Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (11): 1173-1178.DOI: 10.15541/jim20180027

• Orginal Article • Previous Articles Next Articles

WEI Jing1,2, LI Han-Chao1,3, KE Pei-Ling1, WANG Ai-Ying1

Received:2018-01-16

Revised:2018-03-09

Published:2018-11-16

Online:2018-10-20

About author:WEI Jing. E-mail: weijing@nimte.ac.cn

Supported by:CLC Number:

WEI Jing, LI Han-Chao, KE Pei-Ling, WANG Ai-Ying. Characterization of Tetrahedral Amorphous Carbon Film with Various Thickness by High Through-put Method[J]. Journal of Inorganic Materials, 2018, 33(11): 1173-1178.

| Process | Duct voltage/V | Arc current/A | Bias voltage/V | Ar flux/sccm | Time/min |

|---|---|---|---|---|---|

| Arc plasma etching | 10.0 | 50.0 | -300 | 20.0 | 5.0 |

| Film deposition | 10.0 | 50.0 | -80 | 3.0 | 15/30/45 |

Table 1 Parameter of arc plasma etching and deposition for ta-C films

| Process | Duct voltage/V | Arc current/A | Bias voltage/V | Ar flux/sccm | Time/min |

|---|---|---|---|---|---|

| Arc plasma etching | 10.0 | 50.0 | -300 | 20.0 | 5.0 |

| Film deposition | 10.0 | 50.0 | -80 | 3.0 | 15/30/45 |

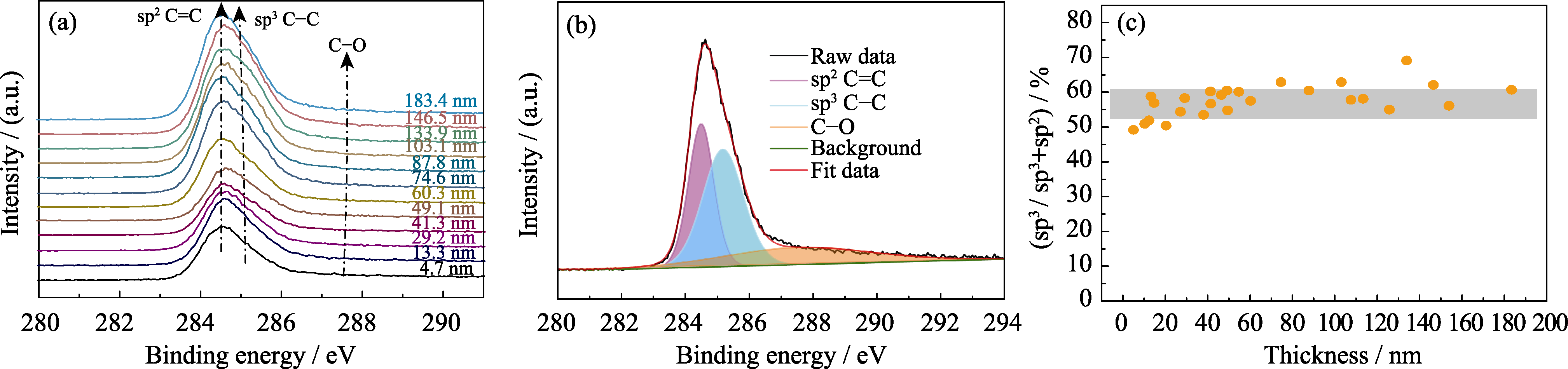

Fig. 5 XPS C1s core level spectra (a) and sp3 content (c) of ta-C films with various film thickness, typical C1s core level spectrum of ta-C film (41.3 nm) (b)

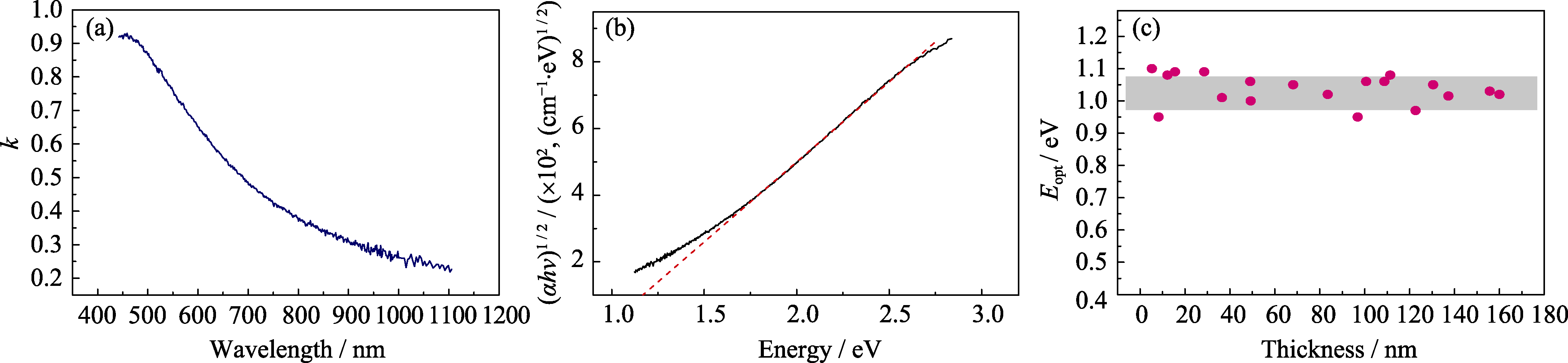

Fig. 6 Typical extinction coefficient (a) and optical bandgap (b) spectra of ta-C film with thickness of 41.3 nm, optical band gap of ta-C with different film thicknesses (c)

| [1] | ROBERTSON J.Diamond-like amorphous carbon.Materials Science and Engineering R, 2002, 37(4/5/6): 129-281. |

| [2] | ERDEMIR A, FENSKE G R, TERRY J, et al. Effect of source gas and deposition method on friction and wear performance of diamond-like carbon films. Surface and Coatings Technology, 1997, 94-95(1): 525-530. |

| [3] | WANG M, JIANG X, STRIZKER B, et al.Adhesion of hydrogenated amorphous carbon films on silicon substrates and its enhancement.Thin Solid Films, 1991, 197(1/2): 57-66. |

| [4] | ENKE K.Some new results on the fabrication of and the mechanical, electrical and optical properties of I-carbon layers.Thin Solid Films, 1981, 80(1/2/3): 227-234. |

| [5] | PALOMAKI T, WESTER N, CARO M A, et al.Electron transport determines the electrochemical properties of tetrahedral amorphous carbon (ta-C) thin films.Electrochimica Acta, 2017, 225: 1-10. |

| [6] | MCCANN R, ROY S S, PAPAKONSTANTINOU P, et al.The effect of thickness and arc current on the structural properties of FCVA synthesised ta-C and ta-C: N films.Diamond and related materials, 2005, 14(3): 983-988. |

| [7] | SHEEJA D, TAY B K, LEONG K W, et al.Effect of film thickness on the stress and adhesion of diamond-like carbon coatings.Diamond and Related Materials, 2002, 11(9): 1643-1647. |

| [8] | ZAVALEYEV V, WALKOWICZ J, KUZNETSOVA T, et al.The dependence of the structure and mechanical properties of thin ta-C coatings deposited using electromagnetic venetian blind plasma filter on their thickness.Thin Solid Films, 2017, 638: 153-158. |

| [9] | LI X W, XU S P, KE P L, et al.Thickness dependence of properties and structure of ultrathin tetrahedral amorphous carbon films: a molecular dynamics simulation.Surface & Coatings Technology, 2014, 258: 938-942. |

| [10] | MIYAKE S, KUROSAKA W, OSHIMOTO K.Nanometre scale mechanical properties of extremely thin diamond-like carbon films.Tribology - Materials, Surfaces & Interfaces, 2013, 3(4): 158-164. |

| [11] | SUNDARARAJAN S, BHUSHAN B.Development of a continuous microscratch technique in an atomic force microscope and its application to study scratch resistance of ultrathin hard amorphous carbon coatings.Journal of Materials Research, 2001, 16(2): 437-445. |

| [12] | MA X G, KOMVOPOULOS K, WAN D, et al.Effects of film thickness and contact load on nanotribological properties of sputtered amorphous carbon thin films.Wear, 2003, 254(10): 1010-1018. |

| [13] | LI H B, SUN L L, WU G S, et al.Simulation of magnetic field distribution in doubly-bent filter cathode of vacuum arc film growth setup.Chinese Journal of Vacuum Science and Technology, 2008, 29(3): 614-620. |

| [14] | CAI J, YANG W, DAI W, et al.Effect of substrate bias on structure and properties of Ta-C films.China Surface Engineering, 2011, 24(6): 62-67. |

| [15] | CAI J, YANG W, KE P L, et al.Influence of Ar flow rate on microstructures and tribological properties of tetrahedral amorphous carbon films.Chinese Journal of Vacuum Science and Technology, 2012, 32(8): 740-745. |

| [16] | XU S P, LI X W, HUANG M D, et al. Stress reduction dependent on incident angles of carbon ions in ultrathin tetrahedral amorphous carbon films. Applied Physics Letters, 2014,104(14): 141908-1-4. |

| [17] | GUO T, ZUO X, GUO P, et al.Effect of etching process on growth and properties of tetrahedral amorphous carbon film.Surface Technology, 2017, 46(4): 143-149. |

| [18] | ZHAO J C.A perspective on the materials genome initiative.Chinese Journal of Nature, 2014, 36(2): 89-104. |

| [19] | WANG HAI-ZHOU, WANG HONG, DING HONG, et al.Progress in high-throughput materials synthesis and characterization.Science & Technology Review, 2015, 33(10): 31-49. |

| [20] | EVANS J W.Factors mediating smoothness in epitaxial thin-film growth.Physical Review B, 1991, 43(5): 3897-3905. |

| [21] | ZHONG M, ZHANG C H, LUO J B.Effect of substrate morphology on the roughness evolution of ultrathin DLC films.Applied Surface Science, 2008, 254(21): 6742-6748. |

| [22] | FERRARI A C, ROBERTSON J.Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond.Philosophical Transactions, 2004, 362(1824): 2477-2512. |

| [23] | TAUC J, GRIGOROV R, VANCU A.Optical properties and electronic structure of amorphous germ anium.Phys. Status Solidi, 1966, 15(2): 627-637. |

| [24] | 薛群基, 王立平. 类金刚石碳基薄膜材料. 北京: 科学出版社, 2012, 585. |

| [1] | JIA Xianghua, ZHANG Huixia, LIU Yanfeng, ZUO Guihong. Cu2O/Cu Hollow Spherical Heterojunction Photocatalysts Prepared by Wet Chemical Approach [J]. Journal of Inorganic Materials, 2025, 40(4): 397-404. |

| [2] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [3] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [4] | CHEN Qian, SU Haijun, JIANG Hao, SHEN Zhonglin, YU Minghui, ZHANG Zhuo. Progress of Ultra-high Temperature Oxide Ceramics: Laser Additive Manufacturing and Microstructure Evolution [J]. Journal of Inorganic Materials, 2024, 39(7): 741-753. |

| [5] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [6] | ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang. Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering [J]. Journal of Inorganic Materials, 2024, 39(6): 707-714. |

| [7] | XUE Yifan, LI Weijie, ZHANG Zhongwei, PANG Xu, LIU Yu. Process Control of PyC Interphases Microstructure and Uniformity in Carbon Fiber Cloth [J]. Journal of Inorganic Materials, 2024, 39(4): 399-408. |

| [8] | SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing. SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization [J]. Journal of Inorganic Materials, 2024, 39(3): 267-273. |

| [9] | ZHENG Jiaqian, LU Xiao, LU Yajie, WANG Yingjun, WANG Zhen, LU Jianxi. Functional Bioadaptability in Medical Bioceramics: Biological Mechanism and Application [J]. Journal of Inorganic Materials, 2024, 39(1): 1-16. |

| [10] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [11] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [12] | XIE Jiaye, LI Liwen, ZHU Qiang. Contrastive Study on in Vitro Antibacterial Property and Biocompatibility of Three Clinical Pulp Capping Agents [J]. Journal of Inorganic Materials, 2023, 38(12): 1449-1456. |

| [13] | LI Jianbo, TIAN Zhen, JIANG Quanwei, YU Lifeng, KANG Huijun, CAO Zhiqiang, WANG Tongmin. Effects of Different Element Doping on Microstructure and Thermoelectric Properties of CaTiO3 [J]. Journal of Inorganic Materials, 2023, 38(12): 1396-1404. |

| [14] | HUANG Yihua, HUANG Zhengren, SHA Wenhao, ZHOU Yabin, TAN Zhouxi, ZHANG Mingkang. Thick SiC Green Bodies: Degreasing Analysis and Pressureless High Density Sintering [J]. Journal of Inorganic Materials, 2023, 38(10): 1163-1168. |

| [15] | WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition [J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||