Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (4): 452-460.DOI: 10.15541/jim20220542

Special Issue: 【信息功能】透明与闪烁陶瓷(202506)

• RESEARCH LETTER • Previous Articles Next Articles

WU Junlin1,2( ), DING Jiyang1,3, HUANG Xinyou3, ZHU Danyang1,2, HUANG Dong1,3, DAI Zhengfa1, YANG Wenqin4,5, JIANG Xingfen4,5, ZHOU Jianrong4,5, SUN Zhijia4,5, LI Jiang1,2(

), DING Jiyang1,3, HUANG Xinyou3, ZHU Danyang1,2, HUANG Dong1,3, DAI Zhengfa1, YANG Wenqin4,5, JIANG Xingfen4,5, ZHOU Jianrong4,5, SUN Zhijia4,5, LI Jiang1,2( )

)

Received:2022-09-16

Revised:2022-10-13

Published:2023-04-20

Online:2022-12-30

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cnAbout author:WU Junlin (1998-), male, Master candidate. E-mail: wujunlin20@mails.ucas.ac.cn

Supported by:CLC Number:

WU Junlin, DING Jiyang, HUANG Xinyou, ZHU Danyang, HUANG Dong, DAI Zhengfa, YANG Wenqin, JIANG Xingfen, ZHOU Jianrong, SUN Zhijia, LI Jiang. Fabrication and Microstructure of Gd2O2S:Tb Scintillation Ceramics from Water-bath Synthesized Nano-powders: Influence of H2SO4/Gd2O3 Molar Ratio[J]. Journal of Inorganic Materials, 2023, 38(4): 452-460.

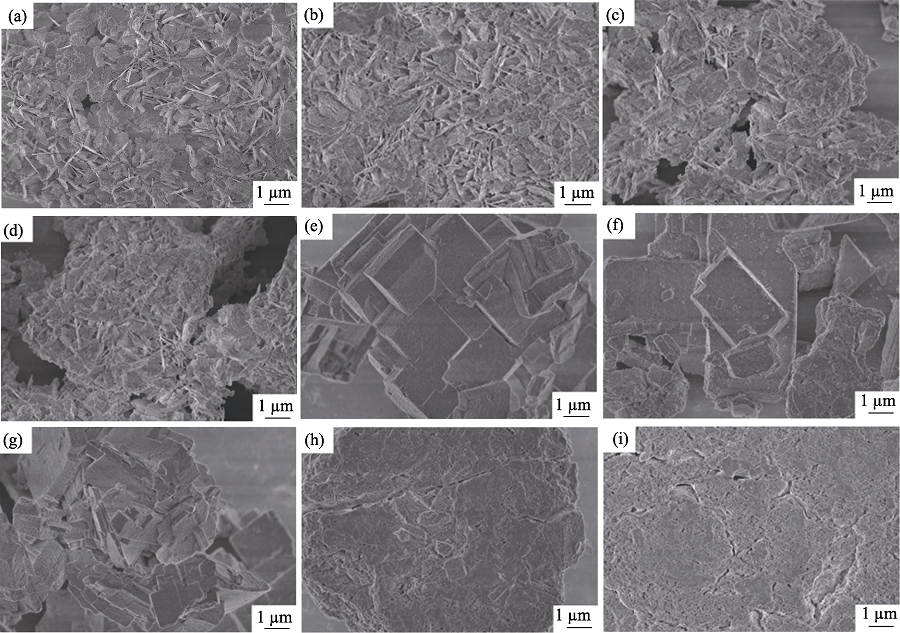

Fig. 4 FESEM morphologies of Gd2O2S: Tb powders with different n (a) n=1.00; (b) n=1.25; (c) n=1.50; (d) n=1.75; (e) n=2.00; (f) n=2.25; (g) n=2.50; (h) n=2.75; (i) n=3.00

Fig. 5 XEL spectra and normalized integral intensity curves in the range of 350-700 nm of Gd2O2S:Tb powders with different n (a) XEL spectra; (b) Normalized integral intensity curves; Colorful figures are available on website

Fig. 6 Relative densities of Gd2O2S:Tb ceramics vacuum pre-sintered at 1300 ℃ for 3 h and HIP post-treatment at 1450 ℃ for 3 h fabricated from the powders with different n

Fig. 7 FESEM micrograph and EDS patterns (white area) of the Gd2O2S:Tb ceramics vacuum pre-sintered at 1300 ℃ for 3 h and HIP post-treatment at 1450 ℃ for 3 h fabricated from the powders prepared with n=1.00

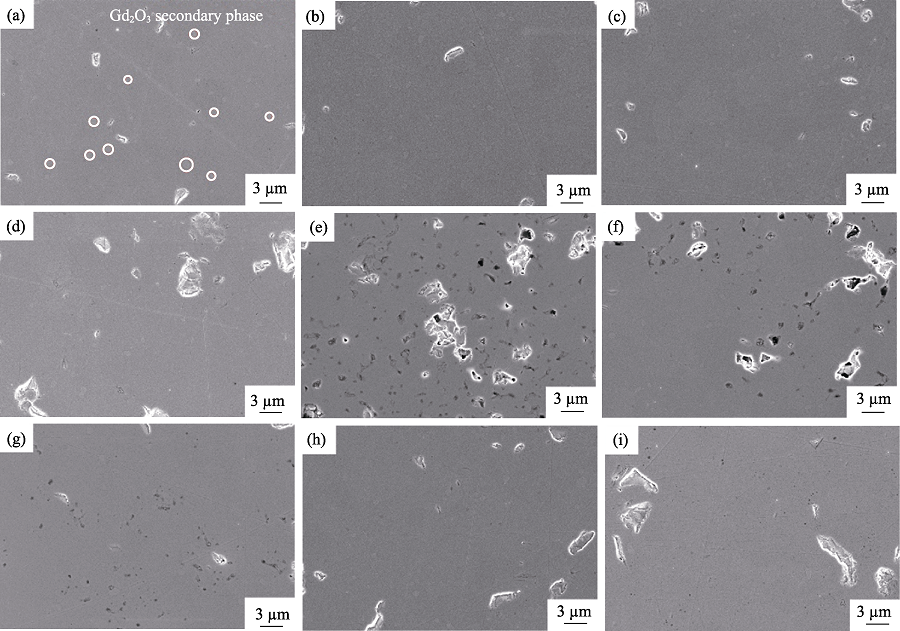

Fig. 8 FESEM morphologies of Gd2O2S:Tb ceramics fabricated from the powders prepared with different n (a) n=1.00; (b) n=1.25; (c) n=1.50; (d) n=1.75; (e) n=2.00; (f) n=2.25; (g) n=2.50; (h) n=2.75; (i) n=3.00

Fig. 9 XEL spectra and normalized integral intensity curves in the range of 350-700 nm of Gd2O2S:Tb ceramics fabricated from the powders with different n (a) XEL spectra; (b) Normalized integral intensity curves; Colorful figures are available on website

| [1] |

YANAGIDA T. Inorganic scintillating materials and scintillation detectors. Proceedings of the Japan Academy Series B Physical and Biological Sciences, 2018, 94(2):75.

DOI URL |

| [2] |

VAN EIJK C W E, BESSIèRE A, DORENBOS P.Inorganic thermal-neutron scintillators. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2004, 529(1/2/3):260.

DOI URL |

| [3] | LI J, XIE T F, KOU H M, et al. Effect of trace SiO2 addition on optical and scintillation property of Pr:Lu3Al5O12 ceramics. Journal of Inorganic Materials, 2019, 35(7):796. |

| [4] | IKESUE A. Processing of Ceramics:Breakthroughs in Optical Materials. New York: Wiley, 2021: 73-141. |

| [5] |

QU Z X, YU C J, WEI Y T, et al. Thermal conductivity of boron carbide under fast neutron irradiation. Journal of Advanced Ceramics, 2022, 11(3):482.

DOI |

| [6] | KHARIEKY A A, EBRAHIM SARAEE K R. Synthesis and characterization of radio and thermoluminescence properties of Sm doped Gd2O3, Gd2O2S and Gd2O2SO4 nanocrystalline phosphors. Journal of Luminescence, 2020, 220: 116979. |

| [7] | QIAN B F, WANG Y L, ZHAO Q R, et al. Adjustable multi-color luminescence and energy transfer of capsule-shaped Gd2O2S: Tb3+, Sm3+ phosphors. Journal of Luminescence, 2022, 244: 118715. |

| [8] |

WANG W, KOU H M, LIU S P, et al. Optical and scintillation properties of Gd2O2S: Pr, Ce, F ceramics fabricated by spark plasma sintering. Ceramics International, 2015, 41(2):2576.

DOI URL |

| [9] |

BLAHUTA S, VIANA B, BESSIèRE A, et al. Luminescence quenching processes in Gd2O2S:Pr3+,Ce3+ scintillating ceramics. Optical Materials, 2011, 33(10):1514.

DOI URL |

| [10] | WANG W, KOU H M, LIU S P, et al. Comparison of the optical and scintillation properties of Gd2O2S: Pr, Ce ceramics fabricated by hot pressing and pressureless sintering. Optical Materials, 2015, 42: 199. |

| [11] |

BAGHERI A, REZAEE EBRAHIM SARAEE K, SHAKUR H R, et al. Synthesis and characterization of physical properties of Gd2O2S:Pr3+ semi-nanoflower phosphor. Applied Physics A, 2016, 122(5):553.

DOI URL |

| [12] |

POPOVICI E J, MURESAN L, HRISTEA-SIMOC A, et al. Synthesis and characterisation of rare earth oxysulphide phosphors. I. Studies on the preparation of Gd2O2S:Tb phosphor by the flux method. Optical Materials, 2004, 27(3):559.

DOI URL |

| [13] |

ZHAN Y H, AI F R, CHEN F, et al. Intrinsically zirconium-89 labeled Gd2O2S:Eu nanoprobes for in vivo positron emission tomography and gamma-ray-induced radioluminescence imaging. Small, 2016, 12(21):2872.

DOI URL |

| [14] | TRTIK P, HOVIND J, GRüNZWEIG C, et al. Improving the spatial resolution of neutron imaging at Paul Scherrer Institut-The Neutron Microscope Project. Physics Procedia, 2015, 69: 169. |

| [15] |

WANG F, YANG B, ZHANG J C, et al. Highly enhanced luminescence of Tb3+-activated gadolinium oxysulfide phosphor by doping with Zn2+ ions. Journal of Luminescence, 2010, 130(3):473.

DOI URL |

| [16] |

CHEN L, WU Y, HUO H Y, et al. Nanoscale Gd2O2S:Tb scintillators for high-resolution fluorescent imaging of cold neutrons. ACS Applied Nano Materials, 2022, 5(6):8440.

DOI URL |

| [17] |

KANDARAKIS I, CAVOURAS D. Experimental and theoretical assessment of the performance of Gd2O2S:Tb and La2O2S:Tb phosphors and Gd2O2S:Tb-La2O2S:Tb mixtures for X-ray imaging. European Radiology, 2001, 11(6):1083.

PMID |

| [18] | TRTIK P, LEHMANN E H. Progress in high-resolution neutron imaging at the Paul Scherrer Institut-The Neutron Microscope Project. Journal of Physics: Conference Series, 2016, 746: 012004. |

| [19] |

YAN X, FERN G R, WITHNALL R, et al. Effects of the host lattice and doping concentration on the colour of Tb3+ cation emission in Y2O2S:Tb3+ and Gd2O2S:Tb3+ nanometer sized phosphor particles. Nanoscale, 2013, 5(18):8640.

DOI URL |

| [20] |

GIAKOUMAKIS G E, NOMICOS C D, SANDILOS P X. Absolute efficiency of Gd2O2S:Tb screens under fluoroscopic conditions. Physics in Medicine and Biology, 1989, 34(6):673.

DOI URL |

| [21] |

WESTPHAL E R, BROWN A D, QUINTANA E C, et al. Visible emission spectra of thermographic phosphors under X-ray excitation. Measurement Science and Technology, 2021, 32(9):094008.

DOI |

| [22] |

WANG W, LI Y S, KOU H M, et al. Gd2O2S: Pr scintillation ceramics from powder synthesized by a novel carbothermal reduction method. Journal of the American Ceramic Society, 2015, 98(7): 2159.

DOI URL |

| [23] | TRTIK P, LEHMANN E H. Isotopically-enriched gadolinium-157 oxysulfide scintillator screens for the high-resolution neutron imaging. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2015, 788: 67. |

| [24] | YASUDA R, KATAGIRI M, MATSUBAYASHI M. Influence of powder particle size and scintillator layer thickness on the performance of Gd2O2S:Tb scintillators for neutron imaging. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2012, 680: 139. |

| [25] |

KATARIA V, MEHTA D S. Multispectral harvesting rare-earth oxysulphide based highly efficient transparent luminescent solar concentrator. Journal of Rare Earths, 2022, 40(1):41.

DOI URL |

| [26] |

HUANG X Y, DING J Y, LI J. Rare earth doped Gd2O2S scintillation ceramics. Journal of Inorganic Materials, 2021, 36(8):789.

DOI URL |

| [27] |

DANIEL J H, SAWANT A, TEEPE M, et al. Fabrication of high aspect-ratio polymer microstructures for large-area electronic portal X-ray imagers. Sensors and Actuators A-Physical, 2007, 140(2):185.

DOI URL |

| [28] | WU G Q, QIN H M, FENG S W, et al. Ultrafine Gd2O2S:Pr powders prepared via urea precipitation method using SO2/SO42- as sulfuration agent—a comparative study. Powder Technology, 2017, 305: 382. |

| [29] | HE C, XIA Z G, LIU Q L. Microwave solid state synthesis and luminescence properties of green-emitting Gd2O2S:Tb3+ phosphor. Optical Materials, 2015, 42: 11. |

| [30] |

PEARSON R G. Hard and soft acids and bases. Journal of the American Chemical Society, 1963, 85(22):3533.

DOI URL |

| [31] |

DING Y J, HAN P D, WANG L X, et al. Preparation, morphology and luminescence properties of Gd2O2S:Tb with different Gd2O3 raw materials. Rare Metals, 2015, 38(3):221.

DOI URL |

| [32] |

SONG Y H, YOU H P, HUANG Y J, et al. Highly uniform and monodisperse Gd2O2S:Ln3+ (Ln = Eu, Tb) submicrospheres: solvothermal synthesis and luminescence properties. Inorganic Chemistry, 2010, 49(24):11499.

DOI URL |

| [33] |

HAN P D, ZHANG L, WANG L X, et al. Investigation on the amounts of Na2CO3 and sulphur to obtain pure Y2O2S and up-conversion luminescence of Y2O2S:Er. Journal of Rare Earths, 2011, 29(9):849.

DOI URL |

| [34] | LIU Q, PAN H M, CHEN X P, et al. Gd2O2S:Tb scintillation ceramics fabricated from high sinterability nanopowders via hydrogen reduction. Optical Materials, 2019, 94: 299. |

| [35] |

WANG X J, MENG Q H, LI M T, et al. A low temperature approach for photo/cathodoluminescent Gd2O2S:Tb (GOS:Tb) nanophosphors. Journal of the American Ceramic Society, 2018, 102(6):3296.

DOI URL |

| [36] | LIU Q, WU F, CHEN X P, et al. Fabrication of Gd2O2S:Pr scintillation ceramics from water-bath synthesized nanopowders. Optical Materials, 2020, 104: 109946. |

| [37] |

WANG X J, WANG X J, WANG Z H, et al. Photo/cathodoluminescence and stability of Gd2O2S:Tb,Pr green phosphor hexagons calcined from layered hydroxide sulfate. Journal of the American Ceramic Society, 2018, 101(12):5477.

DOI URL |

| [38] | PAN H M, LIU Q, CHEN X P, et al. Fabrication and properties of Gd2O2S:Tb scintillation ceramics for the high-resolution neutron imaging. Optical Materials, 2020, 105: 109909. |

| [39] | WANG X J, LI J G, MOLOKEEV M S, et al. Layered hydroxyl sulfate: controlled crystallization, structure analysis, and green derivation of multi-color luminescent (La,RE)2O2SO4 and (La,RE)2O2S phosphors (RE=Pr, Sm, Eu, Tb, and Dy). Chemical Engineering Journal, 2016, 302: 577. |

| [40] |

WANG X, LI J G, ZHU Q, et al. Facile and green synthesis of (La0.95Eu0.05)2O2S red phosphors with sulfate-ion pillared layered hydroxides as a new type of precursor: controlled hydrothermal processing, phase evolution and photoluminescence. Science and Technology of Advanced Materials, 2014, 15(1):014204.

DOI URL |

| [41] |

JIANG P, LI Z P, LU W, et al. The pH value control of morphology and luminescence properties of Gd2O2S: Tb3+ phosphors. Materials, 2022, 15(2):646.

DOI URL |

| [42] | LEPPERT J. Method for Producing Rare Earth Oxysulfide Powder. United States, C01F17/00, US6296824B1. 2001. 10.02. |

| [43] | TERAZAWA S, NITTA H. Production Method of Rare Earth Oxysulfide, Ceramic Scintillator and Its Production Method, Scintillator Array, and Radiation Detector. United States, C09K 11/77, US9896623B2. 2018. 02.20. |

| [44] |

PAWLIK N, SZPIKOWSKA-SROKA B, PIETRASIK E, et al. Photoluminescence and energy transfer in transparent glass-ceramics based on GdF3:RE3+ (RE = Tb, Eu) nanocrystals. Journal of Rare Earths, 2019, 37(11):1137.

DOI URL |

| [1] | LI Jiang, DING Jiyang, HUANG Xinyou. Rare Earth Doped Gd2O2S Scintillation Ceramics [J]. Journal of Inorganic Materials, 2021, 36(8): 789-806. |

| [2] | FAN Ling-Cong, SHI Ying, XIE Jian-Jun. Fabrication and Luminescent Property of Polycrystalline Cerium-doped Lutetium Oxyorthsilicate Scintillation Ceramics [J]. Journal of Inorganic Materials, 2018, 33(2): 237-244. |

| [3] | LIN Ting, XU Zhi-Bin, DENG Lian-Yun, REN Yu-Ying, SHI Ying, XIE Jian-Jun. Spark Plasma Sintering of Ce3+:Lu2SiO5 Scintillation Ceramics and Its Luminescent Characteristics [J]. Journal of Inorganic Materials, 2011, 26(11): 1210-1214. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||