无机材料学报 ›› 2023, Vol. 38 ›› Issue (8): 947-953.DOI: 10.15541/jim20230009 CSTR: 32189.14.10.15541/jim20230009

所属专题: 【能源环境】储能电池(202506); 【能源环境】锂离子电池(202412)

收稿日期:2023-01-05

修回日期:2023-02-20

出版日期:2023-08-20

网络出版日期:2023-03-06

通讯作者:

王治宇, 教授. E-mail: zywang@dlut.edu.cn;作者简介:苏 楠(1998-), 女, 硕士研究生. E-mail: 18895369203@163.com

基金资助:

SU Nan1( ), QIU Jieshan1,3(

), QIU Jieshan1,3( ), WANG Zhiyu1,2(

), WANG Zhiyu1,2( )

)

Received:2023-01-05

Revised:2023-02-20

Published:2023-08-20

Online:2023-03-06

Contact:

WANG Zhiyu, professor. E-mail: zywang@dlut.edu.cn;About author:SU Nan (1998-), female, Master candidate. E-mail: 18895369203@163.com

Supported by:摘要:

具有超高储锂比容量的硅材料是备受瞩目的高性能锂离子电池负极材料, 但硅嵌锂时巨大的体积膨胀效应使之快速失效, 从而限制了其应用性能。本研究提出一种简易低毒的气相氟化方法制备氟掺杂碳包覆纳米硅材料。通过在纳米硅表面包覆高缺陷度的氟掺杂碳层, 抑制硅材料嵌锂体积膨胀, 提供丰富的锂离子输运通道, 同时形成富含LiF的稳定SEI膜。获得的氟掺杂碳包覆纳米硅负极在0.2~5.0 A·g-1电流密度下, 比容量达1540~ 580 mAh·g-1, 循环200次后容量保持率>75%。本方法解决了传统氟化技术氟源(如XeF2、F2等)高成本、高毒性的问题。

中图分类号:

苏楠, 邱介山, 王治宇. 高容量氟掺杂碳包覆纳米硅负极材料: 气相氟化法制备及其储锂性能[J]. 无机材料学报, 2023, 38(8): 947-953.

SU Nan, QIU Jieshan, WANG Zhiyu. F-doped Carbon Coated Nano-Si Anode with High Capacity: Preparation by Gaseous Fluorination and Performance for Lithium Storage[J]. Journal of Inorganic Materials, 2023, 38(8): 947-953.

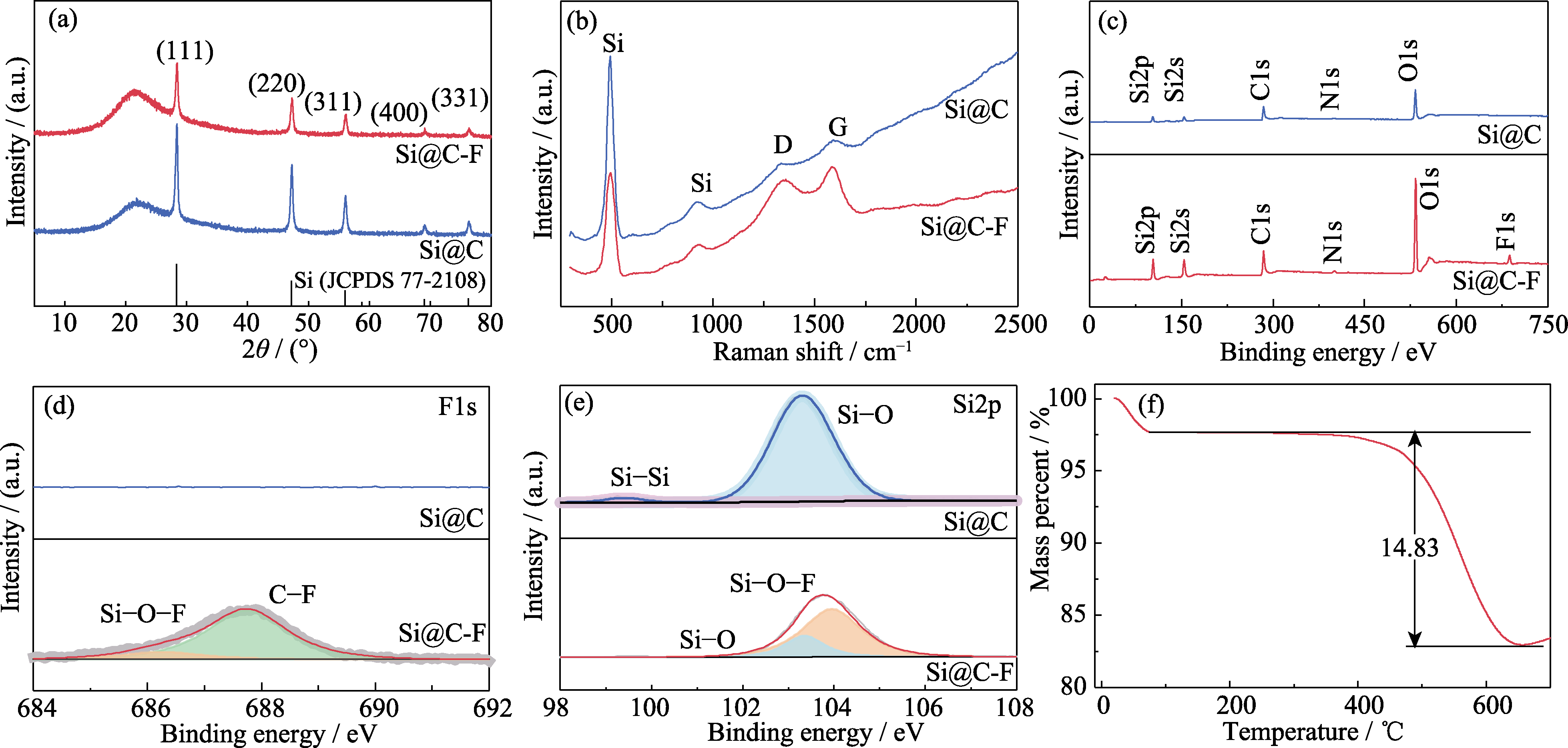

图2 Si@C和Si@C-F的(a)XRD谱图, (b)Raman谱图, (c)XPS全谱图, 高分辨(d)F1s和(e)Si2p XPS谱图; (f)Si@C-F的TGA曲线

Fig. 2 (a) XRD patterns, (b) Raman spectra, (c) XPS survey scan, (d) high-resolution F1s and (e) Si2p XPS spectra of Si@C and Si@C-F, (f) TGA curve of Si@C-F

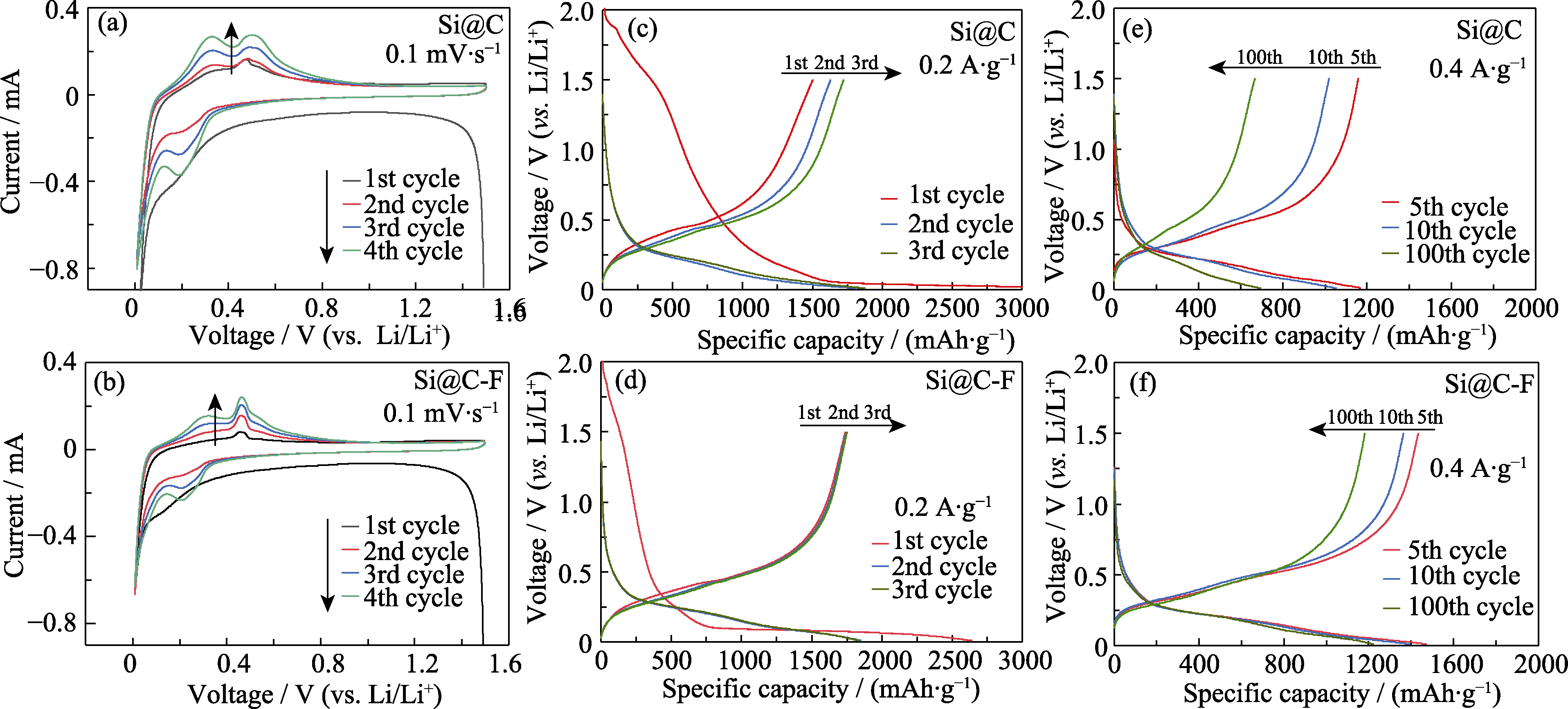

图4 (a, c, e) Si@C和(b, d, f) Si@C-F负极在 (a, b) 0.1 mV·s-1扫速下的CV曲线, 电流密度为(c, d) 0.2和(e, f) 0.4 A·g-1时的充放电曲线

Fig. 4 (a, b) CV curves at a scan rate of 0.1 mV·s-1 and charge-discharge voltage curves at (c, d) 0.2 and (e, f) 0.4 A·g-1 for (a, c, e) Si@C and (b, d, f) Si@C-F anodes

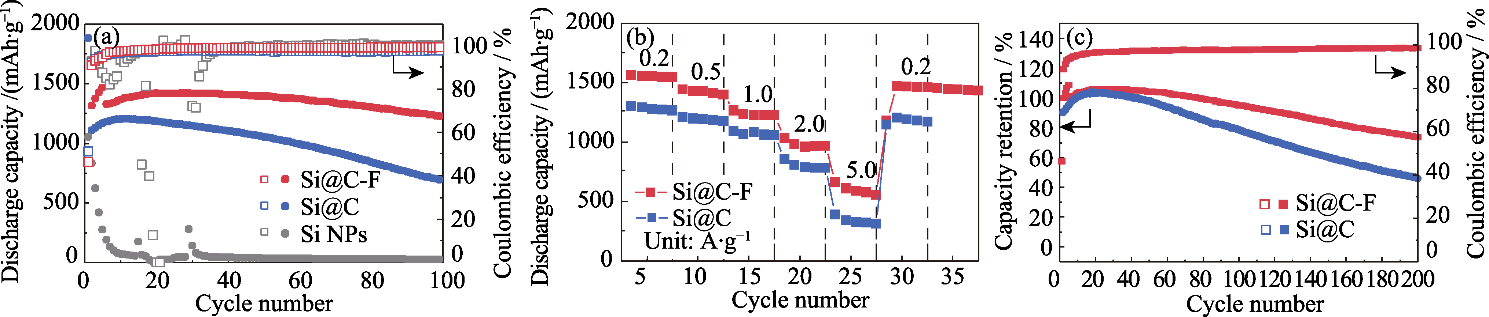

图5 Si@C和Si@C-F负极(a)在电流密度为0.4 A·g-1时的循环性能(先在0.2 A·g-1电流密度下活化4圈); (b)在电流密度0.2~5.0 A·g−1范围的倍率性能; (c)在电流密度为0.2 A·g-1时的长循环容量保持率

Fig. 5 (a) Cycling stability at a current density of 0.4 A·g-1 with anodes activated by 4 cycles at 0.2 A·g-1 before cycling, and (b) rate capability at various current densities ranging from 0.2 to 5.0 A·g−1 and (c) capacity retention at a current density of 0.2 A·g-1 for lithium storage in Si@C and Si@C-F anode Colorful figures are available on website

| Materials | Initial CE | Initial capacity/(mAh·g-1) | Capacity retention | Ref. |

|---|---|---|---|---|

| Si@C-F | 65.9% | 2640 | 85% (100 cycles) 75 % (cycles) | This work |

| nano-Si/TiN@ carbon | 71% | 2716 | 59.4% (110 cycles) | [ |

| Si@C@RGO | 74.5% | 1474 | 48.9% (40 cycles) | [ |

| Si@FA | 65% | 1334 | 68.7% (100 cycles) | [ |

| p-Si@C | 58% | 3460 | 57.5% (100 cycles) | [ |

| Si@void@C | - | 900 | 70% (100 cycles) | [ |

| Si/C@C | - | 1120 | 80% (100 cycles) | [ |

表1 Si@C-F负极与文献报道硅负极的电化学性能比较

Table 1 Comparison of Si@C-F anode with reported Si-based anode in electrochemical performance

| Materials | Initial CE | Initial capacity/(mAh·g-1) | Capacity retention | Ref. |

|---|---|---|---|---|

| Si@C-F | 65.9% | 2640 | 85% (100 cycles) 75 % (cycles) | This work |

| nano-Si/TiN@ carbon | 71% | 2716 | 59.4% (110 cycles) | [ |

| Si@C@RGO | 74.5% | 1474 | 48.9% (40 cycles) | [ |

| Si@FA | 65% | 1334 | 68.7% (100 cycles) | [ |

| p-Si@C | 58% | 3460 | 57.5% (100 cycles) | [ |

| Si@void@C | - | 900 | 70% (100 cycles) | [ |

| Si/C@C | - | 1120 | 80% (100 cycles) | [ |

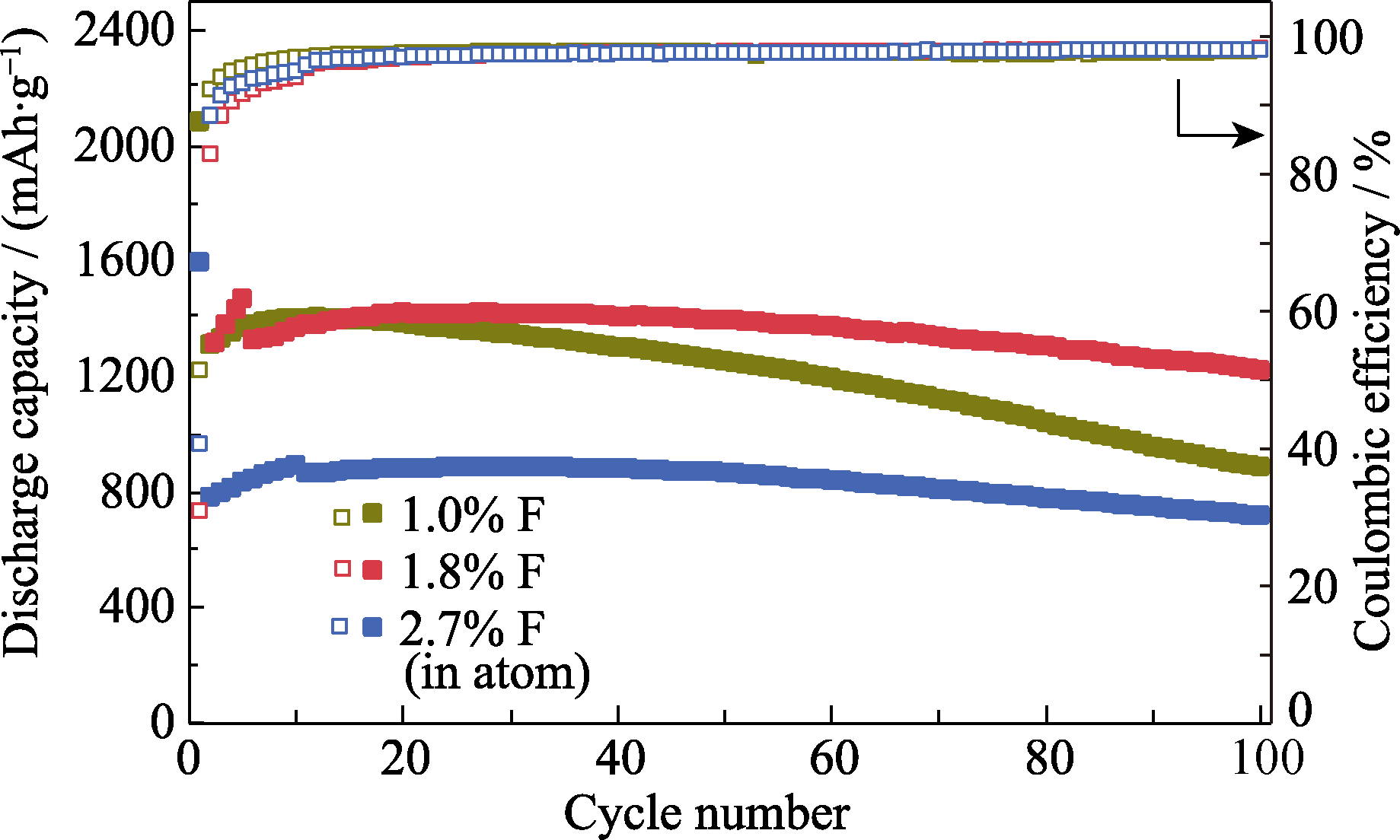

图6 不同氟掺杂量Si@C-F负极在0.4 A·g-1电流密度的循环性能(先在0.2 A·g-1电流密度下活化4~10圈)

Fig. 6 Cycling stability of Si@C-F anodes with different F ratios at a current density of 0.4 A·g-1 with anodes activated by 4-10 cycles at 0.2 A·g-1 before cycling Colorful figures are available on website

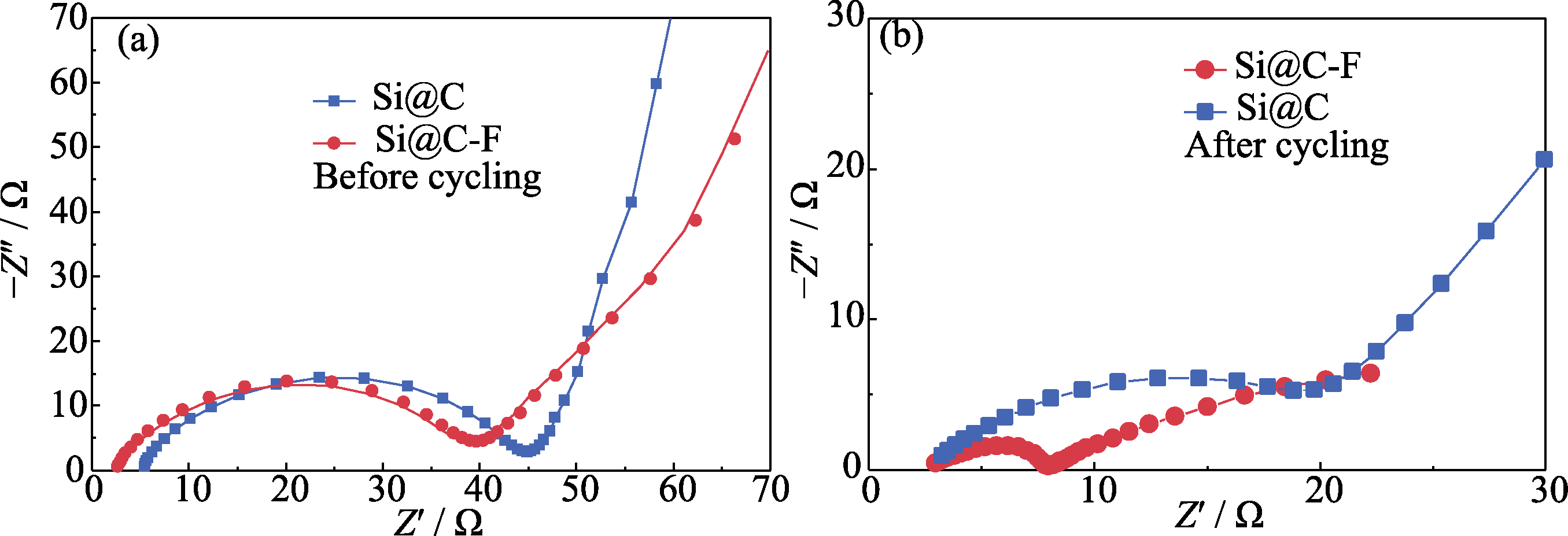

图7 Si@C和Si@C-F负极在循环(a)前(b)后的电化学阻抗谱图(电流密度为0.4 A·g-1)

Fig. 7 Nyquist plots of the Si@C and Si@C-F anodes (a) before and (b) after cycling at a current density of 0.4 A·g-1

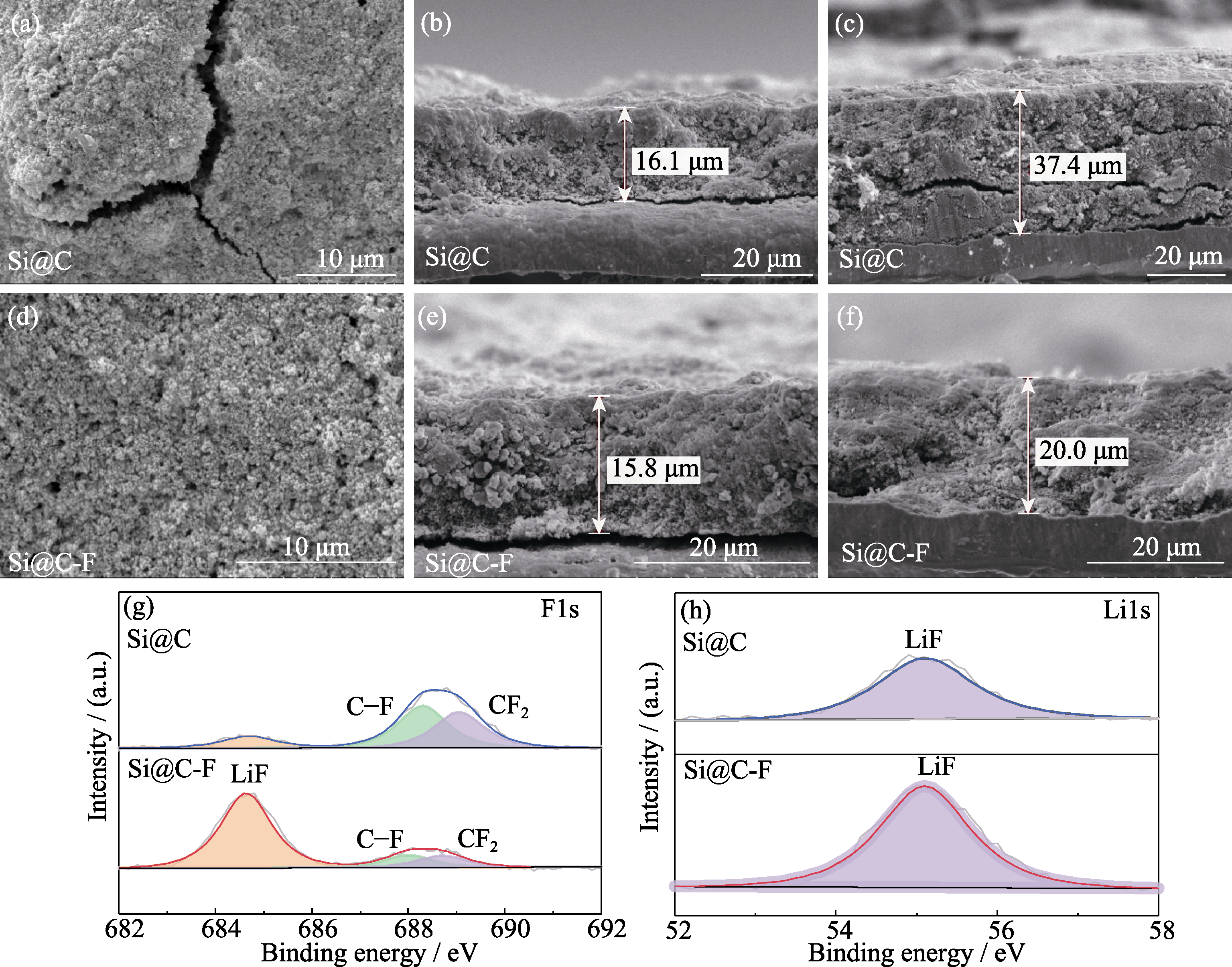

图8 (a)充放电循环后的Si@C和(d)Si@C-F负极的表面SEM照片; (b, e)循环前和(c, f)循环后(b, c)Si@C和(e, f) Si@C-F负极截面的SEM照片; 充放电循环后Si@C和Si@C-F负极表面SEI膜的高分辨(g)F1s及(h)Li1s XPS谱图

Fig. 8 Top SEM images of (a) Si@C and (d) Si@C-F anodes after cycling; Cross-section SEM images of (b, c) Si@C and (e, f) Si@C-F anodes (b, e) before and (c, f) after cycling; High-resolution (g) F1s and (h) Li1s XPS spectra of SEI on Si@C and Si@C-F anodes after cycling

| [1] |

NIU S S, WANG Z Y, YU M L, et al. MXene-based electrode with enhanced pseudocapacitance and volumetric capacity for power- type and ultra-long life lithium storage. ACS Nano, 2018, 12(4): 3928.

DOI URL |

| [2] | SU X, WU Q L, LI J C, et al. Silicon-based nanomaterials for lithium-ion batteries: a review. Advanced Energy Materials, 2014, 4(1): 1300882. |

| [3] | GE M Z, CAO C Y, GILL M B, et al. Recent advances in silicon- based electrodes: from fundamental research toward practical applications. Advanced Materials, 2021, 33(16): 2004577. |

| [4] |

LI P, ZHAO G Q, ZHENG X B, et al. Recent progress on silicon- based anode materials for practical lithium-ion battery applications. Energy Storage Materials, 2018, 15: 422.

DOI URL |

| [5] |

LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6(2): 1522.

DOI URL |

| [6] |

LUO W, WANG Y X, CHOU S L, et al. Critical thickness of phenolic resin-based carbon interfacial layer for improving long cycling stability of silicon nanoparticle anodes. Nano Energy, 2016, 27: 255.

DOI URL |

| [7] |

DOU F, SHI L Y, CHEN G R, Silicon/carbon composite anode materials for lithium-ion batteries. Electrochemical Energy Reviews, 2019, 2(1): 149.

DOI |

| [8] | JIA H P, ZOU L F, GAO P Y, et al. High-performance silicon anodes enabled by nonflammable localized high-concentration electrolytes. Advanced Energy Materials, 2019, 9(31): 1900784. |

| [9] |

CHOI S H, KWON T W, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science, 2017, 357: 279.

DOI URL |

| [10] | LI Z H, ZHANG Y P, LIU T F, et al. Silicon anode with high initial Coulombic efficiency by modulated trifunctional binder for high‐areal-capacity lithium-ion batteries. Advanced Energy Materials, 2020, 10(20): 1903110. |

| [11] |

XU Z L, CAO K, ABOUALI S, et al. Study of lithiation mechanisms of high performance carbon-coated Si anodes by in-situ microscopy. Energy Storage Materials, 2016, 3: 45.

DOI URL |

| [12] |

TEKI R, MONI K D, RAHUL K, et al. Nanostructured silicon anodes for lithium ion rechargeable batteries. Small, 2009, 5(20): 2236.

DOI URL |

| [13] | XIA S X, ZHANG X, LUO L L, et al. Highly stable and ultrahigh- rate Li metal anode enabled by fluorinated carbon fibers. Small, 2021, 17: 2006002. |

| [14] |

ZHANG S L, WANG X, HO K S, et al. Raman spectra in a broad frequency region of p-type porous silicon. Journal of Applied Physics, 1994, 76(5): 3016.

DOI URL |

| [15] |

HUANG W, WANG Y, LUO G H, et al. 99.9% Purity multi-walled carbon nanotubes by vacuum high-temperature annealing. Carbon, 2003, 41(13): 2585.

DOI URL |

| [16] |

MCDOWELL M T, LEE S W, NIX W D, et al. 25th Anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Advanced Materials, 2013, 25(36): 4966.

DOI URL |

| [17] |

KEY B, MORCRETTE M, TARASCON J M. Pair distribution function analysis and solid state NMR studies of silicon electrodes for lithium ion batteries: understanding the (de)lithiation mechanisms. Journal of American Chemical Society, 2011, 133(3): 503.

DOI URL |

| [18] |

GAO H, XIAO L S, PLUMEL I, et al. Parasitic reactions in nanosized silicon anodes for lithium-ion batteries. Nano Letters, 2017, 17(3): 1512.

DOI URL |

| [19] |

CHEN J, FAN X L, LI Q, et al. Electrolyte design for LiF-rich solid-electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nature Energy, 2020, 5(5): 386.

DOI |

| [20] | ZHANG P, GAO Y Q, RU Q, et al. Scalable preparation of porous nano-silicon/TiN@carbon anode for lithiumion batteries. Applied Surface Science, 2019, 498: 143829. |

| [21] |

SU M R, WAN H F, LIU Y J, et al. Multi-layered carbon coated Si-based composite as anode for lithium-ion batteries. Powder Technology, 2018, 323: 294.

DOI URL |

| [22] | PU J B, QIN J, WANG Y Z, et al. Synthesis of micro-nano sphere structure silicon-carbon composite as anode material for lithium- ion batteries. Chemical Physics Letters, 2022, 806: 140006. |

| [23] | GAO R S, TANG J, YU X L, et al. A sandwich-like silicon-carbon composite prepared by surface-polymerization for rapid lithium-ion storage. Nano Energy, 2020, 70: 104444. |

| [24] |

GONG X H, ZHENG Y B, ZHENG J, et al. Yolk-shell silicon/ carbon composites prepared from aluminum-silicon alloy as anode materials for lithium-ion batteries. Ionics, 2021, 27: 1939.

DOI |

| [25] |

LIA Y R, WANG R Y, ZHANG J W, et al. Sandwich structure of carbon-coated silicon/carbon nanofiber anodes for lithium-ion batteries. Ceramics International, 2019, 45: 16195.

DOI URL |

| [26] | YANG X M AND ROGACH A L. Electrochemical techniques in battery research: a tutorial for nonelectrochemists. Advanced Energy Materials, 2019, 9(25): 1900747. |

| [1] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [2] | 刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004. |

| [3] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [4] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| [5] | 杨卓, 卢勇, 赵庆, 陈军. X射线衍射Rietveld精修及其在锂离子电池正极材料中的应用[J]. 无机材料学报, 2023, 38(6): 589-605. |

| [6] | 宿拿拿, 韩静茹, 郭印毫, 王晨宇, 石文华, 吴亮, 胡执一, 刘婧, 李昱, 苏宝连. 基于ZIF-8的三维网络硅碳复合材料锂离子电池性能研究[J]. 无机材料学报, 2022, 37(9): 1016-1022. |

| [7] | 王洋, 范广新, 刘培, 尹金佩, 刘宝忠, 朱林剑, 罗成果. 钾离子掺杂提高锂离子电池正极锰酸锂性能的微观机制[J]. 无机材料学报, 2022, 37(9): 1023-1029. |

| [8] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [9] | 冯锟, 朱勇, 张凯强, 陈长, 刘宇, 高彦峰. 勃姆石纳米片增强锂离子电池隔膜性能研究[J]. 无机材料学报, 2022, 37(9): 1009-1015. |

| [10] | 陈莹, 栾伟玲, 陈浩峰, 朱轩辰. 基于应力场的锂离子电池正极多尺度失效研究[J]. 无机材料学报, 2022, 37(8): 918-924. |

| [11] | 江依义, 沈旻, 宋半夏, 李南, 丁祥欢, 郭乐毅, 马国强. 双功能电解液添加剂对锂离子电池高温高电压性能的影响[J]. 无机材料学报, 2022, 37(7): 710-716. |

| [12] | 苏东良, 崔锦, 翟朋博, 郭向欣. 石榴石型Li6.4La3Zr1.4Ta0.6O12对Si/C负极表面固体电解质中间相的调控机制研究[J]. 无机材料学报, 2022, 37(7): 802-808. |

| [13] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [14] | 王禹桐, 张非凡, 许乃才, 王春霞, 崔立山, 黄国勇. 水系锂离子电池负极材料LiTi2(PO4)3的研究进展[J]. 无机材料学报, 2022, 37(5): 481-492. |

| [15] | 李昆儒, 胡省辉, 张正富, 郭玉忠, 黄瑞安. 源于溪木贼的高性能锂离子电池三维多孔生物质硅/碳复合负极材料[J]. 无机材料学报, 2021, 36(9): 929-935. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||