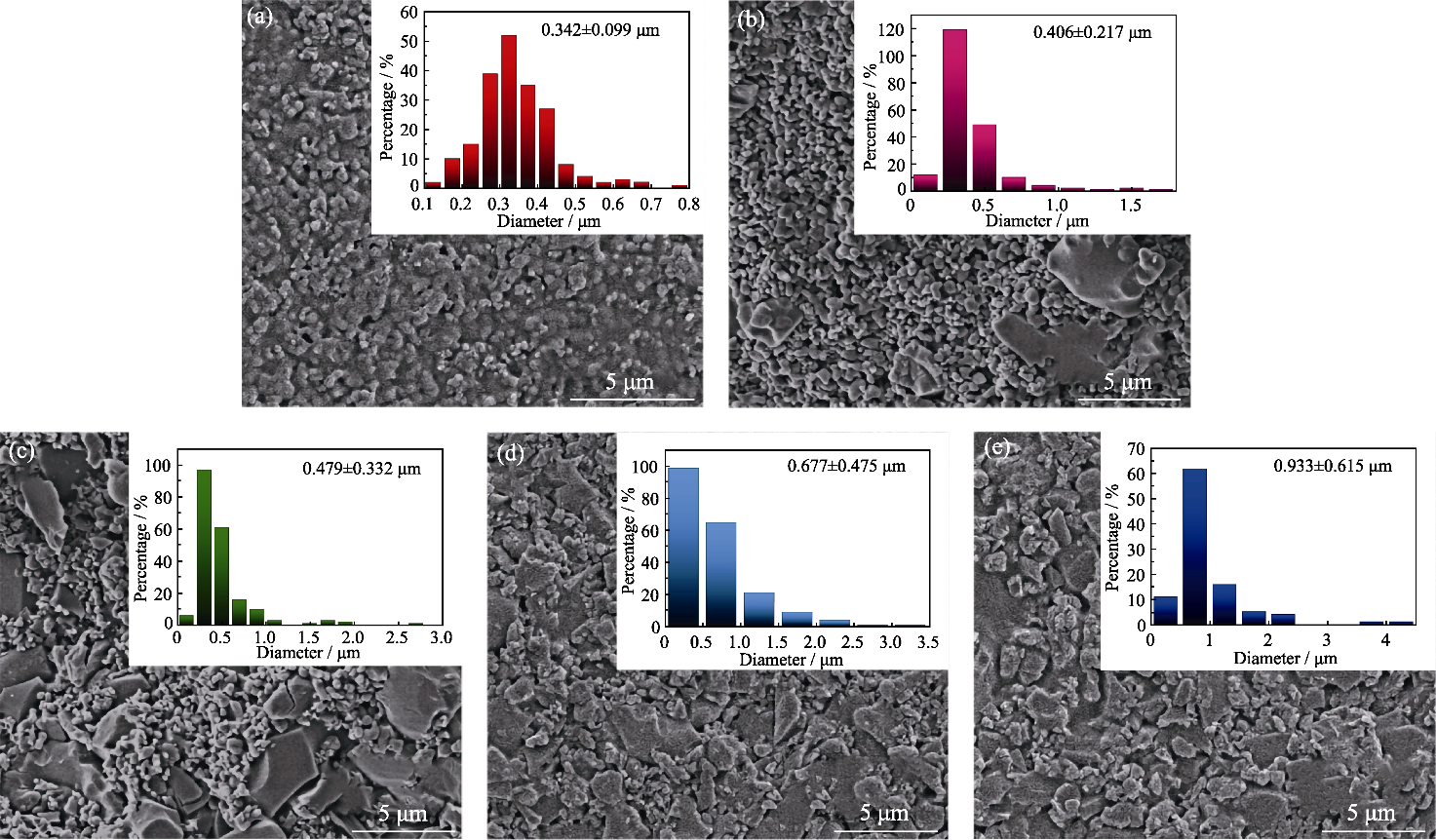

Fig. 2 SEM images of different microsphere composites with insets showing their corresponding particle size distributions (a)TCP; (b) 25% TMP; (c) 50% TMP; (d) 75% TMP; (e) TMP

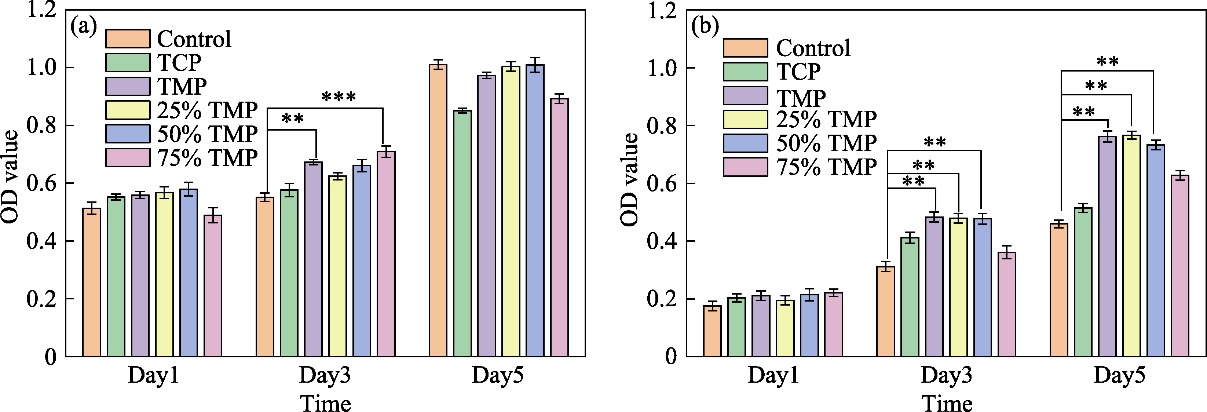

Fig. 5 Cell viabilities of (a) MC3T3-E1 and (b) HUVECs assessed by CCK-8 assay (a) MC3T3-E1 and (b) HUVECs assayed on day 1, 3, 5 cultured with different microspheres concentration extracts *: p < 0.01; **: p < 0.005; ***: p < 0.0002; Colorful figures are available on website

| [1] |

NARITA K, KOBAYASHI E, SATO TJMT. Sintering behavior and mechanical properties of magnesium/β-tricalcium phosphate composites sintered by spark plasma sintering. Materials Transactions, 2016, 57(9):1620.

DOI URL |

| [2] | CHUTHATHIP M, AHMAD-FAUZI M N, YANNY-MARLIANA B I, et al. Effect of magnesium oxide on physical and biological properties in β-tricalcium phosphate ceramic. Journal of Physics Conference Series, 2018, 1082(1):012026. |

| [3] |

BASU S, BASU B. Doped biphasic calcium phosphate: synthesis and structure. Journal of Asian Ceramic Societies, 2019, 7(3):265.

DOI |

| [4] |

GHIȚULICĂ C D, CUCURUZ A, VOICU G, et al. Ceramics based on calcium phosphates substituted with magnesium ions for bone regeneration. International Journal of Applied Ceramic Technology, 2020, 17(1):342.

DOI URL |

| [5] | MAJI K, DASGUPTA S. Effect of β-tricalcium phosphate nanoparticles additions on the properties of gelatin-chitosan scaffolds. Bioceramics Development & Applications, 2017, 7(2):1000103. |

| [6] |

MURAKAMI S, MIYAJI H, NISHIDA E, et al. Dose effects of beta-tricalcium phosphate nanoparticles on biocompatibility and bone conductive ability of three-dimensional collagen scaffolds. Dental Materials Journal, 2017, 36(5):573.

DOI PMID |

| [7] | FANG Z Z. Sintering of advanced materials. Cambridge: Elsevier, 2010: 33- 85. |

| [8] | KAUR I, ELLIS L J, ROMER I, et al. Dispersion of nanomaterials in aqueous media: towards protocol optimization. Journal of Visualized Experiments, 2017, 130: e56074. |

| [9] |

XUE W, DAHLQUIST K, BANERJEE A, et al. Synthesis and characterization of tricalcium phosphate with Zn and Mg based dopants. Journal of Materials Science: Materials in Medicine, 2008, 19(7):2669.

DOI URL |

| [10] |

GUO X, LONG Y, LI W, et al. Osteogenic effects of magnesium substitution in nano-structured β-tricalcium phosphate produced by microwave synthesis. Journal of Materials Science, 2019, 54(16):11197.

DOI |

| [11] |

ELIAZ N, METOKI N J M. Calcium phosphate bioceramics: a review of their history, structure, properties, coating technologies and biomedical applications. Materials, 2017, 10(4):334.

DOI URL |

| [12] |

RAO R R, ROOPA H N, KANNAN T S. Solid state synthesis and thermal stability of HAP and HAP-β-TCP composite ceramic powders. Journal of Materials Science: Materials in Medicine, 1997, 8(8):511.

DOI URL |

| [13] |

RUIZ-AGUILAR C, OLIVARES-PINTO U, AGUILAR-REYES E A, et al. Characterization of β-tricalcium phosphate powders synthesized by Sol-Gel and mechanosynthesis. Boletín de la Sociedad Española de Cerámica y Vidrio, 2018, 57(5):213.

DOI URL |

| [14] |

ANDO J. Tricalcium phosphate and its variation. Bulletin of the Chemical Society of Japan, 1958, 31(2):196.

DOI URL |

| [15] | OLSSON M. Chemical stability of grain boundariesinβ-tricalcium phosphate ceramics: β-TCP as bone substitute material. Department of Chemistry-Ångström, 2012, 42586904. |

| [16] | SGLAVO VM, FRASNELLI M. Effect of Mg2+ doping on beta- alpha phase transition in tricalcium phosphate (TCP) bioceramics. Acta Biomaterialia, 2016, 33: 283. |

| [17] |

MA Y, DAI H, HUANG X, et al. 3D printing of bioglass-reinforced β-TCP porous bioceramic scaffolds. Journal of Materials Science, 2019, 54(14):10437.

DOI |

| [18] | GALLO M, SANTONI B L G, DOUILLARD T, et al. Effect of grain orientation and magnesium doping on β-tricalcium phosphate resorption behavior. Acta Biomaterialia, 2019, 89: 391. |

| [19] |

TAVARES D D S, CASTRO L D O, SOARES G D D A, et al. Synthesis and cytotoxicity evaluation of granular magnesium substituted β-tricalcium phosphate. Journal of Applied Oral Science, 2013, 21(1):37.

DOI URL |

| [20] |

LEE D, SFEIR C, KUMTA P N J M S, et al. Novel in-situ synthesis and characterization of nanostructured magnesium substituted β-tricalcium phosphate (β-TCMP). Materials Science, 2009, 29(1):69.

DOI URL |

| [21] |

MARCHI J, DANTAS A, GREIL P, et al. Influence of Mg-substitution on the physicochemical properties of calcium phosphate powders. Materials Research Bulletin, 2007, 42(6):1040.

DOI URL |

| [22] |

RYU H-S, HONG KS, LEE J-K, et al. Magnesia-doped HA/β-TCP ceramics and evaluation of their biocompatibility. Biomaterials, 2004, 25(3):393.

DOI URL |

| [23] |

ZHANG X, JIANG F, GROTH T, et al. Preparation, characterization and mechanical performance of dense β-TCP ceramics with/ without magnesium substitution. Journal of Materials Science: Materials in Medicine, 2008, 19(9):3063.

DOI URL |

| [24] |

ONUMA K, IIJIMA M J C. Nanoparticles in β-tricalcium phosphate substrate enhance modulation of structure and composition of an octacalcium phosphate grown layer. CrystEngComm, 2017, 19(44):6660.

DOI URL |

| [25] |

SADER M S, LEGEROS R Z, SOARES G A. Human osteoblasts adhesion and proliferation on magnesium-substituted tricalcium phosphate dense tablets. Journal of Materials Science: Materials in Medicine, 2009, 20(2):521.

DOI URL |

| [26] |

LIN L C, CHANG S J, KUO S M, et al. Preparation and evaluation of β-TCP/polylactide microspheres as osteogenesis materials. Journal of Applied Polymer Science, 2008, 108(5):3210.

DOI URL |

| [27] | YUAN Z, WEI P, HUANG Y, et al. Injectable PLGA microspheres with tunable magnesium ion release for promoting bone regeneration. Acta Biomaterialia. 2019, 85: 294. |

| [28] | WANG J, XU J, HOPKINS C, et al. Biodegradable magnesium ased implants in orthopedics: a general review and perspectives. Advanced Science, 2020, 7(8):201902443. |

| [29] |

LIN S, YANG G, JIANG F, et al. Bone regeneration: a magnesiumnriched 3D culture system that mimics the bone development microenvironment for vascularized bone regeneration. Advanced Science, 2019, 6(12):1900209.

DOI URL |

| [30] | PAN C, SUN X, XU G, et al. The effects of β-TCP on mechanical properties, corrosion behavior and biocompatibility of beta- TCP/Zn-Mg composites. Materials Science & Engineering C, 2020, 108: 110397. |

| [31] |

ZHANG H, SHEN Y, XIONG Y, et al. Microstructural, mechanical properties and strengthening mechanism of DLP produced β-tricalcium phosphate scaffolds by incorporation of MgO/ZnO/58S bioglass. Ceramics International, 2021, 47(18):25863.

DOI URL |

| [32] |

ZHANG J. TANG L, QI H, et al. Dual function of magnesium in bone biomineralization, Advanced Healthcare Materials, 2019, 8(21):1901030.

DOI URL |

| [33] | LIN X, GE J, WEI D, et al. Surface degradation-enabled osseointegrative, angiogenic and antiinfective properties of magnesium- modified acrylic bone cement. Journal of Orthopaedic Translation. 2019, 17: 121. |

| [34] |

HE F, TIAN Y, FANG X, et al. Porous calcium phosphate composite bioceramic beads. Ceramics International, 2018, 44(11):13430.

DOI URL |

| [35] | HO V H, TRIPATHI G, GWON J, et al. Novel TOCNF reinforced injectable alginate/β-tricalcium phosphate microspheres for bone regeneration. Materials & Design, 2020, 194: 108892. |

| [36] |

MURAKAMI M, NGUYEN L T, HATANAKA K, et al. FGF-dependent regulation of VEGF receptor 2 expression in mice. The Journal of Clinical Investigation, 2011, 121(7):2668.

DOI URL |

| [37] |

OLIVARES-NAVARRETE R, HYZY S L, GITTENS R A, et al. Rough titanium alloys regulate osteoblast production of angiogenic factors. The Spine Journal, 2013, 13(11):1563.

DOI URL |

| [38] |

MATKAR P N, ARIYAGUNARAJAH R, LEONG-POI H, et al. Friends turned foes: angiogenic growth factors beyond angiogenesis. Biomolecules, 2017, 7(4):74.

DOI URL |

| [39] |

CHIM S M, TICKNER J, CHOW S T, et al. Angiogenic factors in bone local environment. Cytokine Growth Factor Reviews, 2013, 24(3):297.

DOI URL |

| [40] |

TAN A W, LIAU L L, CHUA K H, et al. Enhanced in vitro angiogenic behaviour of human umbilical vein endothelial cells on thermally oxidized TiO2 nanofibrous surfaces. Scientific Reports, 2016, 6(1):21828

DOI |

| [41] |

PRZYBYLSKI M. A review of the current research on the role of bFGF and VEGF in angiogenesis. Journal of Wound Care, 2009, 18(12):516.

PMID |

| [42] | CHEN Y, OU Y, DONG J, et al. Osteopontin promotes collagen I synthesis in hepatic stellate cells by miRNA-129-5p inhibition. Experimental Cell Research, 2017, 363(1):343. |

| [43] | BHASKAR B, OWEN R, BAHMAEE H, et al. Composite porous scaffold of PEG/PLA support improved bone matrix deposition in vitro compared to PLA-only scaffolds, Journal of Biomedical Research Part A, 2018, 106(5):1334. |

| [1] | LI Chengyu, DING Ziyou, HAN Yingchao. In vitro Antibacterial and Osteogenic Properties of Manganese Doped Nano Hydroxyapatite [J]. Journal of Inorganic Materials, 2024, 39(3): 313-320. |

| [2] | LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs [J]. Journal of Inorganic Materials, 2024, 39(2): 145-152. |

| [3] | CHEN Mengjie, WANG Qianqian, WU Chengtie, HUANG Jian. Predicting the Degradability of Bioceramics through a DFT-based Descriptor [J]. Journal of Inorganic Materials, 2024, 39(10): 1175-1181. |

| [4] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [5] | SHI Zhe, LIU Weiye, ZHAI Dong, XIE Jianjun, ZHU Yufang. Akermanite Scaffolds for Bone Tissue Engineering: 3D Printing Using Polymer Precursor and Scaffold Properties [J]. Journal of Inorganic Materials, 2023, 38(7): 763-770. |

| [6] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [7] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [8] | WU Junlin, DING Jiyang, HUANG Xinyou, ZHU Danyang, HUANG Dong, DAI Zhengfa, YANG Wenqin, JIANG Xingfen, ZHOU Jianrong, SUN Zhijia, LI Jiang. Fabrication and Microstructure of Gd2O2S:Tb Scintillation Ceramics from Water-bath Synthesized Nano-powders: Influence of H2SO4/Gd2O3 Molar Ratio [J]. Journal of Inorganic Materials, 2023, 38(4): 452-460. |

| [9] | LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend [J]. Journal of Inorganic Materials, 2023, 38(2): 113-124. |

| [10] | SUN Jingwei, WANG Honglei, SUN Chuhan, ZHOU Xingui, JI Xiaoyu. Effects of Carbon Sources on Structure and Properties of TaC Ceramic Powder Prepared by Polymer Derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(2): 184-192. |

| [11] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [12] | KANG Wenshuo, GUO Xiaojie, ZOU Kai, ZHAO Xiangyong, ZHOU Zhiyong, LIANG Ruihong. Enhanced Resistivity Induced by the Second Phase with Layered Structure in BiFeO3-BaTiO3 Ceramics [J]. Journal of Inorganic Materials, 2023, 38(12): 1420-1426. |

| [13] | LI Haiyan, KUANG Fenghua, WU Haolong, LIU Xiaogen, BAO Yiwang, WAN Detian. Temperature Dependence of Residual Tensile Stresses and Its Influences on Crack Propagation Behaviour [J]. Journal of Inorganic Materials, 2023, 38(11): 1265-1270. |

| [14] | HUANG Yihua, HUANG Zhengren, SHA Wenhao, ZHOU Yabin, TAN Zhouxi, ZHANG Mingkang. Thick SiC Green Bodies: Degreasing Analysis and Pressureless High Density Sintering [J]. Journal of Inorganic Materials, 2023, 38(10): 1163-1168. |

| [15] | WU Songze, ZHOU Yang, LI Runfeng, LIU Xiaoqian, LI Cuiwei, HUANG Zhenying. Reaction Sintered Porous Ceramics Using Iron Tailings: Preparation and Properties [J]. Journal of Inorganic Materials, 2023, 38(10): 1193-1199. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||