Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (7): 763-770.DOI: 10.15541/jim20220635

Special Issue: 【生物材料】骨骼与齿类组织修复(202506); 【制备方法】3D打印(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

SHI Zhe1,2( ), LIU Weiye2,3, ZHAI Dong2, XIE Jianjun1(

), LIU Weiye2,3, ZHAI Dong2, XIE Jianjun1( ), ZHU Yufang2(

), ZHU Yufang2( )

)

Received:2022-10-27

Revised:2022-11-23

Published:2023-12-30

Online:2022-12-28

Contact:

XIE Jianjun, associate professor. E-mail: xiejianjun@shu.edu.cn;About author:SHI Zhe (1998-), male, Master candidate. E-mail: zheshi1998@163.com

Supported by:CLC Number:

SHI Zhe, LIU Weiye, ZHAI Dong, XIE Jianjun, ZHU Yufang. Akermanite Scaffolds for Bone Tissue Engineering: 3D Printing Using Polymer Precursor and Scaffold Properties[J]. Journal of Inorganic Materials, 2023, 38(7): 763-770.

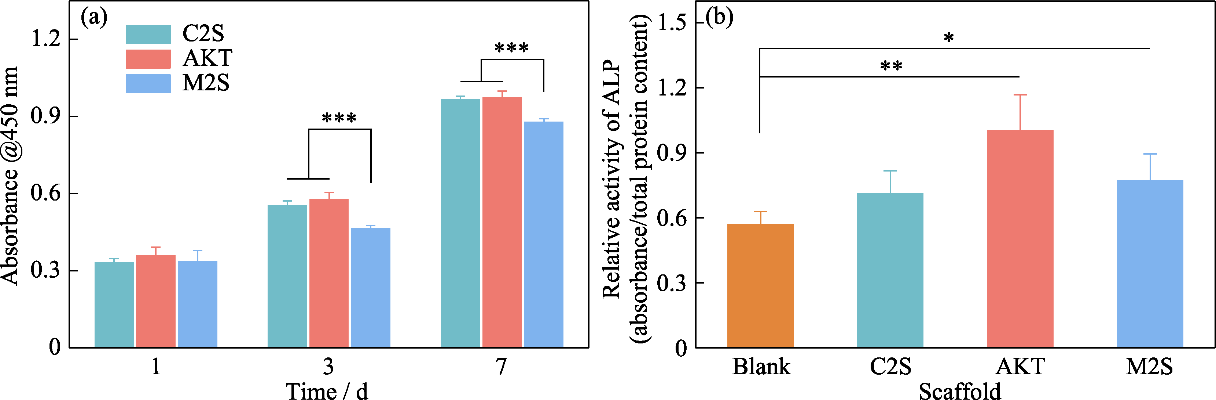

Fig. 6 (a) Cell proliferation of culturing for 1, 3 and 7 d and (b) relative activity of alkaline phosphatase of rBMSCs culturing for 7 d on C2S, AKT and M2S bioceramic scaffolds, respectively *P < 0.05; **P < 0.01; ***P < 0.001

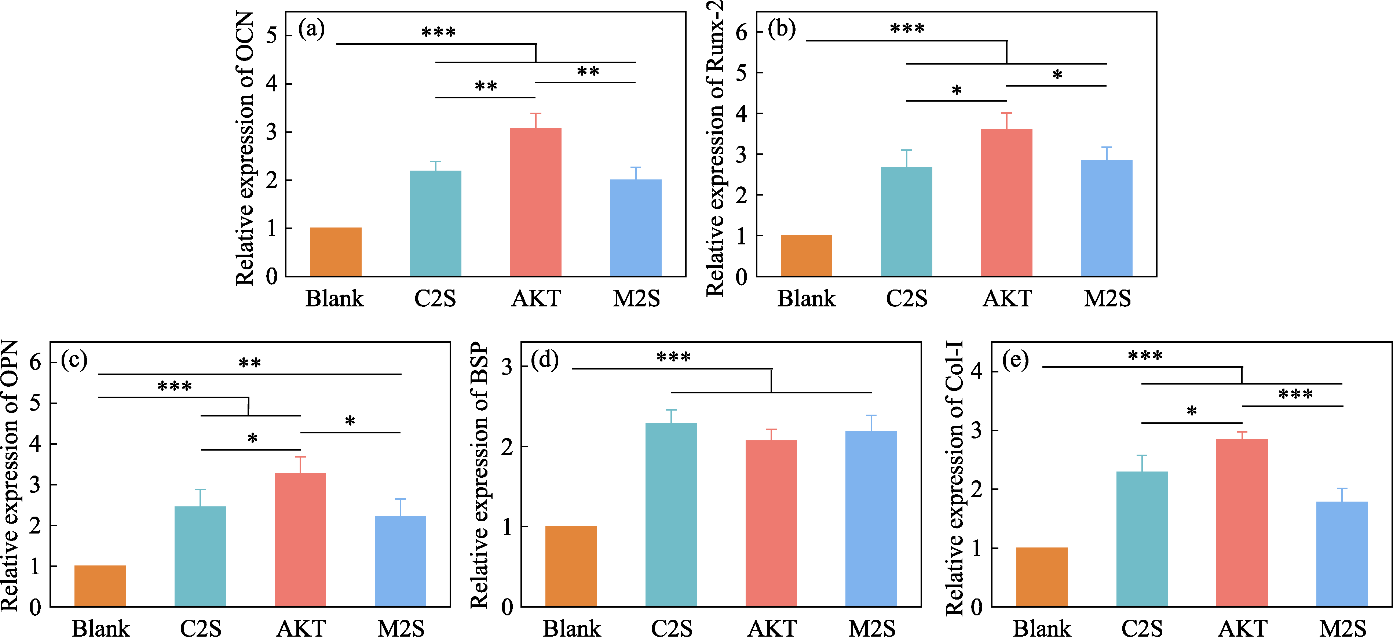

Fig. 7 Related osteogenic gene expression of rBMSCs on C2S, AKT and M2S scaffolds after culturing for 7 d (a) OCN; (b) Runx-2; (c) OPN; (d) BSP; (e) Col-Ⅰ *P < 0.05; **P < 0.01; ***P < 0.001

| [1] |

YAO Y X, QIN W, XING B H, et al. High performance hydroxyapatite ceramics and a triply periodic minimum surface structure fabricated by digital processing 3D printing. Journal of Advanced Ceramics, 2021, 10(1):39.

DOI |

| [2] |

PAN M Z, HUA S B, WU J M, et al. Preparation and properties of T-ZnOw enhanced BCP scaffolds with double-layer structure by digital light processing. Journal of Advanced Ceramics, 2022, 11(4):570.

DOI |

| [3] |

HAUGEN H J, LYNGSTADAAS S P, ROSSI F, et al. Bone grafts: which is the ideal biomaterial. J. Clin. Periodontology, 2019, 46(Suppl 21):92.

DOI URL |

| [4] |

WANG C, HUANG W, ZHOU Y, et al. 3D printing of bone tissue engineering scaffolds. Bioactive Materials, 2020, 5(1):82.

DOI PMID |

| [5] |

KOONS G L, DIBA M, MIKOS A G. Materials design for bone- tissue engineering. Nature Reviews Materials, 2020, 5(8):584.

DOI |

| [6] |

ZHANG Y, LIU X, ZENG L, et al. Polymer fiber scaffolds for bone and cartilage tissue engineering. Advanced Functional Materials, 2019, 29(36):1903279.

DOI URL |

| [7] | XU C, WU F, YANG J, et al. 3D printed long-term structurally stable bioceramic dome scaffolds with controllable biodegradation favorable for guided bone regeneration. Chemical Engineering Journal, 2022, 450: 138003. |

| [8] | WANG J, PENG Y, CHEN M, et al. Next-generation finely controlled graded porous antibacterial bioceramics for high- efficiency vascularization in orbital reconstruction. Bioactive Materials, 2022, 16: 334. |

| [9] |

TURNBULL G, CLARKE J, PICARD F, et al. 3D bioactive composite scaffolds for bone tissue engineering. Bioactive Materials, 2018, 3(3):278.

DOI PMID |

| [10] | MA H S, FENG C, CHANG J, et al. 3D-printed bioceramic scaffolds: from bone tissue engineering to tumor therapy. Acta Biomaterialia, 2018, 79: 37. |

| [11] |

ELIAZ N, METOKI N. Calcium phosphate bioceramics: a review of their history, structure, properties, coating technologies and biomedical applications. Materials, 2017, 10(4):334.

DOI URL |

| [12] | YU X, WU C. Recent development on function improvements of 3D printed bioceramics. Journal of the Chinese Ceramic Society, 2021, 49(5):829. |

| [13] |

LI T, ZHAI D, MA B, et al. 3D printing of hot dog-like biomaterials with hierarchical architecture and distinct bioactivity. Advanced Science, 2019, 6(19):1901146.

DOI URL |

| [14] |

WU C T, CHANG J. A novel akermanite bioceramic: preparation and characteristics. Journal of Biomaterials Applications, 2006, 21(2):119.

PMID |

| [15] |

LIU Q H, CEN L, YIN S, et al. A comparative study of proliferation and osteogenic differentiation of adipose-derived stem cells on akermanite and beta-TCP ceramics. Biomaterials, 2008, 29(36):4792.

DOI PMID |

| [16] |

CASTILHO M, RODRIGUES J, PIRES I, et al. Fabrication of individual alginate-TCP scaffolds for bone tissue engineering by means of powder printing. Biofabrication, 2015, 7(1):015004.

DOI URL |

| [17] |

ZHANG M, LIN R C, WANG X, et al. 3D printing of Haversian bone-mimicking scaffolds for multicellular delivery in bone regeneration. Science Advances, 2020, 6(12):eaaz6725.

DOI URL |

| [18] |

FENG C, ZHANG W J, DENG C J, et al. 3D printing of lotus root-like biomimetic materials for cell delivery and tissue regeneration. Advanced Science, 2017, 4(12):1700401.

DOI URL |

| [19] |

WU C, CHANG J. Degradation, bioactivity, and cytocompatibility of diopside, akermanite, and bredigite ceramics. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2007, 83B(1):153

DOI URL |

| [20] |

YU W, SUN X, MENG H Y, et al. 3D printed porous ceramic scaffolds for bone tissue engineering: a review. Biomaterials Science, 2017, 5(9):1690.

DOI PMID |

| [21] | HAN Z K, FENG P, GAO C D, et al. Microstructure, mechanical properties and in vitro bioactivity of akermanite scaffolds fabricated by laser sintering. Biomedical Materials and Engineering, 2014, 24(6): 2073. |

| [22] |

WU C T, CHANG J A, ZHAI W Y, et al. Porous akermanite scaffolds for bone tissue engineering: preparation, characterization, and in vitro studies. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2006, 78B(1):47.

DOI URL |

| [23] |

CHEN L, ZHAI D, WU C T, et al. Poly(D, L-lactic)-reinforced akermanite bioceramic scaffolds: preparation and characterization. Ceramics International, 2014, 40(8):12765.

DOI URL |

| [24] | NAJAFINEZHAD A, ABDELLAHI M, NASIRI-HARCHEGANI S, et al. On the synthesis of nanostructured akermanite scaffolds via space holder method: the effect of the spacer size on the porosity and mechanical properties. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 69: 242. |

| [25] |

FU S Y, ZHU M, ZHU Y F. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4):457.

DOI |

| [26] |

ZOCCA A, ELSAYED H, BERNARDO E, et al. 3D-printed silicate porous bioceramics using a non-sacrificial preceramic polymer binder. Biofabrication, 2015, 7(2):025008.

DOI URL |

| [27] | FIOCCO L, LI S, STEVENS M M, et al. Biocompatibility and bioactivity of porous polymer-derived Ca-Mg silicate ceramics. Acta Biomaterialia, 2017, 50: 56. |

| [28] |

FIOCCO L, ELSAYED H, FERRONI L, et al. Bioactive wollastonite-diopside foams from preceramic polymers and reactive oxide fillers. Materials, 2015, 8(5):2480.

DOI URL |

| [29] |

ELSAYED H, ZOCCA A, BERNARDO E, et al. Development of bioactive silicate-based glass-ceramics from preceramic polymer and fillers. Journal of the European Ceramic Society, 2015, 35(2):731.

DOI URL |

| [30] | FU S Y, HU H R, CHEN J J, et al. Silicone resin derived larnite/C scaffolds via 3D printing for potential tumor therapy and bone regeneration. Chemical Engineering Journal, 2020, 382: 122928. |

| [31] |

LIU W Y, ZUO R T, ZHU T L, et al. Forsterite-hydroxyapatite composite scaffolds with photothermal antibacterial activity for bone repair. Journal of Advanced Ceramics, 2021, 10(5):1095.

DOI |

| [32] |

BERNARDO E, FIOCCO L, GIFFIN G A, et al. Microstructure development and dielectric characterization of forsterite-based ceramics from silicone resins and oxide fillers. Advanced Engineering Materials, 2014, 16(6):806.

DOI URL |

| [33] |

ELSAYED H, CARRARO F, AGNOLI S, et al. Direct ink writing of silica-carbon-calcite composite scaffolds from a silicone resin and fillers. Journal of the European Ceramic Society, 2018, 38(15):5200.

DOI URL |

| [34] |

ANDRIANOV N T, ABDEL'-GAVAD S R, ZENKOVA N V. Synthesis and sintering of cordierite sol-gel powders based on different magnesium salts. Glass and Ceramics, 2006, 63(11/12):415.

DOI URL |

| [35] |

LIU W, WANG T, YANG C, et al. Alkaline biodegradable implants for osteoporotic bone defects-importance of microenvironment pH. Osteoporosis International, 2016, 27(1):93.

DOI URL |

| [36] |

WANG C, XUE Y, LIN K, et al. The enhancement of bone regeneration by a combination of osteoconductivity and osteostimulation using β-CaSiO3/β-Ca3(PO4)2 composite bioceramics. Acta Biomaterialia, 2012, 8(1):350.

DOI URL |

| [37] | LI M, BAI J, TAO H, et al. Rational integration of defense and repair synergy on PEEK osteoimplants via biomimetic peptide clicking strategy. Bioactive Mateirials, 2022, 8: 309. |

| [38] | CHEN M W, HU Y, HOU Y H, et al. Magnesium/gallium-layered nanosheets on titanium implants mediate osteogenic differentiation of MSCs and osseointegration under osteoporotic condition. Chemical Engineering Journal, 2022, 427: 130982. |

| [39] |

LANGER R, VACANTI J P. Tissue engineering. Science, 1993, 260(5110):920.

DOI PMID |

| [40] |

JO S, HAN J, LEE Y L, et al. Regulation of osteoblasts by alkaline phosphatase in ankylosing spondylitis. International Journal of Rheumatic Diseases, 2019, 22(2):252.

DOI PMID |

| [41] | PEREIRA D D, DAVISON N, HABIBOVIC P. Human osteoclast formation and resorptive function on biomineralized collagen. Bioactive Materials, 2022, 8: 241. |

| [42] |

JUNG G Y, PARK Y J, HAN J S. Effects of HA released calcium ion on osteoblast differentiation. Journal of Materials Science- Materials in Medicine, 2010, 21(5):1649.

DOI URL |

| [43] | ZHANG X Z, ZU H Y, ZHAO D W, et al. Ion channel functional protein kinase TRPM7 regulates Mg ions to promote the osteoinduction of human osteoblast via PI3K pathway: In vitro simulation of the bone-repairing effect of Mg-based alloy implant. Acta Biomaterialia, 2017, 63: 369. |

| [44] |

QIAO W, WONG K H M, SHEN J, et al. TRPM7 kinase-mediated immunomodulation in macrophage plays a central role in magnesium ion-induced bone regeneration. Nature Communications, 2021, 12(1):2885.

DOI PMID |

| [45] |

YAN L X, LI H Y, XIA W L. Bioglass could increase cell membrane fluidity with ion products to develop its bioactivity. Cell Proliferation, 2020, 53(11):e12906.

DOI URL |

| [1] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [2] | CHEN Mengjie, WANG Qianqian, WU Chengtie, HUANG Jian. Predicting the Degradability of Bioceramics through a DFT-based Descriptor [J]. Journal of Inorganic Materials, 2024, 39(10): 1175-1181. |

| [3] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [4] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [5] | WANG Lukai, FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian. Direct-ink-writing 3D Printing of Ceramic-based Porous Structures: a Review [J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148. |

| [6] | SHI Jixiang, ZHAI Dong, ZHU Min, ZHU Yufang. Preparation and Characterization of Bioactive Glass-Manganese Dioxide Composite Scaffolds [J]. Journal of Inorganic Materials, 2022, 37(4): 427-435. |

| [7] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [8] | ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 317-324. |

| [9] | LI Qi, HUANG Yi, QIAN Bin, XU Beibei, CHEN Liying, XIAO Wenge, QIU Jianrong. Photo Curing and Pressureless Sintering of Orange-emitting Glass-ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 289-296. |

| [10] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [11] | WU Zhongcao, HUAN Zhiguang, ZHU Yufang, WU Chengtie. 3D Printing and Characterization of Microsphere Hydroxyapatite Scaffolds [J]. Journal of Inorganic Materials, 2021, 36(6): 601-607. |

| [12] | ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties [J]. Journal of Inorganic Materials, 2021, 36(4): 436-442. |

| [13] | Zhi-Qiang SUN, Xiao-Bo YANG, Hua-Dong WANG, De-Li LI, Shu-Qin LI, Yi LÜ. Ceramic/Resin Composite Powders with Uniform Resin Layer Synthesized from SiO2 Spheres for 3D Technology [J]. Journal of Inorganic Materials, 2019, 34(5): 567-572. |

| [14] | Sheng-Yang FU, Bin YU, Hui-Feng DING, Guo-Dong SHI, Yu-Fang ZHU. Zirconia Incorporation in 3D Printed β-Ca2SiO4 Scaffolds on Their Physicochemical and Biological Property [J]. Journal of Inorganic Materials, 2019, 34(4): 444-454. |

| [15] | XIN Chen, QI Xin, ZHU Min, ZHAO Shi-Chang, ZHU Yu-Fang. Hydroxyapatite Whisker-reinforced Composite Scaffolds Through 3D Printing for Bone Repair [J]. Journal of Inorganic Materials, 2017, 32(8): 837-844. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||