Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (11): 1179-1185.DOI: 10.15541/jim20180021

Special Issue: 二维材料

• Orginal Article • Previous Articles Next Articles

WANG Meng-Qian, JIA Lin-Tao, LI Ai-Jun, PENG Yu-Qing, ZHANG Fang-Zhou

Received:2018-01-12

Revised:2018-04-26

Published:2018-11-16

Online:2018-10-20

About author:WANG Meng-Qian. E-mail: luckyqian@shu.edu.cn

Supported by:CLC Number:

WANG Meng-Qian, JIA Lin-Tao, LI Ai-Jun, PENG Yu-Qing, ZHANG Fang-Zhou. Preparation of Boron Nitride Coating from BCl3-NH3-H2-N2 Precursor by Chemical Vapor Deposition[J]. Journal of Inorganic Materials, 2018, 33(11): 1179-1185.

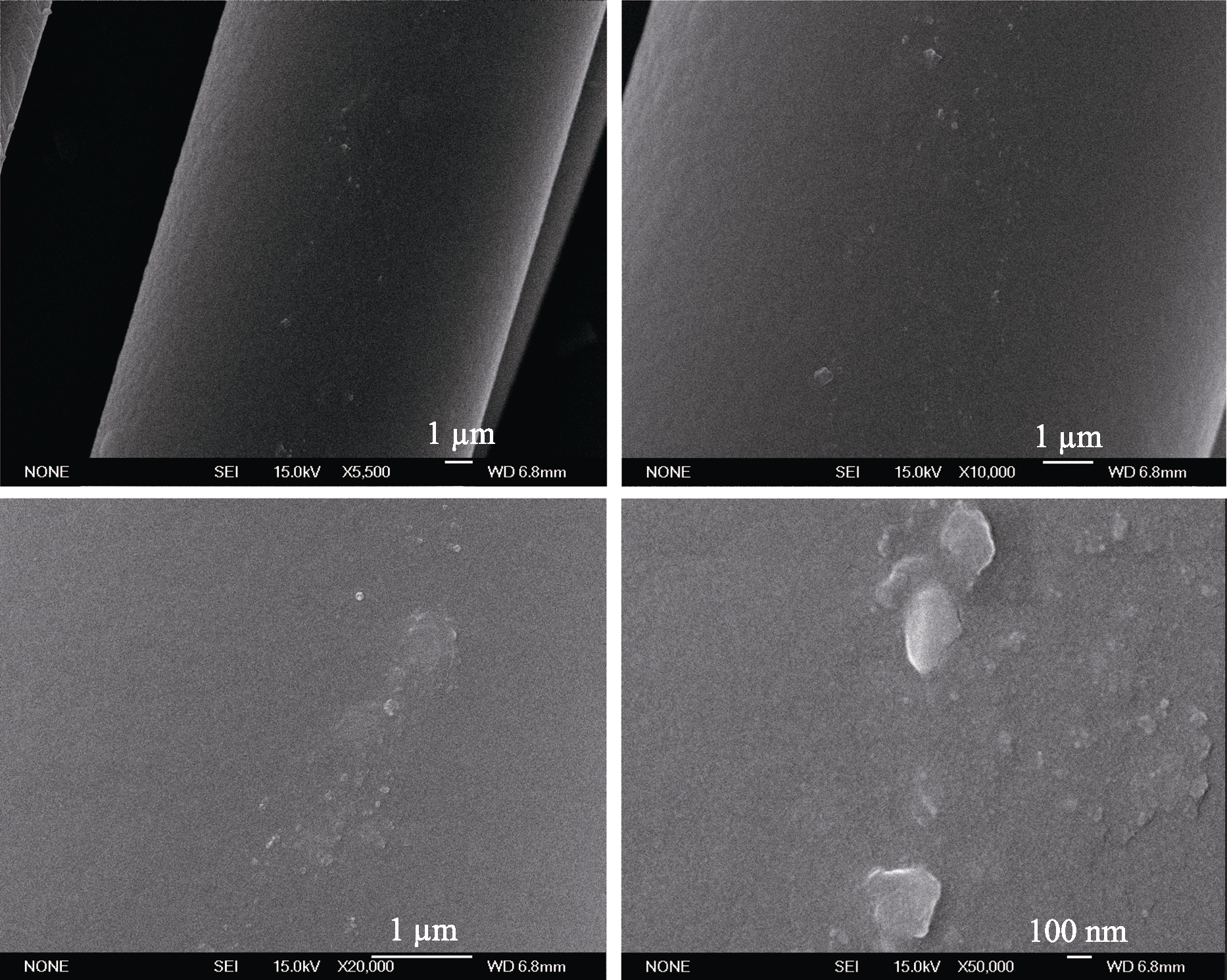

Fig. 5 Different magnification SEM images of BN coatings deposited on SiC fibers surface at 650℃, 7 kPa and 0.5 s, while nBCl3 : nNH3 : nH2 : nN2=1 : 3 : 1 : 6

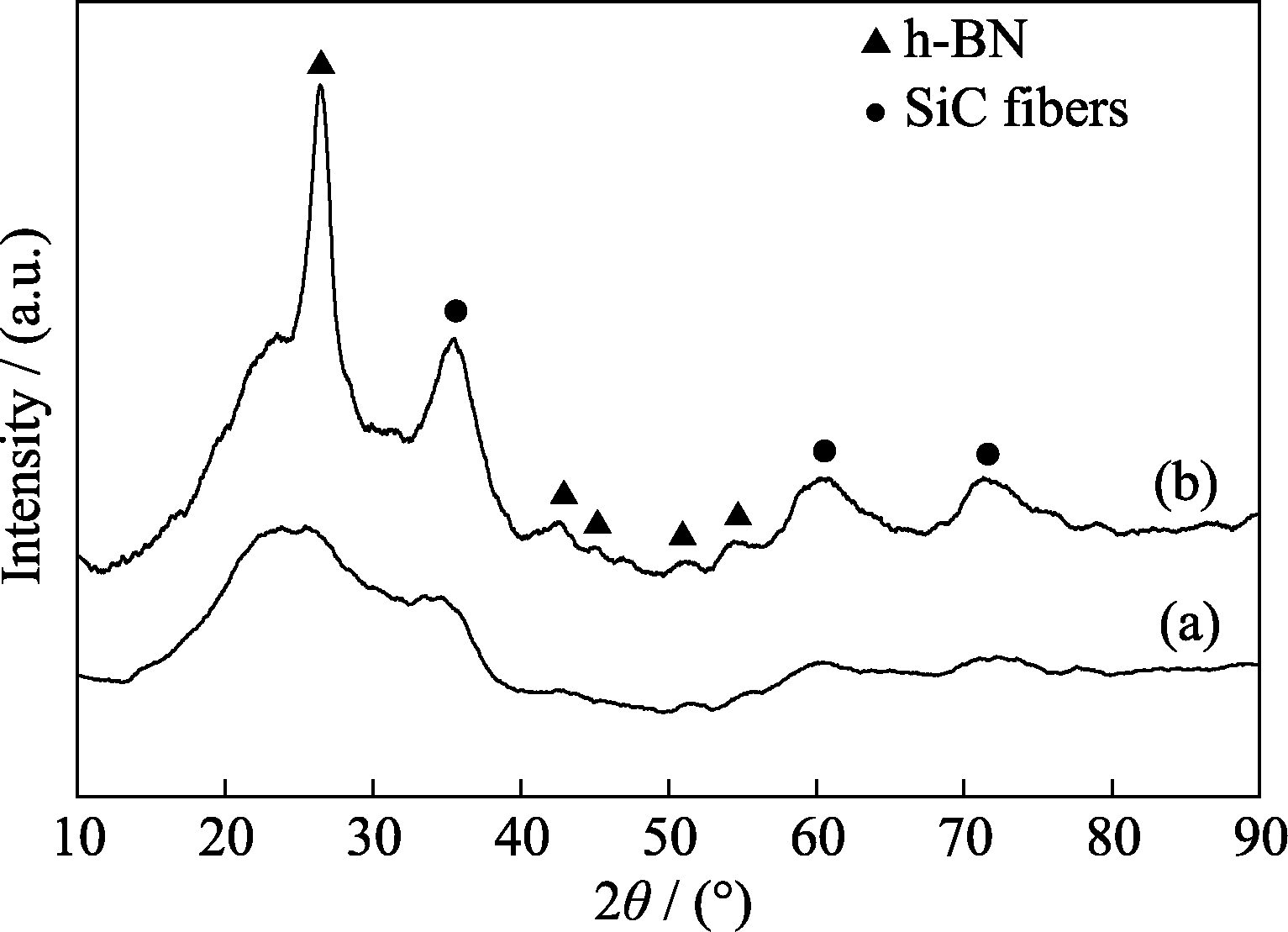

Fig. 7 XRD patterns of BN coatings deposited on SiC fibers surface at 650℃, 7 kPa and 0.5 s, while nBCl3 : nNH3 : nH2 : nN2=1 : 3 : 1 : 6^(a) Deposited at 650℃; (b) Deposited at 650℃ and then heat-treated at 1200℃

| Species | ci | dci/dt |

|---|---|---|

| BCl3 | c1 | c1×(-k1-kⅠ) |

| NH3 | c2 | c2× (-k1-kⅠ) |

| Cl2BNH2 | c3 | c1×k1-c3× (k2+k4+kⅡ) |

| ClBNH | c4 | c3×k4-c4×kⅢ |

| ClB(NH2)2 | c5 | c3×k2-c5× (k3+kⅣ) |

| B(NH2)3 | c6 | c5×k3-c6×kⅤ |

| HCl | c7 | c1×k1+c3× (k2+k4+kⅡ)+c4×kⅢ+c5×kⅣ+c6×kⅤ |

Table 1 Reaction terms of related gaseous species

| Species | ci | dci/dt |

|---|---|---|

| BCl3 | c1 | c1×(-k1-kⅠ) |

| NH3 | c2 | c2× (-k1-kⅠ) |

| Cl2BNH2 | c3 | c1×k1-c3× (k2+k4+kⅡ) |

| ClBNH | c4 | c3×k4-c4×kⅢ |

| ClB(NH2)2 | c5 | c3×k2-c5× (k3+kⅣ) |

| B(NH2)3 | c6 | c5×k3-c6×kⅤ |

| HCl | c7 | c1×k1+c3× (k2+k4+kⅡ)+c4×kⅢ+c5×kⅣ+c6×kⅤ |

| Reactions | Pre-exponential factor, A/(cm3•mol-1•s-1) | Apparent activation energy, Ea/(kJ•mol-1) |

|---|---|---|

| 1 | 4.21×1011 | 34.95 |

| 2 | 3.88×1011 | 77.44 |

| 3 | 1.66×1011 | 83.30 |

| 4 | 3.89×1014 | 330.68 |

Table 2 Thermodynamic data for gaseous reactions

| Reactions | Pre-exponential factor, A/(cm3•mol-1•s-1) | Apparent activation energy, Ea/(kJ•mol-1) |

|---|---|---|

| 1 | 4.21×1011 | 34.95 |

| 2 | 3.88×1011 | 77.44 |

| 3 | 1.66×1011 | 83.30 |

| 4 | 3.89×1014 | 330.68 |

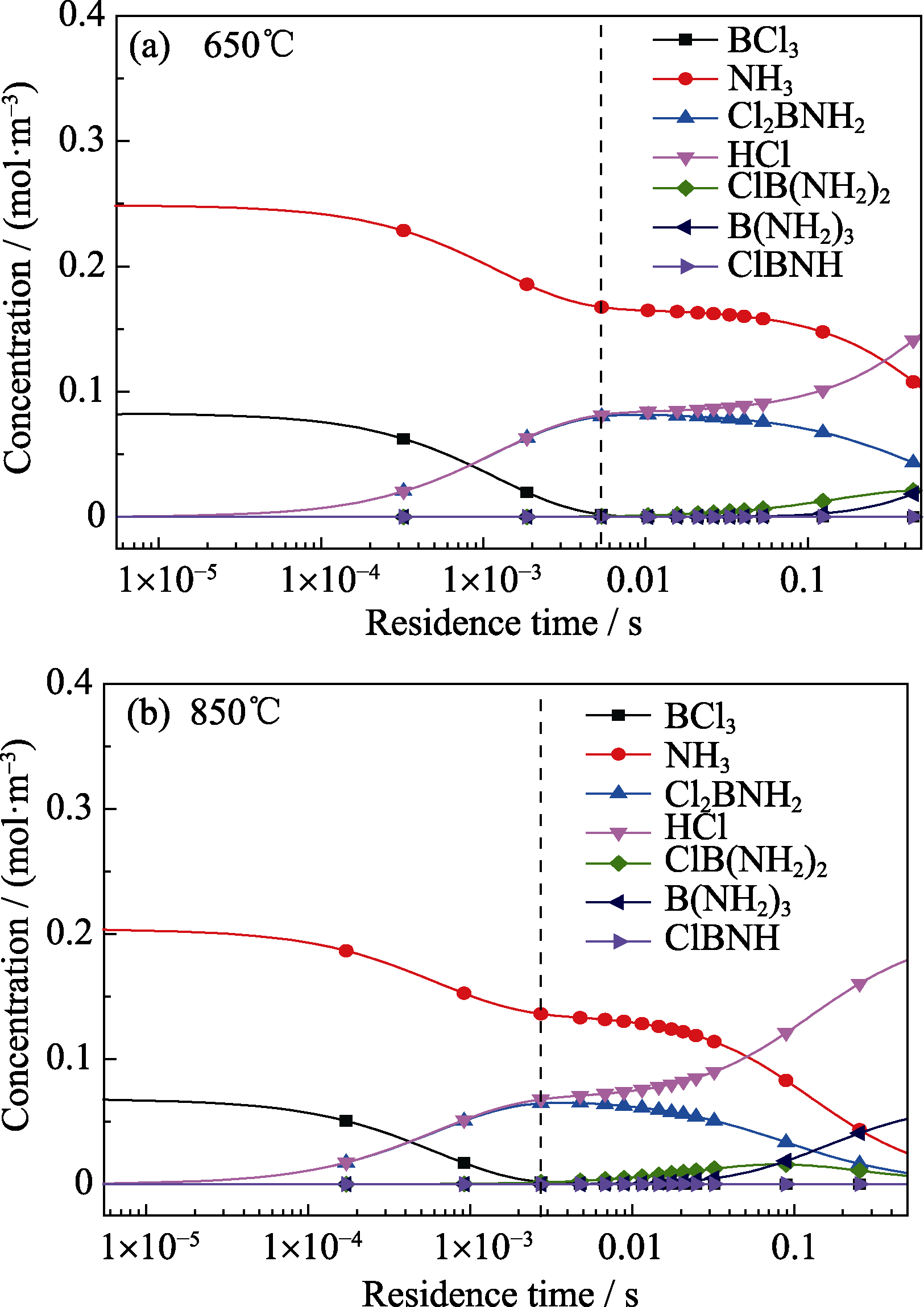

Fig. 9 Gas-phase concentrations changes during deposition process of BN at 650℃ (a) and 850℃ (b)^(7 kPa, 0.5 s, nBCl3 : nNH3 : nH2 : nN2=1 : 3 : 1 : 6)

| [1] | XU L, BAI S, WU J F, et al.Pyrolytic Boron Nitride. Proceedings of the 8th National Symposium on New Carbon Materials. 2007: 91-100. |

| [2] | SONG GUI-HONG, DU HAO, HE CHUN-LIN.Hard and Superhard Coating. Beijing: Chemical Industry Press. 2007: 167-171. |

| [3] | PEASE R S.An X-ray study of boron nitride.Acta Crystallographica, 1952, 5(3): 356-361. |

| [4] | LI R, ZHANG C R, LI B, et al.Research progress and prospect of boron nitride materials.Bulletin of the Chinese Ceramic Society, 2010, 29(5): 1072-1078. |

| [5] | DU S, LI F, GAO L Q.The preparation of BN by chemical vapor deposition.Electron Compon, Mater. 1995, 14(1): 8-13. |

| [6] | ROGER R NASLAIN, PAILLER J F, LAMON J L.Single- and multi-layered interphases in SiC/SiC composites exposed to severe environmental conditions: an overview.International Journal of Applied Ceramic Technology, 2010, 7(3): 263-275. |

| [7] | LI J S, ZHANG C R, LI B.Research progress of boron nitride interface in ceramic matrix composites.Material Review, 2011, 25(9): 14-21. |

| [8] | ZHOU Y, ZHOU W C, LUO F, et al.Research progress of BN interface in SiCf/SiC composites.Material Review, 2013, 27(7): 10-14. |

| [9] | JACQUES S, VINCENT H, VINCENT C, et al . Multilayered BN coatings processed by a continuous LPCVD treatment onto Hi-Nicalon fibers.Journal of Solid State Chemistry, 2001, 162(2): 358-363. |

| [10] | ZHANG L T, CHENG L F.Preparation and Application of Self-healing Ceramic Matrix Composites. Beijing: Chemical Industry Press. 2015: 131-132. |

| [11] | LEE W Y, LACKEY W J, AGRAWAL P K.Kinetic analysis of chemical vapor deposition of boron nitride. Journal of the American Ceramic Society, 1991, 74(10): 2642-2648. |

| [12] | CHOLET V, VANDENBULCKE L.Chemical vapor infiltration of boron nitride interphase in ceramic fiber preforms: discussion of some aspects of the fundamentals of the isothermal chemical vapor infiltration process. Journal of the American Ceramic Society, 1993, 76(11): 2846-2858. |

| [13] | PATIBANDLA N.Chemical vapor deposition of boron nitride.Journal of the Electrochemical Society, 1992, 139(12): 3558-3565. |

| [14] | MATSUDA T, NAKAE H, IRAI T.Density and deposition rate of chemical-vapor-deposited boron nitride.Journal of Materials Science, 1988, 23(2): 509-514. |

| [15] | BLOCHER J M.Structure/property/process relationships in chemical vapor deposition CVD.Journal of Vacuum Science & Technology, 1974, 11(4): 680-686. |

| [16] | LI J S, ZHANG C R, LI B.Preparation and characterization of boron nitride coatings on carbon fibers from borazine by chemical vapor deposition.Applied Surface Science, 2011, 257(17): 7752-7757. |

| [17] | GUIMON C, GONBEAU D, PFISTER-GUILLOUZO G, et al.XPS study of BN thin films deposited by CVD on SiC plane substrates.Surface & Interface Analysis, 1990, 16(1-12): 440-445. |

| [18] | ALKOY S, TOY C,GÖNÜL T, et al. Crystallization behavior and characterization of turbostratic boron nitride. Journal of the European Ceramic Society, 1997, 17(12): 1415-1422. |

| [19] | CHOI J Y, KANG S J L, FUKUNAGA O, et al. Effect of B2O3 and HBN crystallinity on CBN synthesis.Journal of the American Ceramic Society, 2010, 76(10): 2525-2528. |

| [20] | GALLET S L, CHOLLON G, REBILLAT F, et al.Microstructural and microtextural investigations of boron nitride deposited from BCl3-NH3-H2, gas mixtures.Journal of the European Ceramic Society, 2004, 24(1): 33-44. |

| [21] | ALLENDORF M D, MELIUS C F, OSTERHELD T H.A model of the gas-phase chemistry of boron nitride CVD from BCl3 and NH3.Materials Research Society, 1996, 410: 459-464. |

| [22] | ANTHONY M D, ALLENDORF M D.Flow-tube investigation of the high-temperature reaction between BCl3 and NH3.Journal of Physical Chemistry A, 1998, 102(40): 7804-7812. |

| [1] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [2] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [3] | LI Li, GUO Xiaojie, JIN Yang, CHEN Chaogui, Abdullah M Asiri, Hadi M Marwani, ZHAO Qingzhou, SHENG Guodong. Distinguished Cd(II) Capture with Rapid and Superior Ability using Porous Hexagonal Boron Nitride: Kinetic and Thermodynamic Aspects [J]. Journal of Inorganic Materials, 2020, 35(3): 284-292. |

| [4] | GAO Tian, XIAO Qinglin, XU Chenyang, WANG Xuebin. Blowing Route to Fabricate Foams of 2D Materials [J]. Journal of Inorganic Materials, 2020, 35(12): 1315-1326. |

| [5] | LIU Fengqi, FENG Jian, JIANG Yonggang, LI Liangjun. Preparation and Application of Boron Nitride Aerogels [J]. Journal of Inorganic Materials, 2020, 35(11): 1193-1202. |

| [6] | ZHENG Qian, CAO Yuehan, HUANG Nanjian, DONG Fan, ZHOU Ying. BiOBr-BN Photocatalysts for Promoting Photocatalytic NO Oxidation and Inhibiting Toxic By-products [J]. Journal of Inorganic Materials, 2020, 35(11): 1255-1262. |

| [7] | SUN Futong, FENG Aihu, CHEN Bingbing, YU Yun, YANG Hong. Effect of Copper Pretreatment on Growth of Graphene Films by Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2020, 35(10): 1177-1182. |

| [8] | ZHU Meng-Meng, LI Guo-Hua, ZHANG Xue-Ming, ZHAI Jia-Xin, GAN Si-Ping, SONG Xiao. Boron Nitride Nanosheets Supported Cu2O Nanoparticles: Synthesis and Catalytic Reduction for 4-nitrophenol [J]. Journal of Inorganic Materials, 2019, 34(8): 817-826. |

| [9] | HAN Jie-Min, WANG Mei, TONG Zhao-Min, MA Yi-Fei. Triboelectric Nanogenerator Based on Graphene Forest Electrodes [J]. Journal of Inorganic Materials, 2019, 34(8): 839-843. |

| [10] | Ren-Jie GENG, Song-Feng E, Chao-Wei LI, Tao-Tao LI, Jun WU, Ya-Gang YAO. High Crystallinity Boron Nitride Nanosheets: Preparation and the Property of BNNSs/Polyvinyl Alcohol Composite Film [J]. Journal of Inorganic Materials, 2019, 34(4): 401-406. |

| [11] | YAN Shi-Sheng, PENG Hong-Yan, ZHAO Zhi-Bin, PAN Meng-Mei, YANG Da-Li, A Jin-Hua, YE Guo-Lin, WANG Chong-Tai, GUO Xin-Wei. Nitrogen-doped Diamond Electrode Property and Anodic Catalytic Degradation of Nitrobenzene [J]. Journal of Inorganic Materials, 2018, 33(5): 565-569. |

| [12] | ZHANG Cui-Ping, GAO Xiang-Wei, RU Hong-Qiang, SUN Wei-Kang, ZHU Jing-Hui, ZONG Hui. Effect of Forming Pressure on Microstructure and Mechanical Properties of SiC/TiB2 Composites [J]. Journal of Inorganic Materials, 2017, 32(5): 502-508. |

| [13] | QIAO Zhen-Jie, GAO Le, FENG Qian, HU Jian-Bao, DONG Shao-Ming, MA Liang-Lai. Boron Content on Microstructure and Mechanical Properties of Amorphous Boron Carbide by Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2017, 32(11): 1228-1232. |

| [14] | SUN Qing-Lei, ZHOU Hong-Qing, QIAN-Lei, WANG Ya-Zhou, ZHU Hai-Kui, YUE Zhen-Xing. Effects of MgO, SrO and La2O3 Co-doping on Structure and Properties of (Zr0.8Sn0.2)TiO4 Ceramics [J]. Journal of Inorganic Materials, 2016, 31(8): 812-818. |

| [15] | YANG Chao, LI Ying, YAN Lu, CAO Yun-Zhen. Influence of Catalyst Film Thickness Deposited by Atomic Layer Deposition on Growth of Aligned Carbon Nanotubes [J]. Journal of Inorganic Materials, 2016, 31(7): 681-686. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||